Large-diameter thin-wall steel pipe straightening machine and its anti-deformation side roll device

A thin-walled steel pipe and straightening machine prevention technology, which is applied to the large-diameter thin-walled steel pipe straightener anti-deformation side roll device and the large-diameter thin-walled steel pipe straightening machine field, can solve the problem that the large-diameter thin-walled steel pipe is easily flattened Ellipse, deformation and other problems, to achieve the effect of compact structure, low failure rate and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

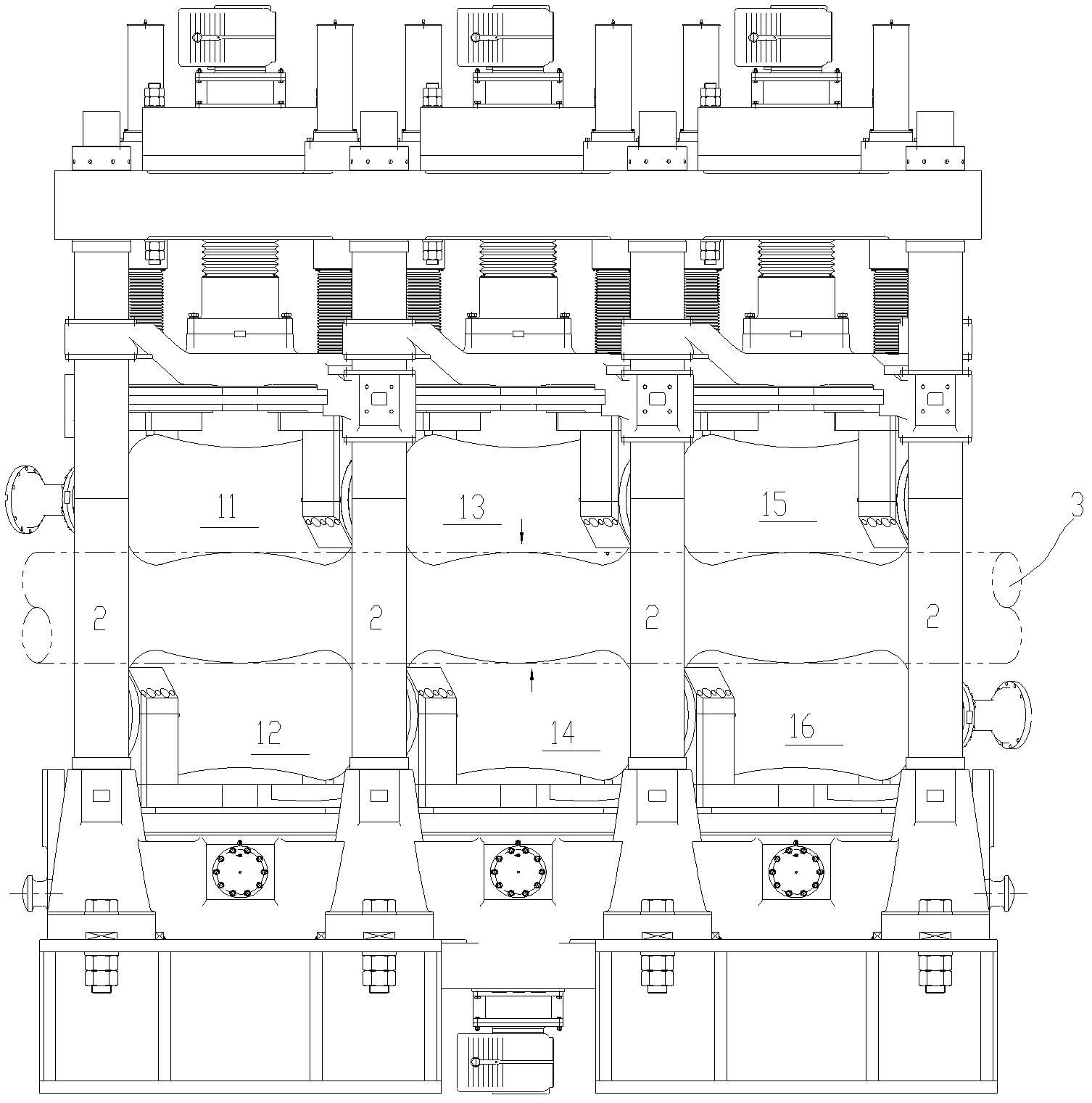

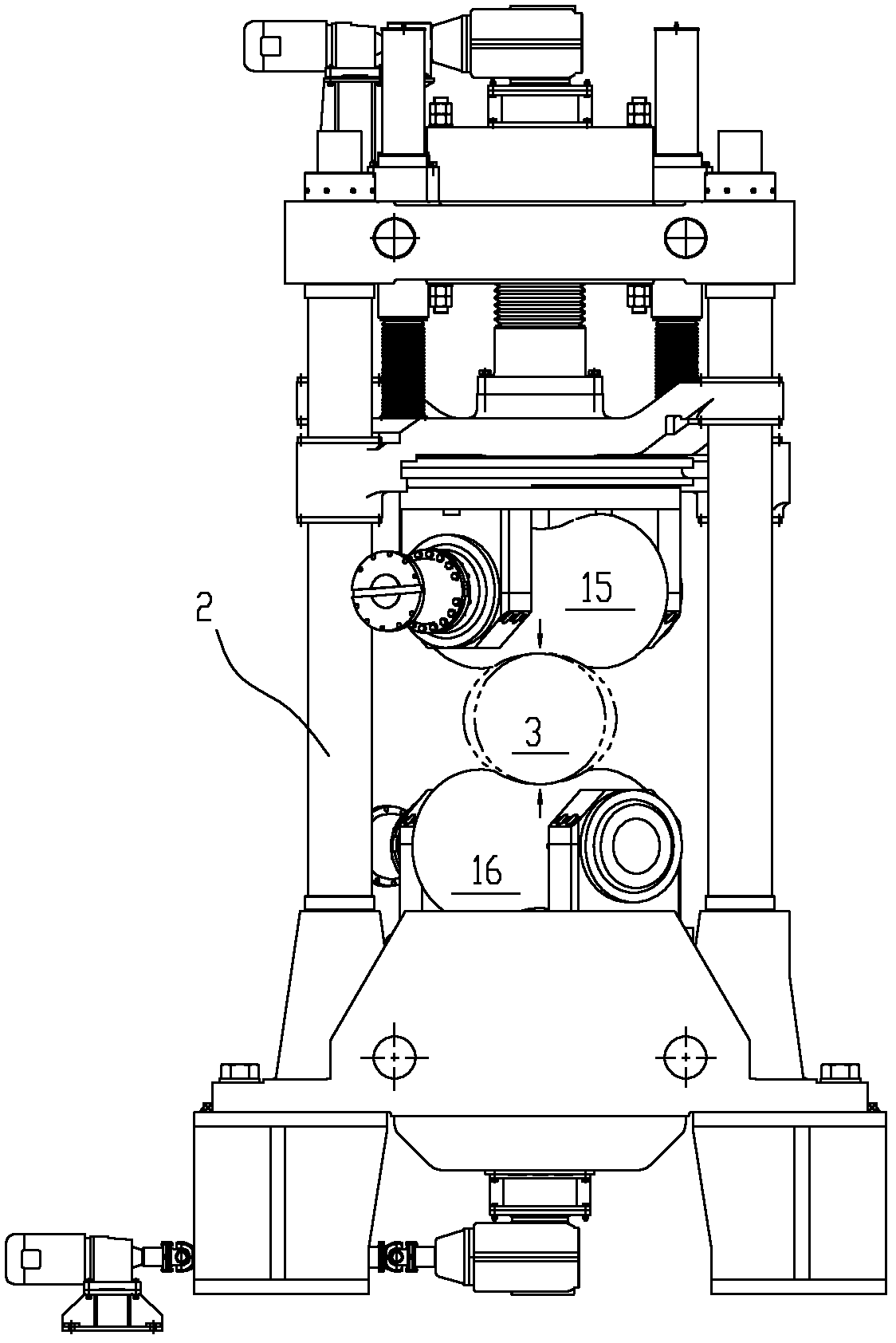

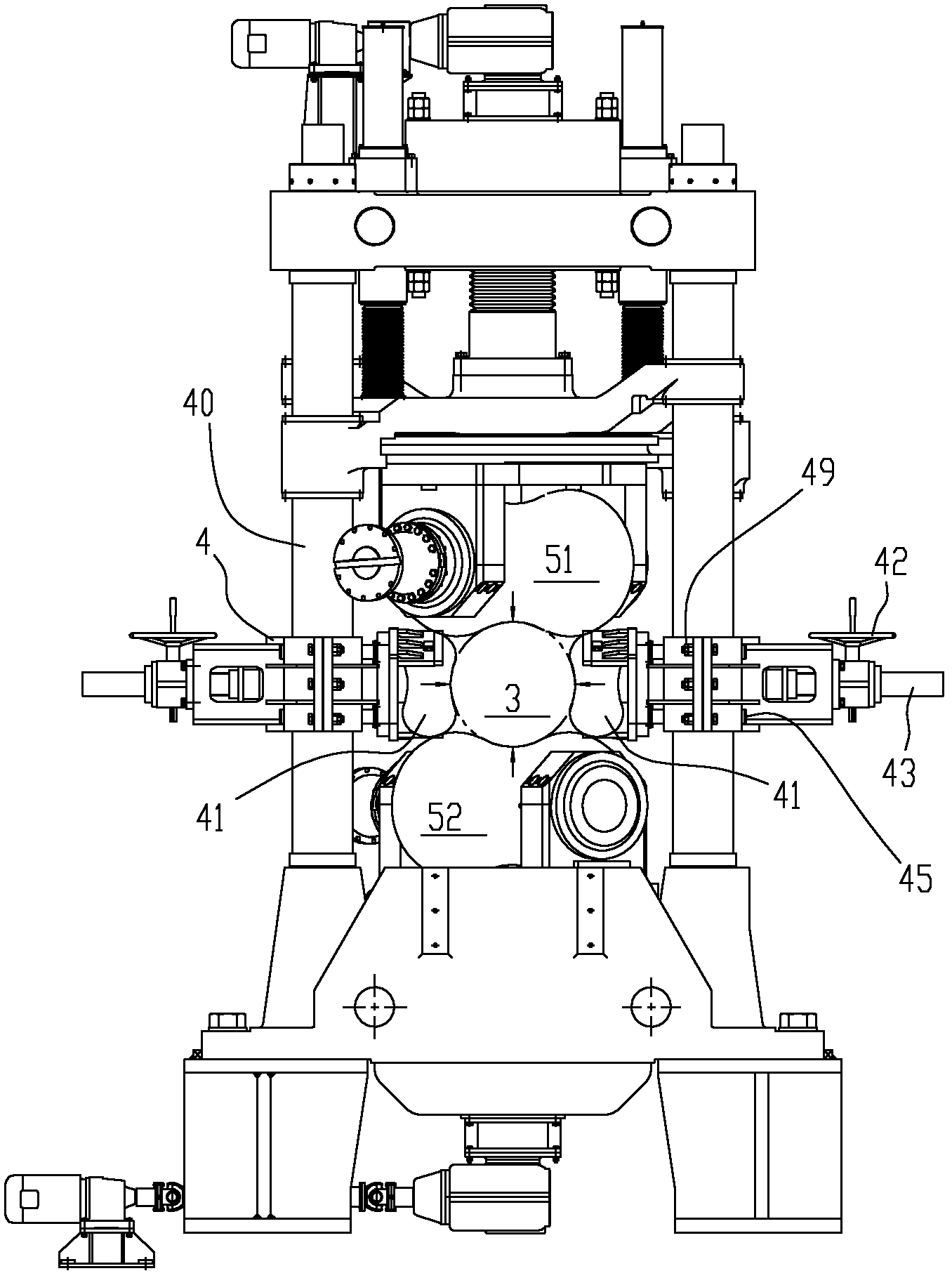

[0015] image 3 The structure of the preferred embodiment of the large-diameter thin-walled steel pipe straightening machine of the present invention is shown, Figure 4-Figure 6 Then the structure of the preferred embodiment of the anti-deformation side roll device of the large-diameter thin-walled steel pipe straightening machine of the present invention is shown, because image 3 The anti-deformation side roll device and Figure 4-Figure 6 The structure of the preferred embodiment of the anti-deformation side roll device of the large-diameter thin-walled steel pipe straightening machine shown in the present invention is the same, so the following will be combined Figure 3-Figure 6 Also explained.

[0016] Such as Figure 3-Figure 6 As shown, the preferred embodiment of the anti-deformation side roller device of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com