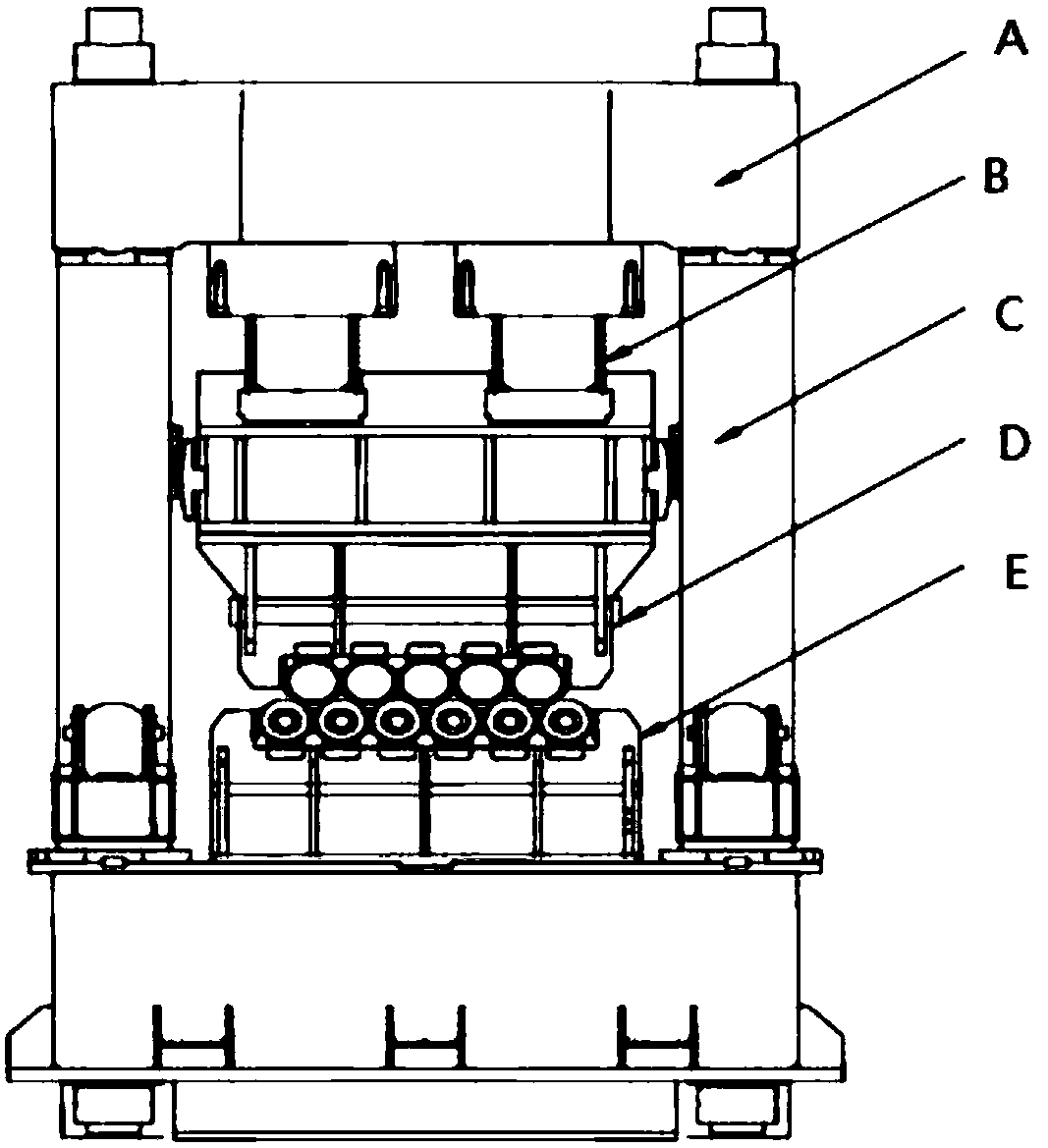

Roller type straightening technological parameter setting method for optimizing head and tail part straightening

A technology of roller straightening and setting method, which is applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of complex roller structure, difficult to eliminate plate defects, and inability to guarantee straightening quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Now take a metal plate whose length, width, and thickness are 10 meters, 2 meters, and 0.3 meters respectively as an example to illustrate the implementation process. First, through the temperature sensor installed in front of the straightening machine, the temperature value of the plate to be straightened is measured to be 550°C. According to the temperature value, σ can be obtained S , and elastic modulus E see the table below

[0070]

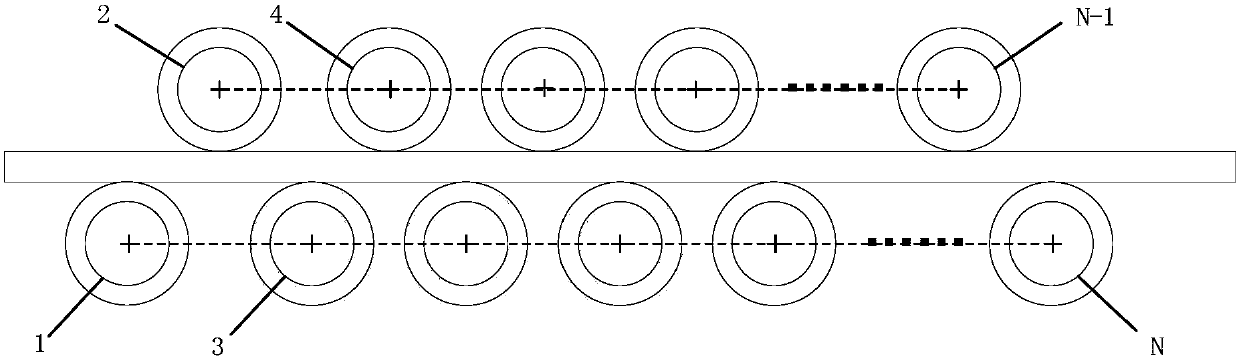

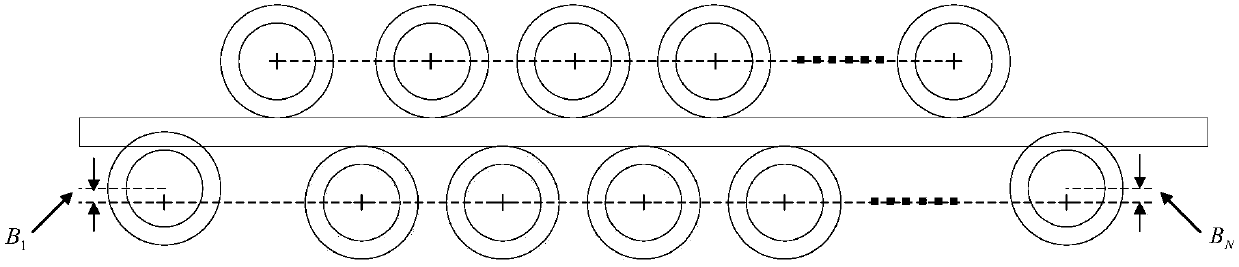

[0071] 1. Construct the straightening process description space, determine the scope of the space, and the reduction S of the first roller in the upper row 2 , the value range is 0 to 5 times Reduction S of the last roller in the upper row N-1 The value range is 0 to 1.5 times Front roller position value B 1 Value range -25~+25mm and rear roller position value B N The value range is -25~+25mm. According to the reduction accuracy of the straightening machine, set the four process values at intervals of 0.1mm, and then tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com