Salt bath purification additive material and use method thereof

An additive material and salt bath technology, applied in the field of salt bath purification of additive materials, can solve the problems of high production cost, environmental damage, and inability to recycle the usage amount, and achieve fast, convenient and quick removal, ensure stability, and reduce impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6

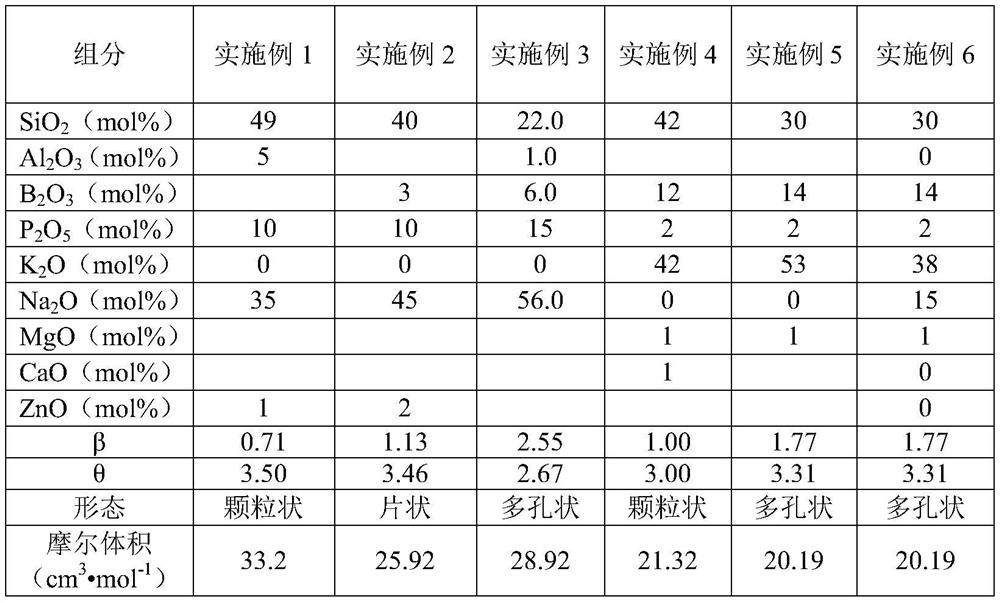

[0049] In Examples 1-6, 6 kinds of salt-bath purification additive materials with different components and forms were prepared by using the commercially available products as raw materials and using the preparation method mentioned above. The components and forms of the salt bath purification additive materials in Examples 1 to 6 are shown in Table 1.

[0050] Table 1

[0051]

[0052] In the table, β refers to the content of alkali metal oxides in the salt bath purification additive material and SiO 2 The ratio of the content; θ refers to the content of the alkali metal oxide in the salt bath purification additive material and P 2 o 5 and B 2 o 3 The content and the ratio of .

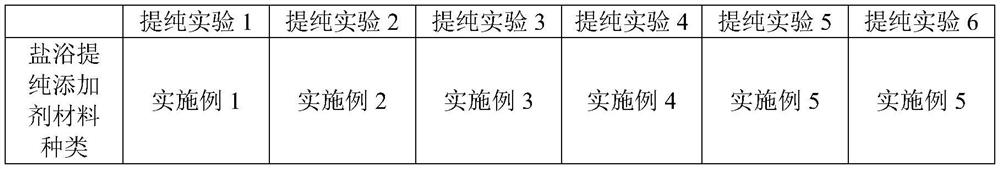

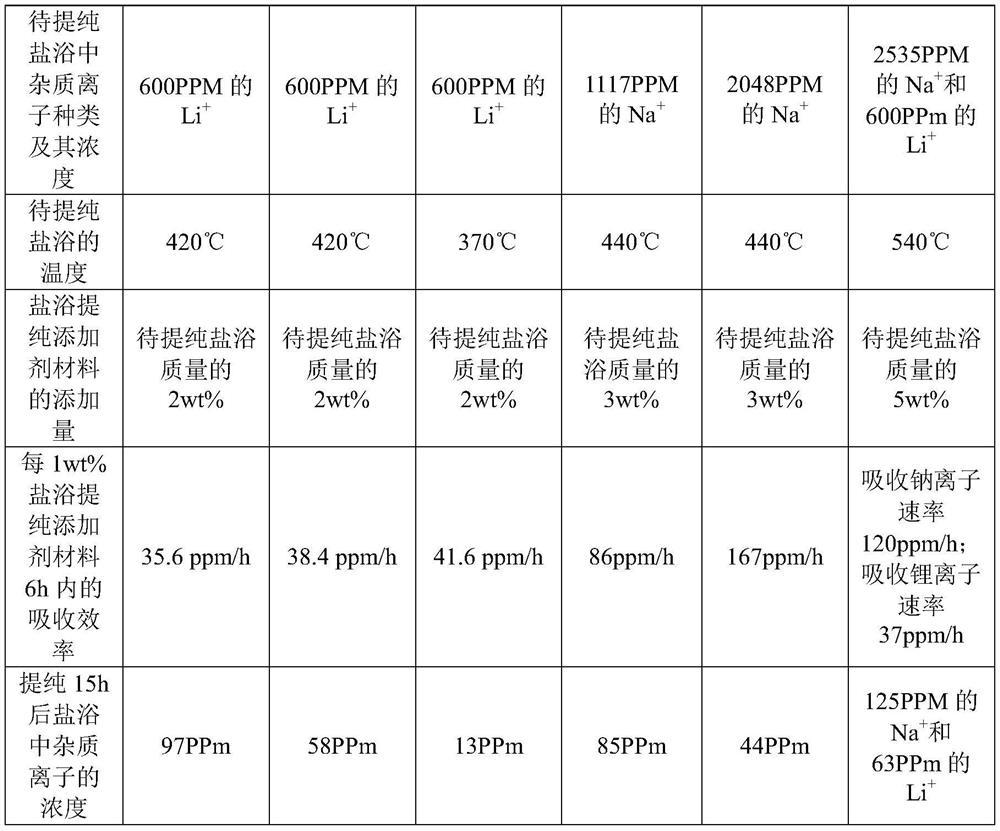

[0053] Purification experiments 1 to 6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com