Model for predicting resilience of bar subjected to two roll straightening

A bar and straightening technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems affecting the calculation accuracy of springback, offset, and the distribution of stress on the section of the bar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

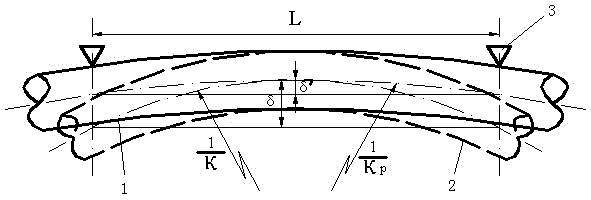

[0046] According to the bar material and specifications produced by a steel factory, alloy steel 40Cr was selected for springback verification. The specific parameters are as follows: yield limit =410MPa, modulus of elasticity E =206GPa, hardening coefficient =0.02812, diameter d =28mm, the original deflection is 10mm / m.

[0047] According to the above data, in the reverse bending radius =915mm, the springback deflection is calculated according to the formula =4.51mm; the experimental value is 4.34mm, and the relative error is 3.92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com