Bending device of joint flexible turnout

A technology of deflection device and turnout, which is applied to roads, tracks, buildings, etc., can solve the problems of difficult installation and adjustment, difficult to ensure accuracy, and unfavorable maintenance, and achieve the effect of improving service life, improving accuracy and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

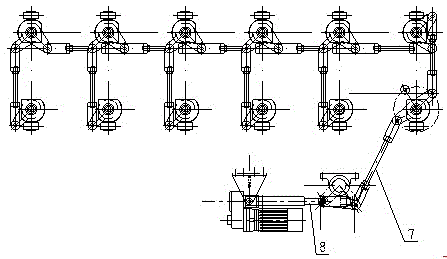

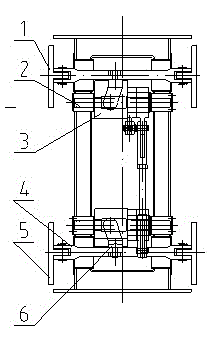

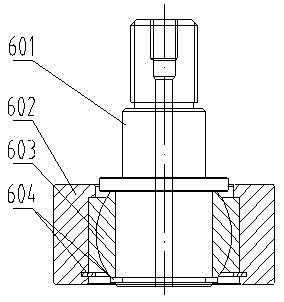

Embodiment 1

[0020] Embodiment 1: with reference to attached Figure 1-Figure 6-1 . A joint flexible turnout deflection device, including a guide panel, a stable panel, a mounting support, a cam support shaft, an axial cam, a double plug connecting rod, a roller assembly, a connecting rod pair, an electric push rod, and a deflection device The driving form of the serial connection of cam rods is used to realize the synchronous bending of the guide surface and the stable surface. The guide panel 1 and the stabilizer panel 5 are connected to the two ends of the double-fork pull rod 4 through hinged holes, and the double-fork pull rod 4 is connected to the driven assembly. Connected, the driven assembly is connected with the cylindrical cam mechanism, and the upper two adjacent cylindrical cam mechanisms and the upper and lower corresponding two cylindrical cam mechanisms 3 are connected through connecting rods. When the electric push rod 8 starts to push and pull; the pull rod drives The gu...

Embodiment 2

[0028] Embodiment 2: with reference to attached Figure 7 . A turnout line shape of a joint-flexible turnout device, including the fixed end of the turnout, the position of the lateral line of the movable end, and the linear position of the movable end. The transition curve is between the fixed end 501 of the turnout and the arc curve, and the arc curve and the movable end Between the end side line positions 502 is a gentle curve. Number 503 is the linear position of the movable end. Namely: Japan and Chuandong shipyard turnout adopted a single circular curve linear design. During use, there will be hard point transitions at the joints in the line; at the same time, due to the influence of beam width, there will be about 3mm of misaligned teeth on the guide surface and stable surface of the open end. The line shape of the turnout designed in this application takes into account the influence of the concrete beams at both ends, and the deflection line adopts a combination of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com