Automatic production line for keyboard conducting film silk screen and quality testing

An automated production line and conductive film technology, which is applied to screen printing machines, printing machines, printing machines, etc., can solve the problem of long distances between quality inspection stations and silk screen printing stations, high labor costs for keyboard conductive film silk screen printing, and worker skill dependence Strong and other problems, to achieve the effect of easy manufacturing, convenient maintenance, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

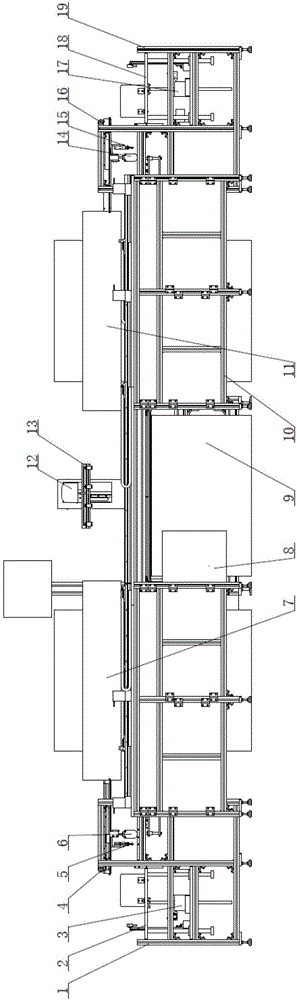

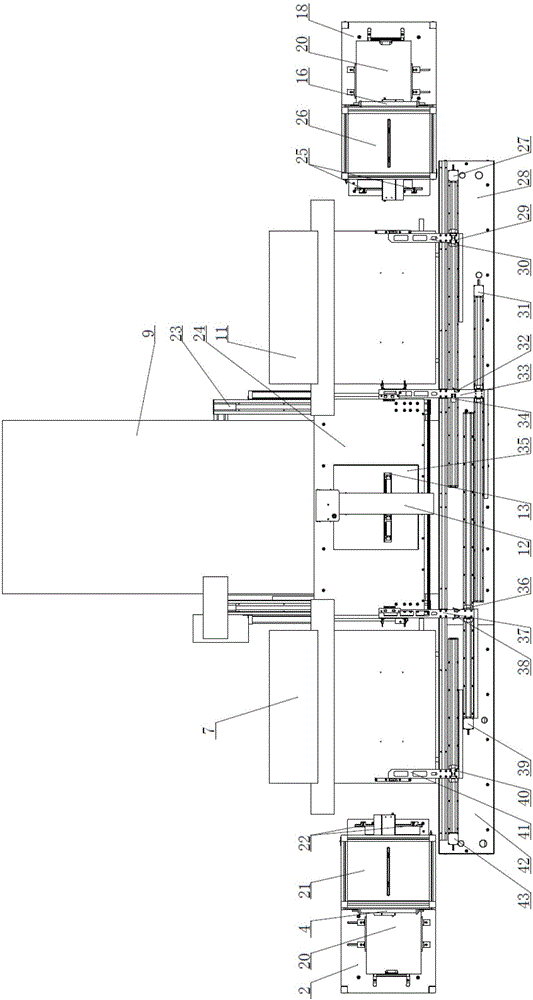

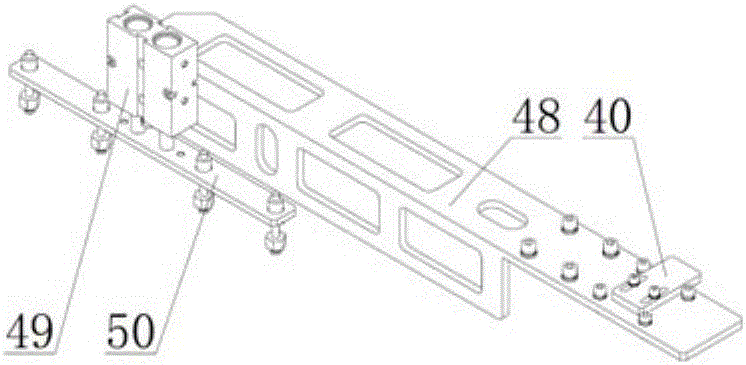

[0045] figure 1 The shown automatic production line for keyboard conductive film screen printing and quality inspection is an embodiment of the present invention, including a first screen printing production line, a second screen printing production line, a visual inspection system 24, a transfer system and a conveyor belt 9. The second silk-screen printing production line and the first silk-screen printing production line are arranged symmetrically on both sides of the visual inspection system to form symmetrical stations. Set up two sets of silk screen printing production lines. When one of the production lines breaks down or the product has quality problems, it can stop for manual inspection, and the other set of production lines can still continue to carry out normal production work, avoiding the shutdown of the entire production line, thereby reducing equipment costs. The impact of failures on production efficiency. The structure of the first screen printing production l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com