Pipe rod bar with major diameter double-roller unbender concave roller curve

A large-diameter tube and concave roll technology, which is applied in the field of concave rolls of large-diameter tube/bar two-roll straightening machines, can solve the problems of tail flicking accidents, the roll shape curve of concave rolls is difficult to meet the straightening quality, etc., and reaches the application range. Wide, improve straightening quality, convenient processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

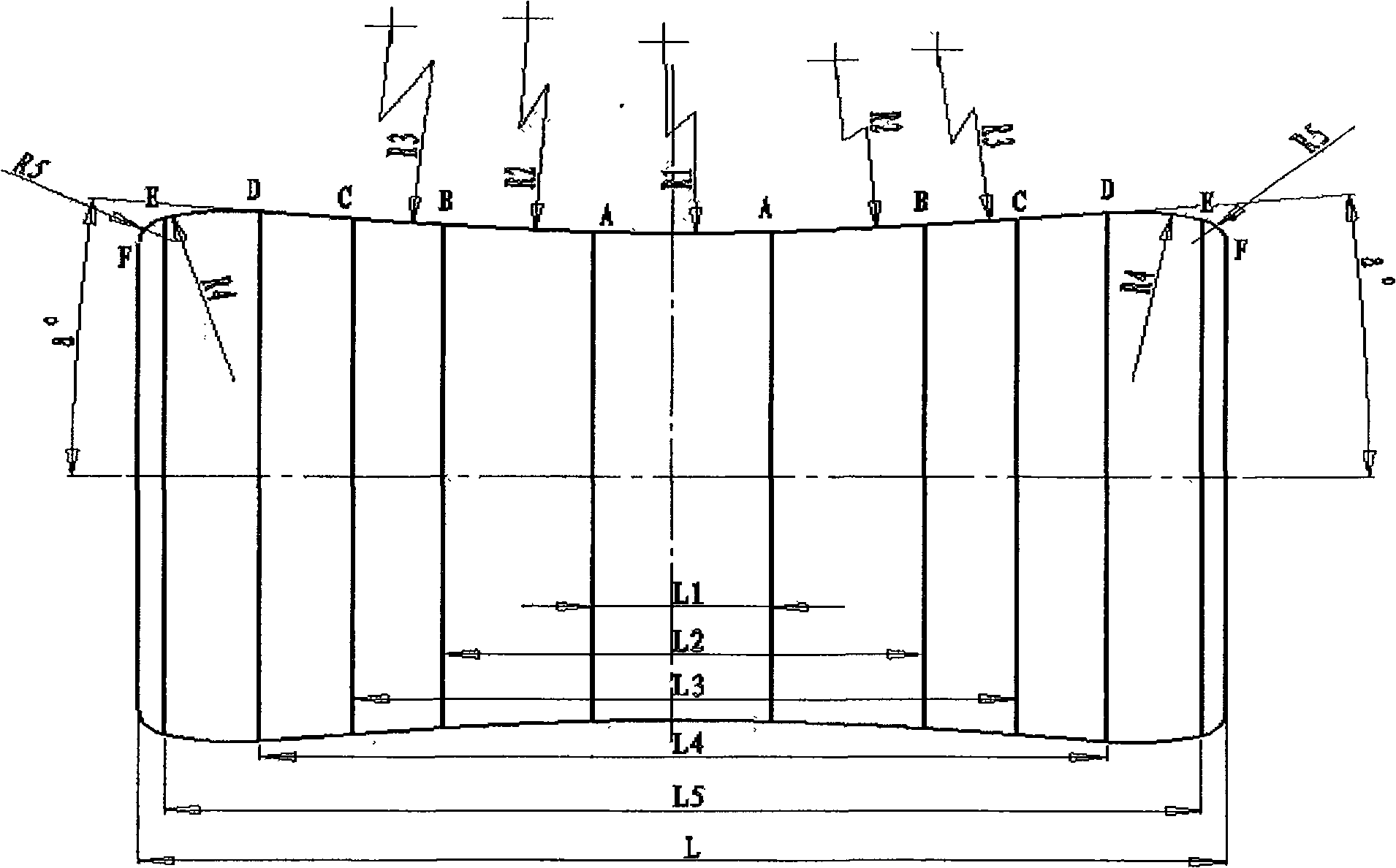

[0029] when pipe diameter d min =100mm, the maximum angle α between the straightening roller and the straightening direction max When = 20°, the value of each parameter in the roll curve is calculated as follows:

[0030] R1=16×100×π×tg20°=1827.58;

[0031] R2=24×100×π×tg20°=2741.37;

[0032] R3=40×100×π×tg20°=4568.949;

[0033] R4=2.4×100×π×tg20°=274.137;

[0034] R5=30mm;

[0035] L1=1.6×100×π×tg20°=182.758;

[0036] L2=3.2×100×π×tg20°=365.5159;

[0037] L3=4.8×100×π×tg20°=548.2739;

[0038] L4=6.4×100×π×tg20°=731.0319;

[0039] L5=7.6×100×π×tg20°=868.1004.

[0040] Take the roller-shaped symmetry line as the axis of symmetry, make the arc AA / 2 tangent to the arc AB, the arc AB to the arc BC, the arc BC to the oblique line CD, and the oblique line CD to the arc DE Tangent, tangent between arc DE and arc EF can get the generatrix of concave roll curve. Each parameter can be rounded up in a specific application.

[0041] The DC section of the entrance and exit of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com