Method for designing roller shape of two-roller straightener concave roller

A technology of straightening and deformation stress, which is applied in the design field of the concave roll curve of the two-roll leveling machine, which can solve the problems of unsatisfactory, inaccurate description, and difficult determination of the reverse bending ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

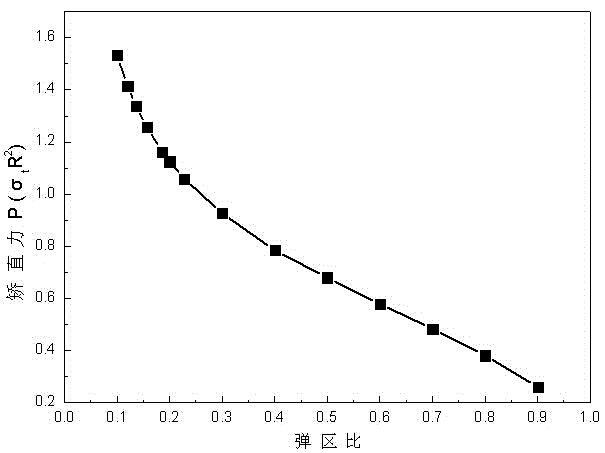

[0035] According to the actual production of a steel factory, the high-strength alloy steel 42CrMo is selected as the straightening workpiece, and the corresponding parameters are as follows: modulus of elasticity E =210GPa, yield limit =930MPa, the diameter is 35mm, and the original maximum deflection is 10mm / m.

[0036] According to the above data, according to the plastic deformation stress-strain model 6 Hardening coefficient ≈0.00489; the straightening force and hidden deflection of different plastic deformation depths of the roll waist section are shown in Table 2.

[0037] Table 2 Straightening force and hidden deflection of different plastic deformation depths

[0038] Cw1 ζ Straightening force (KN) Hidden Deflection (mm / m) 5 0.12 402.896 0.0437 4.5 0.136 380.994 0.0637 4 0.157 357.725 0.0979 3.5 0.186 331.151 0.1628 3.35 0.20 320.414 0.2024 3 0.228 301.759 0.2999

[0039] It can be seen from the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com