Process parameter setting method for roll straightening machine for small-batch multi-specification plate products

A technology for a roller leveler and process parameters, which is applied in the field of sheet metal straightening, can solve the problems of difficult setting of process parameters, temperature difference, and large changes in process parameters of the roller leveler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is 10 meters, 2 meters, 0.3 meters certain Q345 metal plates with length, width and thickness respectively as an example to illustrate the implementation process.

[0043] 1. First, through the temperature sensor set in front of the straightening machine, measure the value of the plate to be straightened in different areas of the entire plate, in this case, it is 500 to 600 degrees. According to the temperature range, by querying the material performance database (data obtained through mechanical performance tests), and assigning the yield strength of the material according to the temperature every 10°C, σ can be obtained S , and elastic modulus E are shown in the table below.

[0044]

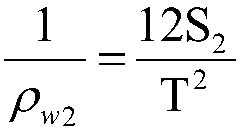

[0045] 2. Measure the thickness of the plate with the thickness gauge in front of the straightening machine to determine the range of thickness difference of the plate, and measure the thickness of the plate to be 30.5mm to 29.5mm. Take the standard thickness val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com