Straightening method of steel plate hot straightening machine

A hot straightening machine and hot straightening technology, applied in the straightening field of steel plate hot straightening machine, can solve the problems of consuming a lot of time, restricted production rhythm, quality and efficiency, etc., and achieve low production efficiency and straightening Improved quality and shorter straightening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

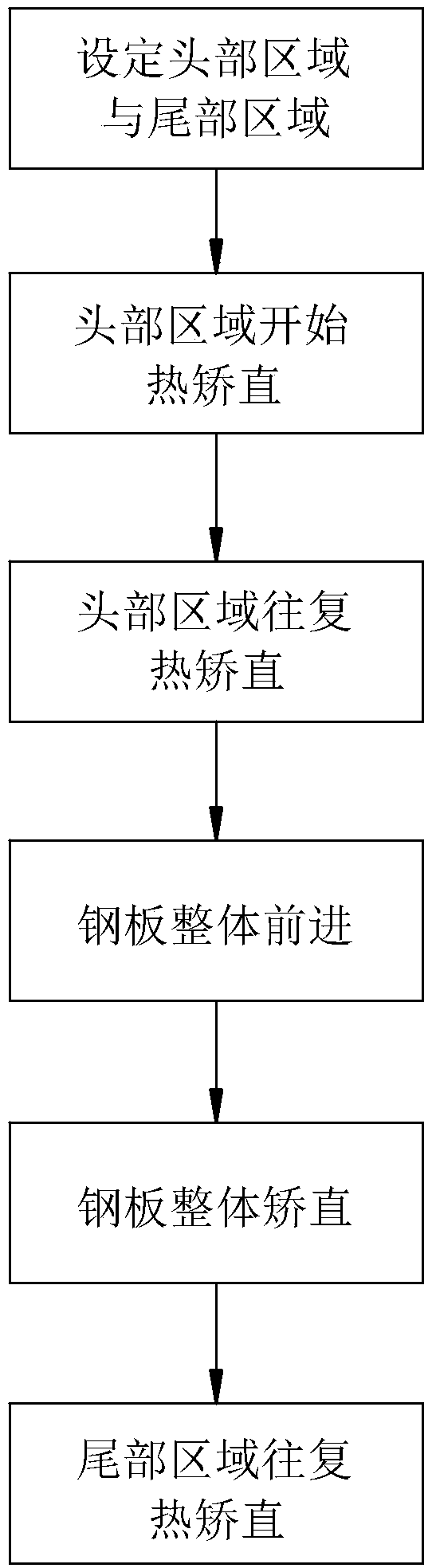

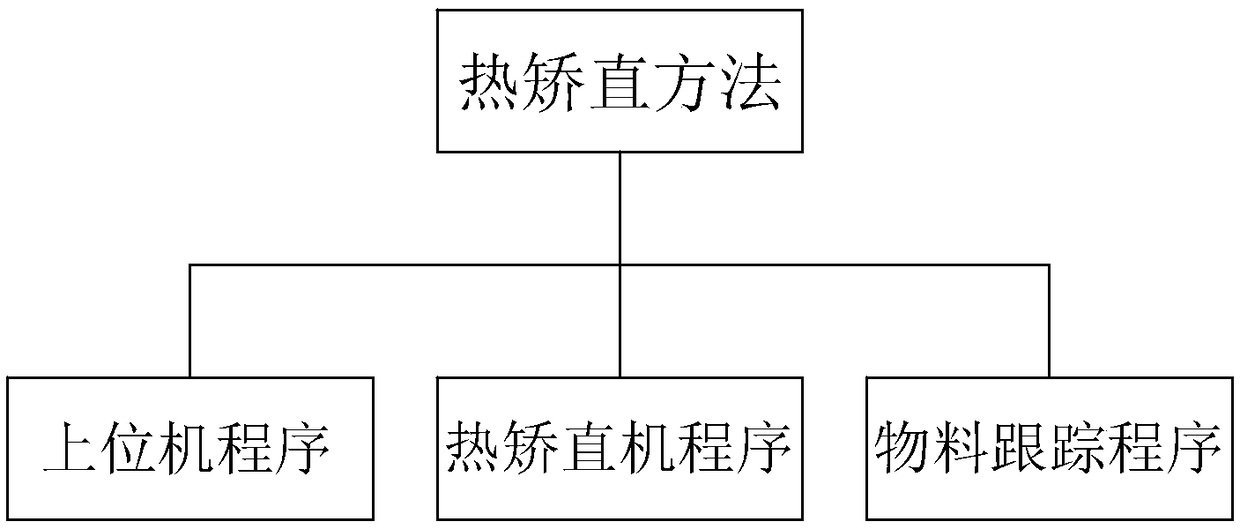

[0018] Such as figure 1 figure 2 Shown, a kind of straightening method of steel plate thermal straightening machine comprises the following steps:

[0019] a. Select the head area and the tail area of the steel plate, the head area is located in front of the steel plate movement direction, and the tail area is located behind the steel plate movement direction, so that the steel plate enters the hot straightening machine;

[0020] b. After the head area enters the straightening machine, it starts to straighten. After one round of straightening, the steel plate moves in reverse. During the reverse movement, it straightens again. After straightening, the whole steel plate continues to move forward for thermal straightening. In this process, the head is straightened three times, the middle part is straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com