Solvent-free epoxy self-leveling terrace

A solvent-free, epoxy-based technology, applied in the field of floor coatings, can solve the problems of unfavorable human health, easy to hide dirt, and breed bacteria, etc., and achieve good application prospects, easy maintenance, and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

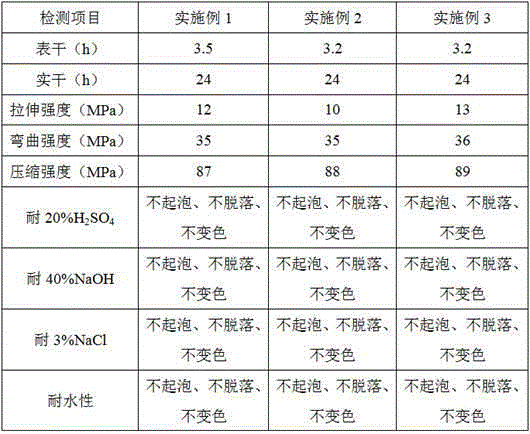

Examples

Embodiment 1

[0016] A solvent-free epoxy self-leveling floor, the floor structure includes a primer, a leveling layer and a topcoat from bottom to top;

[0017] The undercoat is prepared from 80 parts by weight of E-54 epoxy resin, 3 parts of phenyl glycidyl ether, 0.6 part of defoamer, and 10 parts of alicyclic amine;

[0018] The leveling layer is 80 parts by weight of E-54 epoxy resin, 2 parts of n-butyl glycidyl ether, 3 parts of allyl glycidyl ether, 0.6 parts of defoamer, 10 parts of grease Cyclic amine and 80 parts of talcum powder are prepared as raw materials;

[0019] Described surface coating is to be the E-54 epoxy resin of 60 parts by weight, the ethylene glycol diglycidyl ether of 20 parts, the phenyl glycidyl ether of 2.5 parts, the alicyclic amine of 10 parts, the alicyclic amine of 0.1 part Elastic polyurethane, 8 parts of talcum powder, 2 parts of heavy calcium carbonate powder, 10 parts of 80 mesh quartz sand, 0.5 part of wetting and dispersing agent, 0.7 part of organi...

Embodiment 2

[0021] A solvent-free epoxy self-leveling floor, the floor structure includes a primer, a leveling layer and a topcoat from bottom to top;

[0022] The undercoat is prepared from 85 parts by weight of E-54 epoxy resin, 4 parts of phenyl glycidyl ether, 0.8 part of defoamer, and 12 parts of alicyclic amine;

[0023] The leveling layer is 85 parts by weight of E-54 epoxy resin, 4 parts of n-butyl glycidyl ether, 4 parts of allyl glycidyl ether, 0.8 parts of defoamer, 15 parts of grease Cyclic amine, 0.3 parts of white carbon black, and 90 parts of talcum powder are prepared as raw materials;

[0024] Described surface coating is to be the E-54 epoxy resin of 70 parts by weight, the ethylene glycol diglycidyl ether of 30 parts, the phenyl glycidyl ether of 3 parts, the alicyclic amine of 15 parts, the alicyclic amine of 0.6 part Elastic polyurethane, 9 parts of talcum powder, 3 parts of heavy calcium carbonate powder, 15 parts of 80-mesh quartz sand, 5 parts of 120-mesh quartz s...

Embodiment 3

[0026] A solvent-free epoxy self-leveling floor, the floor structure includes a primer, a leveling layer and a topcoat from bottom to top;

[0027] The base coat is prepared from 90 parts by weight of E-54 epoxy resin, 6 parts of phenyl glycidyl ether, 1 part of defoamer, and 15 parts of alicyclic amine;

[0028] The leveling layer is 90 parts by weight of E-54 epoxy resin, 5 parts of n-butyl glycidyl ether, 5 parts of allyl glycidyl ether, 1 part of defoamer, 20 parts of grease Cyclic amine, 0.5 parts of white carbon black, and 100 parts of talcum powder are prepared as raw materials;

[0029] Described surface coating is to be the E-54 epoxy resin of 80 parts by weight, the ethylene glycol diglycidyl ether of 40 parts, the phenyl glycidyl ether of 5 parts, the alicyclic amine of 20 parts, the alicyclic amine of 0.8 part Elastic polyurethane, 10 parts of talcum powder, 4 parts of heavy calcium carbonate powder, 20 parts of 80 mesh quartz sand, 10 parts of 120 mesh quartz san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com