Dry ice cleaning machine

A dry ice cleaning and dry ice technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, unsuitable cleaning of hand tools, damage to equipment, etc., and achieve the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

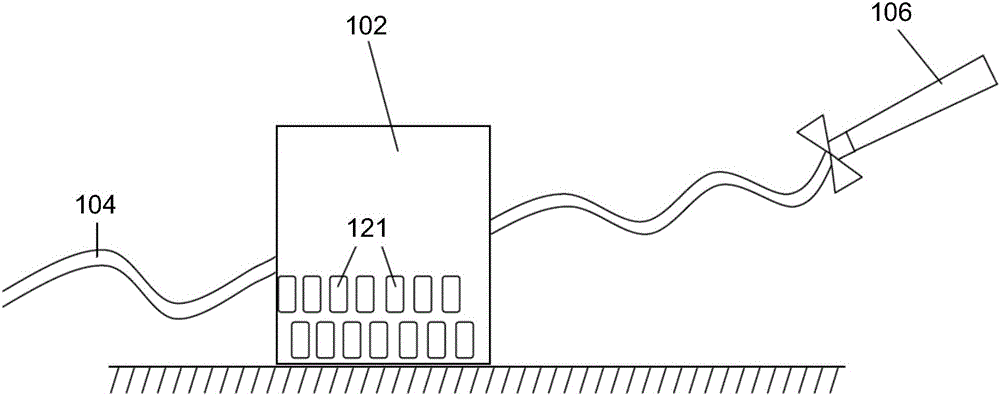

[0020] refer to figure 1 as shown, figure 1 A structural diagram of a dry ice blasting machine according to an embodiment of the present invention is disclosed. The dry ice blasting machine includes: a dry ice container 102 , a compressed air generator 104 and an ejector 106 .

[0021] Dry ice pellets 121 are stored in the dry ice container 102 . In one embodiment, the dry ice particles 121 are cylinders with a diameter of 2.8mm˜3.2mm and a length of 2.5mm˜10mm. The dry ice particles are prepared through the following process: firstly, carbon dioxide is condensed into a colorless liquid at a temperature of 20±5°C and a pressure of 6000 kPa. Then, the liquid formed by the above-mentioned condensation evaporates rapidly under low pressure, and condenses into an ice-snow-like solid substance, that is, dry ice. Put the dry ice into the mold, and press it through the abrasive tool to form dry ice particles with a diameter of 2.8 mm to 3.2 mm and a length of 2.5 mm to 10 mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com