Patents

Literature

76results about How to "The impact of reducing productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

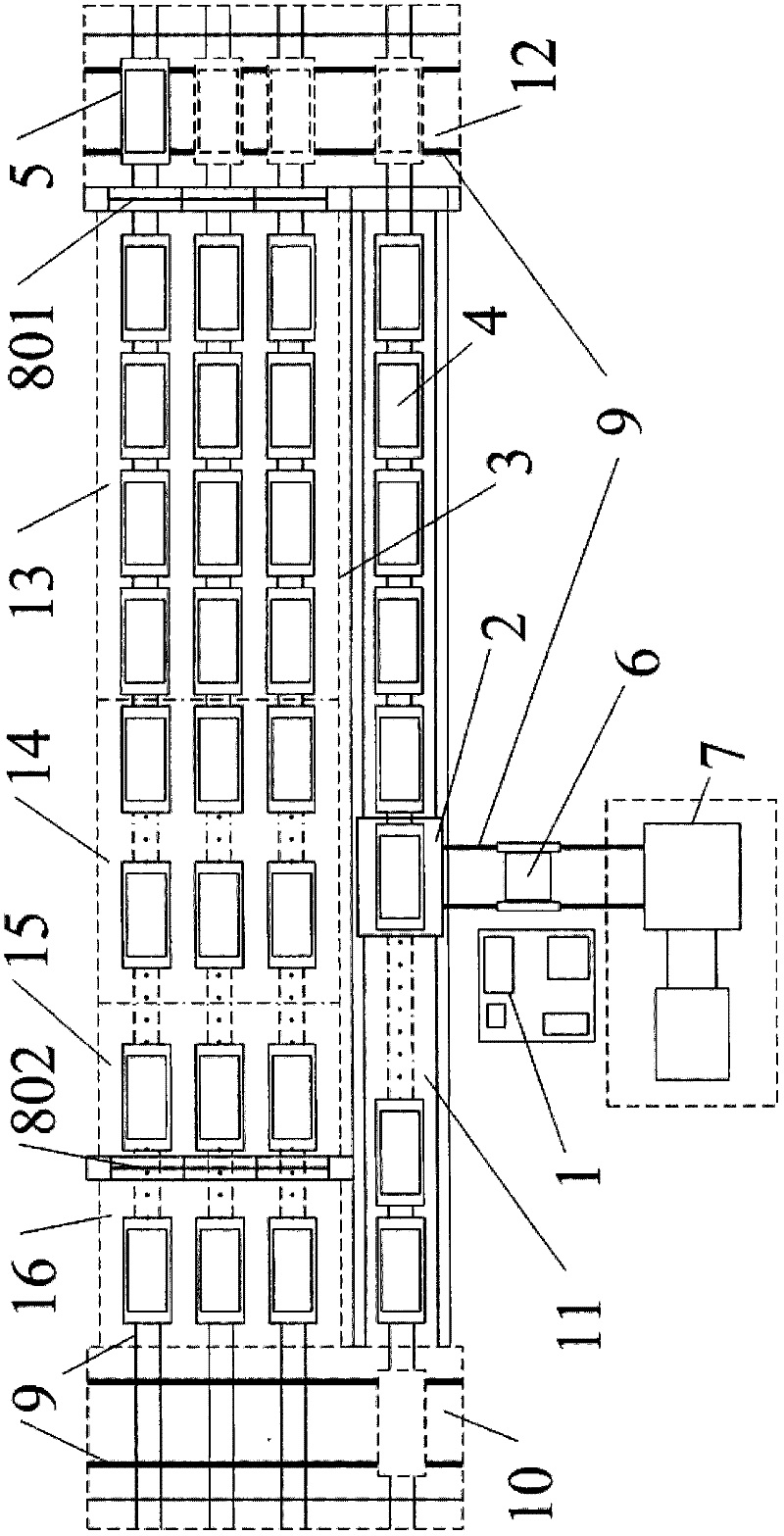

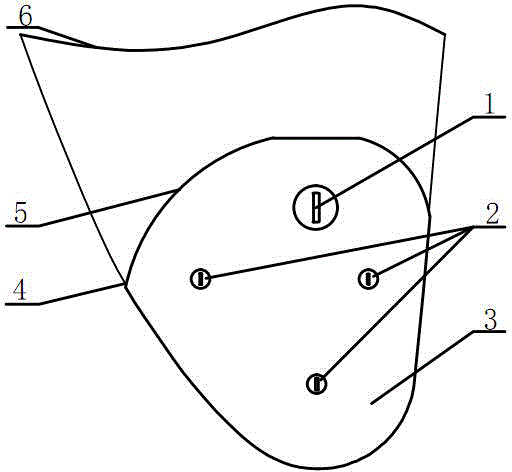

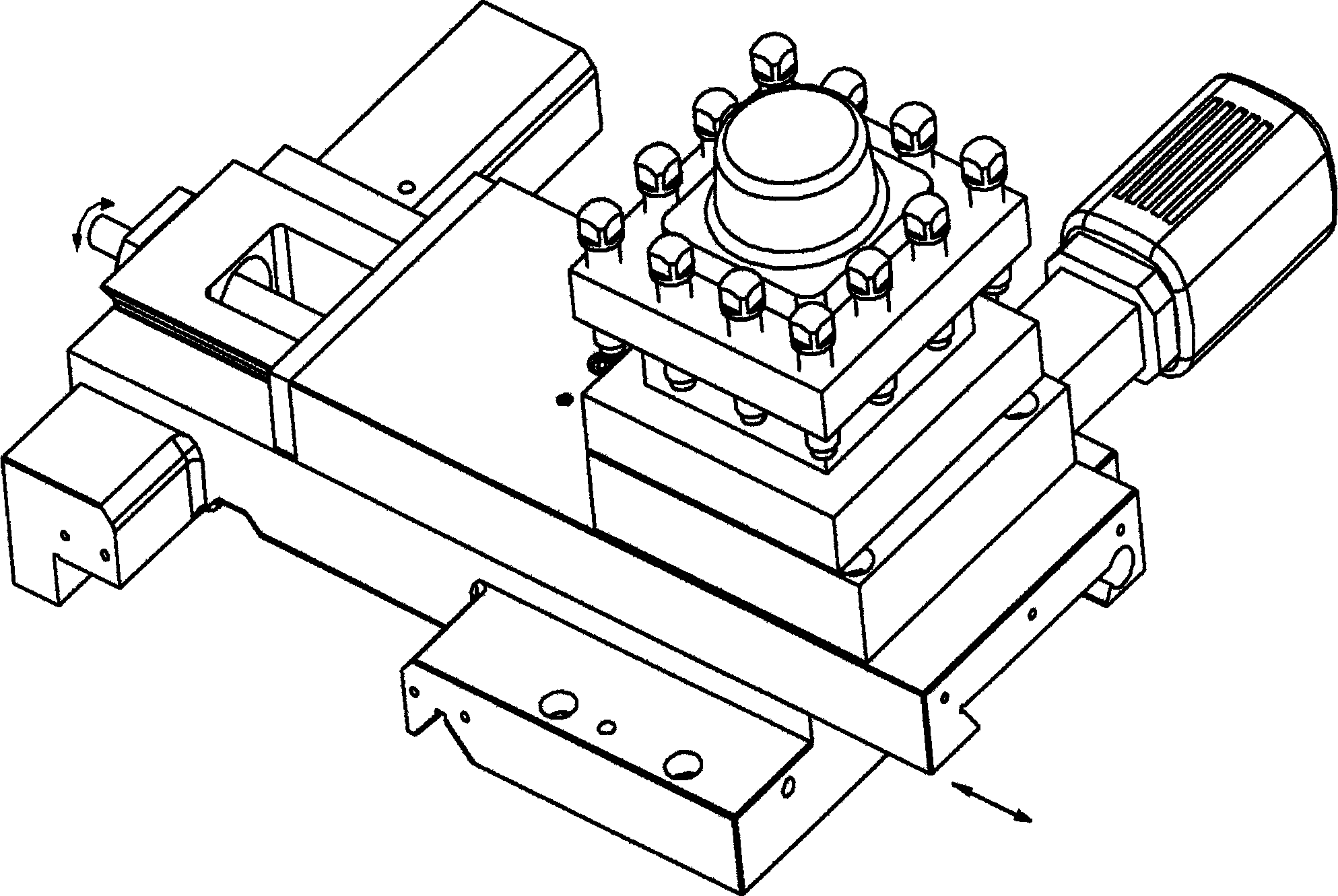

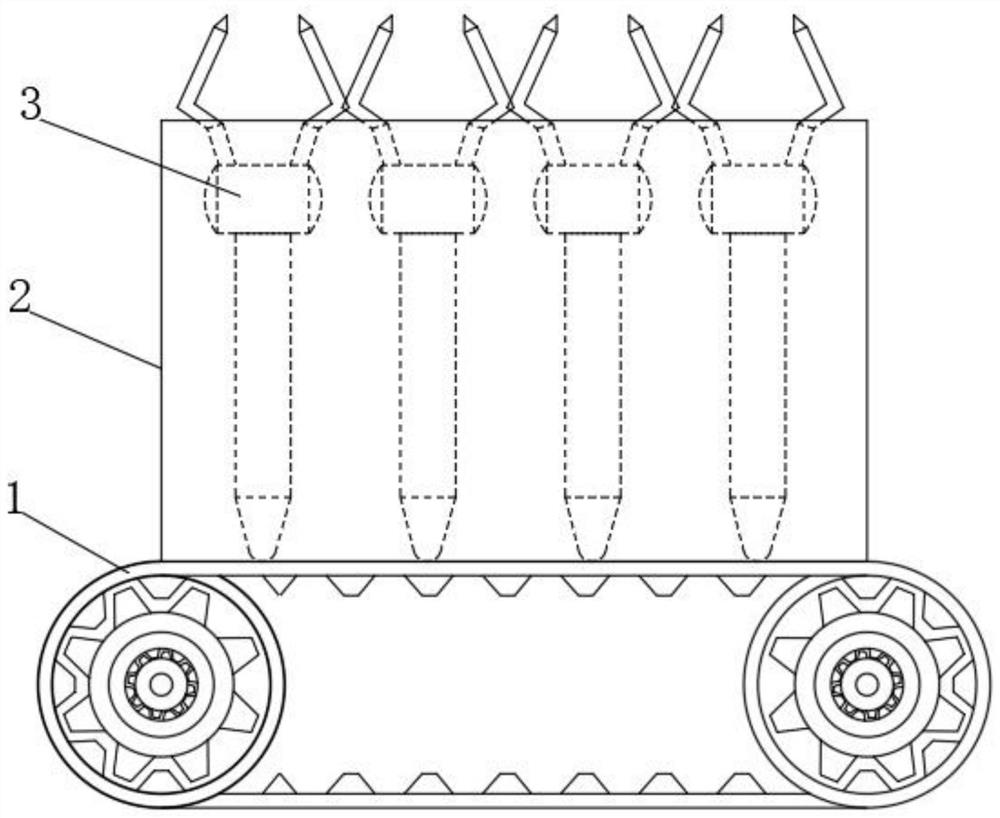

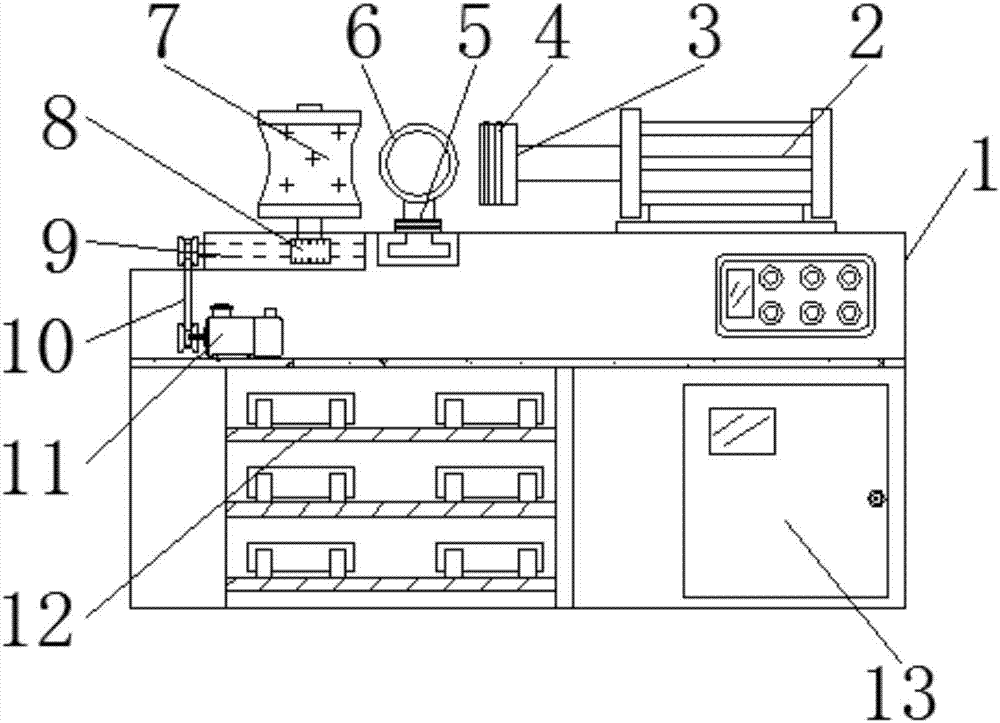

Automatic assembly mechanism for perforating bullet

ActiveCN103801930AProtection securityGuaranteed isolationMetal working apparatusProduction lineEngineering

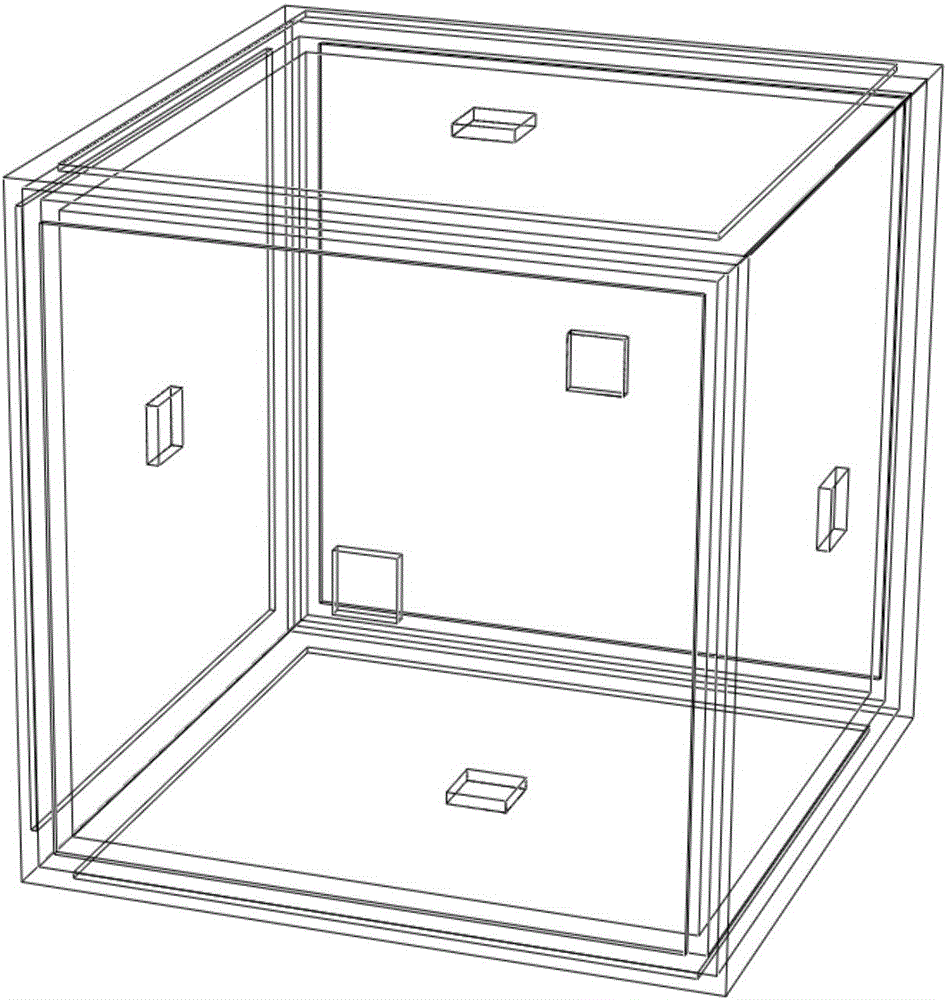

The invention provides an automatic assembly mechanism for a perforating bullet. The automatic assembly mechanism is characterized in that a powder liner (arranged on an upper-layer conveyor belt) and a casing filled with an explosive (arranged on a lower-layer conveyor belt) are respectively taken from an dual-layer plane turning loading conveyor belt 1 by a dual-claw pneumatic loading mechanical arm 3; the casing and the powder liner are sequentially placed in a hydraulic press 4; after the casing and powder liner are compressed by the hydraulic press, a product is taken down by a pneumatic product-taking mechanical arm 6 and is placed into a die 2 of a plane turning product-taking conveyor belt 7. According to the automatic assembly mechanism disclosed by the invention, the assembly process of loading, conveying, pressing explosive and taking product is realized, the safety coefficient is improved, the work condition of a production line can be monitored by an isolating explosion-proof wall window 5 while the isolation of an operator and an explosive pressing scene is ensured, potential safety hazards are eliminated and the assembly precision and efficiency are improved. The automatic assembly mechanism is suitable for assembly and production of perforating bullets in the petroleum industry.

Owner:严格集团股份有限公司

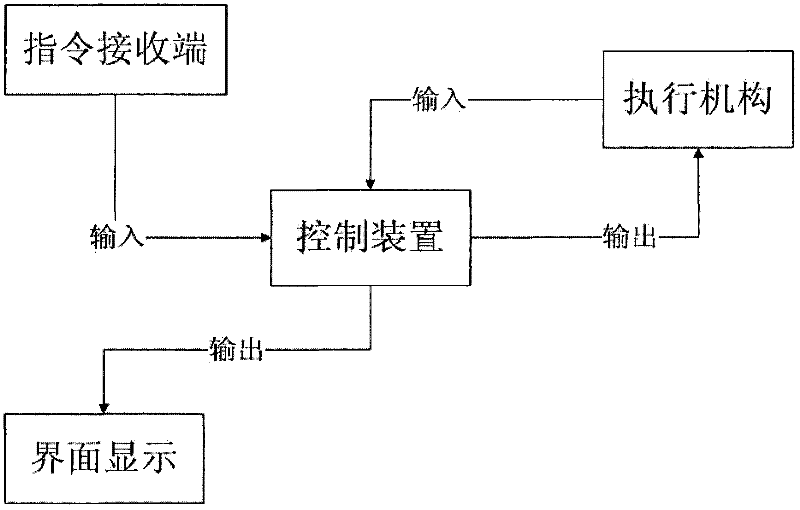

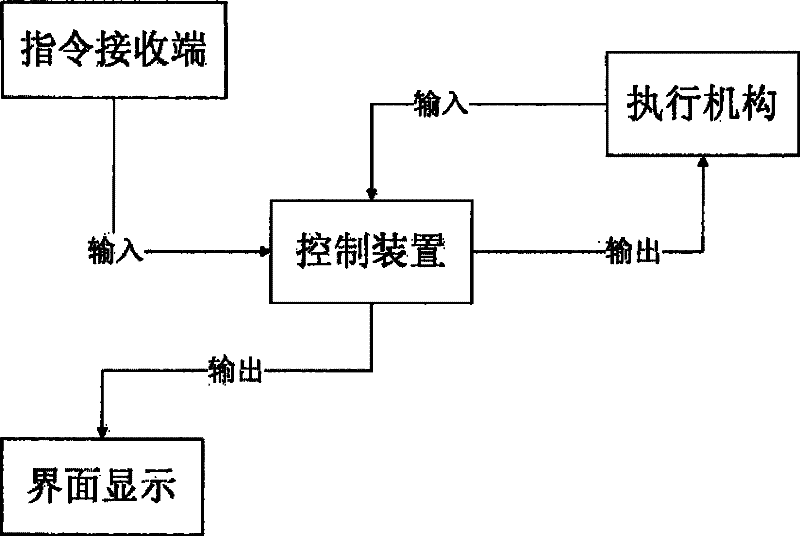

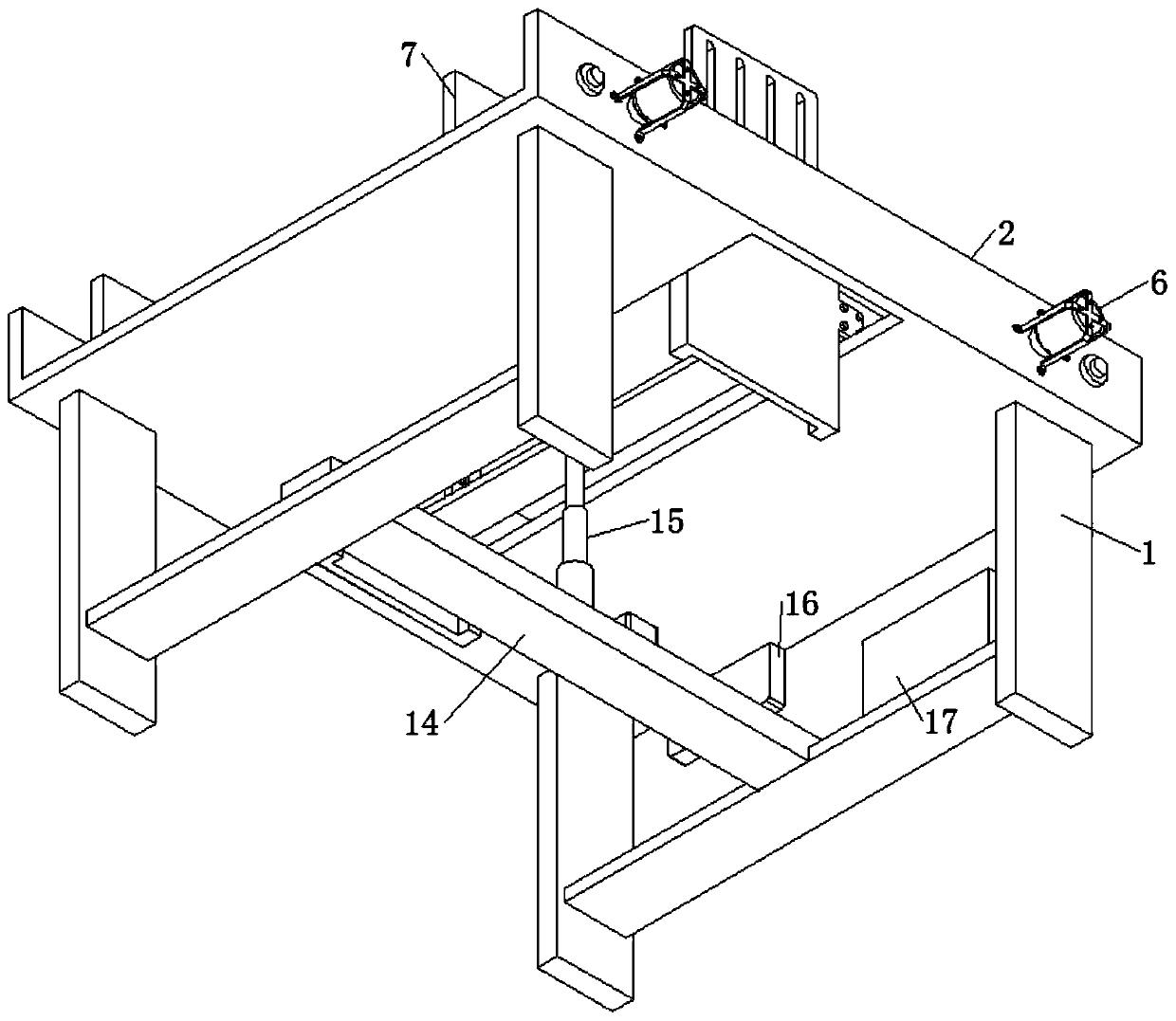

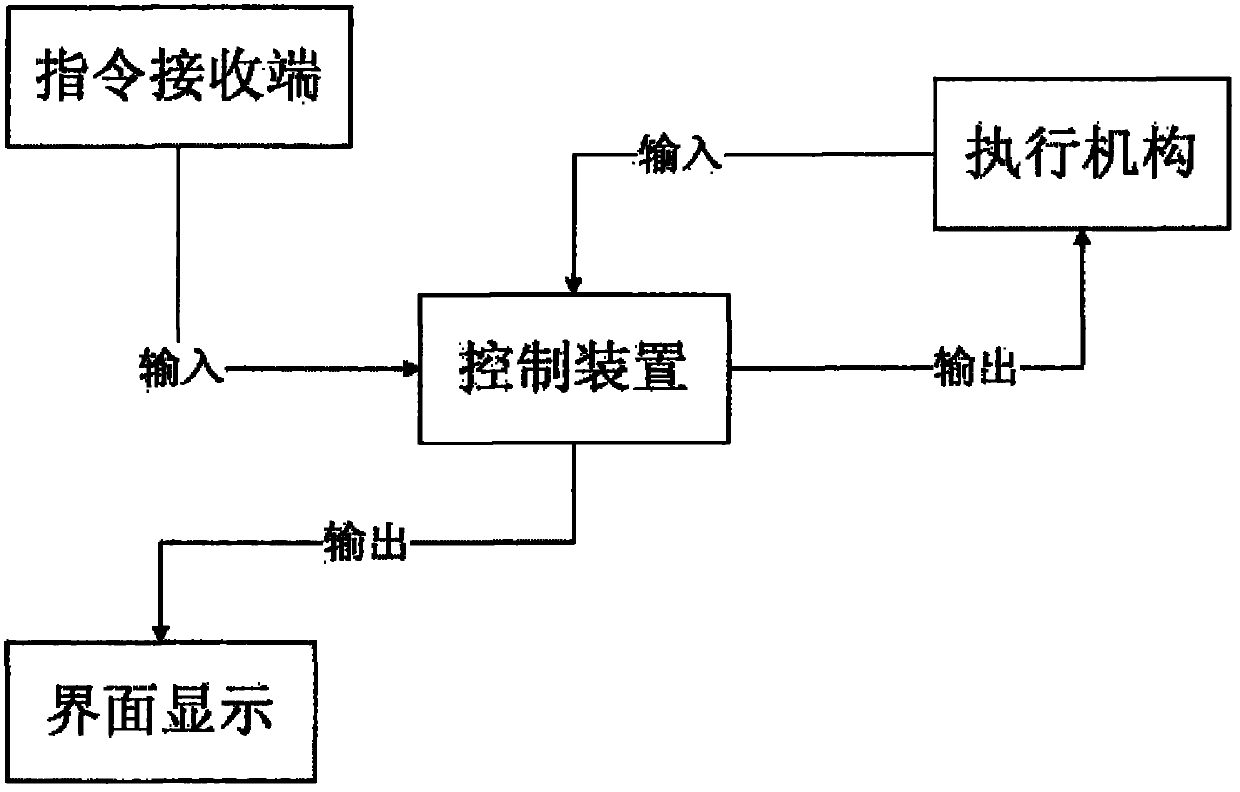

Duct piece production control system and duct piece production system

InactiveCN102350732ASave human effortSave moneyCeramic shaping plantsAuxillary shaping apparatusTemperature controlHuman–machine interface

The invention discloses a duct piece production control system and a duct piece production system. The duct piece production control system comprises an actuating mechanism, a programmable controller, an information receiving unit, a communication unit and an interface displayer, wherein the actuating mechanism comprises duct piece moulds, a carrying trolley, a vibrating device, a material feeding device, a maintenance room and automatic doors; the duct piece moulds are loaded and transported by the carrying trolley; the programmable controller comprises an automatic coding and identificationmodule for the moulds, an automatic positioning module for the carrying trolley, a vibrating device control module, a material feeding device control module, an automatic temperature control module for a maintenance device, an automatic door control module, an original point returning module of an assembly line, and a human-computer interface monitoring module; and the duct piece production system comprises the duct piece moulds, a transporting system, a vibrating system, a material feeding system, a maintenance system and the duct piece production control system. By adopting the duct piece production control system and the duct piece production system, the defects of low production efficiency and low safety in the prior art are overcome.

Owner:浙江广天构件集团股份有限公司

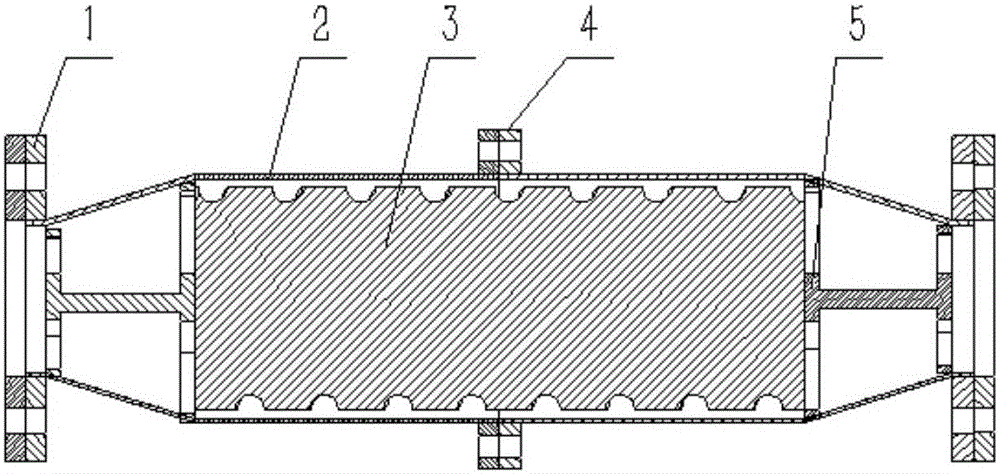

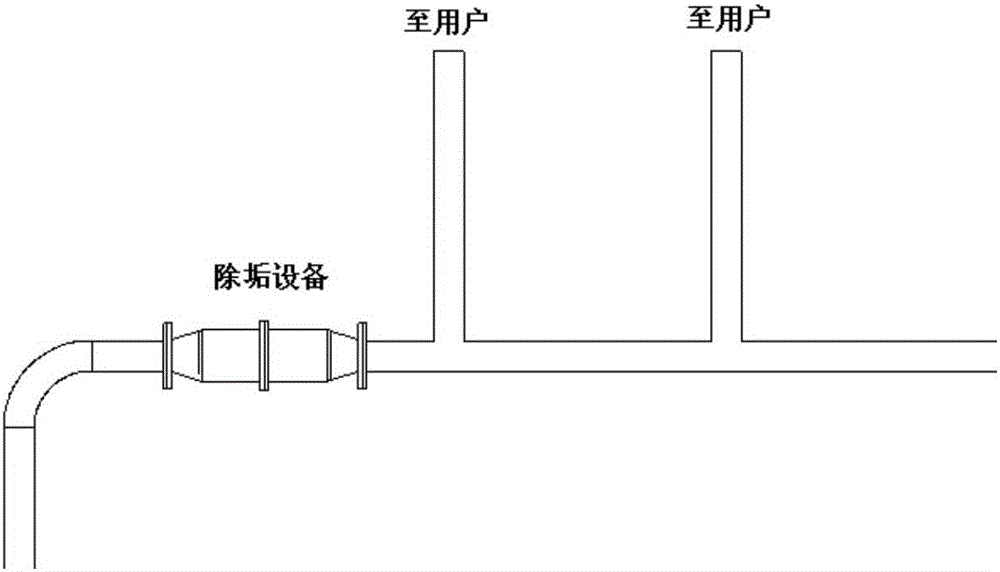

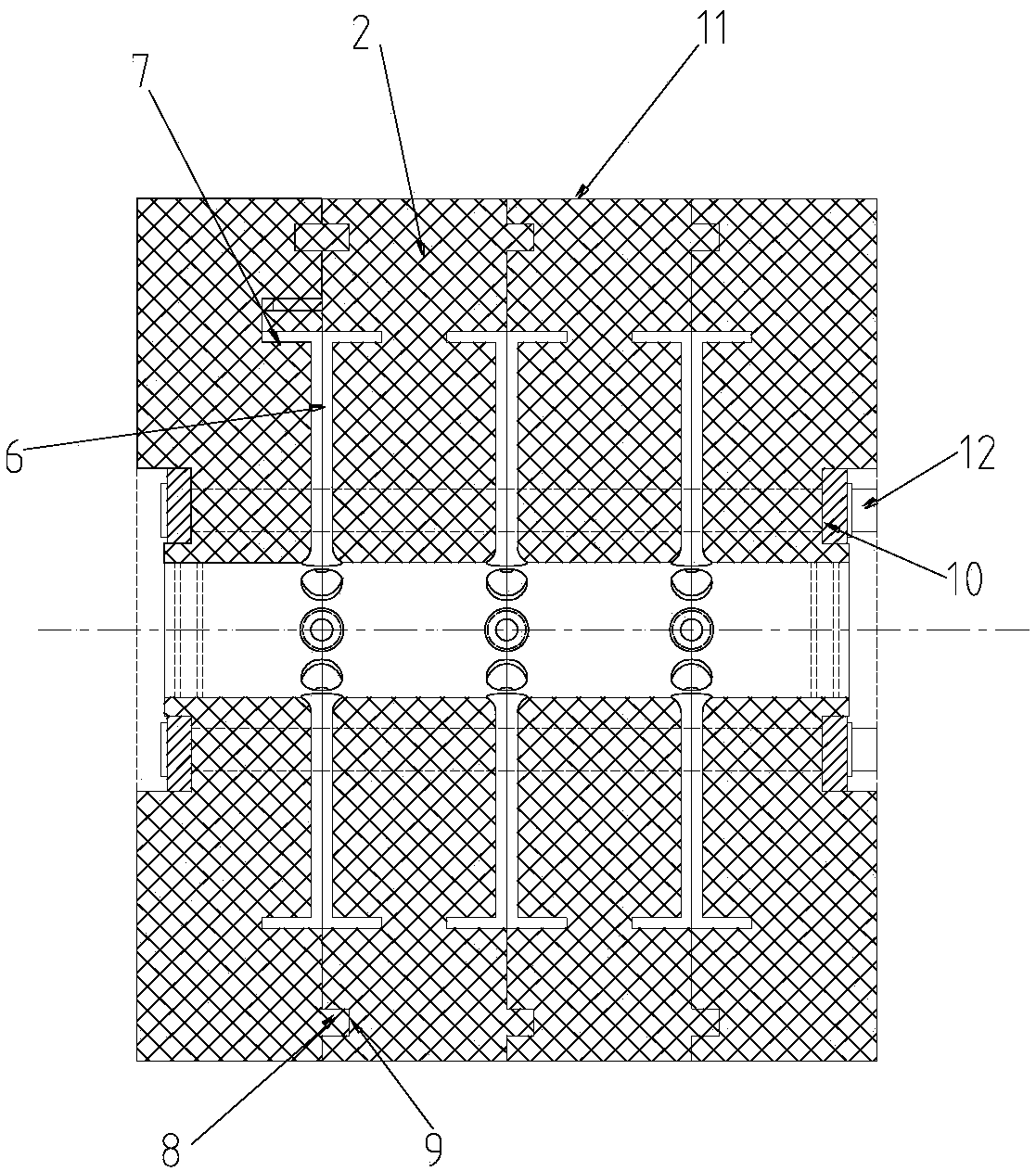

Water body scale removing and preventing apparatus and applications thereof

InactiveCN106477735AUniversalAccurate Quantitative DesignScale removal and water softeningWater flowEngineering

The present invention discloses a water body scale removing and preventing apparatus, which comprises: a cylindrical housing arranged on a water flowing pipeline; and a core coaxially and fixedly arranged in the housing in a sleeved manner, wherein the outer peripheral surface is provided with a concave groove, and the gap formed between the concave groove and the inner wall of the housing is adopted as the water flowing channel. According to the present invention, with the flowing channel structure of the core, the water can be subjected to contact friction with the core and is impacted during the flowing so as to generate the eddy flow, such that the metal electrons in the alloy can be separated and released to adsorb and combine the ions such as calcium and magnesium in the water so as to achieve the water body scale removing and preventing; the invention further discloses applications of the water body scale removing and preventing apparatus in scale removing and preventing of heat exchangers; and with the water body scale removing and preventing apparatus of the present invention, the effective water body scale removing and preventing can be achieved, and the technical problems of low efficiency and poor scale removing and preventing effect of the existing apparatus can be solved.

Owner:武汉市嘉扬电气有限责任公司

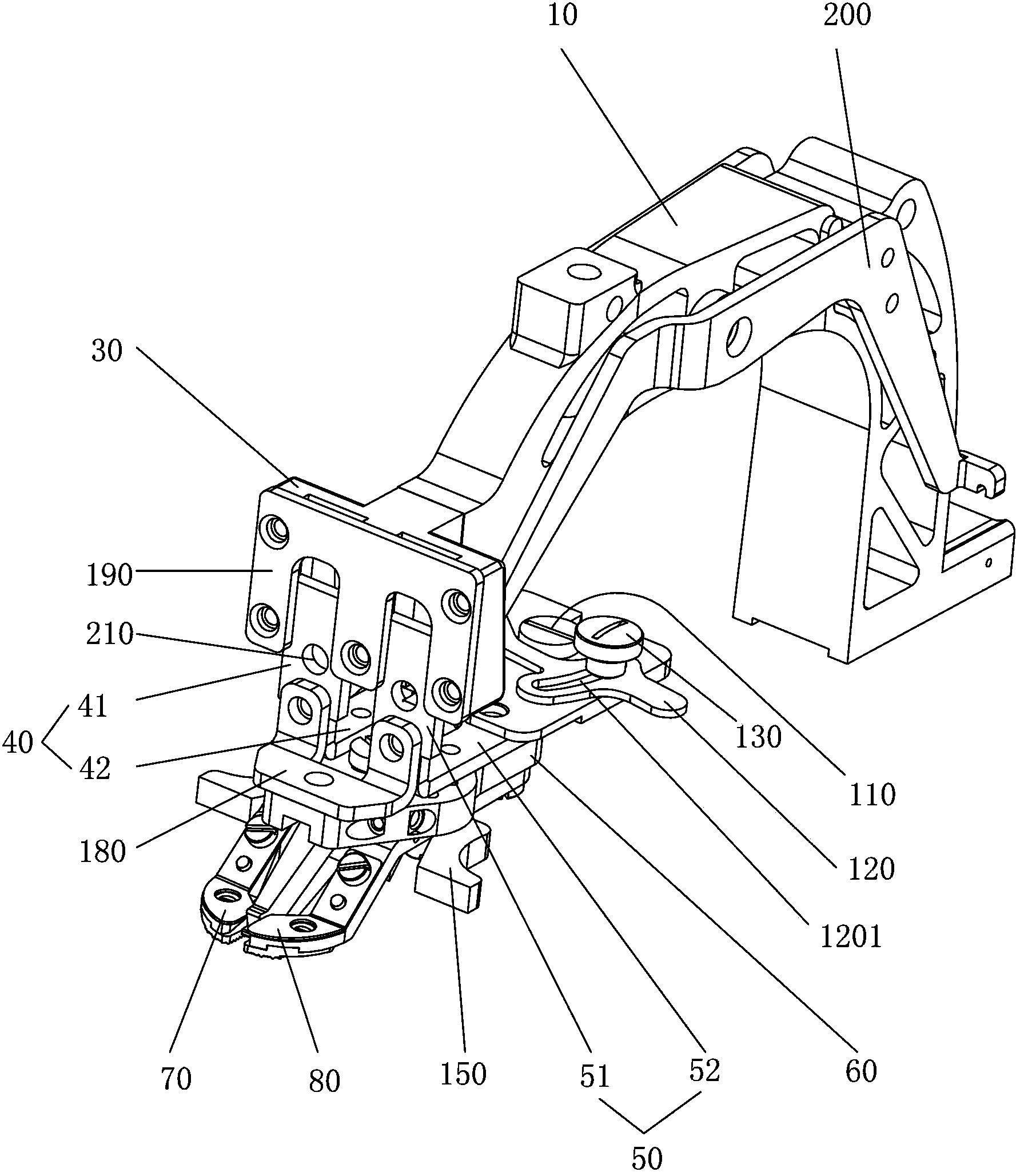

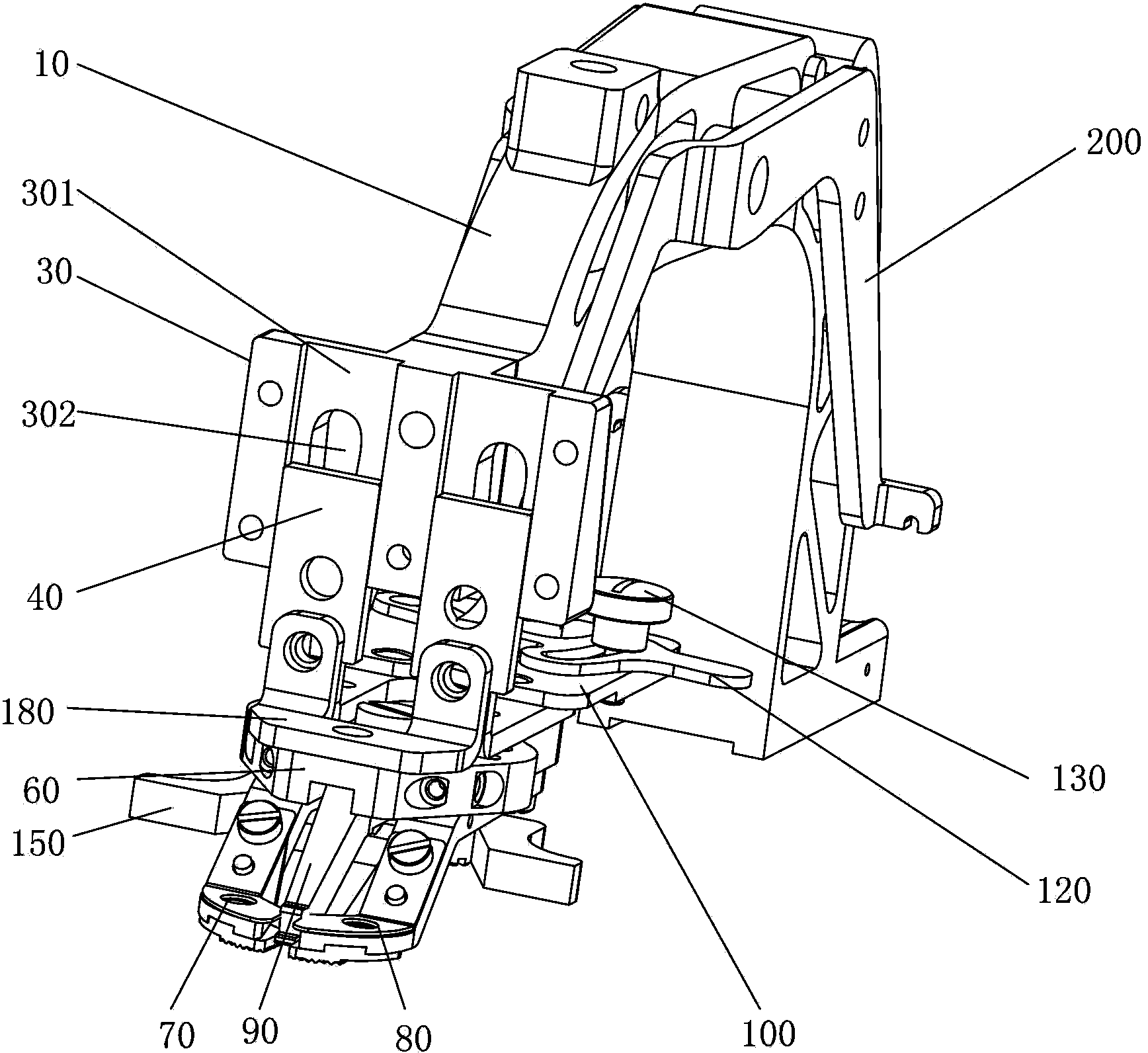

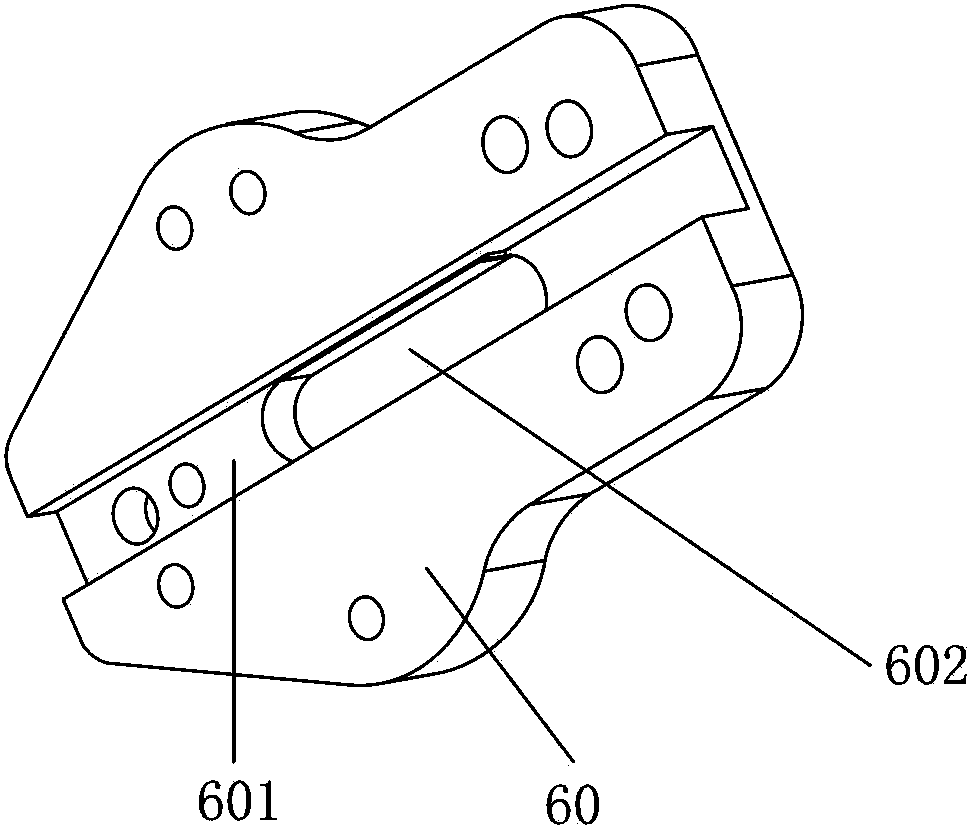

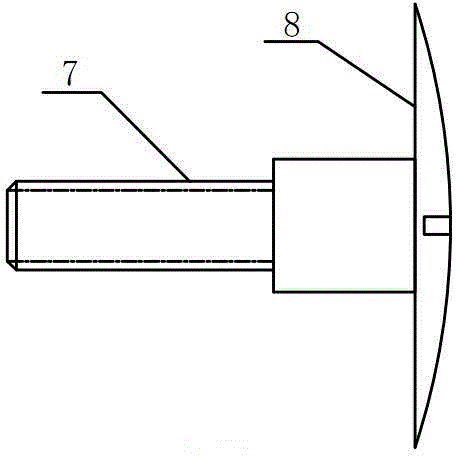

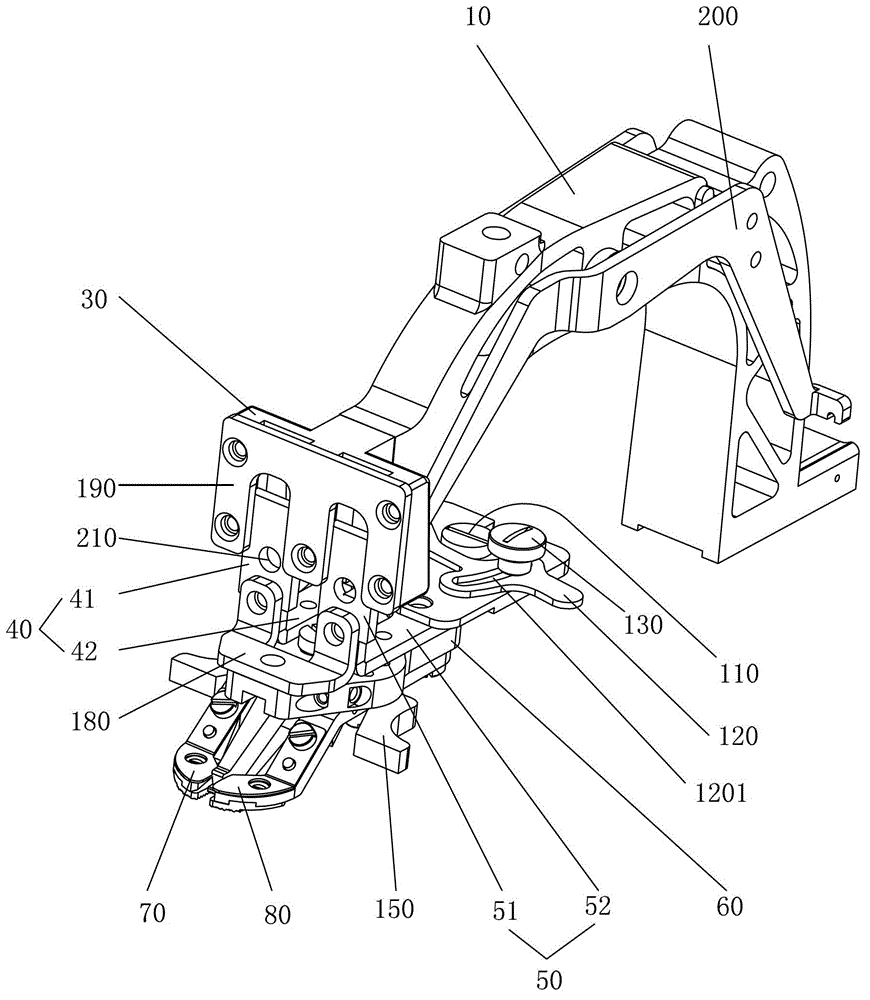

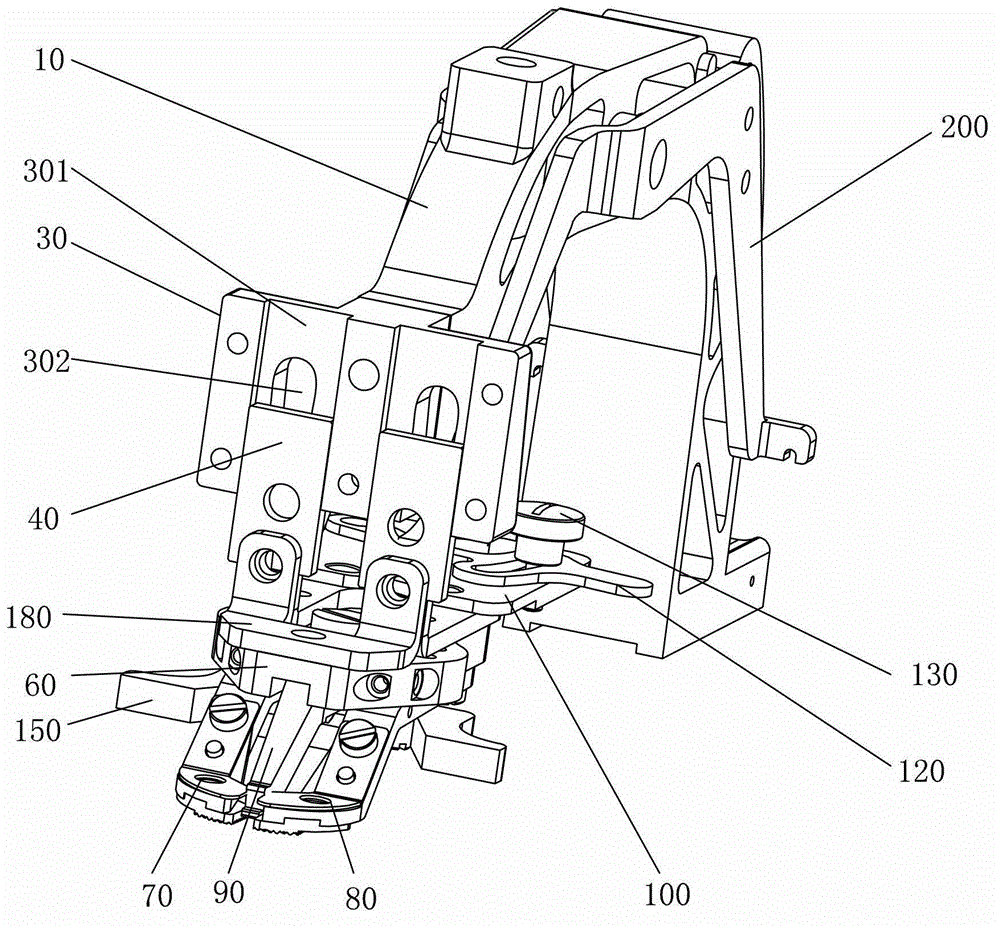

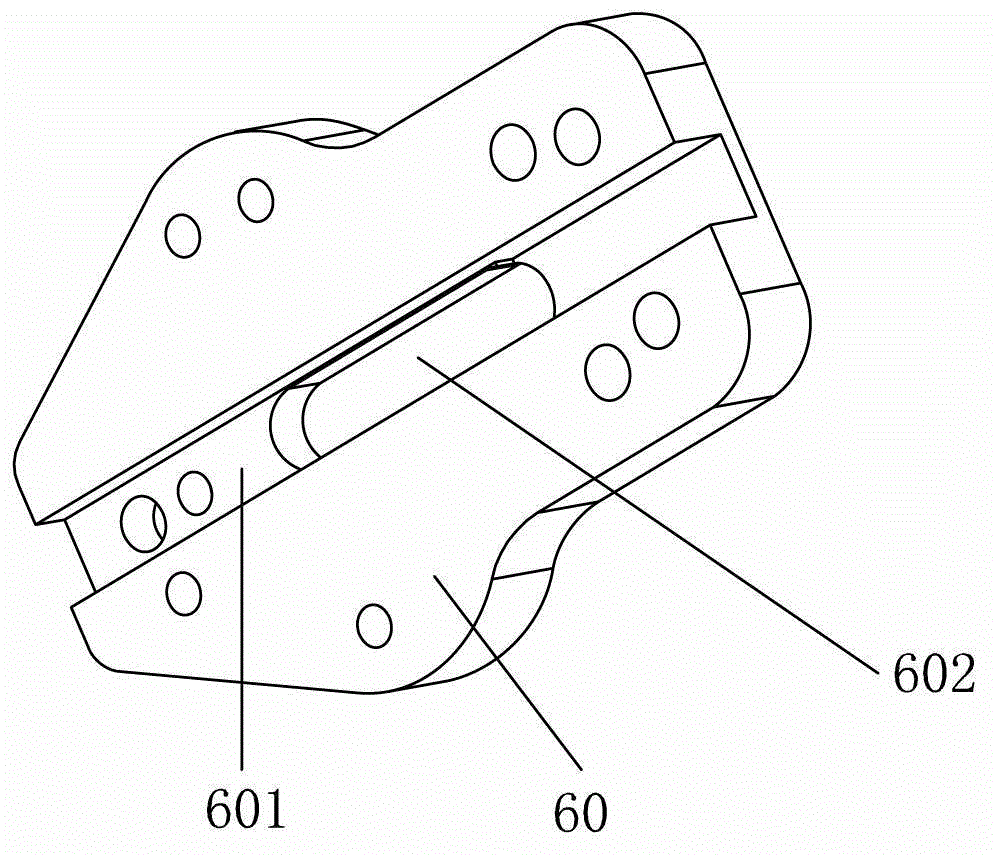

Switching structure of button sewing machine and bar tacking machine

ActiveCN103397479ASave use cost and labor costEasy to assemble and disassemblePressersEngineeringSewing machine

The invention belongs to the technical field of sewing equipment, and particularly relates to a switching structure of a button sewing machine and a bar tacking machine. A bar tacking adapter or a button sewing adapter is arranged at the front end of a supply frame. Correspondingly, a bar tacking presser foot device is connected to the bar tacking adapter, or a button sewing presser foot device is connected to the button sewing adapter. According to the switching structure, the button sewing adapter and the bar tacking adapter are respectively used for connecting the button sewing presser foot device and the bar tacking presser foot device with the supply frame, and the button sewing machine and the bar tacking machine can be switched as long as three or four parts are replaced, so that ordinary operators can also realize switching, utilization cost and labor cost are saved, and detachment and installation are convenient. Meanwhile, switching time is reduced, and the influence on working efficiency is reduced.

Owner:BULLMER ELECTROMECHANICAL TECH

Fan blade lighting protection device

ActiveCN104863800ADoes not affect normal workSo as not to damageMachines/enginesEngine componentsEffect lightEngineering

The invention relates to a fan lightning protection device, in particular to a fan blade lighting protection device. The device comprises a fan blade and a lightning arrester installed on the fan blade. The tip of the fan blade is sleeved with an electric conduction cap, the inner surface of the electric conduction cap is attached to the outer surface of the tip, the electric conduction cap is connected with the fan blade in a fastened mode, and the back of the electric conduction cap and the lightning arrester are connected in an electric conduction mode and assembled in a fastened mode. The fan blade lightning protection device has the advantages of being capable of effectively protecting the tip of the fan blade from being damaged by lightning, good in lightning protection effect, simple in structure, easy and convenient to install and use and good in safety performance.

Owner:张瑞恩

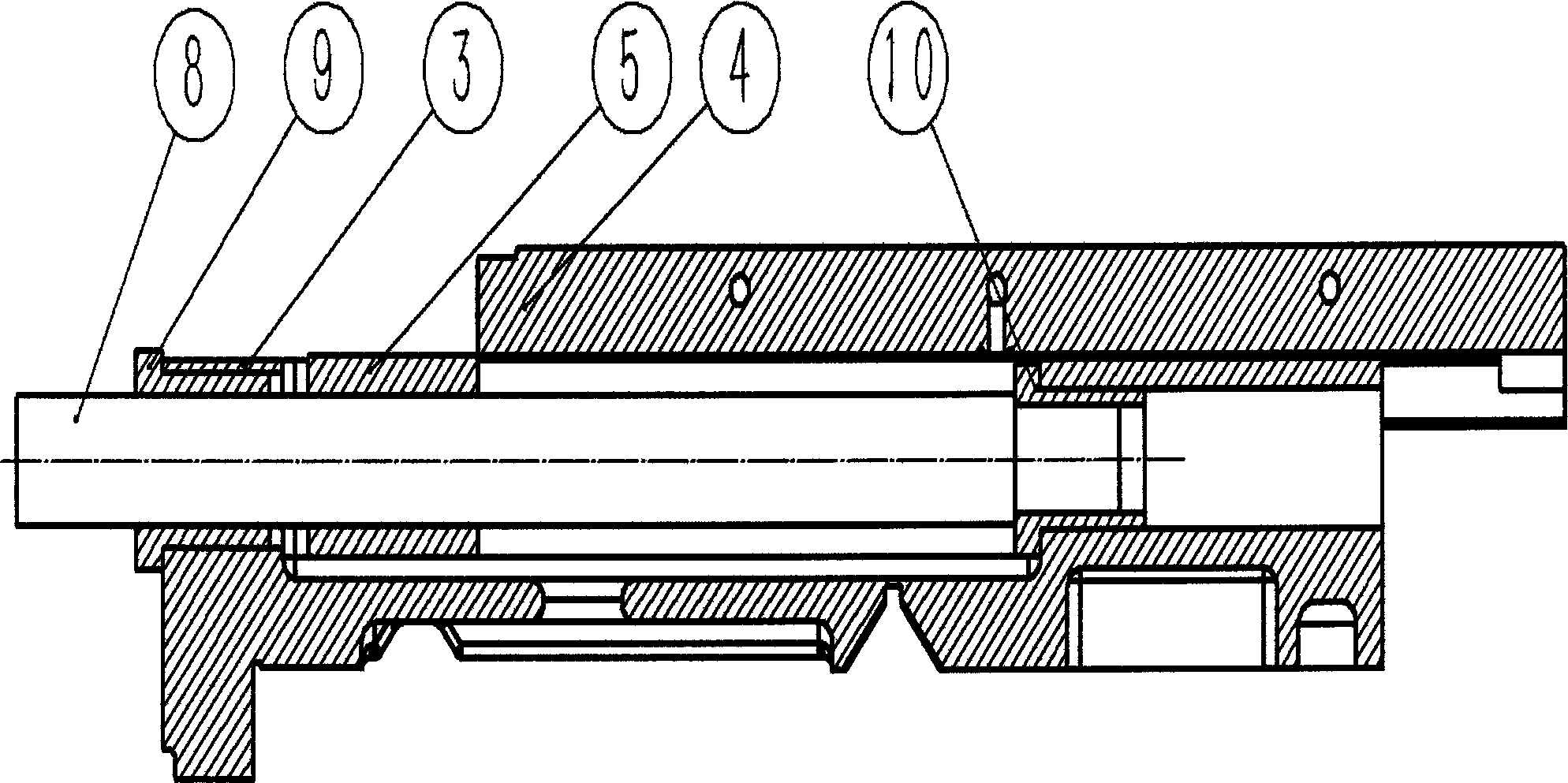

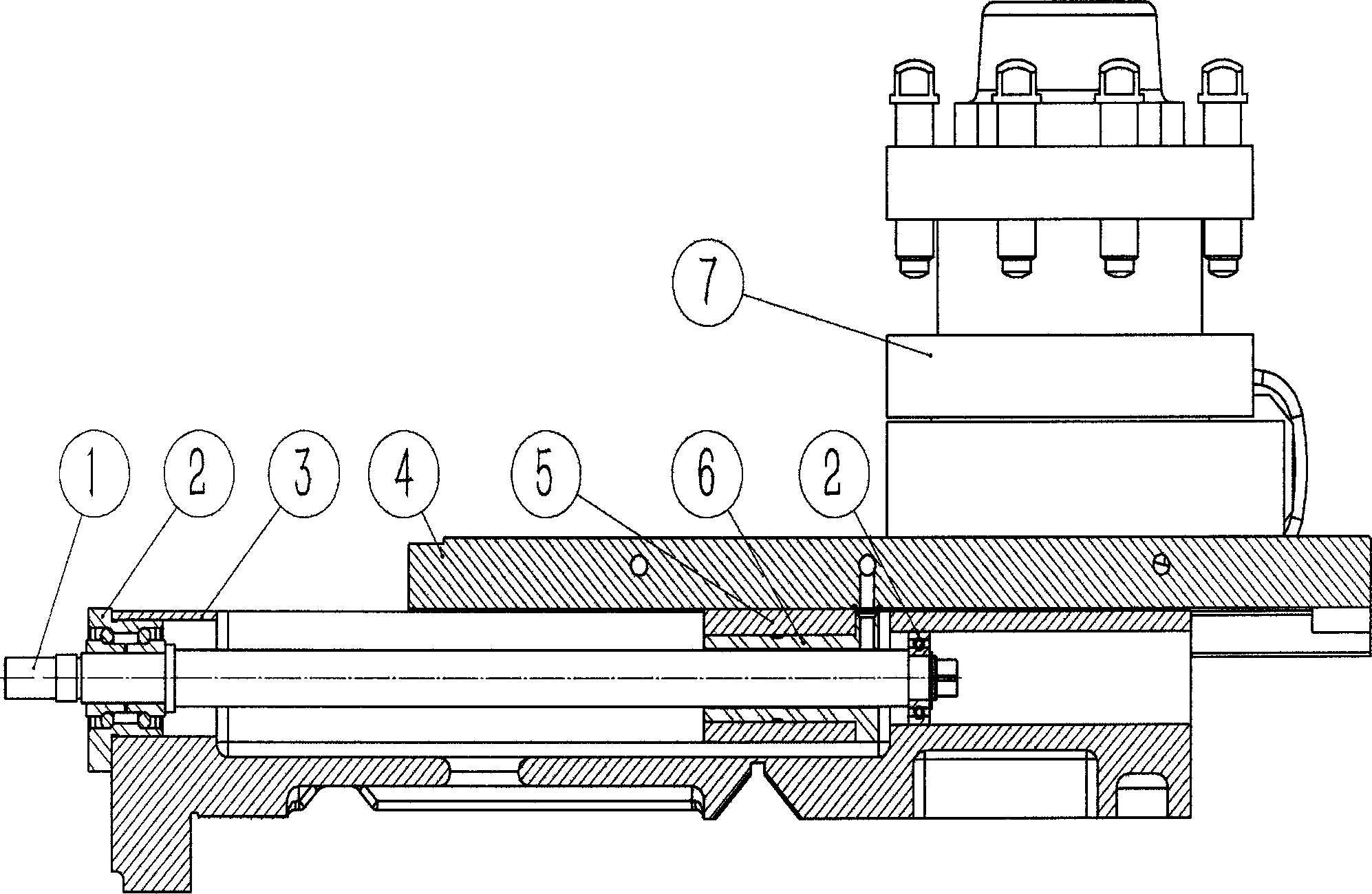

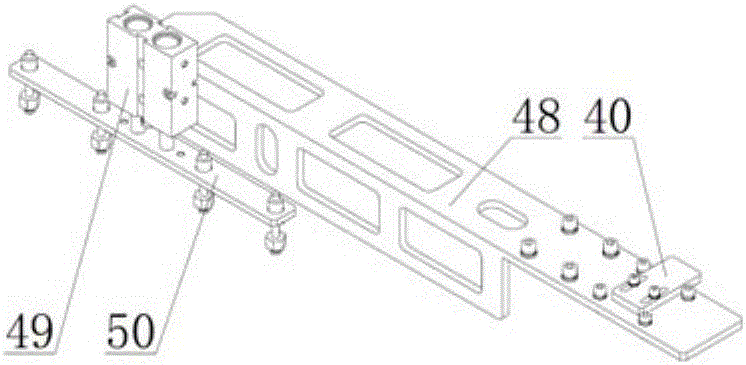

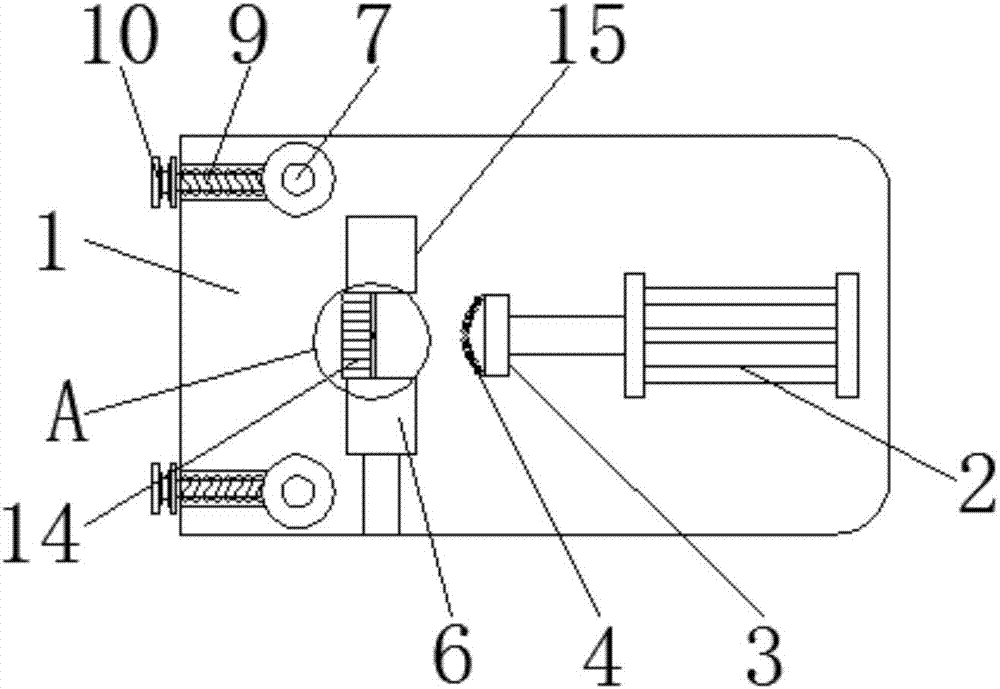

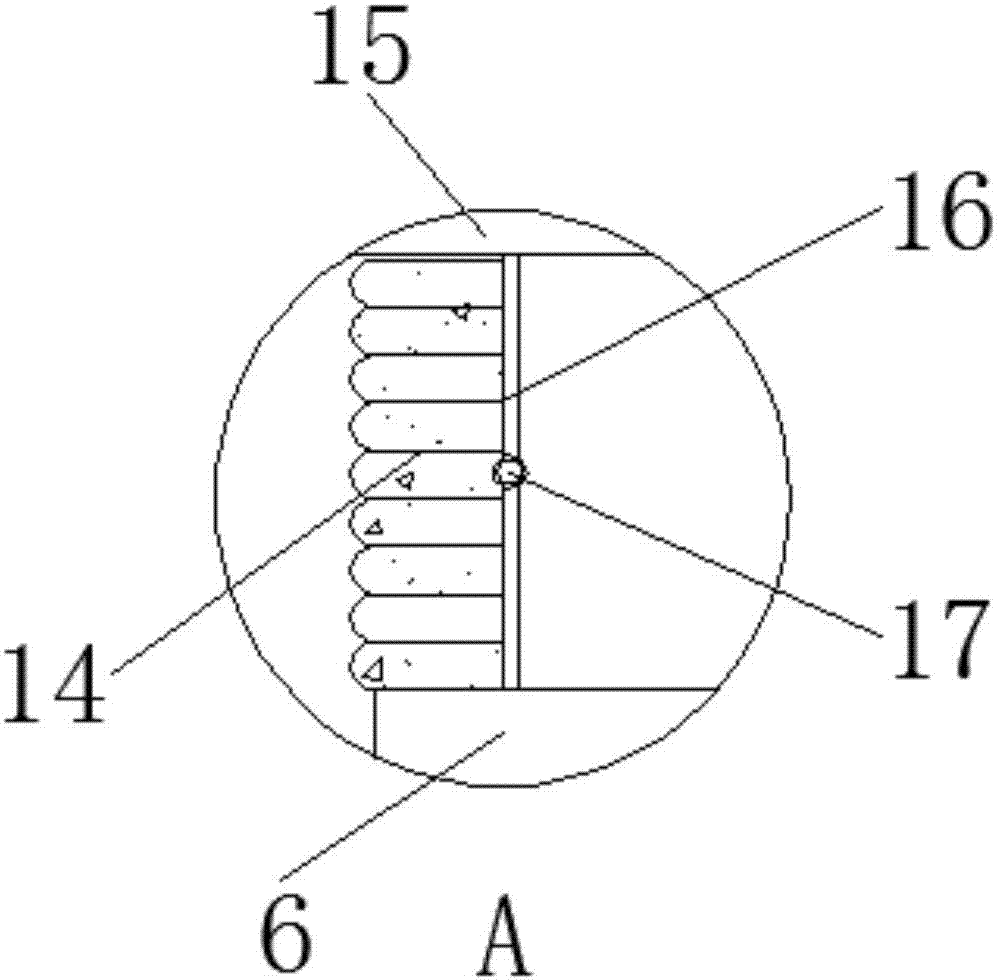

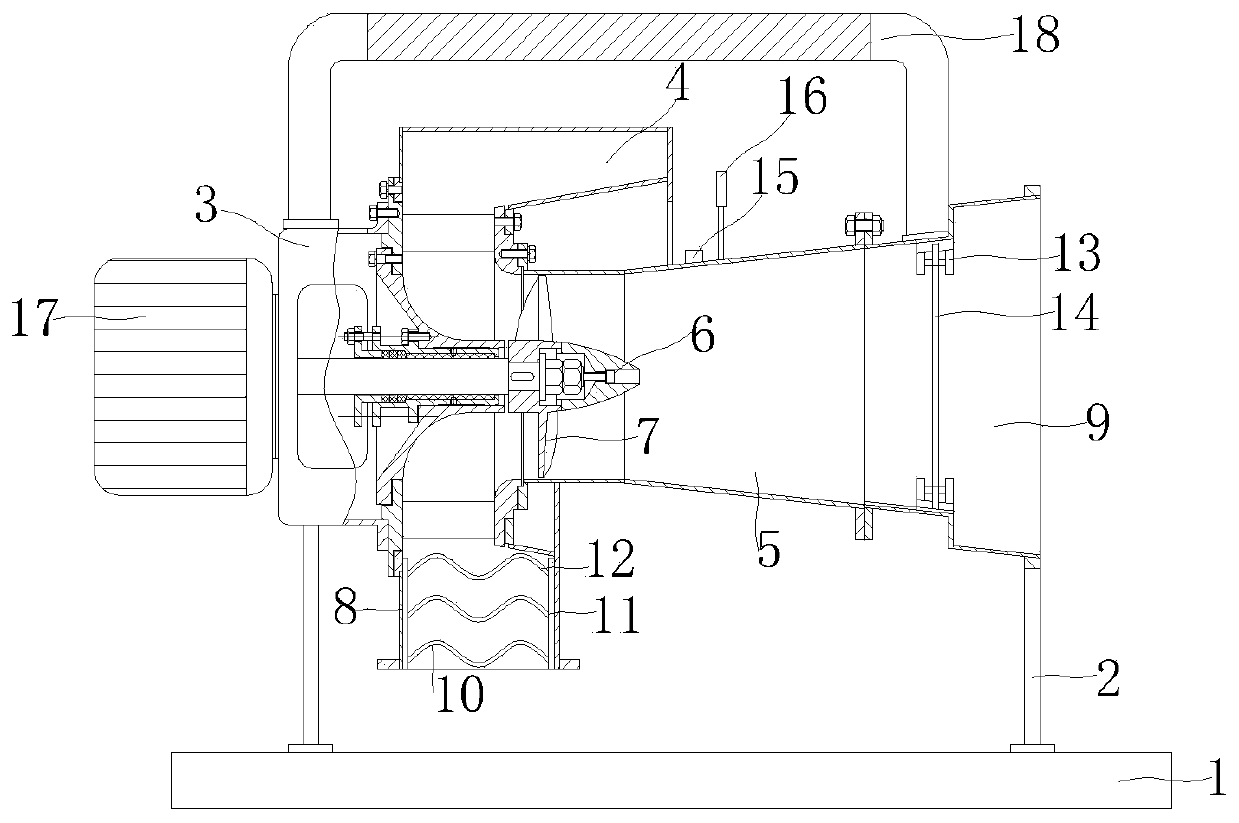

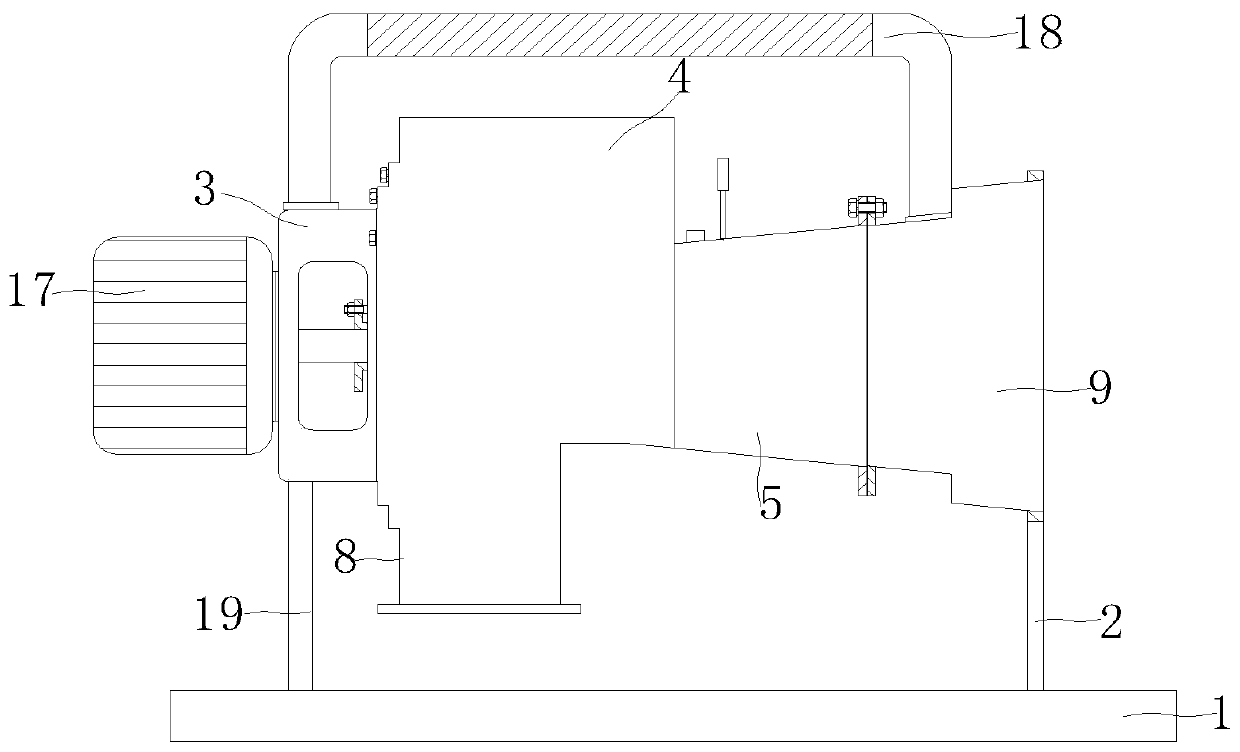

X-axis ball screw assembly fixture of numerically controlled lathe and method for using X-axis ball screw assembly fixture of numerically controlled lathe

The invention discloses an X-axis ball screw assembly fixture of a numerically controlled lathe and a method for using the X-axis ball screw assembly fixture of the numerically controlled lathe. The X-axis ball screw assembly fixture comprises a positioning core rod, a front guide sleeve and a rear guide sleeve. The front guide sleeve and the rear guide sleeve are respectively matched with two holes in a large carriage of the numerically controlled lathe for assembling an X-axis ball screw bearing, the diameter of the positioning core rod is matched with a bore of an X-axis nut seat, and the X-axis nut seat penetrates through the positioning core rod to be in directly matched grinding with a plane on an upper carriage, which is linked with the X-axis nut seat. When the X-axis ball screw assembly fixture is used, complicated measuring and match grinding processes can be reduced when operation workers assemble, the assembly reliability of an X-axis ball screw can be ensured, the assembly quality is improved, the influence of the assembling experience of a worker on the production efficiency is reduced, new workers can also quickly master the operation skill, so that the assembly efficiency is effectively improved, the assembly quality of the X-axis ball screw of the numerically controlled lathe can be ensured, and the lathing quality of the numerically controlled lathe can also be greatly improved.

Owner:ZHEJIANG RUIYUAN MACHINE TOOL

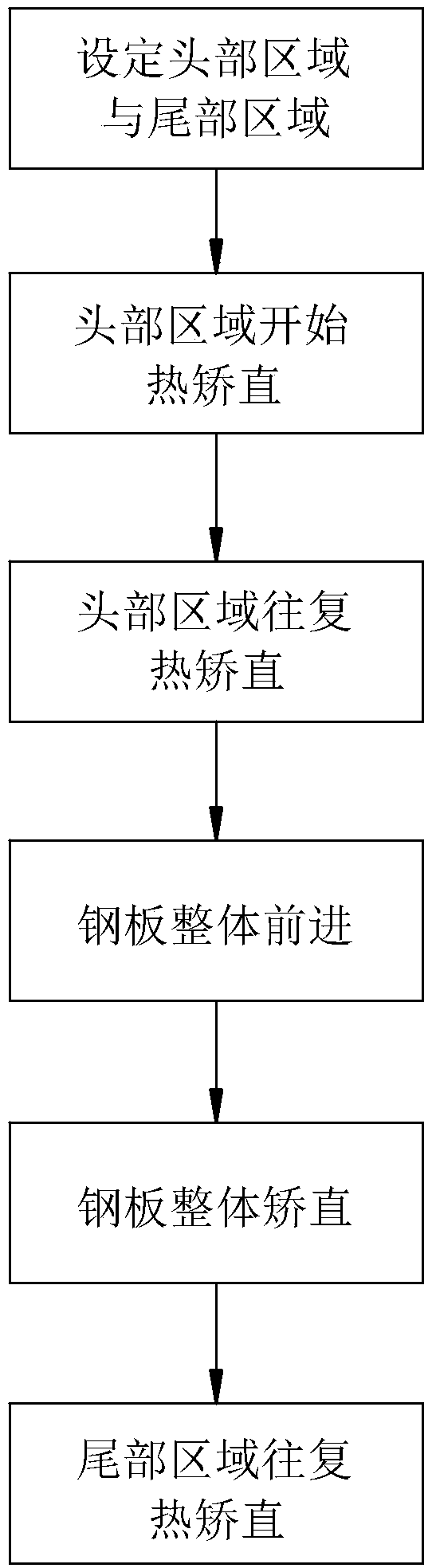

Straightening method of steel plate hot straightening machine

The invention relates to the field of metal sheet hot straightening technologies, in particular to a straightening method of a steel plate hot straightening machine. High efficiency and quality straightening of a medium steel plate is realized rapidly, and the production efficiency is not affected greatly when improving the quality. With the adoption of the straightening method, the head and the tail of the steel plate are independently subjected to three passes of straightening treatment, so that the defects of warping, bending and the like are overcome, the maximized straightening capabilityof the steel plate hot straightening machine is fully played, and the yield of the steel plate is improved, and the amendment rate is lowered.

Owner:SHANXIN SOFTWARE CO LTD

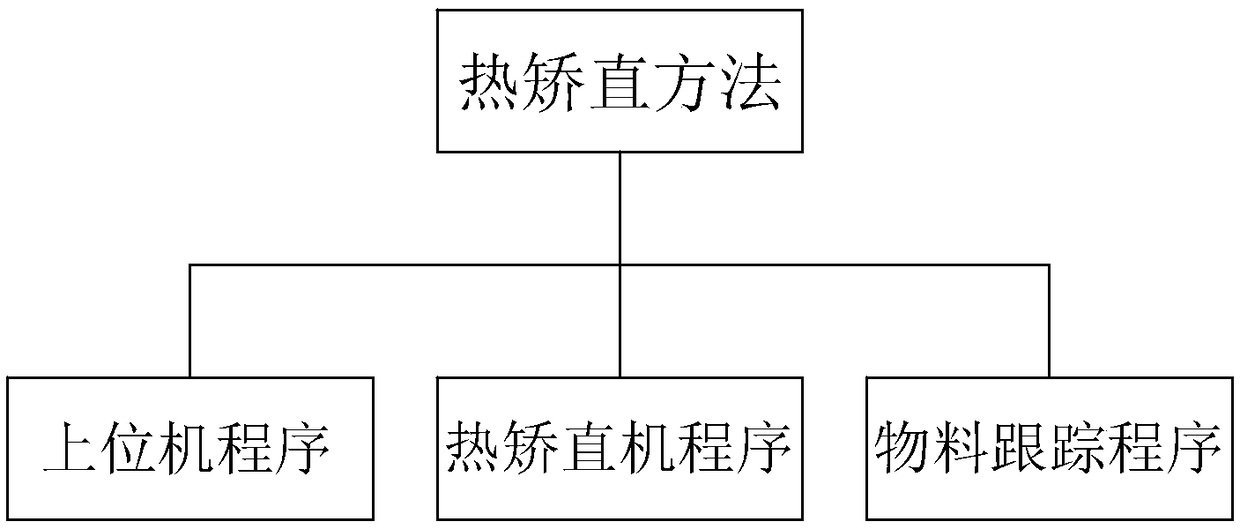

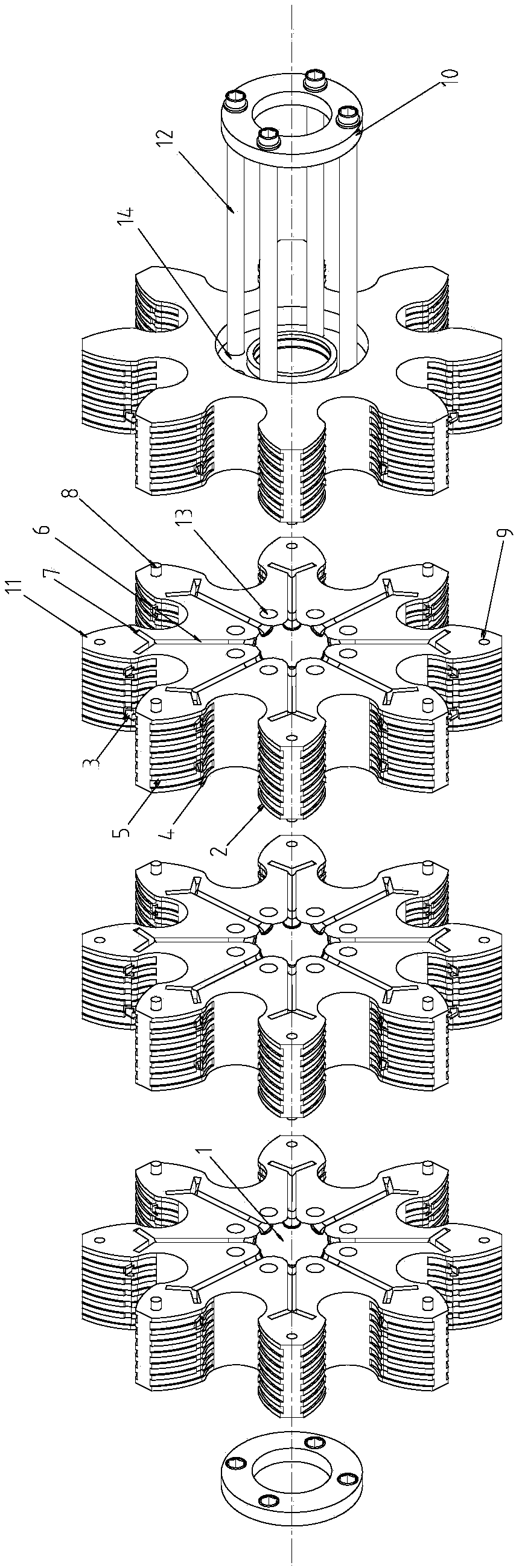

Oil-immersion cooling structure and cooling method for hub motor with dynamic adjustable oil quantity in cavity

ActiveCN106787450AMeet the needs of heat dissipation in all working conditionsReduce resistanceCooling/ventillation arrangementHeat conductingStator coil

The invention provides an oil-immersion cooling structure for a hub motor with dynamic adjustable oil quantity in a cavity. The oil-immersion cooling structure comprises a motor shell, a stator coil mounted on the inner side of the motor shell, and a rotor mounted on the inner side of the motor shell and capable of rotating around the stator coil; a water cooling sleeve is mounted between the motor shell and the stator coil; an oil guiding cavity is formed between the stator coil and the rotor; the upper end and the lower end of the oil guiding cavity are connected to oil path outlets of a first reversing valve and a second reversing valve through oil guiding pipes respectively; oil path inlets of the first reversing valve and the second reversing valve are connected to an oil storage box through the oil guiding pipes; and the first reversing valve and the second reversing valve are connected through an oil pump. The invention also provides an oil-immersion cooling method for the hub motor with dynamic adjustable oil quantity in the cavity. Intelligent dynamic adjustment can be performed according to the operating working conditions of the motor, and heat dissipation requirement of the motor operation in all working conditions can be satisfied; and in addition, relatively high barrier to rotor operation caused by heat conducting oil in the heat dissipation process also can be avoided.

Owner:GUANGDONG HI 1 NEW MATERIALS TECH RES INST CO LTD

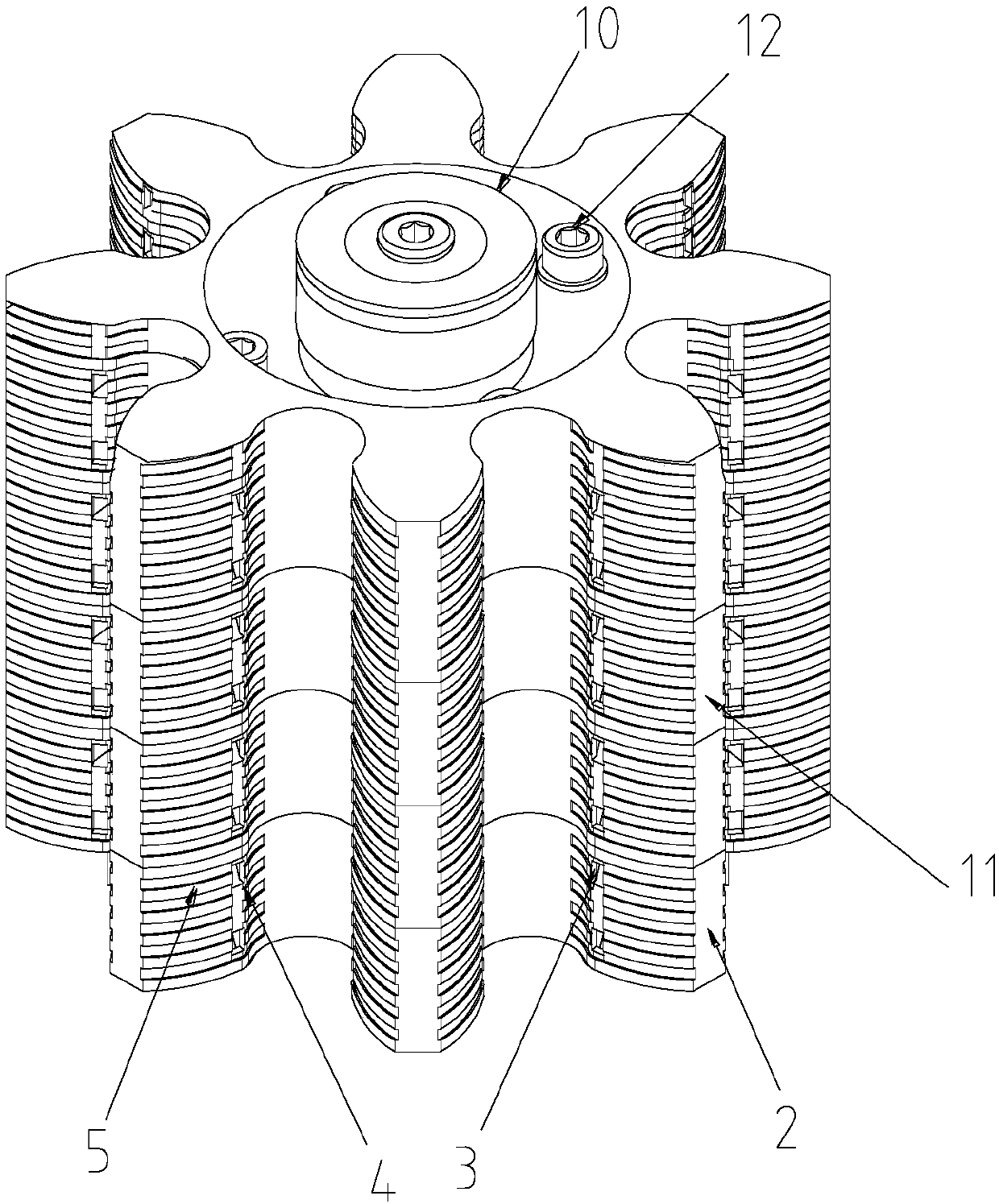

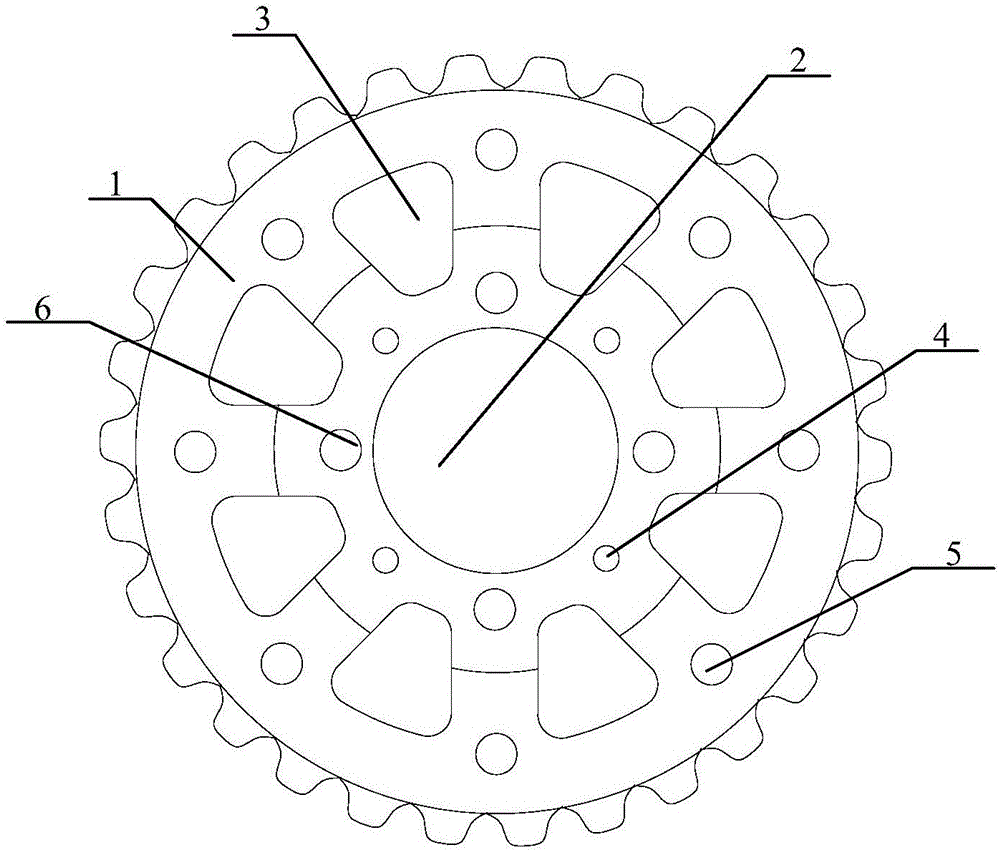

Lubricating gear

InactiveCN107606106AUniform coatingAchieve coatingGear lubrication/coolingPortable liftingOil canEngineering

The invention relates to the field of gears, and discloses a lubricating gear. The lubricating gear is provided with an axially-extending central hole (1) and a plurality of teeth (2), wherein a lubricating oil channel which communicates with the central hole (1) and extends into the teeth (2) is formed in the lubricating gear, and a lubricating oil outlet (3) which communicates with the lubricating oil channel is formed in the tooth surfaces of the teeth. According to the technical scheme, the lubricating oil channel can convey lubricating oil to the tooth surfaces of the lubrication gear through the lubricating oil outlet, so that the lubricating oil can be evenly distributed on all tooth surfaces, and full lubricating for the teeth is achieved; thereof, when the tooth surfaces of the lubricating gear are engaged with the tooth surfaces of a to-be-lubricated gear, the tooth surface of the to-be-lubricated gear can be evenly coated with the lubricating oil, and lubricating for the to-be-lubricated gear is achieved; and the lubricating process can be conducted during normal operation of the gear, and influence on working efficiency is very little.

Owner:张盛银

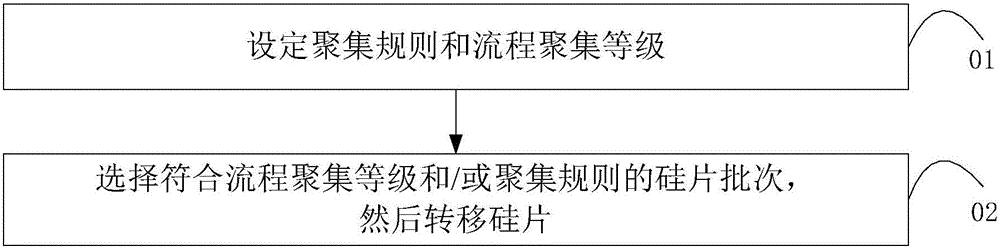

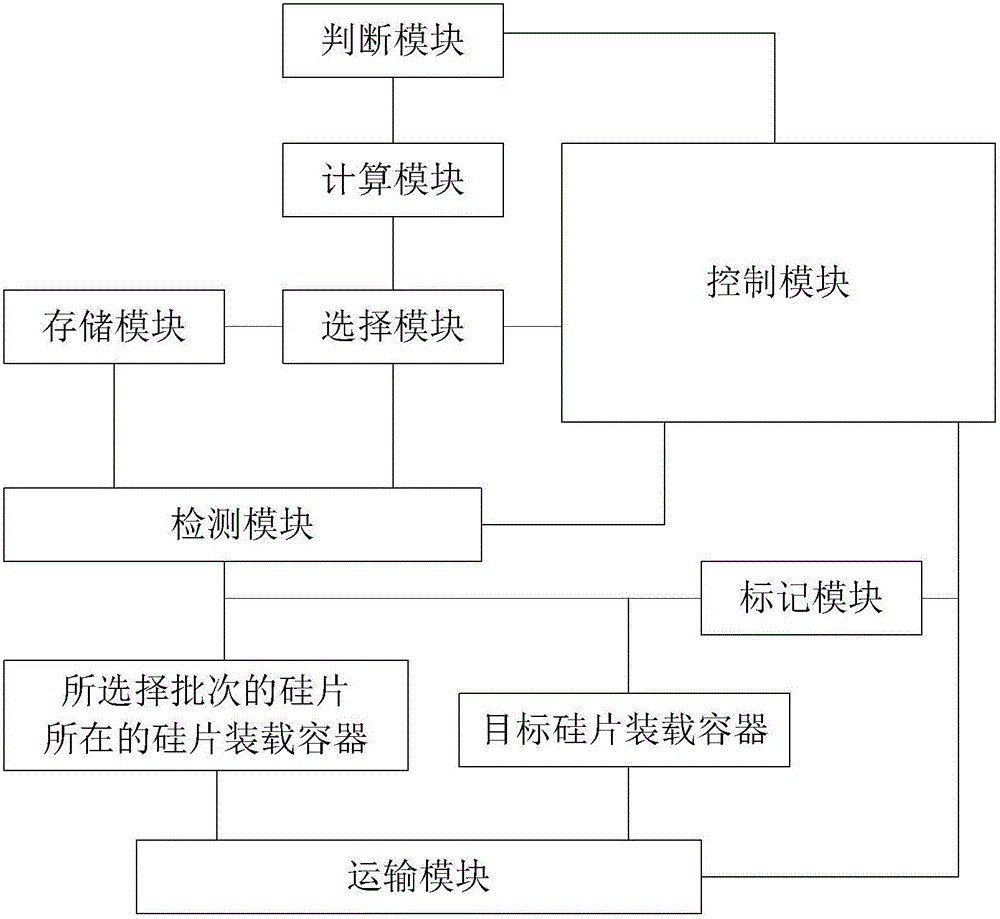

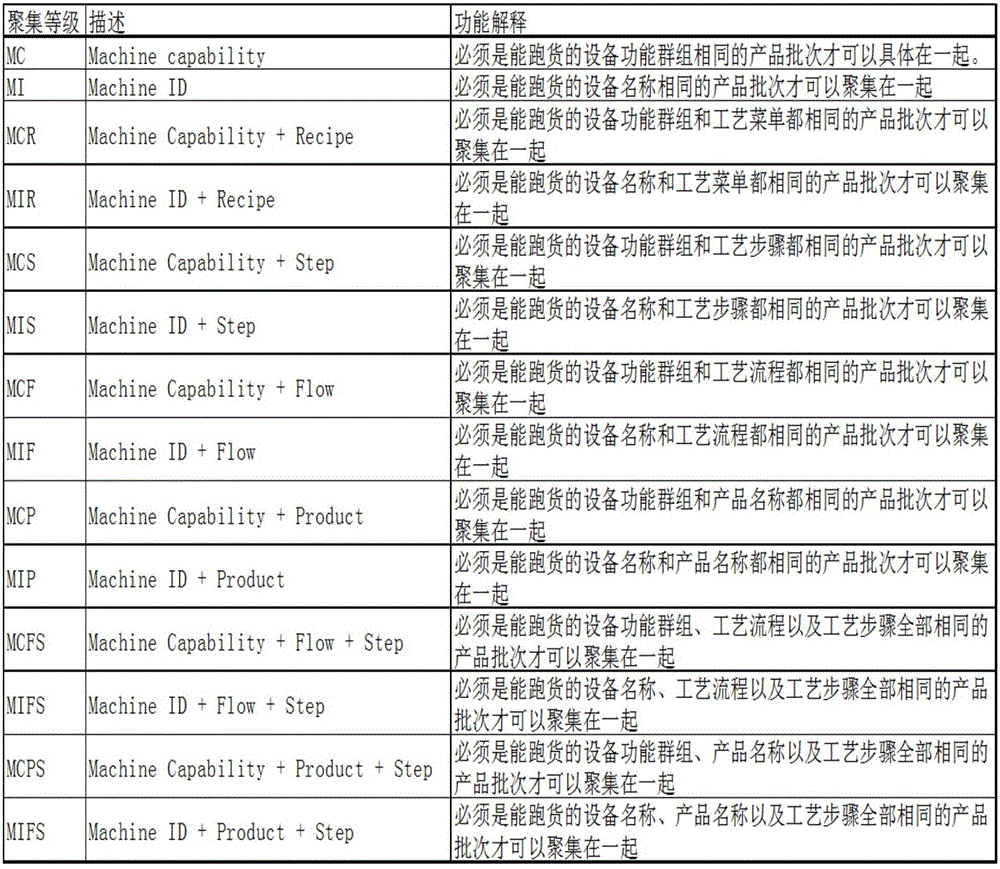

Silicon wafer batch management method and system

InactiveCN106056464AEasy to separateSafe and effective separationData processing applicationsSemiconductor/solid-state device testing/measurementProcess engineeringContamination

The invention relates to a silicon wafer batch management method and system, wherein the method and system are applied to a silicon wafer processing flow. The method comprises: an accumulation rule and flow accumulation levels are set, wherein the flow accumulation levels include different accumulation types; silicon wafer batches meeting the flow accumulation levels and / or the accumulation rule are selected; and then the silicon wafers are transferred. Therefore, the operation and control on automatic batch accumulation or distribution of the system are realized; a cross contamination phenomenon is avoided; and priority control on special products is realized.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

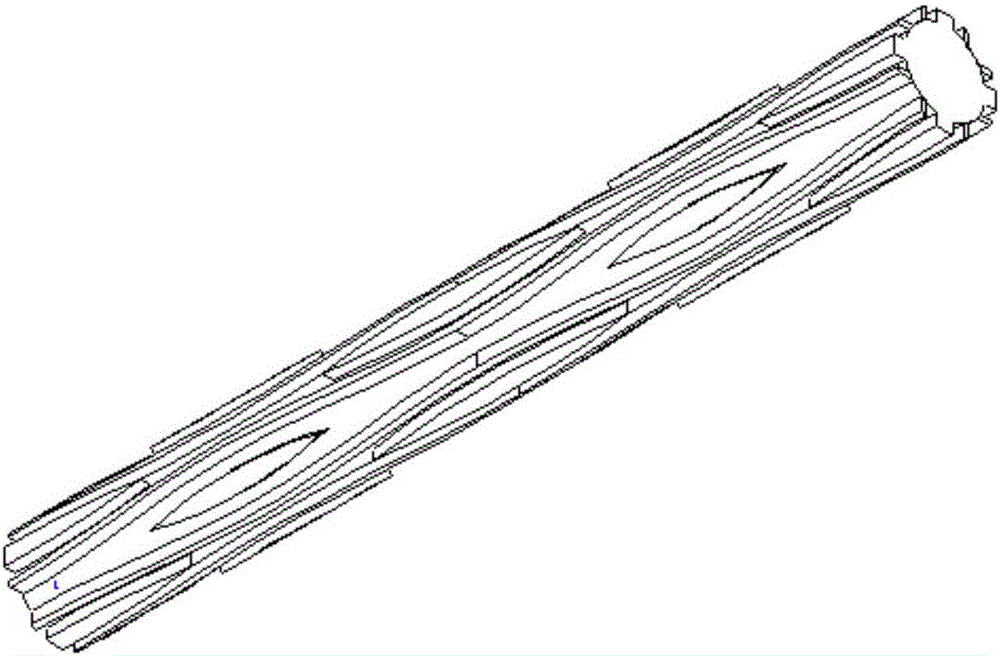

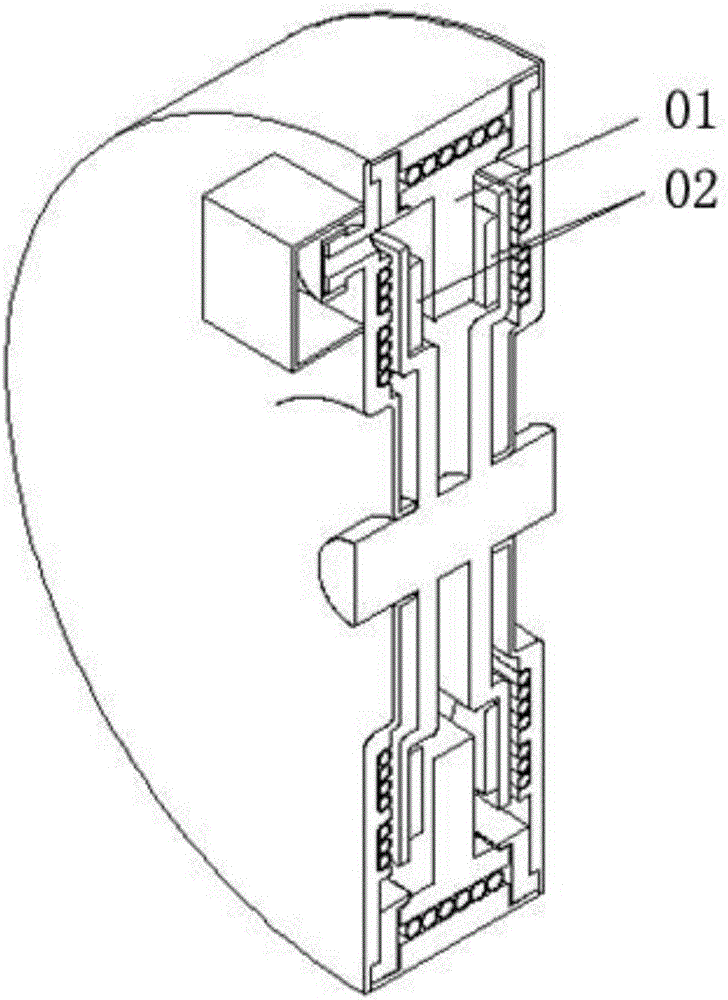

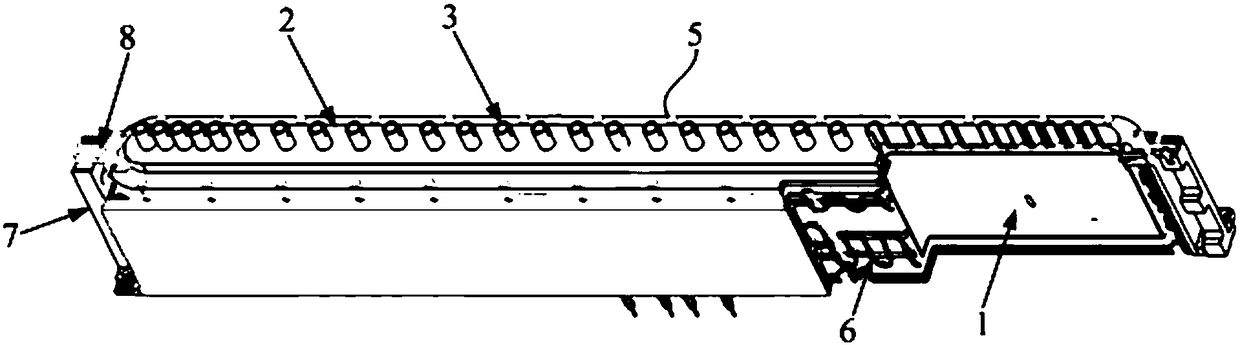

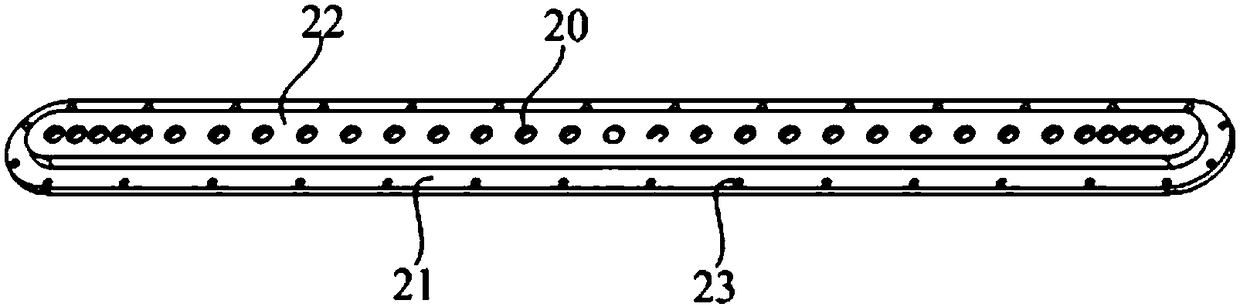

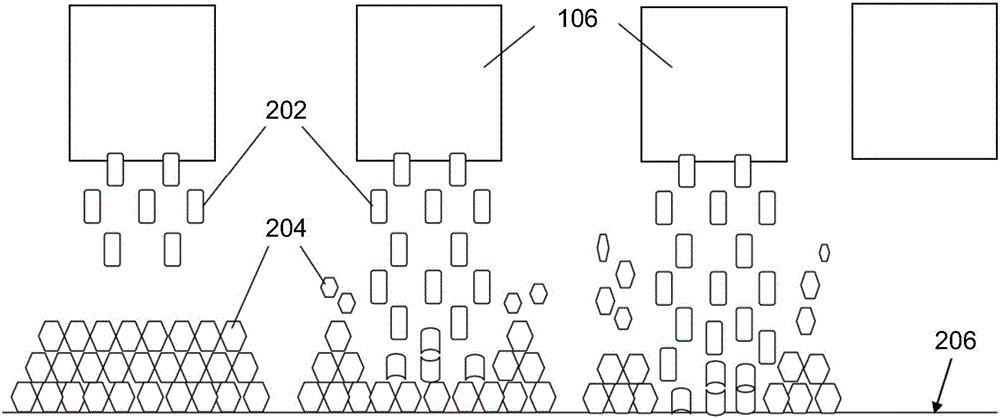

Linear evaporation source and vacuum evaporation device

InactiveCN109234682AImprove uniformityIncrease speedVacuum evaporation coatingSputtering coatingCrucibleSpray nozzle

The invention relates to the technical field of evaporation and discloses a linear evaporation source and a vacuum evaporation device. The linear evaporation source comprises a crucible, a mounting plate and a plurality of nozzles, wherein the crucible is provided with an opening part extending in the length direction of the crucible; the mounting plate is detachably mounted at the opening part ofthe crucible, and a plurality of evaporation holes arranged in the extending direction of the opening part and penetrating the mounting plate in the thickness direction are formed in the mounting plate; the plurality of nozzles are in one-to-one correspondence with the evaporation holes in the mounting plate, and each nozzle is detachably mounted to the corresponding evaporation hole. The linearevaporation source can guarantee long-term stable evaporation uniformity; the crucible and an evaporation material are not needed to be replaced in a maintaining process of the linear evaporation source, so that maintenance operation is simple and convenient and consumes shorter time, influence on the production efficiency is smaller, and update cost is lower.

Owner:合肥欣奕华智能机器股份有限公司

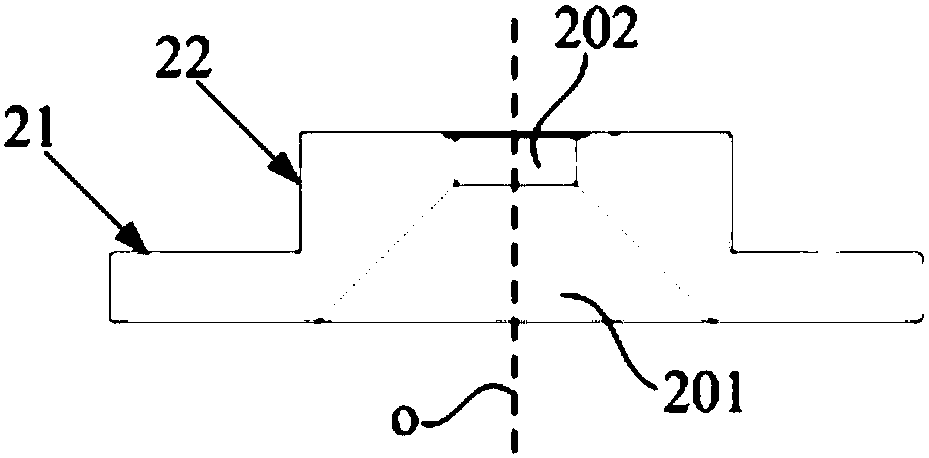

Timing chain wheel

InactiveCN106763651AUniform mass distributionIncrease cooling areaPortable liftingGearing detailsSprocketMass distribution

The invention discloses a timing chain wheel which comprises a chain wheel body; a shaft hole is formed in the chain wheel body; and mounting of the chain wheel body is realized through the shaft hole. According to the scheme disclosed by the invention, the timing chain wheel is improved, first radiating holes are formed in the chain wheel body; the first radiating holes are arranged in the peripheral direction of the chain wheel body; and the first radiating holes are uniformly arranged along the circumference of the chain wheel body, so that mass distribution, in the peripheral direction, of the chain wheel is uniform. A depth extending direction of the first radiating holes is parallel to the axis of the chain wheel body, i.e., the first radiating holes are formed in the axial direction of the chain wheel body; the first radiating holes are formed, so that the radiating area of the chain wheel body is increased, and therefore, heat generated in a rotation process of a chain disc can be effectively radiated, influences, on working efficiency of the timing chain wheel and an engine, of heat are reduced, and service lives of the timing chain wheel and the engine are prolonged.

Owner:CHONGQING JUE LANG MOTORCYCLE SPARE PARTS

A method for removing nodules on the hearth roll of a heat treatment furnace on-line

ActiveCN104896963BThe impact of reducing productivityThe generation of solutionIncrustation removal devicesNumerical controlMaterial resources

Owner:贝斯山钢(山东)钢板有限公司

Method of quickly preparing aerogel by accelerating solvent extraction

The invention discloses a method of quickly preparing aerogel by accelerating solvent extraction. The method comprises the following steps of: (1) mixing and diluting a fixed quantity of inorganic silicon source and water, adding a fixed amount of acid to form salt-bearing silicasol, and obtaining gel after a period of time, (2) accelerating the solvent extraction of the gel obtained in step (1) with an organic solvent aqueous solution of which a concentration is increased with time, and (3) drying the gel obtained in step (2). The method of preparing the aerogel is simple in procedure, shortin production cycle and low in energy consumption, and the aerogel product has the characteristics of complete structure, low heat conductivity coefficient and high mechanical strength.

Owner:浙江岩谷科技有限公司

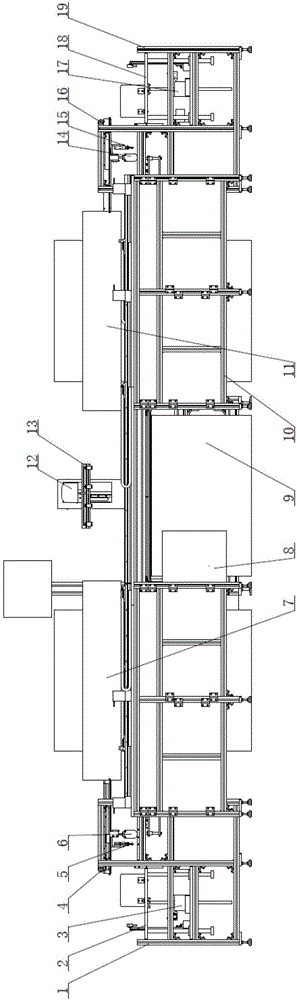

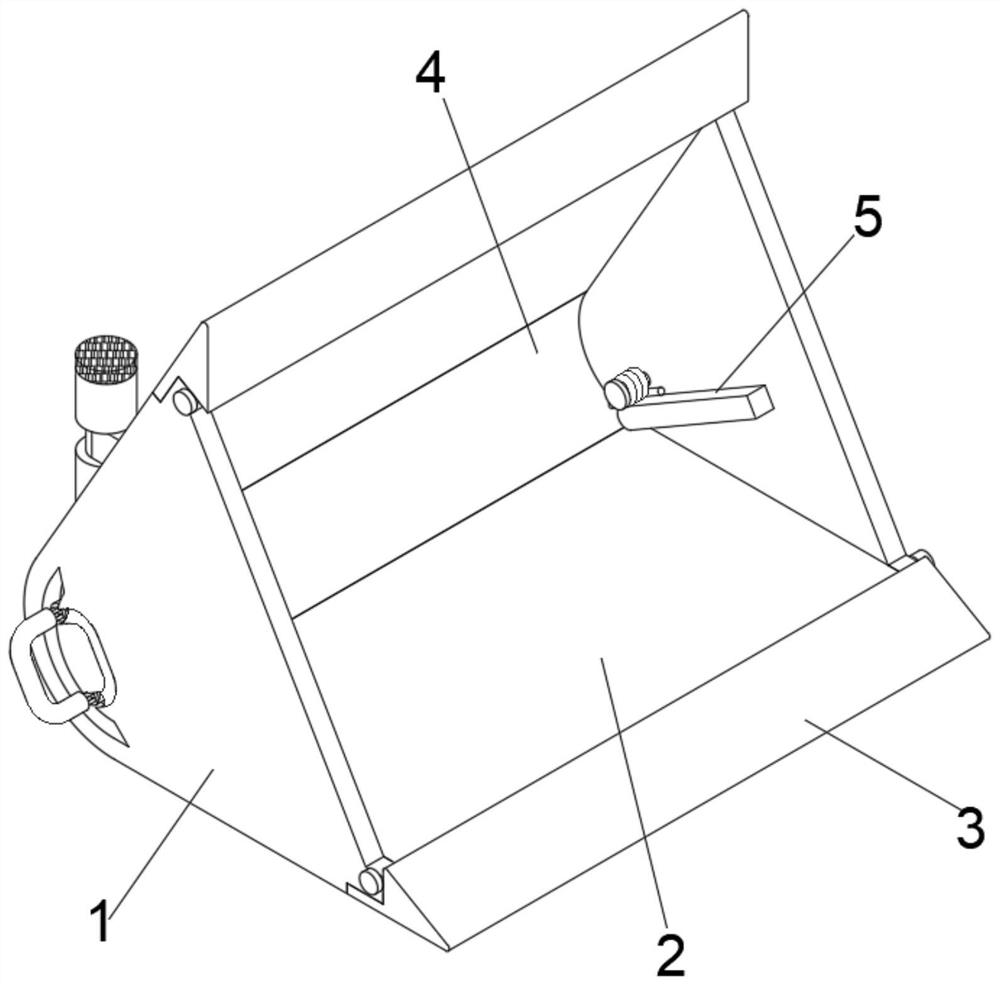

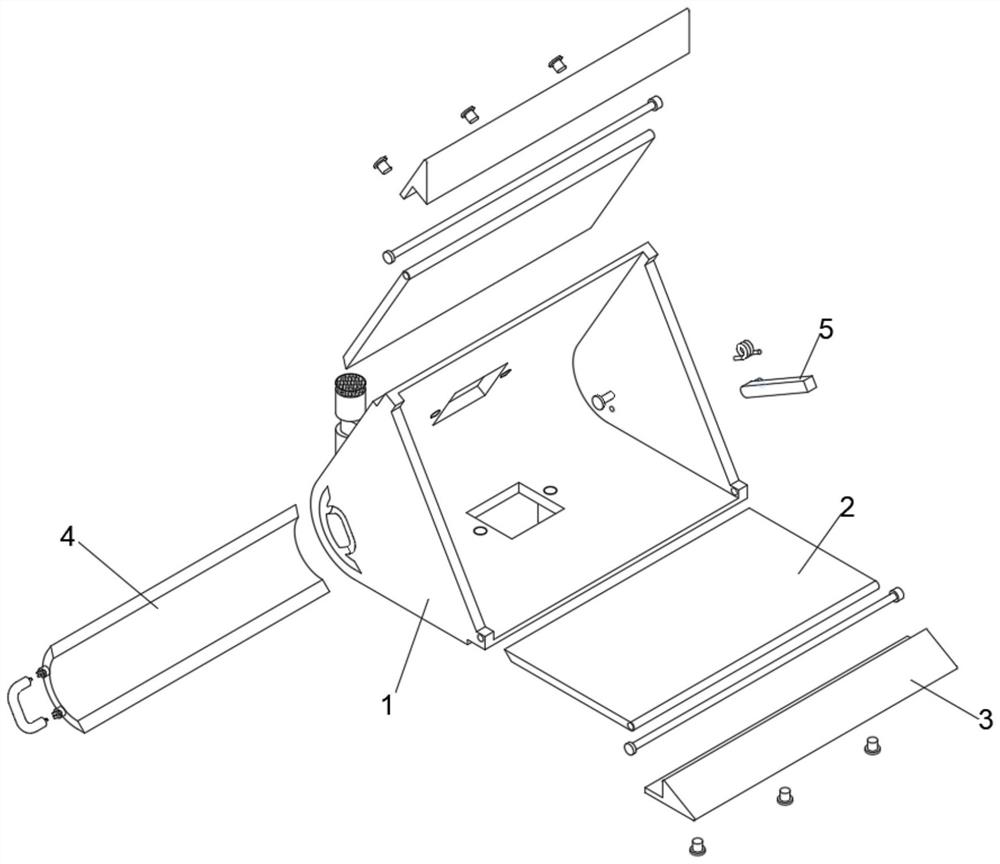

PTB-F screening type conveyor

ActiveCN110304418AThe impact of reducing productivityAdapt to Width RequirementsSievingScreeningCouplingSlide plate

The invention discloses a PTB-F screening type conveyor in the technical field of conveyors. The PTB-F screening type conveyor comprises a conveyor frame, wherein the top of the conveyor frame is welded with supporting side plates in front and back in parallel, two groups of limiting sliding rods and two groups of positioning screws are respectively and longitudinally installed between the two groups of supporting side plates, the two groups of positioning screws are arranged between the two groups of limiting sliding rods, the outer ends of the positioning screws are provided with positioningmotors through couplings, and positioning sliding plates are symmetrically installed between the limiting sliding rods and the positioning screws front and back. The whole belt type transmission is designed to be sectional belt type transmission and multi-wheel interval synchronous transmission, the head part and the tail part are each provided with a section of belt transmission, the middle section is interval transmission of a liftable lifting supporting plate and a plurality of small transmission wheels which are not liftable in a matched mode, screens of different specifications can be fixed by arranging lifting mechanisms, the screens are replaced by lifting very conveniently, the equipment does not need to be stopped, and the influence on production efficiency is reduced.

Owner:深圳市矗鑫电子设备有限公司

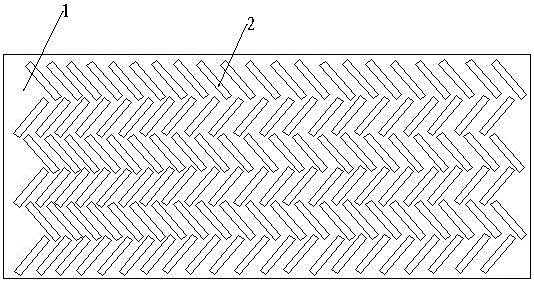

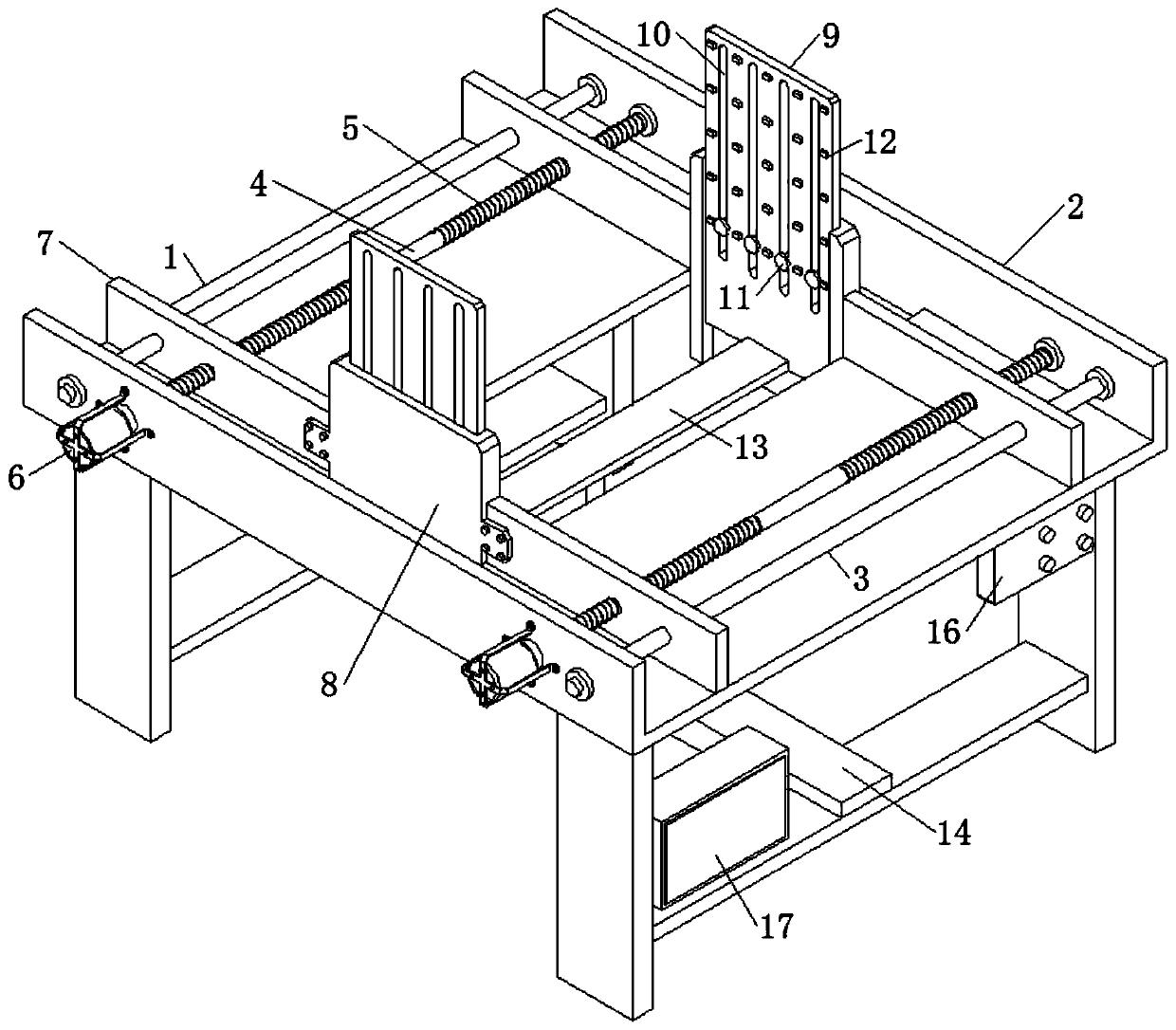

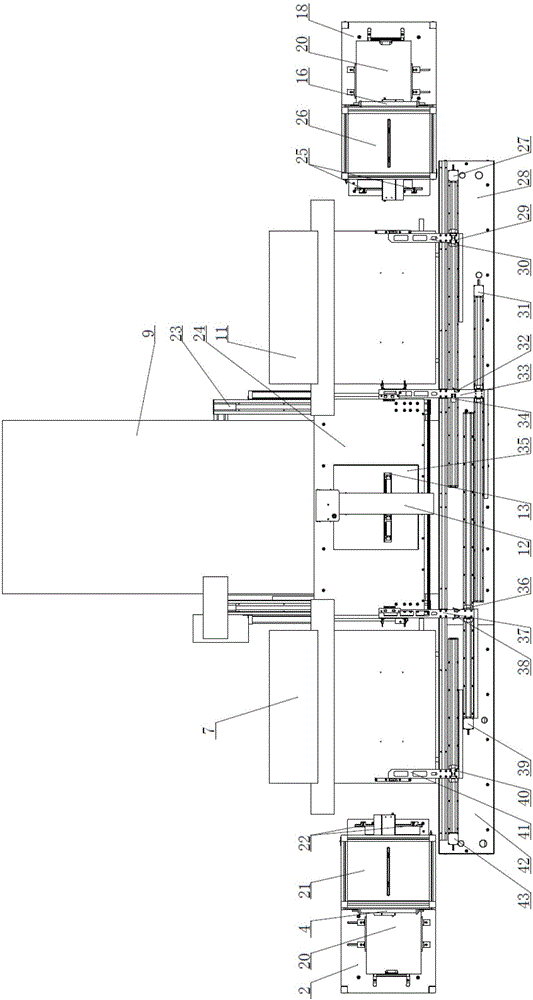

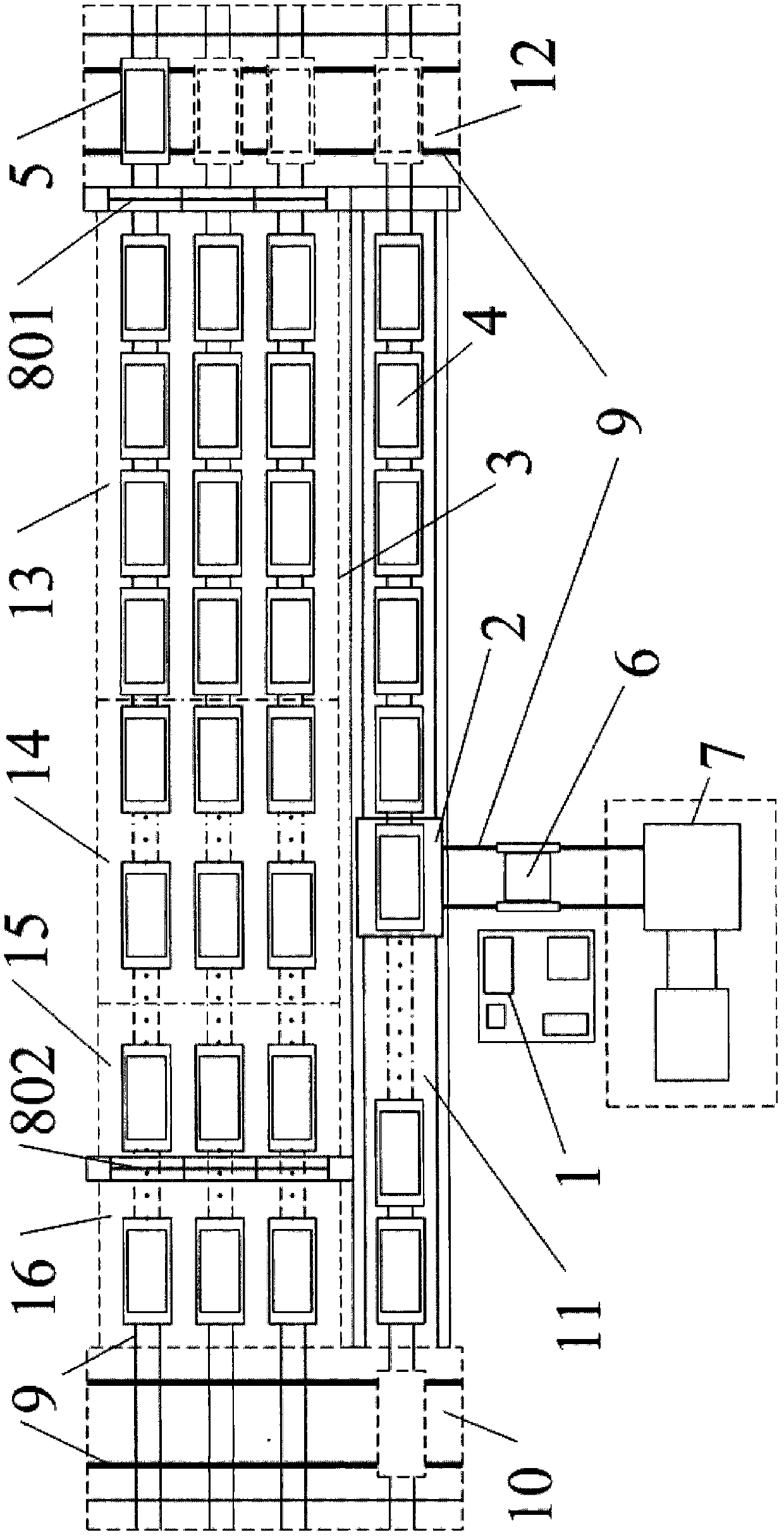

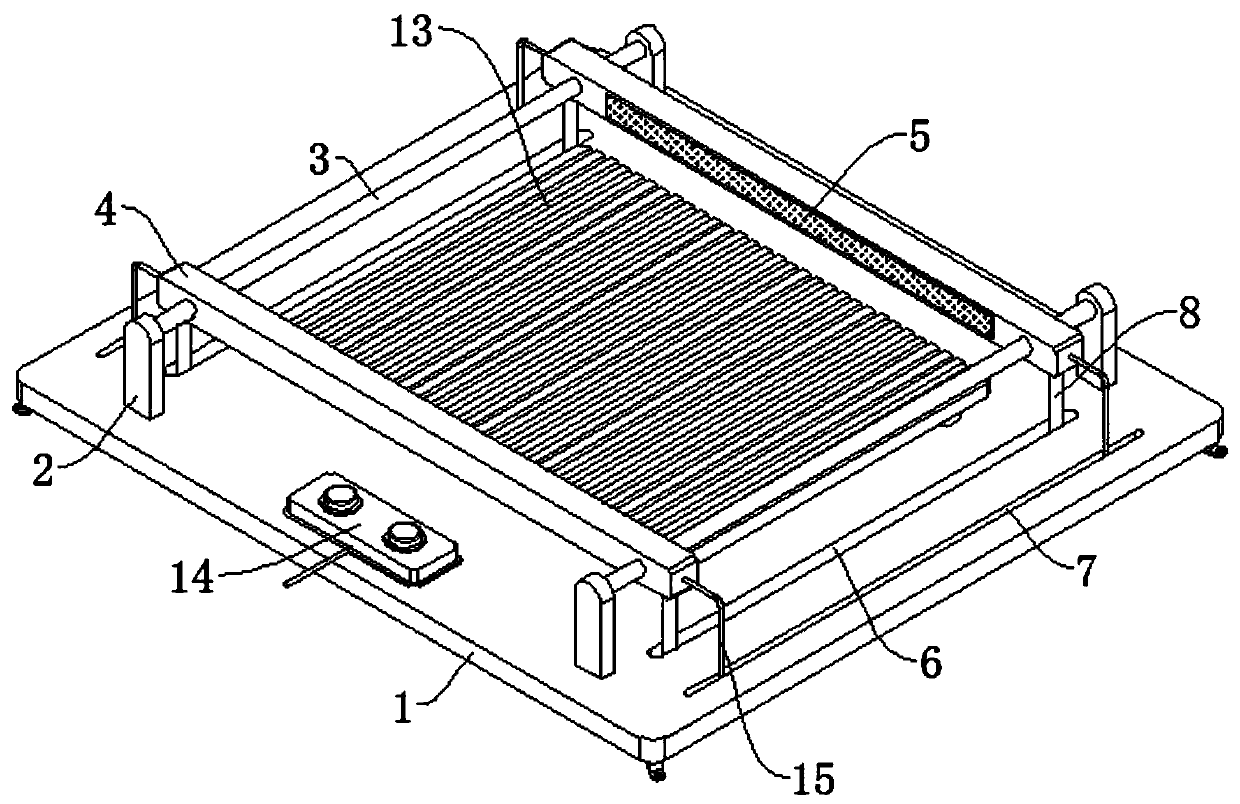

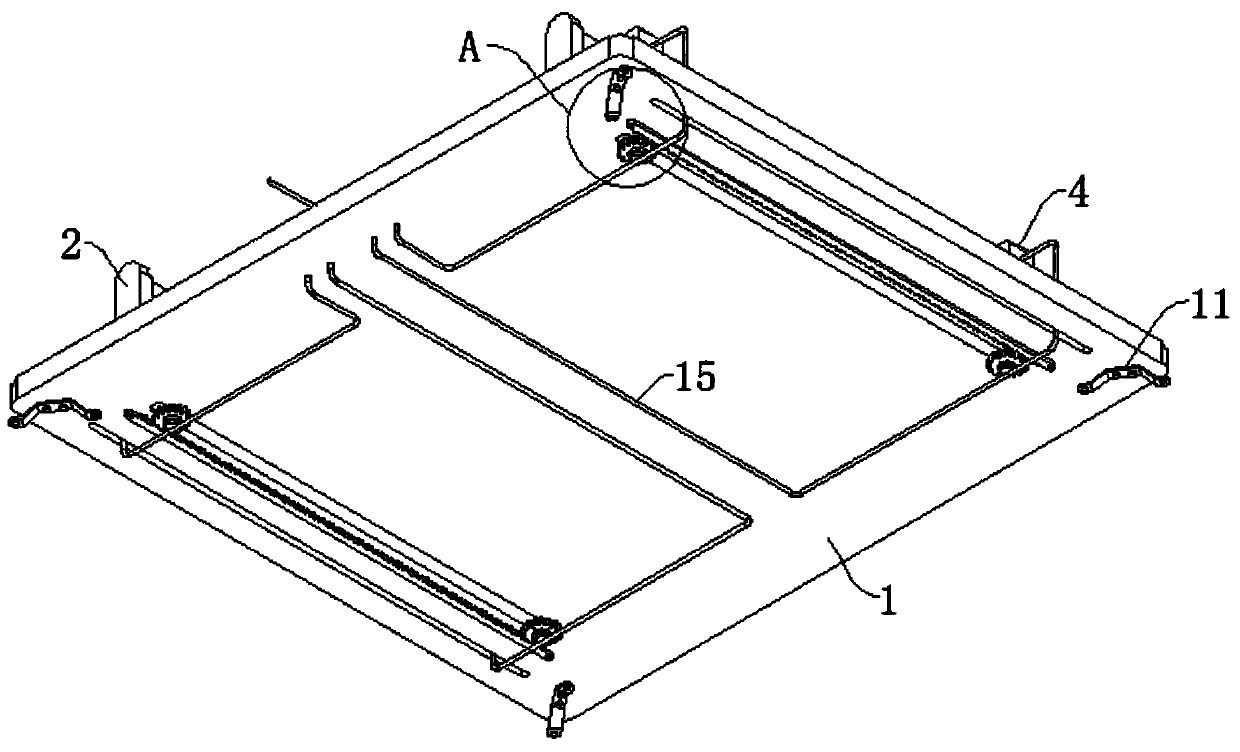

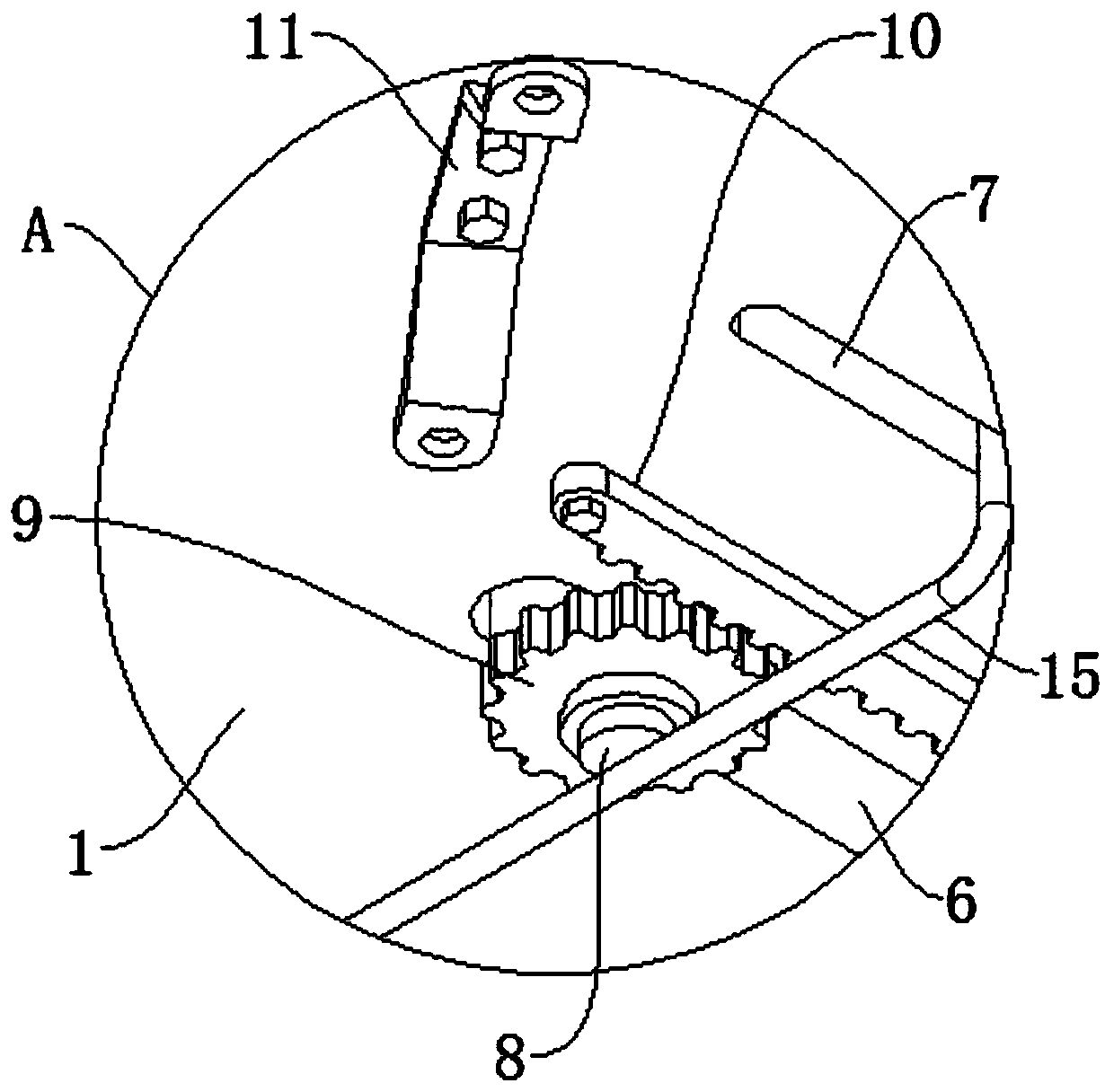

Automatic production line for keyboard conducting film silk screen and quality testing

InactiveCN106379038AReduce paging costsFast paginationScreen printersMaterial analysis by optical meansProduction lineTransfer system

The invention discloses an automatic production line for keyboard conducting film silk screen and quality testing. The automatic production line comprises a silk screen production line, a vision detecting system and a transferring system. The silk screen production line comprises a keyboard conducting film raw material treatment machine and a silk screen machine, and the keyboard conducting film raw material treatment machine, the silk screen machine and the vision detecting system are sequentially arranged and connected through a transferring system. The automatic production line solves the problems that in the prior art, the keyboard conducting film silk screen manual cost is high, the working environment is harsh, the dependency on skills of workers is high, the distribution distance between a quality testing station and a silk screen station is large, and the quality testing efficiency is low; the production efficiency of a keyboard conducting film is improved for an enterprise; and meanwhile, attention is paid for the body health of the workers.

Owner:珠海市捷锐科技有限公司

Dry ice cleaning machine

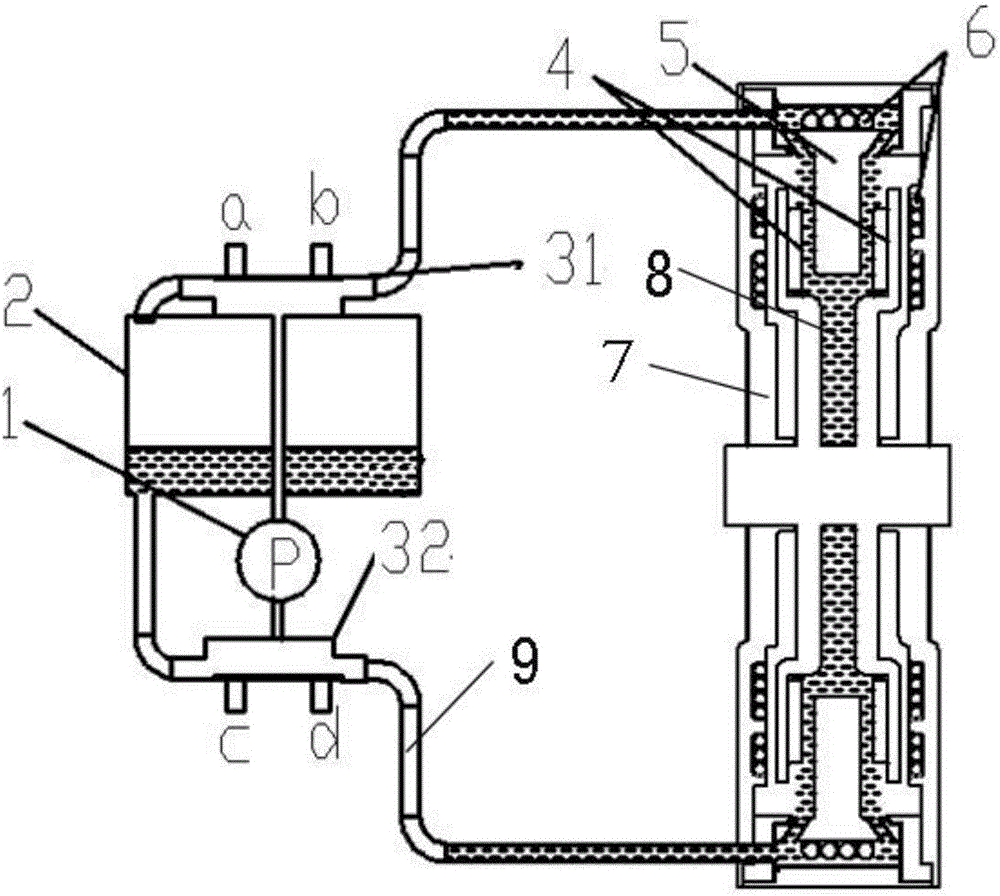

InactiveCN106424019ANo pollution in the processThe impact of reducing productivityCleaning processes and apparatusDry iceEvaporation

The invention provides a dry ice cleaning machine which comprises a dry ice container, a compressed air generator and a jetting device. Dry ice particles are stored in the dry ice container. A compressed air flow is generated by the compressed air generator and is inputted into the dry ice container. The dry ice particles are carried by the compressed air flow and are jetted by the jetting device to form a jet flow. The jet flow is jetted toward a to-be-cleaned surface. The to-be-cleaned surface is cleaned with the dry ice particles. The to-be-cleaned surface is cleaned with the jetted dry ice particles, and the cleaning purpose is achieved by means of air flow jetting energy and transient evaporation energy of the dry ice particles. The dry ice particles transiently evaporate into carbon dioxide under normal temperature and normal pressure, the environment is not polluted, the dry ice cleaning machine only needs to be halted, and the influence on the production efficiency is little.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

Method for power generation by satellite outer surface temperature gradient

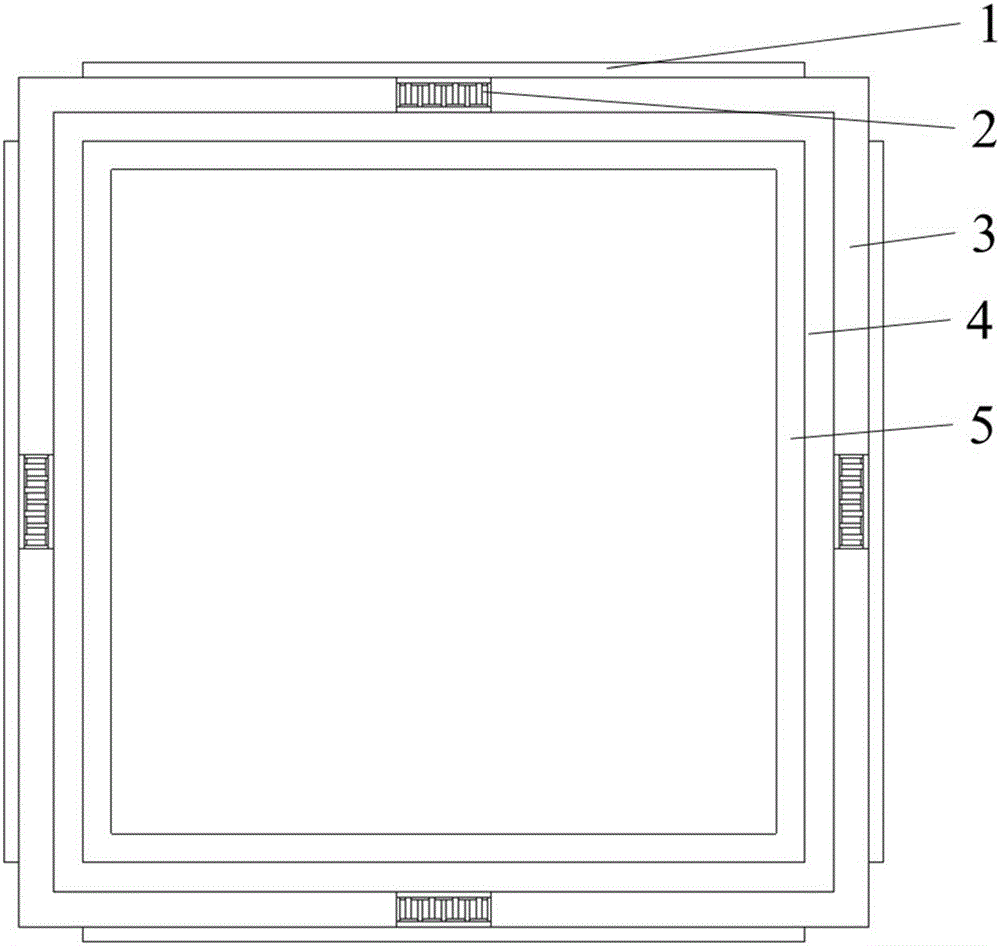

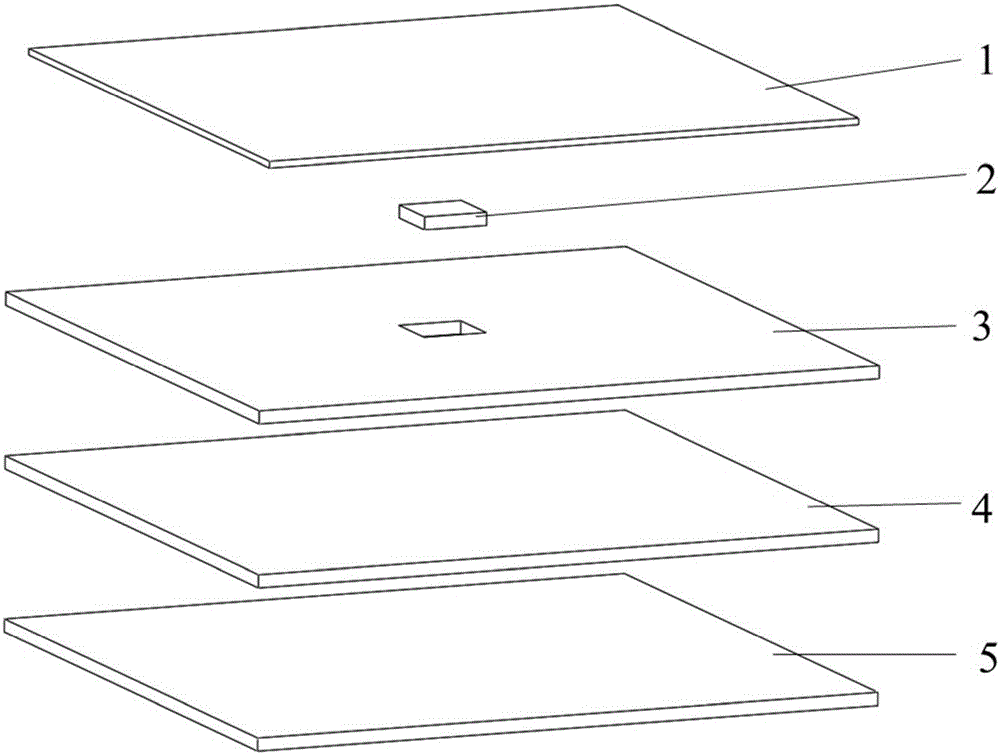

InactiveCN106208814AReduce the temperatureSmall temperature fluctuationsGenerators/motorsThermal isolationThermal break

The invention discloses a device for power generation by satellite outer surface temperature gradient, and belongs to application of a thermoelectric power generation technology in the field of thermal control of a spacecraft. The device comprises first thermal isolation layers, heat conduction layers, second thermal isolation layers, solar cell panels, thermoelectric devices and energy collection circuits, wherein the first thermal isolation layers cover an outer surface of a satellite, the heat conduction layers cover the first thermal isolation layers, the second thermal isolation layers cover the heat conduction layers, the integrated solar cell panels are arranged on the second thermal isolation layers, the thermoelectric devices are embedded into the second thermal isolation layers, the energy collection circuits are connected with heat conduction devices, the thermoelectric device is embedded into the second thermal isolation layer below each solar cell panel, and one end of each thermoelectric device is connected with the other end of each solar cell panel and then is connected with the heat conduction layer. With the method for power generation by the satellite outer surface temperature gradient, energy sources of the satellite can be increased, the temperature of a sunny surface of the satellite can also be reduced, the temperature fluctuation of the outer surface of the satellite is reduced, and the influence of the temperature on the working efficiency of the integrated solar cell panel is reduced. The method has good application prospect in a moonlet.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Switching structure of button sewing machine and bar tacking machine

ActiveCN103397479BEasy to assemble and disassembleShort switching timePressersEngineeringSwitching time

The invention belongs to the technical field of sewing equipment, and particularly relates to a switching structure of a button sewing machine and a bar tacking machine. A bar tacking adapter or a button sewing adapter is arranged at the front end of a supply frame. Correspondingly, a bar tacking presser foot device is connected to the bar tacking adapter, or a button sewing presser foot device is connected to the button sewing adapter. According to the switching structure, the button sewing adapter and the bar tacking adapter are respectively used for connecting the button sewing presser foot device and the bar tacking presser foot device with the supply frame, and the button sewing machine and the bar tacking machine can be switched as long as three or four parts are replaced, so that ordinary operators can also realize switching, utilization cost and labor cost are saved, and detachment and installation are convenient. Meanwhile, switching time is reduced, and the influence on working efficiency is reduced.

Owner:BULLMER ELECTROMECHANICAL TECH

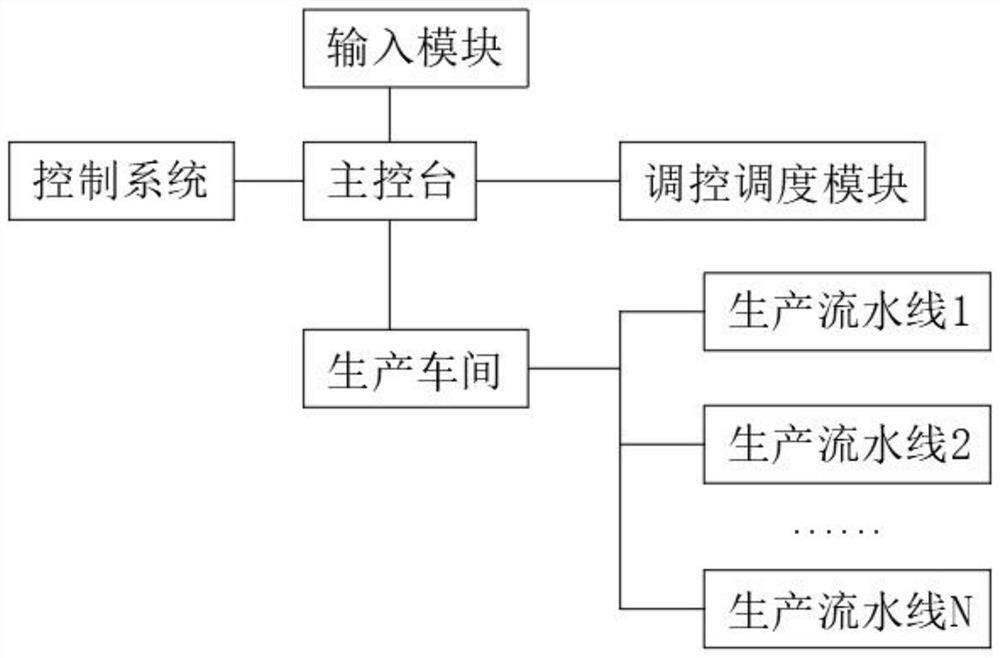

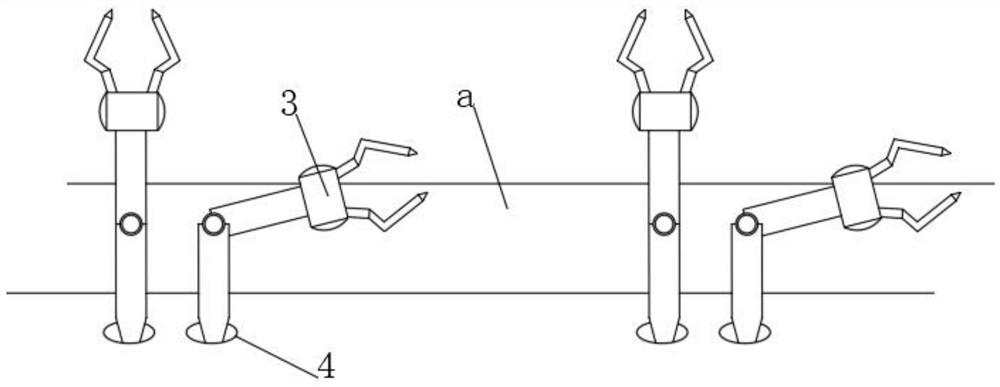

Distributed cooperative control system for production workshop

ActiveCN112192571AThe impact of reducing productivityImprove controllabilityProgramme-controlled manipulatorProduction lineControl system

The invention discloses a distributed cooperative control system for a production workshop, belongs to the field of workshop control systems. By regulating and controlling a scheduling module, the distributed cooperative control system can monitor the product accumulation condition on a production line station in time, and therefore a scheduling robot is regulated and controlled in time to delivera manipulator to a worker at a given time. Through the effect of a self-fluctuating curing bag, the manipulator can be in close contact with the edge of the self-fluctuating curing bag. A staggered abutting column is arranged, the edge of the self-fluctuating curing bag is in an uneven fluctuating wrinkle shape, and the manipulator and the edge of the self-fluctuating curing bag are in multi-point contact fixation. Then, the self-fluctuating curing bag is electrified for curing, and mounting is complete. At the moment, the manipulator can assist the worker at the station to complete stacked products together, so that the pressure of the worker is effectively relieved, then the influence of stacking of the single working product on the production efficiency of the whole production line iseffectively reduced, and the regulation and control performance of the system on the working efficiency of the production line is effectively improved.

Owner:ZHEJIANG SHUREN UNIV

Duct piece production control system and duct piece production system

InactiveCN102350732BSave human effortSave moneyCeramic shaping plantsAuxillary shaping apparatusTemperature controlHuman–machine interface

The invention discloses a duct piece production control system and a duct piece production system. The duct piece production control system comprises an actuating mechanism, a programmable controller, an information receiving unit, a communication unit and an interface displayer, wherein the actuating mechanism comprises duct piece moulds, a carrying trolley, a vibrating device, a material feeding device, a maintenance room and automatic doors; the duct piece moulds are loaded and transported by the carrying trolley; the programmable controller comprises an automatic coding and identificationmodule for the moulds, an automatic positioning module for the carrying trolley, a vibrating device control module, a material feeding device control module, an automatic temperature control module for a maintenance device, an automatic door control module, an original point returning module of an assembly line, and a human-computer interface monitoring module; and the duct piece production system comprises the duct piece moulds, a transporting system, a vibrating system, a material feeding system, a maintenance system and the duct piece production control system. By adopting the duct piece production control system and the duct piece production system, the defects of low production efficiency and low safety in the prior art are overcome.

Owner:浙江广天构件集团股份有限公司

Pipe bending machine for hardware manufacturing

The invention relates to a pipe bending machine for hardware manufacturing. The machine comprises a machine body, a guide wheel and a pipeline inlet end, wherein a hydraulic cylinder is mounted at the upper end of the machine body; a machine head is fixed on the left side of the hydraulic cylinder; a rolling shaft is arranged on the left side of the machine head; the lower end of the left side of a screw rod is connected with an electromotor by a driving belt; a mould placement frame is mounted inside the left side of the machine body; the electromotor is arranged above the mould placement frame; an electric cabinet is mounted on the outer side of the machine body and is positioned on the right side of the mould placement frame; a movable plate is arranged in the middle of the pipeline inlet end and a pipeline outlet end; the middle part of the pipeline inlet end is connected with the pipeline outlet end by a connection frame; a pin shaft is mounted in the middle of the connection frame; and the connection frame is arranged on the inner side of the movable plate. The machine head is arranged in the pipe bending machine for hardware manufacturing, and sliding friction is changed into rolling friction in an operation process of the device, so that the friction force between the device and a product is reduced, and the scratching probability of the machine head to the pipeline is further reduced.

Owner:GUANGZHOU JINLICHANG HARDWARE INSTALLATION CO LTD

Axial flow type miniature vertical water turbine

PendingCN110821734AExtended service lifeEasy to install and removeHydro energy generationReaction enginesElectric generatorHydro generator

The invention discloses an axial flow type miniature vertical water turbine and relates to the technical field of water turbines. The axial flow type miniature vertical water turbine comprises a baseand an axial flow type miniature vertical water turbine body, wherein a first supporting leg and a second supporting leg are fixedly arranged on the outer surface of the top of the base, the bottom ofthe axial flow type miniature vertical water turbine body is fixedly connected with the top of the second supporting leg, a miniature three-phase hydroelectric generator is fixedly arranged on the outer wall of one side of the axial flow type miniature vertical water turbine body, a main shaft is arranged inside the axial flow type miniature vertical water turbine body, the output end of the miniature three-phase hydroelectric generator is fixedly connected with one end of the main shaft, and the outer wall of the main shaft is sleeved with an axial flow type rotating wheel. According to theaxial flow type miniature vertical water turbine, impurities in water are filtered, the influence of the impurities on the working efficiency of the water turbine is reduced, the service life is prolonged, and accidents are prevented.

Owner:扬州聚川水力机械有限公司

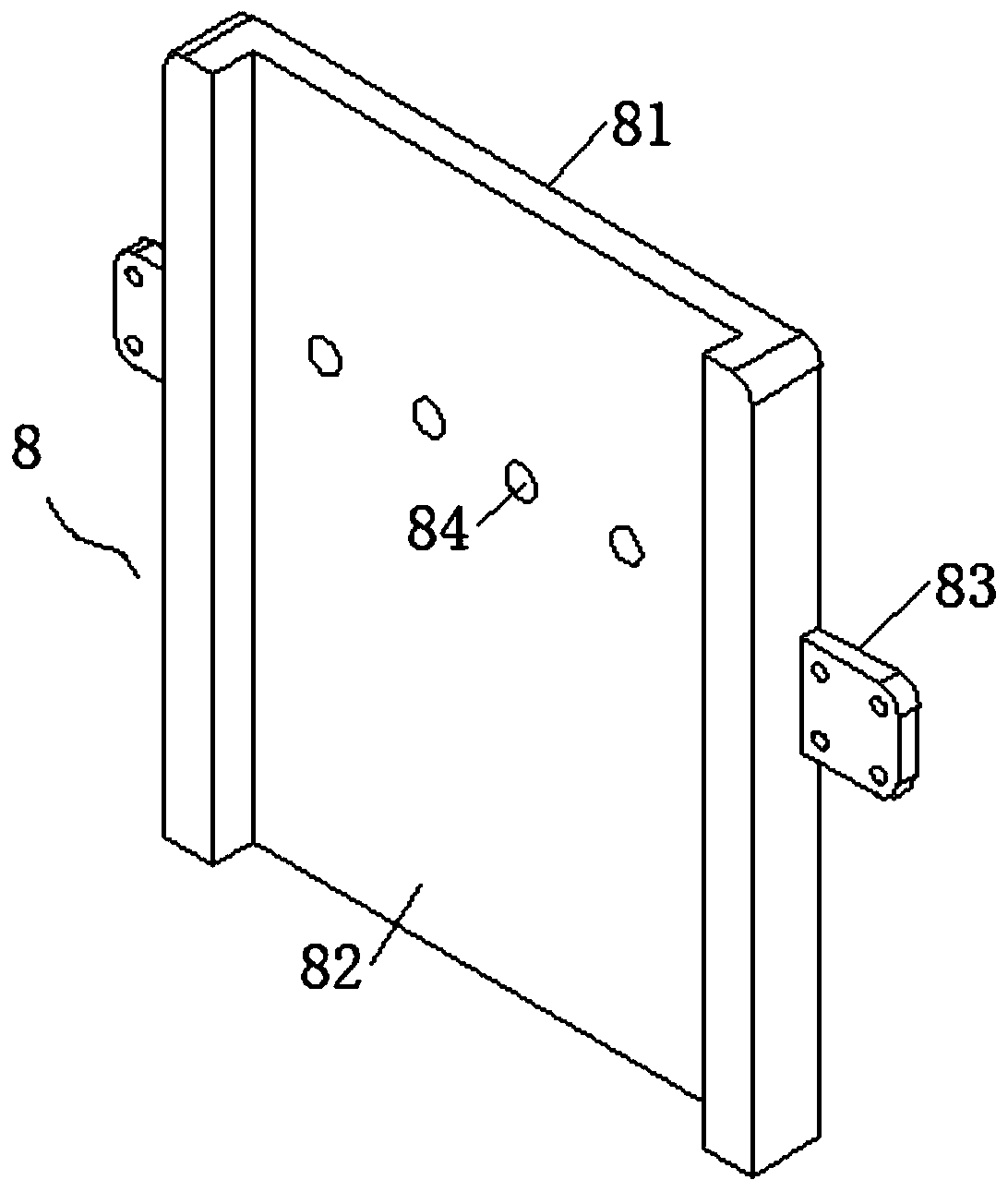

Automobile part stamping device

InactiveCN110814165AReduce complexityReduce Rigid DamageShaping toolsMotor vehicle partStructural engineering

The invention discloses an automobile part stamping device, and belongs to the technical field of part machining. The stamping device comprises a supporting bottom plate, wherein four supporting sideplates are vertically welded to the top of the supporting bottom plate in a rectangular shape, a limiting sliding rod is longitudinally welded between two supporting side plates, and the limiting sliding rods are arranged parallel to the top of the supporting bottom plate; and two movable clamping plates are transversely arranged between the two limiting sliding rods, the two movable clamping plates are symmetrically arranged front and back, and the inner side walls of the movable clamping plates are connected with adsorption electromagnets in a clamped mode. According to the an automobile part stamping device, a stamping die is placed on the top of a supporting platform, and the two movable clamping plates can be adsorbed on the two sides of the die by utilizing the principle that the adsorption electromagnets are magnetic after being energized, so that the stamping die can be fixedly clamped at the top of the supporting platform; and when the stamping die is disassembled, only the circuit of the adsorption electromagnets requires to be disconnect, so that the complexity of assembling and disassembling the stamping die is reduced, and the influence of stamping die replacement on the part production efficiency is reduced.

Owner:浙江郡琳新材料科技有限公司

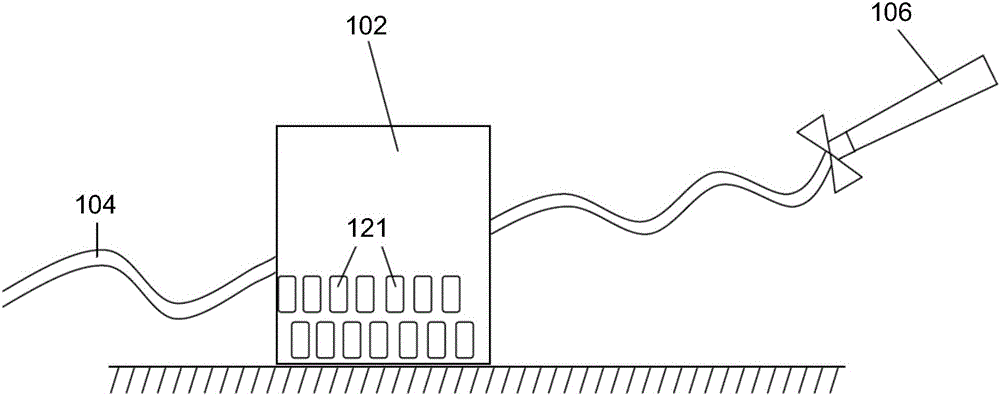

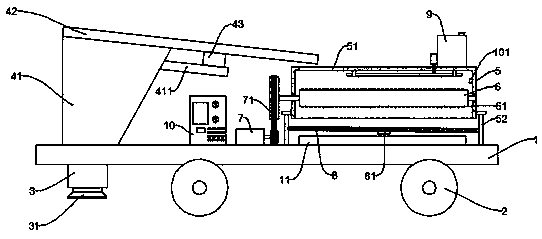

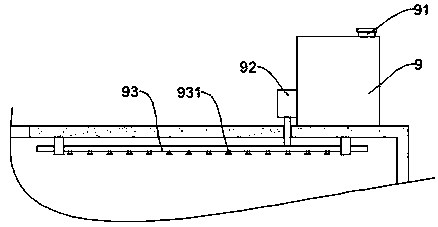

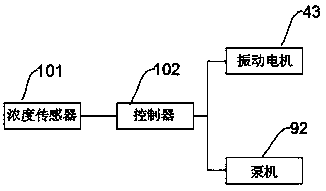

Mobile crushing station with automatic detection and cleaning control system

InactiveCN108837880AReasonable order of activationHigh degree of automationUsing liquid separation agentGrain treatmentsControl systemCavity wall

The invention discloses a mobile crushing station with an automatic detection and cleaning control system. The mobile crushing station comprises a base, a discharging mechanism, a crushing box and a cleaning system. The cleaning system comprises a console and a concentration sensor. The console is installed on the base, a controller is arranged in the console, and the controller is electrically connected with a vibration motor and a pump. The concentration sensor is installed on the inner cavity wall of the crushing box. When the concentration of dust exceeds a preset value, the concentrationsensor sends a signal to the controller, and the controller reduces the vibration frequency of the vibration motor and reduces the input amount of materials or starts the pump to spray into the crushing box. The mobile crushing station has the high degree of automation and convenient and fast operation, can automatically complete dust settling work in the crushing process, effectively saves manpower and reduces production cost; and meanwhile the setting of the first-level preset value and the second-level preset value makes the starting sequence of a dust settling mechanism more reasonable, and the influence on the working efficiency is reduced to the maximum extent.

Owner:ZAOZHUANG RUILONG MACHINERY MFG

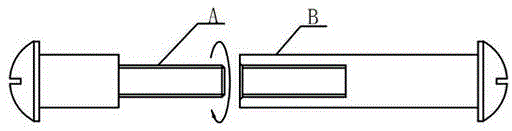

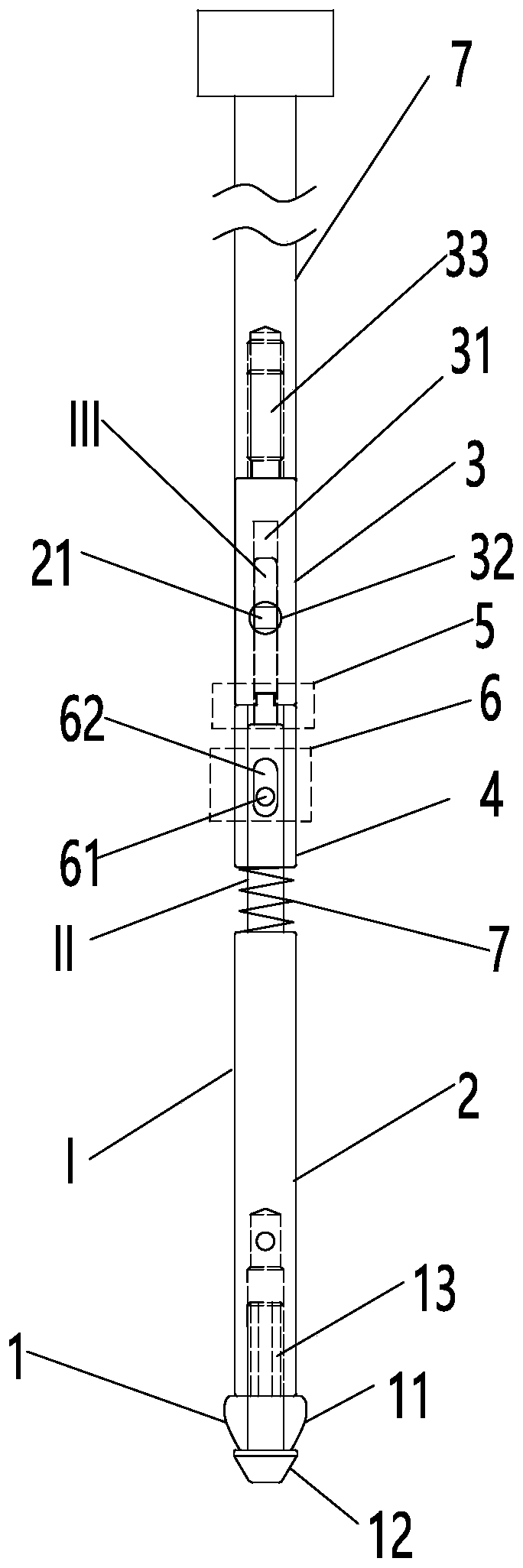

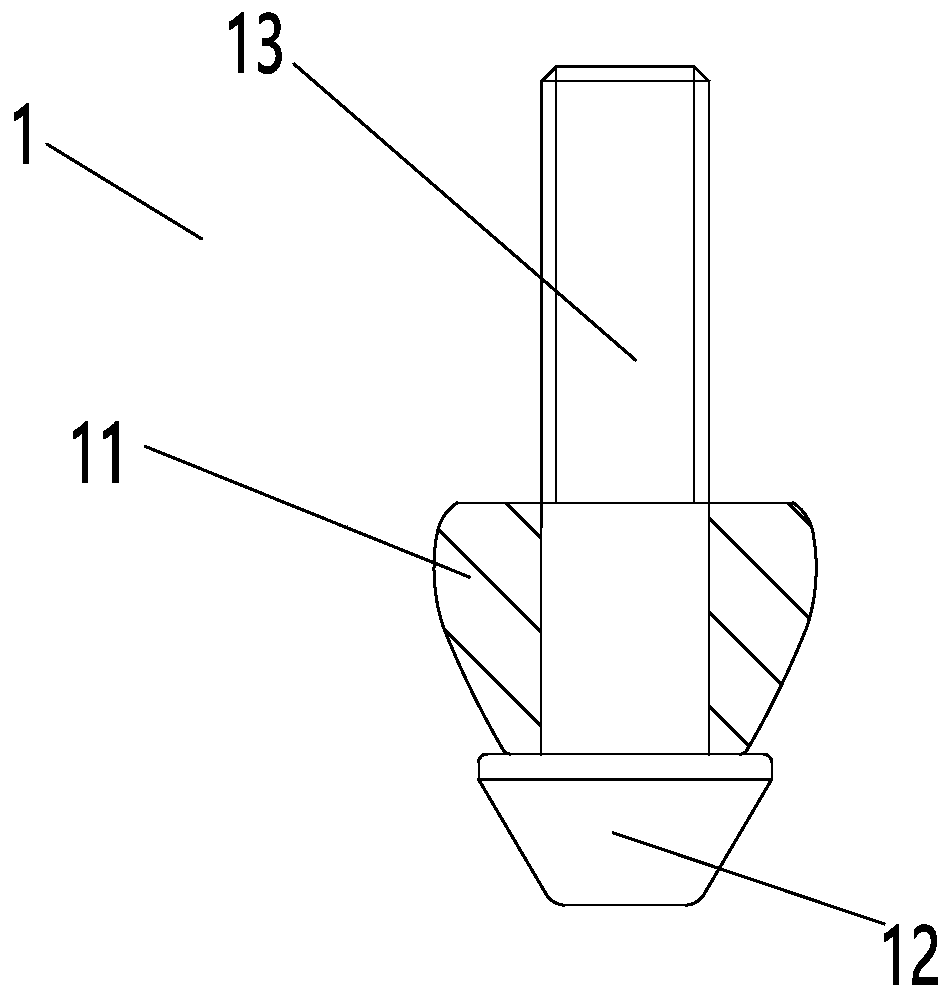

Fast-mounted and dismounted replacement rod for expansion rod

The invention discloses a fast-mounted and dismounted replacement rod for an expansion rod. The replacement rod comprises an expansion head assembly, a connecting rod and a lock rod which are connected in sequence; when the size of a product to be expanded is changed, or one assembly of the expansion head assembly, a rod body of the connecting rod and a rod body of the lock rod wears, the worn assembly can be immediately replaced, the remaining assemblies can be reused, so that materials are saved; the whole replacement rod can also be replaced, so that the influence on the production efficiency is greatly reduced, the use is convenient, and the mounting and dismounting efficiency is high; and for certain pipe bodies, with different lengths, required to be expanded, the connecting rods andthe lock rods with different lengths can be designed, the replacement rods with different lengths can be immediately replaced for use, so that expanding requirements of the pipe bodies with various lengths can be met, it is not needed to use special equipment or replace the expansion rod for processing, and the replacement rod is wider in applicability.

Owner:佛山以卓智能装备制造有限公司

Curing method of novel catalyst

InactiveCN102500427AReduce energy consumptionAvoid damageChemical industryCatalyst activation/preparationEngineeringAmmonia

The invention belongs to the field of catalyst curing, and relates to a curing method of a novel catalyst, which comprises the steps that: a heat exchanger is added between a fan and a heater, a water cooler is arranged between the heat exchanger and the fan, so that the fan, the heat exchanger, the heater, a converter and the water cooler form a closed circulating system, and the novel catalyst is arranged in the converter; and the fan is turned on to convey semi-water gas into the closed circulating system to carry out catalyst curing reaction. The method separates a catalyst curing process from a large system to form the closed catalyst curing system, so that reaction gas is effectively recovered and is not emitted, energy is saved, environment is protected, the safety factor is high, and the production of a whole synthetic ammonia system is not affected.

Owner:SHANXI HUOZHOU CHEM IND

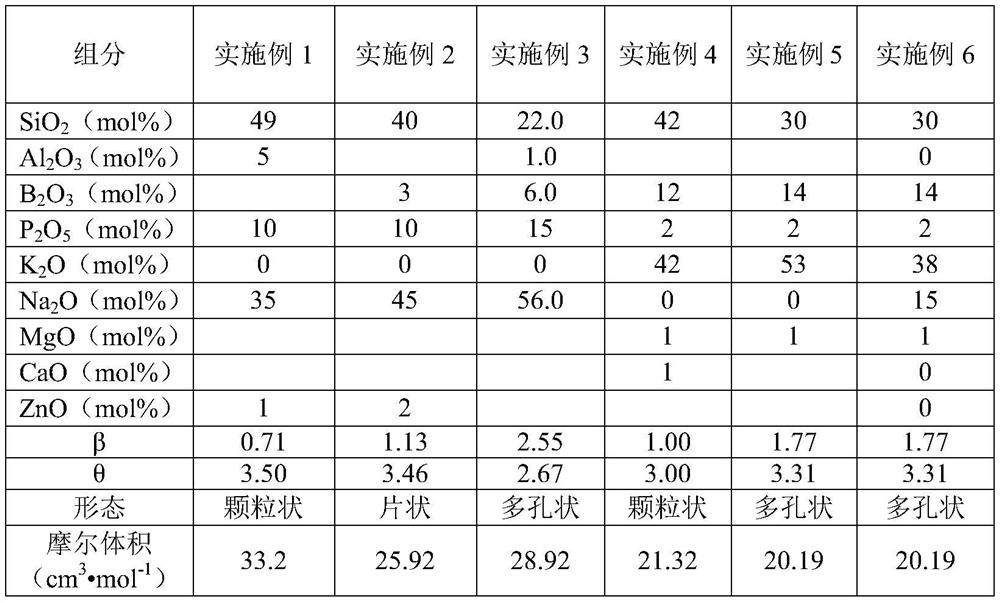

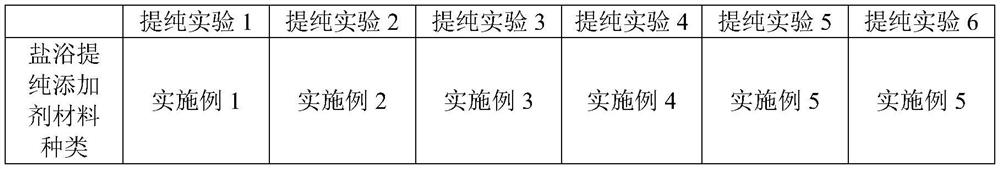

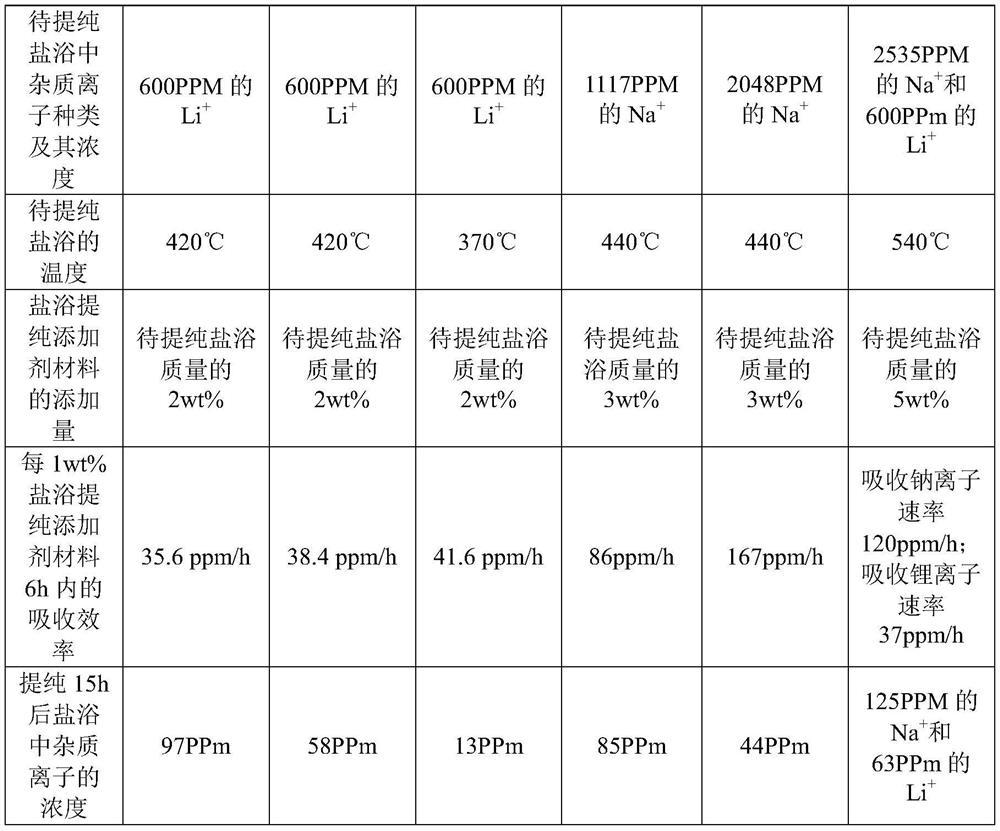

Salt bath purification additive material and use method thereof

The invention discloses a salt bath purification additive material and a use method thereof. The salt bath purification additive material comprises the following components in percentage by mole: 30-60 mol% of alkali metal oxide, 20-50 mol% of SiO2 and 8-25 mol% of other oxides. The use method comprises the following steps: S1, providing a to-be-purified salt bath; S2, adding the salt bath purification additive material into the to-be-purified salt bath; S3, taking out the salt bath purification additive material after the salt bath purification additive material reacts with the to-be-purifiedsalt bath for a certain time. S4, putting the salt bath purification additive material taken out in the step S3 into a pure sodium salt bath; and S5, after the salt bath purification additive material reacts with the pure sodium salt bath for a certain time, taking out the salt bath purification additive material for next use. The salt bath purification additive material has the advantages of being capable of rapidly absorbing lithium ions and sodium ions in a salt bath, convenient and rapid to take out and capable of being repeatedly used.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

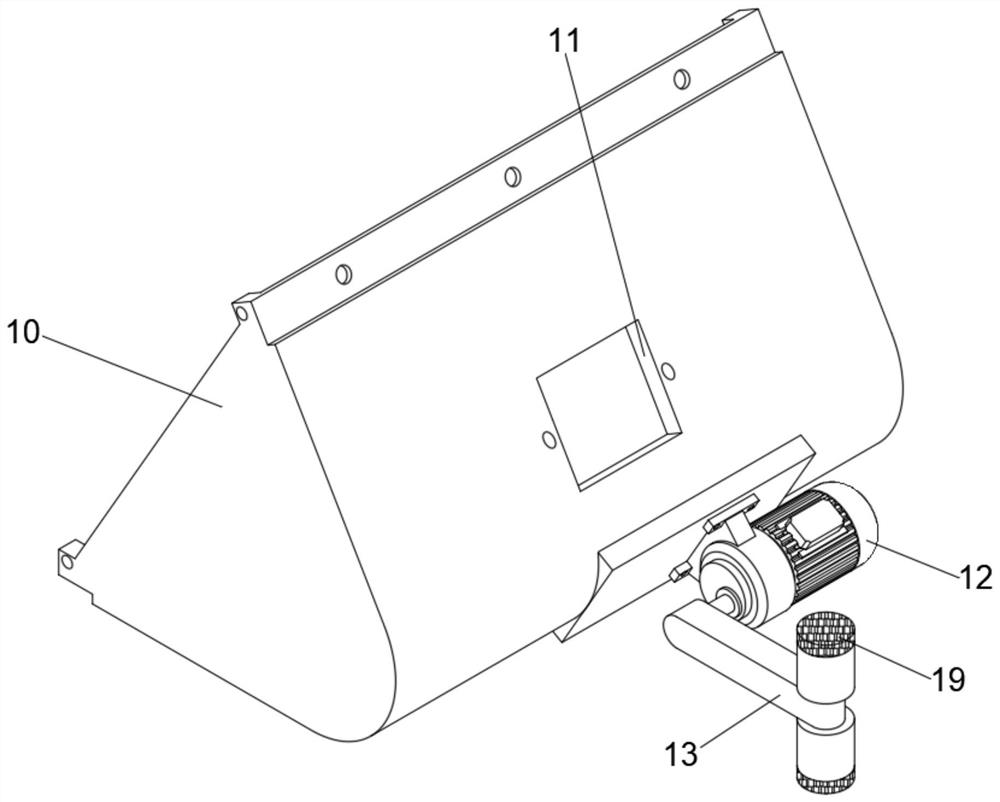

Constructional engineering soil shoveling device based on vibration excavation

InactiveCN112376638ASave internal spaceEasy to cleanMechanical machines/dredgersElectric machineryGeotechnical engineering

The invention relates to a soil shoveling device, in particular to a constructional engineering soil shoveling device based on vibration excavation. The constructional engineering soil shoveling device comprises a shovel box body, a vibration inner plate, a shovel blade body, a side plate body and a mud scraping plate, the shovel box body comprises a shovel box, the interior of the shovel box is of a cavity structure, a motor is installed on the outer wall of the shovel box, a knocking hammer is connected to one end of the motor, through grooves are symmetrically formed in the shovel box, a plurality of installation holes are symmetrically formed in the two ends of the shovel box, the vibration inner plate includes a pair of installation shafts, and the installation shafts are installed inthe installation holes. Through the arrangement of the shovel box body and the vibration inner plate, the knocking hammer is driven by the motor to knock a first inner plate and a second inner plateback and forth in the use process of the device, so that the first inner plate and the second inner plate vibrate, soil attached on the first inner plate and the second inner plate falls off, the soilis prevented from remaining on the first inner plate and the second inner plate, the internal space of the soil shoveling device is reduced, and therefore the influence of the soil remaining in the device on the working efficiency of the soil shoveling device is reduced.

Owner:洪良东

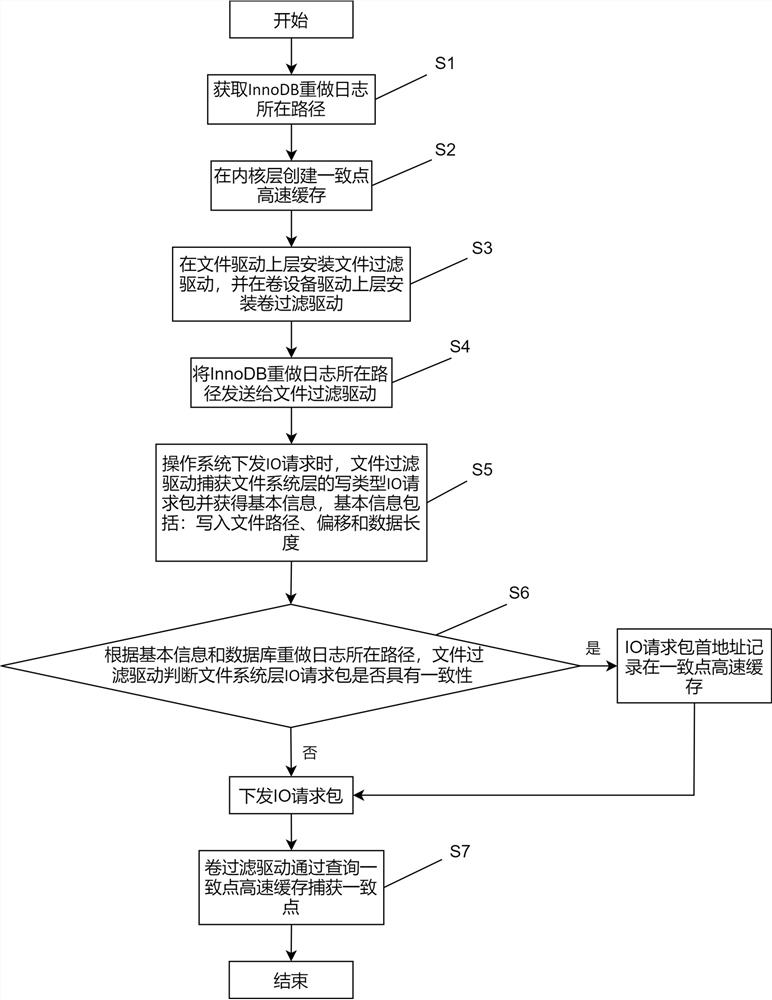

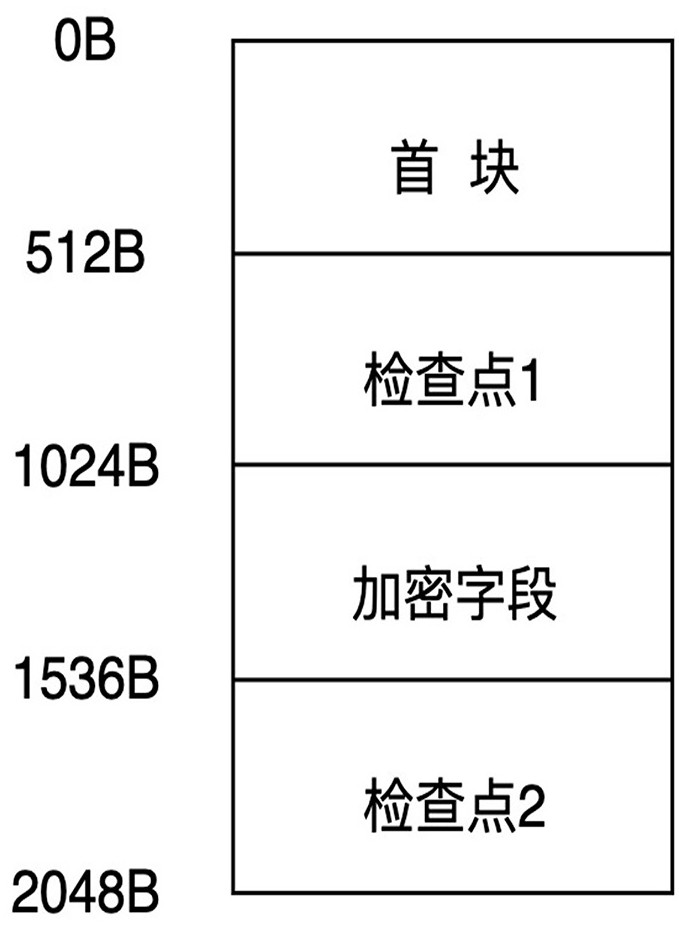

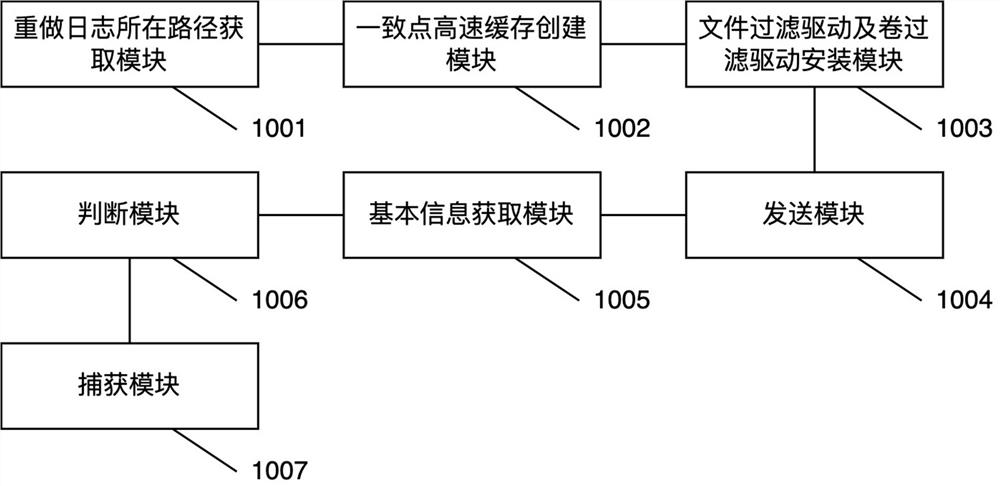

Method and system for capturing database consistent points in block-level CDP, and storage medium

ActiveCN114647624AThe impact of reducing productivityShorten the timeFile/folder operationsSpecial data processing applicationsData recoveryInformation acquisition

The invention relates to a method and system for capturing database consistent points in a block-level CDP and a storage medium, and belongs to the field of data recovery. The method comprises the steps of obtaining a path where a redo log is located; creating a consistent point cache; installing a file filter driver and a roll filter driver; a sending step; a basic information acquisition step; a judgment step; and a capturing step. The system comprises a redo log path acquisition module; a consistent point cache creation module; a file filter drive and roll filter drive installation module; a sending module; a basic information acquisition module; a judgment module; and a capture module. According to the method, the volume filtering driver captures the consistent points, the work of capturing the consistent points is completed through mutual cooperation of the file filtering driver, the consistent point cache and the volume filtering driver, the specific content of an IO request packet does not need to be analyzed, only the InnoDB redo log check points need to be recognized, and the method is simple, convenient and feasible.

Owner:成都云祺科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com