X-axis ball screw assembly fixture of numerically controlled lathe and method for using X-axis ball screw assembly fixture of numerically controlled lathe

A ball screw and CNC lathe technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as unstable movement, screw bending, and low efficiency, so as to reduce the impact of production efficiency and improve assembly efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

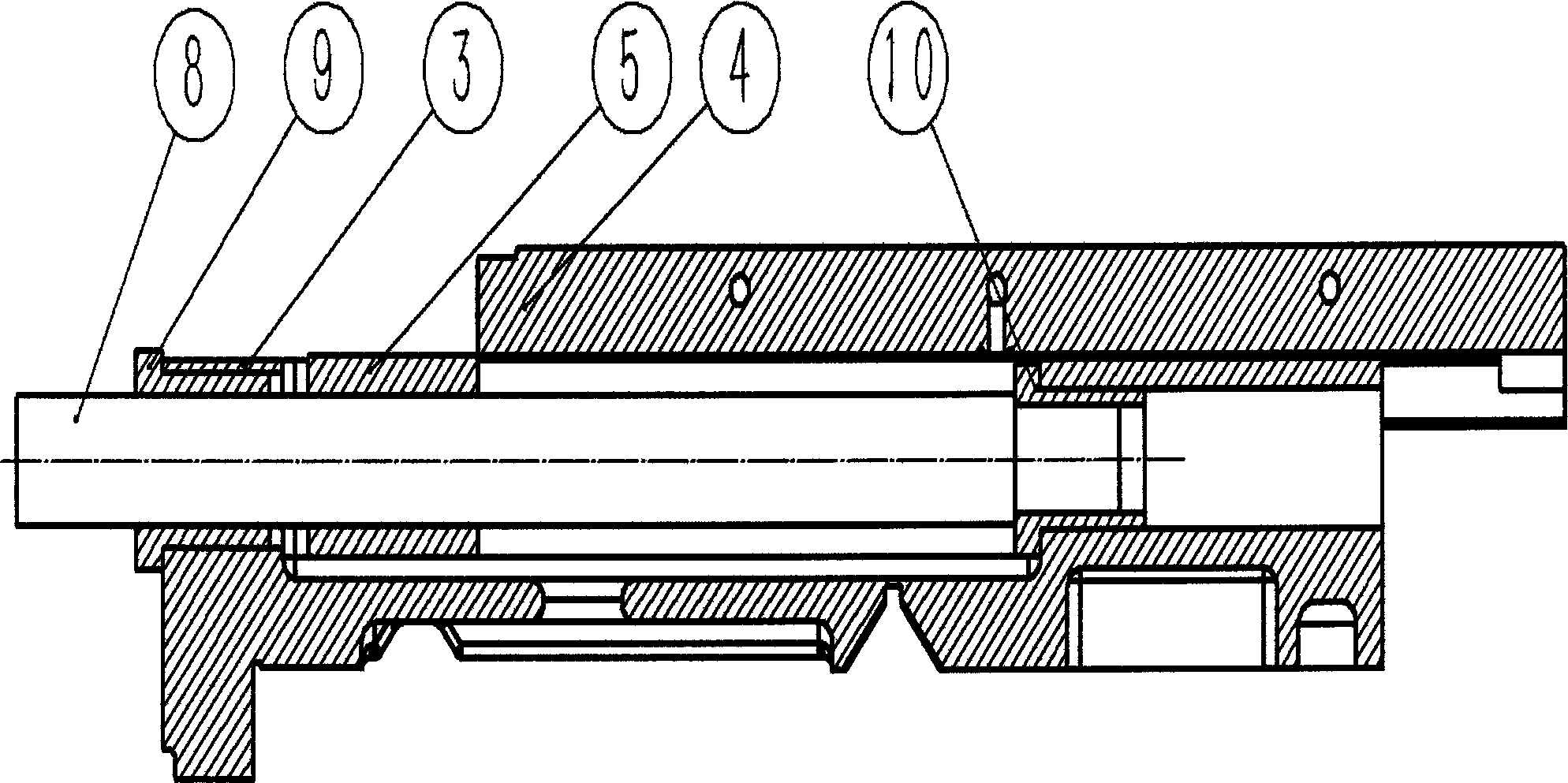

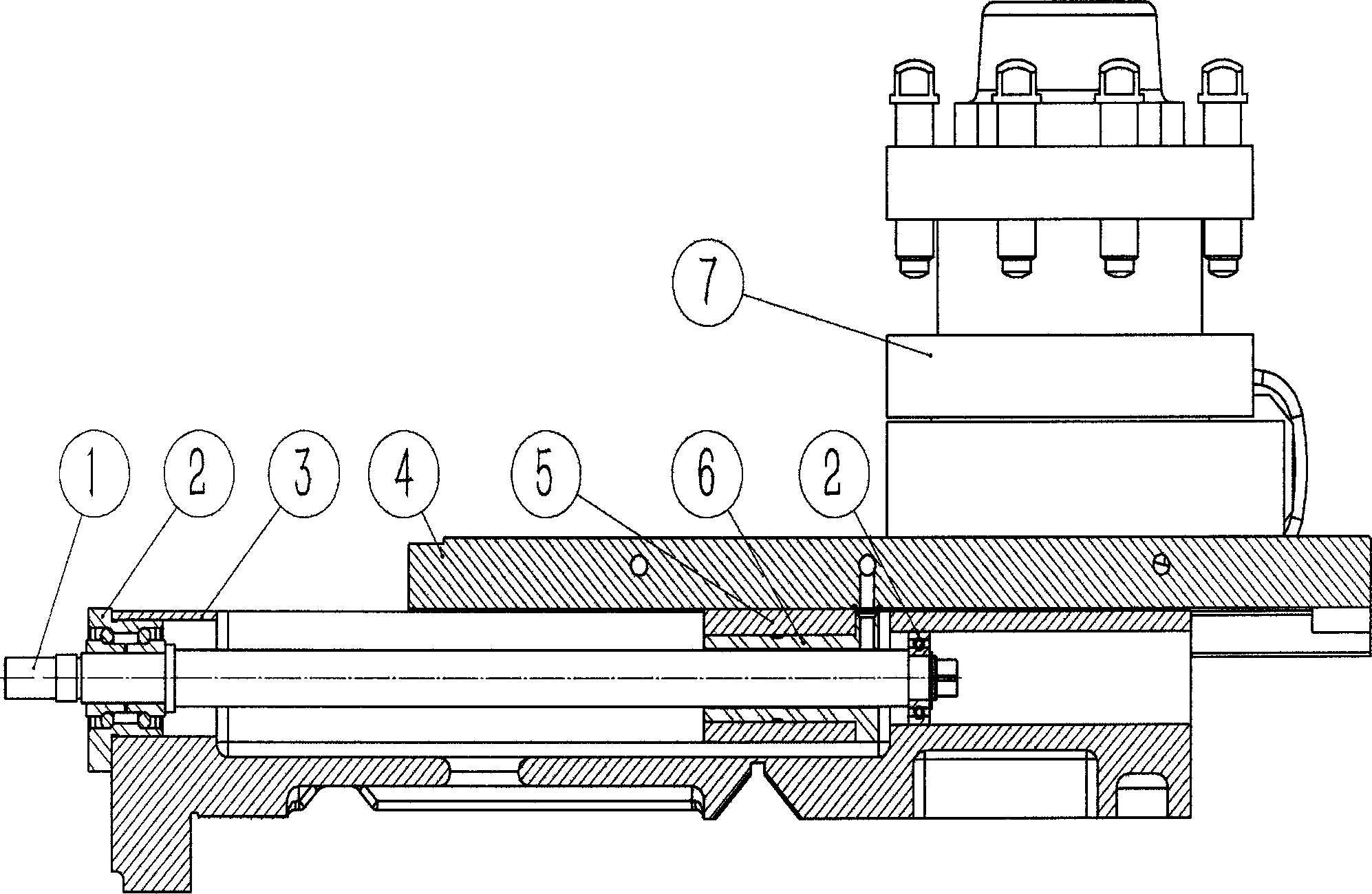

[0016] Such as figure 1 As shown, clean the parts before assembly:

[0017] 1) Install the front guide sleeve (9) and the rear guide sleeve (10) in the holes of the front and rear bearings of the X-axis ball screw on the large pallet (3), and then insert the positioning mandrel (8), The positioning mandrel is penetrated into the X-axis nut seat (5), and the positioning mandrel is required to be able to rotate easily without any gap;

[0018] 2) As large as the measurement of the upper plane of the X-axis nut seat (5) and the joint surface of the upper carriage (4) and the X-axis nut seat is higher than the value, match the grinding of the X-axis nut seat (5), leaving a margin of about 0.2mm carry out scraping;

[0019] 3) Use the surface combined with the X-axis nut seat on the upper carriage (4) to match the upper plane of the X-axis nut seat (5), and the scraping points are required to reach 12-16 points within the range of 25mm×25mm;

[0020] 4) After scraping, take out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com