High-frequency vibration wire rod straightening device and using method thereof

A high-frequency vibration and straightening technology, applied in the field of straightening devices for wire rods, can solve the problems of large wear consumption, large residual stress of materials, and increased production costs, so as to improve efficiency and quality, high production efficiency and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

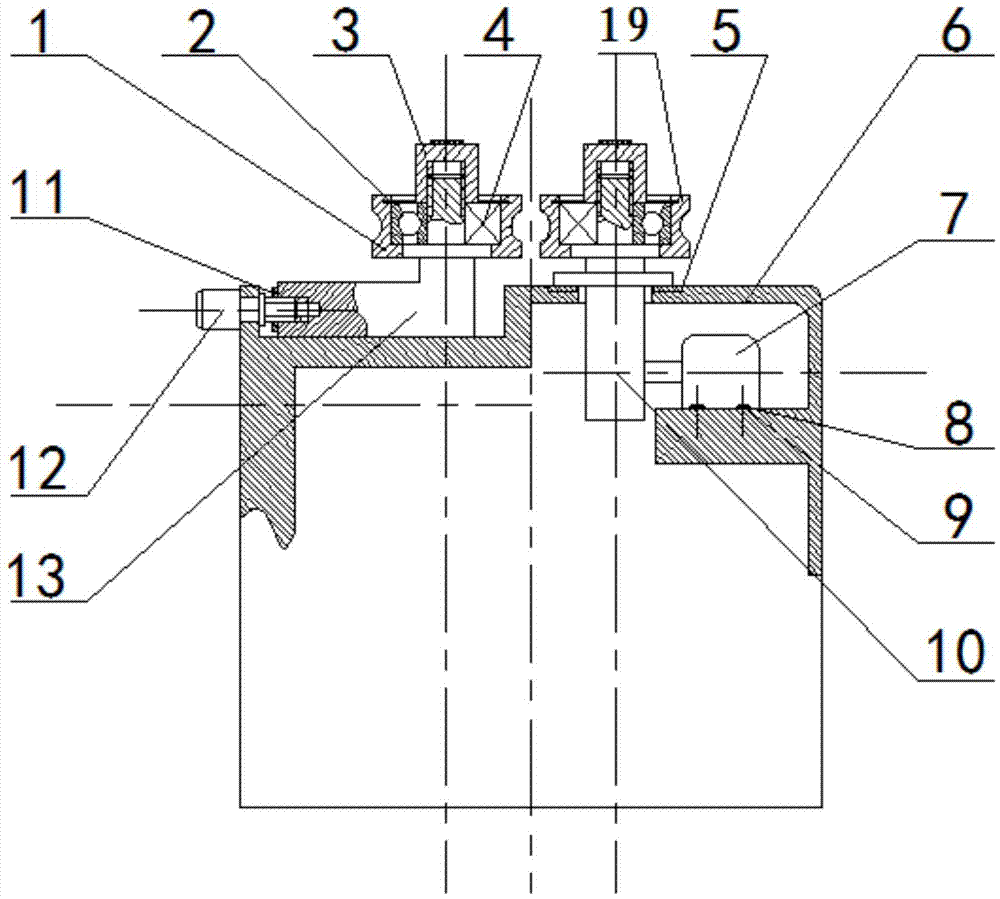

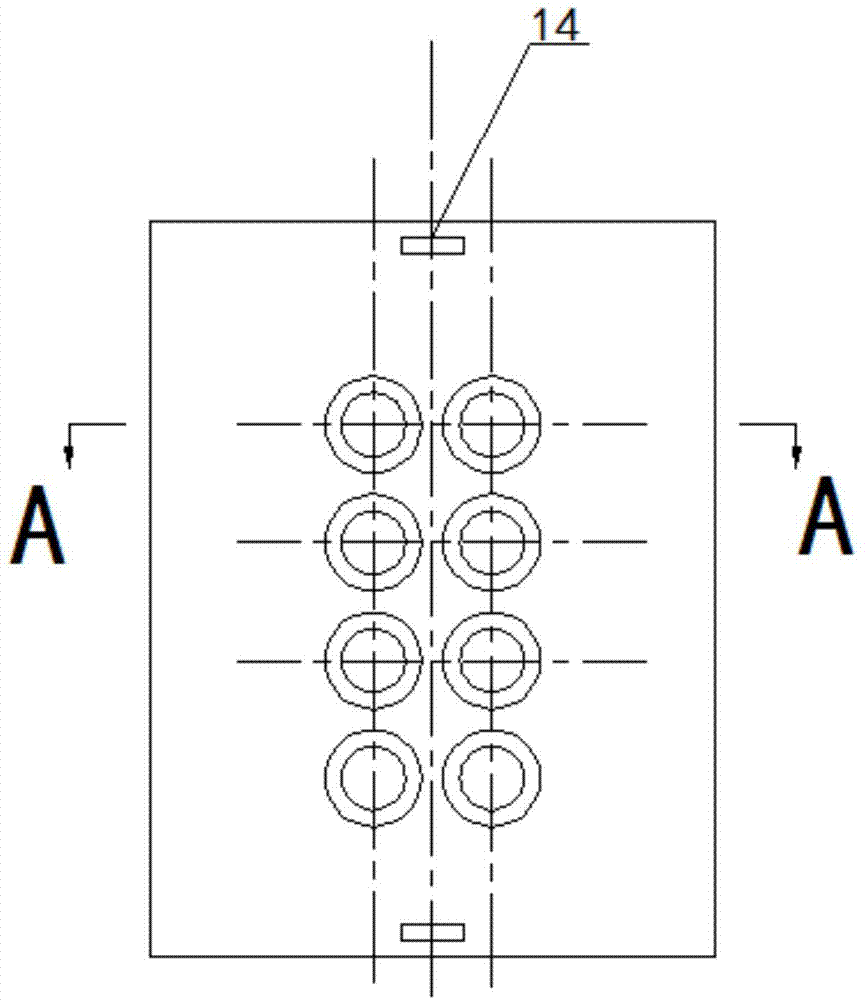

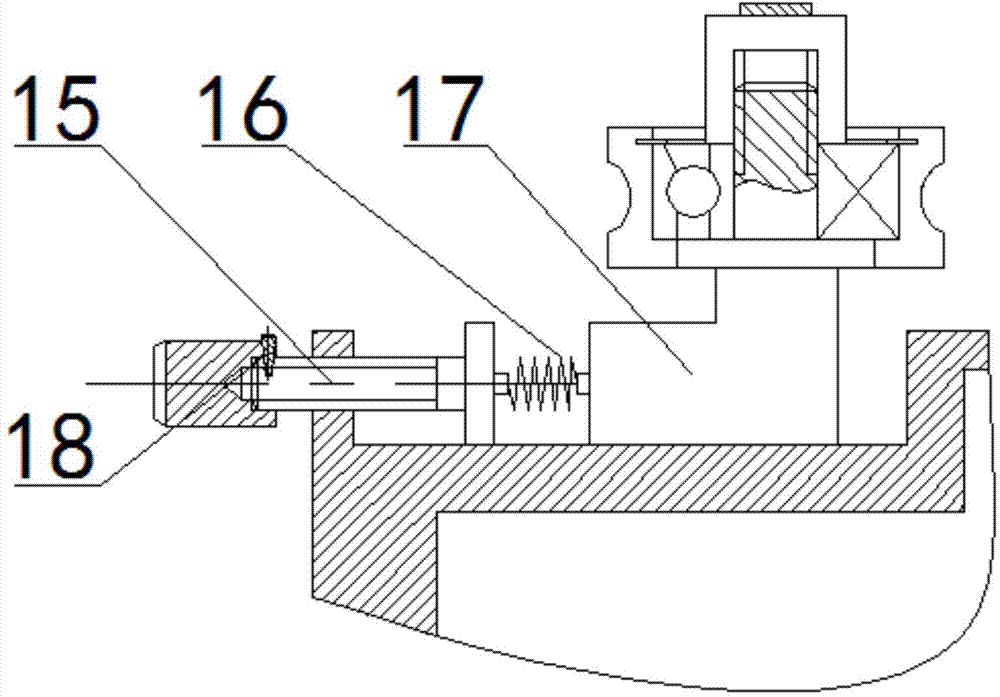

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 1 to Figure 4 As shown, a high-frequency vibration wire straightening device of the present invention includes a housing 6 and at least two groups of clamping devices located on the housing 6, each group of clamping devices includes a first clamping unit and a second clamping unit, The first clamping unit includes a first mold 1, a spring snap ring 2, a bearing 4 and a compression end cover 3, and the second clamping unit includes a second mold 19, a spring snap ring 2, a bearing 4 and a compression end cover 3, The first mold 1 is set on the distance adjustment shaft, and the second mold 19 is set on the high-frequency vibration shaft 10. The first mold 1 and the second mold 19 are provided with arc grooves in the circumferential direction. The first mold 1 and the second mold The mold 19 fixes the wire rod through the arc groove, the first mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com