Combined box iron straightening roller

A straightening roller and combined technology, applied in the field of straightening rollers, to achieve the effects of improving straightening quality, improving car straightening effect, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

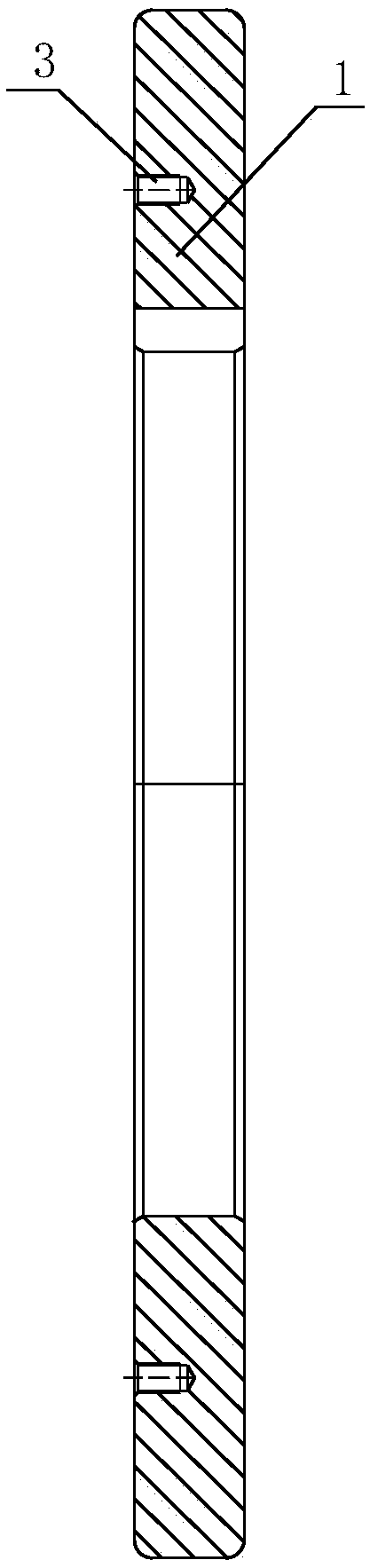

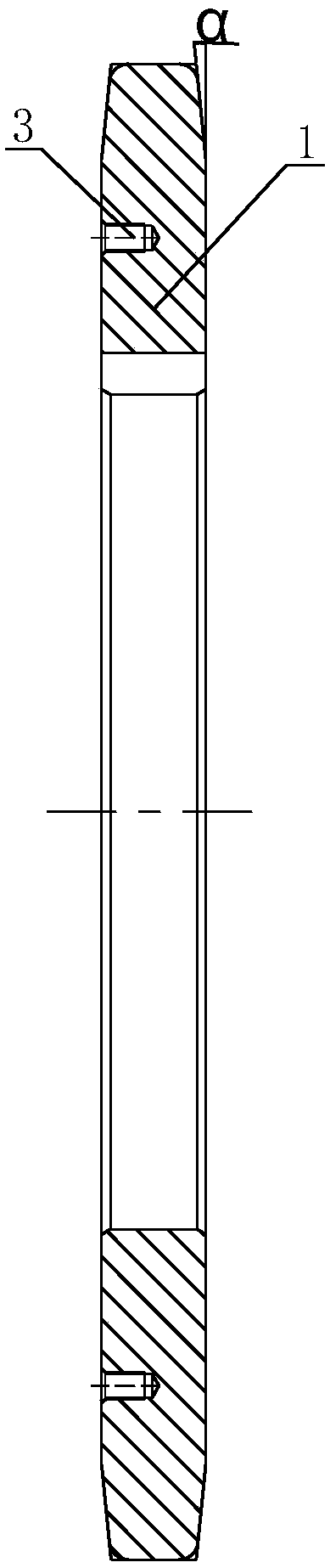

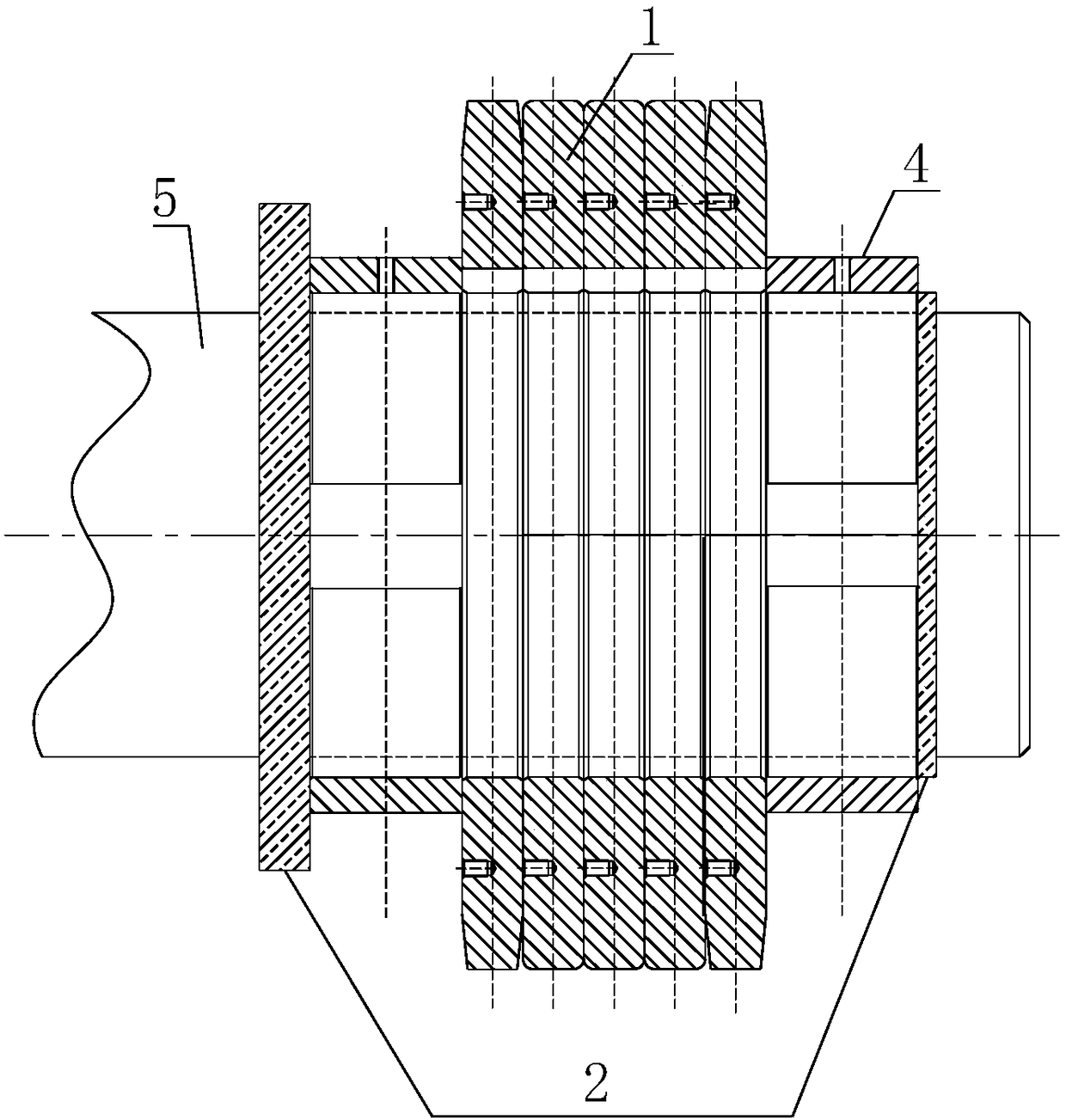

[0024] According to the standard cross-sectional drawing of channel steel, make a single-piece roll ring 1 with corresponding thickness and slope, see figure 1 , figure 2 ; When straightening, according to the size of the channel steel model, reasonably stack and assemble the single roll ring 1 on the roll cover 2, and fix the roll cover 2 with a fastening washer 4 at the end of the roll cover 2 to limit the roll ring 1. The combined channel steel straightening roller is integrally installed on the main shaft 5 of the straightener, and then the combined channel steel straightening roller is fixed on the main shaft 5 by the hydraulic device with the roller cover 2 and the locking device. If the length of the working face of the straightening roller is not enough, a spacer can be added between the roller rings 1 for fine adjustment, and the spacer is made of a steel plate with a thickness of 1 mm or 5 mm. The chamfer angle α=6° of the edges on both sides of the roll ring 1 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com