Harmonic speed reducer of cycloid roller chain

A technology of harmonic reducer and roller chain, which is applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., which can solve the constraints on the development and application of harmonic reducer, complex processing technology of flex spline, and early fatigue fracture of flex spline and other problems, to achieve the effect of eliminating dynamic unbalance defects, avoiding macro deformation requirements, and avoiding early fatigue cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

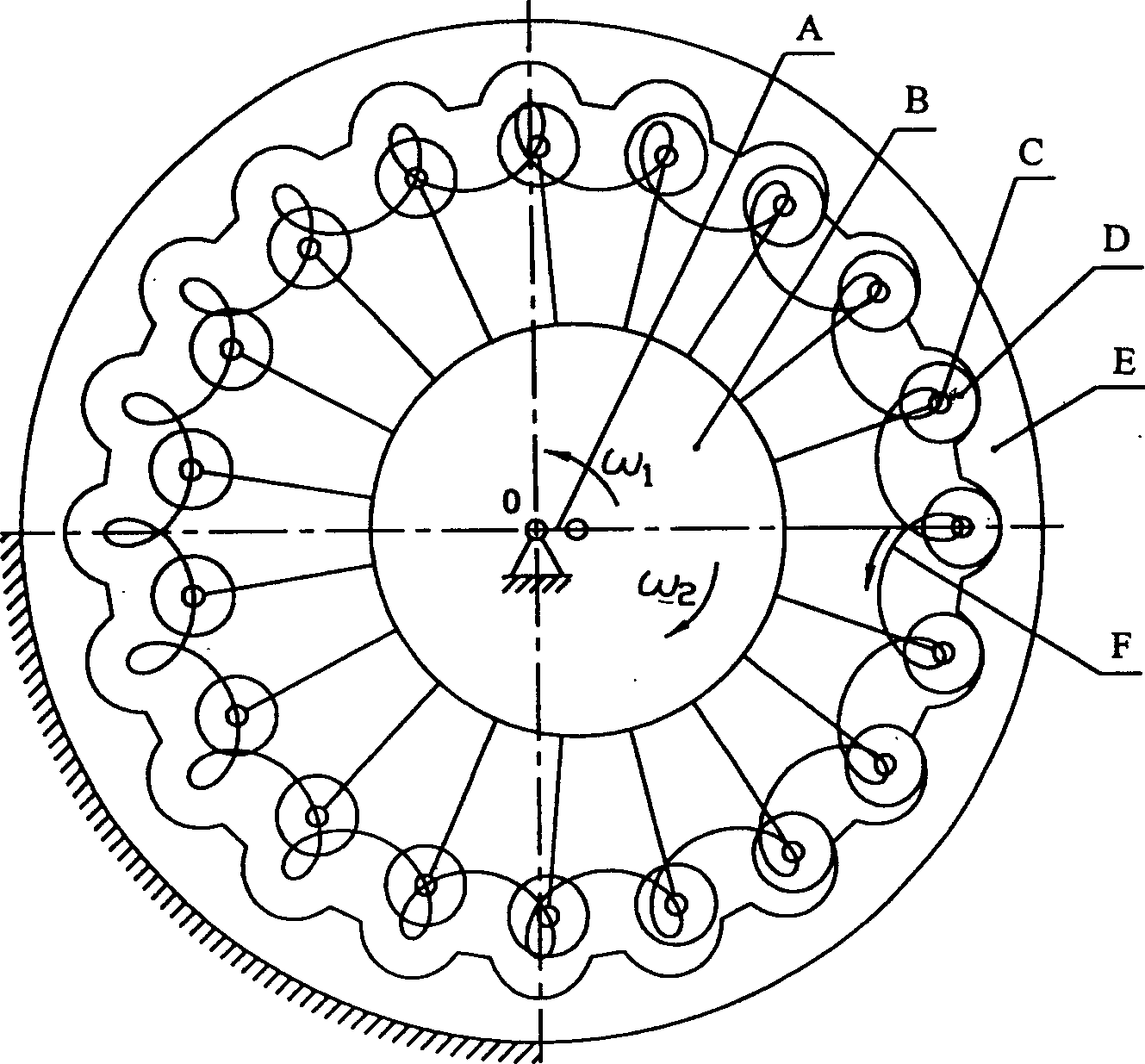

[0026] 1. Long cycloidal pin wheel planetary meshing transmission principle

[0027] Such as figure 1 As shown, the principle of long-width cycloidal pinwheel planetary meshing transmission with few tooth differences, where A is the rotating arm, and the rollers D are evenly distributed on the same radius of the planetary wheel B, when the rotating arm rotates counterclockwise at an angular velocity of ω1, the planetary The rollers on the wheel mesh with the long-width cycloid equidistant tooth profile on the small-tooth-difference internal ring gear E in turn, and the center C of the roller D will move on the long-width cycloid F in the direction of the arrow. Let the number of rollers on the planetary wheel be Z 2 , the number of teeth of the internal gear with small tooth difference is Z 3 , when the rotating arm A rotates once, the planetary gear rotates Z in the direction of ω2 3 -Z 2 a roller.

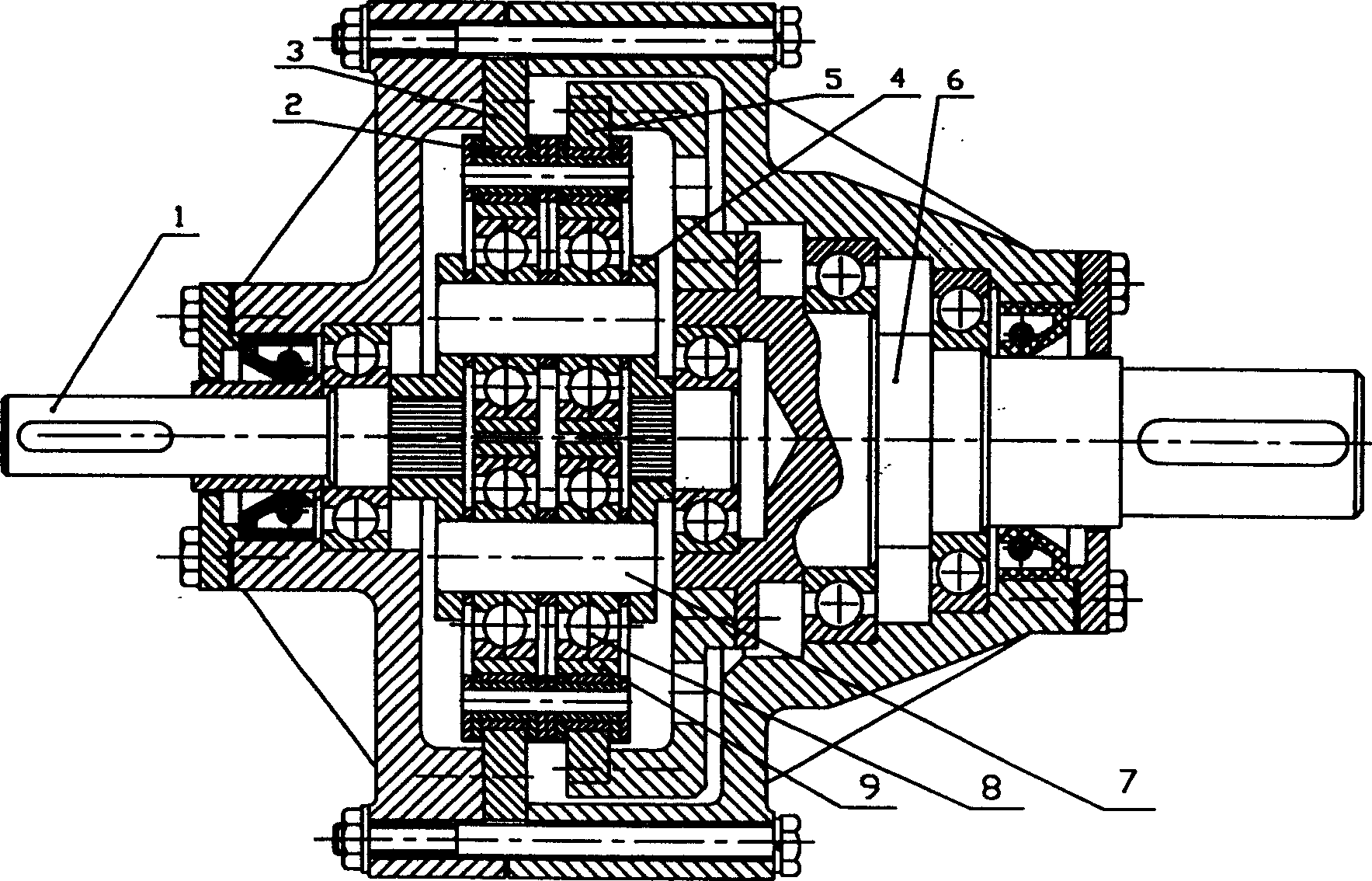

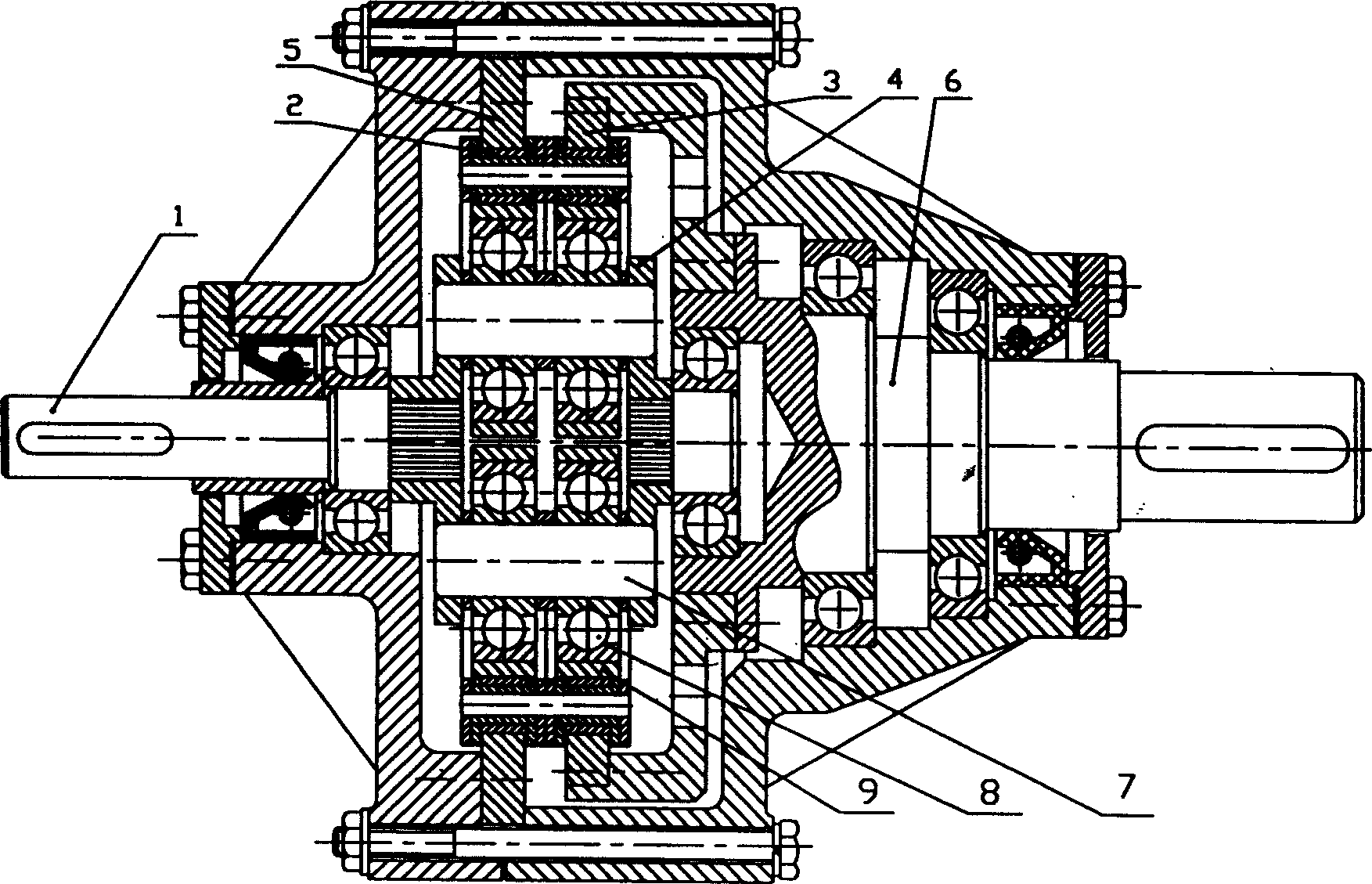

[0028] 2. Cycloidal roller chain harmonic drive principle

[0029] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com