Using method of steel bar straightening equipment in power construction

A technology for electric construction and steel bars, applied in the field of steel bar straightening equipment in electric power construction, can solve the problems of easily scratching oneself, inconvenient to install a straightening machine, inconvenient to carry and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

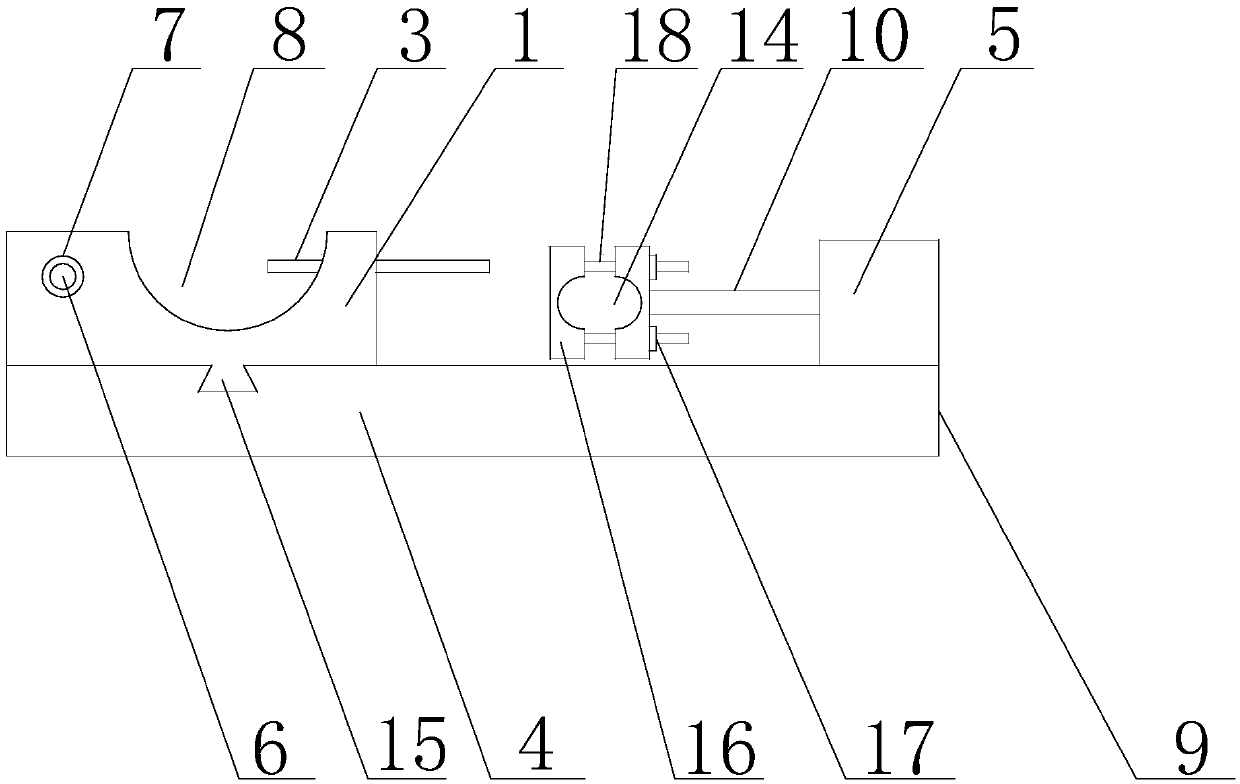

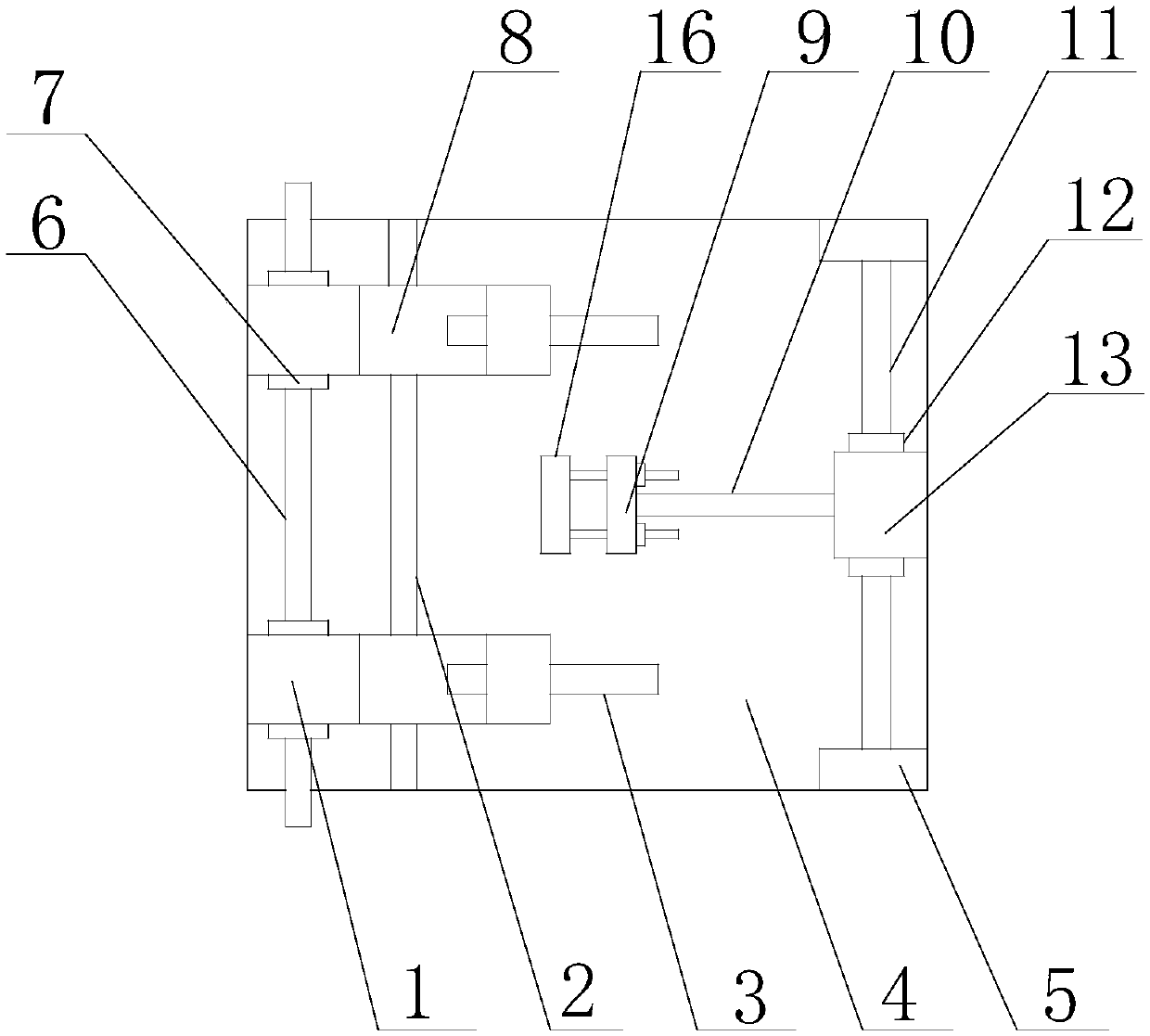

[0024] Such as figure 1 , figure 2 As shown, the method for using the steel bar straightening equipment in the electric power construction of the present invention includes the following steps: first, the base 4 is horizontally placed on the construction ground, the first stop ring 7 is loosened, and the two stop rings are adjusted according to the length of the steel bar to be straightened. Place the two ends of the steel bar to be straightened in the groove 8 of the two support blocks 1, and make the protruding part of the steel bar face the fixed plate 16, rotate the movable rod 3, and fix the steel bar on the fixed plate 16. On the support block 1, then unscrew the second limit ring 12, adjust the position of the driving mechanism 13, so that the fixed plate 16 is aligned with the curved part of the steel bar, then open the driving mechanism 13, and push the fixed plate 16 to move towards the direction of the steel bar. The protruding part of the reinforcing bar is strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com