Switching structure of button sewing machine and bar tacking machine

The technology of bar tacking machine and buttoning machine is applied in the direction of cloth pressing mechanism, sewing machine components, textile and paper making, etc. It can solve the problems of long switching time, delay in construction period, increase cost and other problems, so as to save the use cost and labor cost. , the effect of reducing the switching time and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

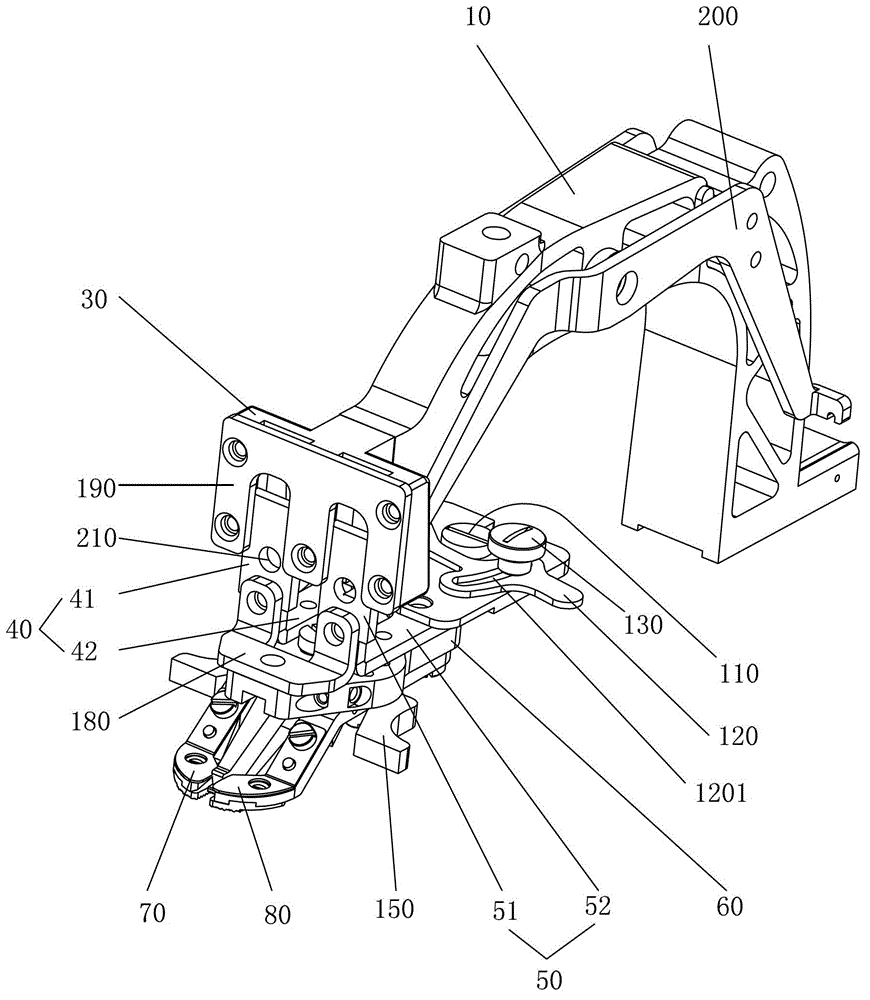

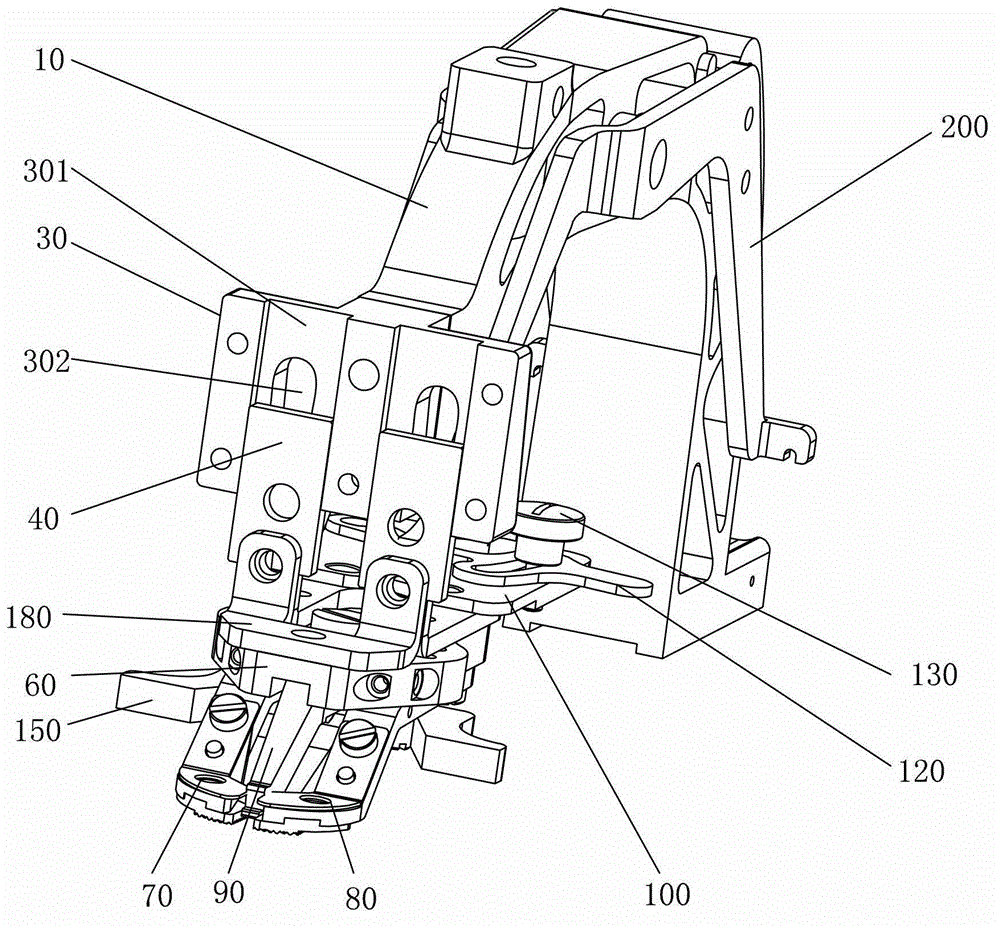

[0026] The present invention will be further described below with specific embodiment, see figure 1 -9:

[0027] A switch structure between a button tacking machine and a tacking machine, in which a tacking adapter 20 or a tacking adapter 30 is provided at the front end of a supply rack 10, and a tacking presser foot device or nailing device is connected to the tacking adapter 20 accordingly. The button adapter 30 is connected with a button presser foot device.

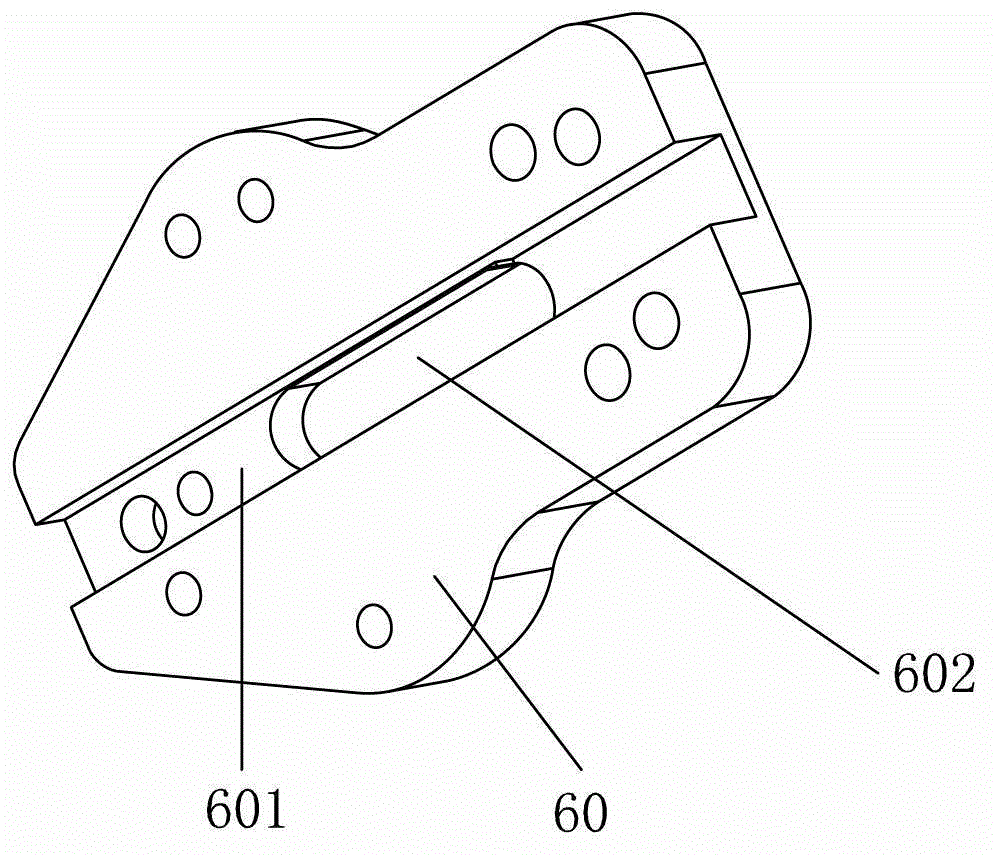

[0028] The front side of the above-mentioned button adapter 30 is provided with two parallel presser foot installation grooves 301 at intervals, and the presser foot installation grooves 301 are respectively provided with strip-shaped opening grooves 302 parallel to the presser foot installation grooves 301. A pin hole and a threaded hole or two threaded holes are provided on the button adapter 30 between the foot mounting grooves 301, and a pin hole and a threaded through hole or two threaded holes are corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com