Corrosion-resistant wear-resistant steel plate and preparation method thereof

A wear-resistant steel plate and anti-corrosion technology, applied in the field of wear-resistant steel and its preparation, can solve the problems of not considering anti-corrosion wear performance, high alloy content addition, harsh preparation process, etc., to achieve excellent anti-corrosion wear performance, excellent anti-corrosion The effect of corrosion and wear, and the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

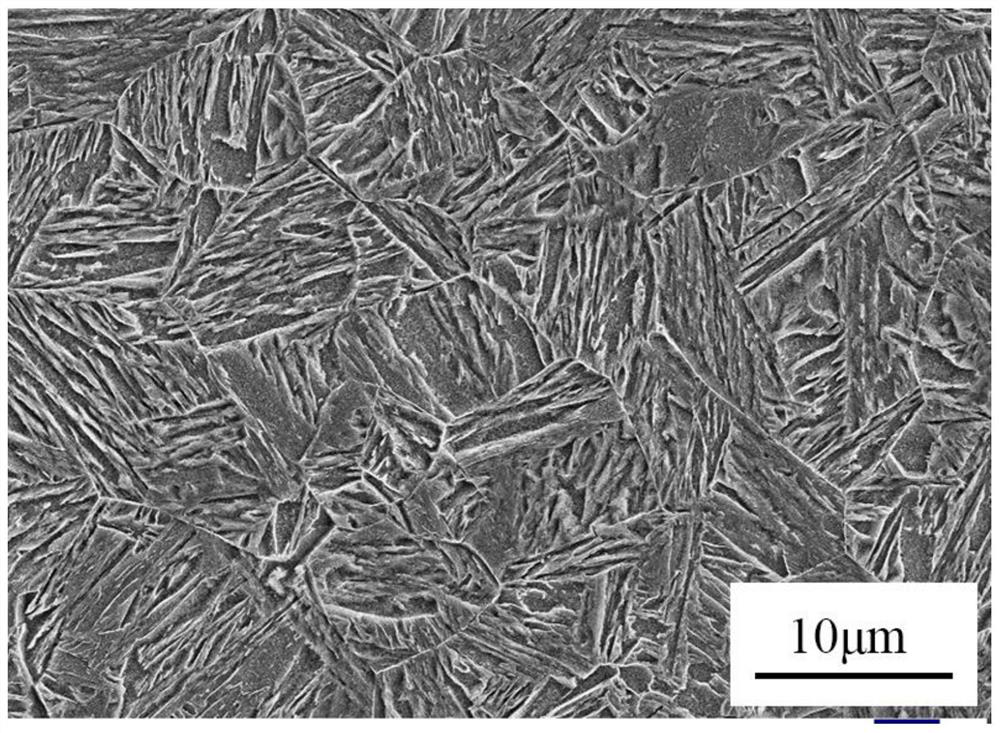

Image

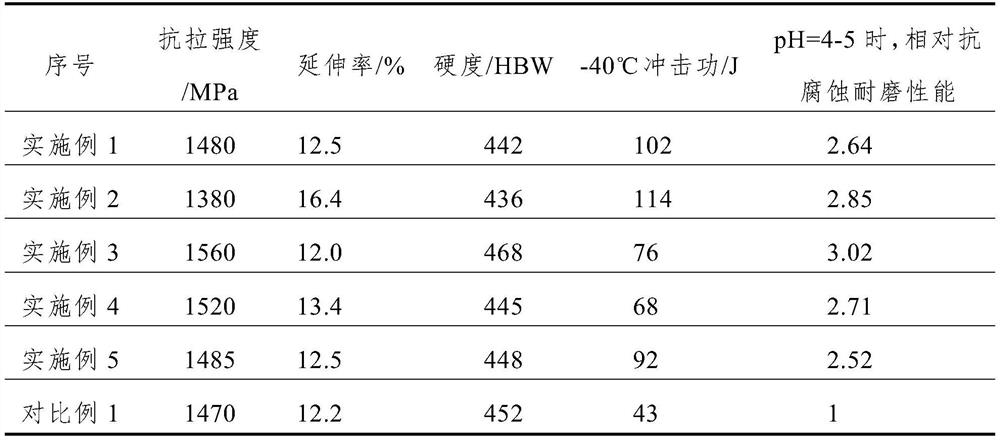

Examples

Embodiment 1

[0049] This embodiment provides the aforementioned anti-corrosion and wear-resistant steel plate and a preparation method thereof.

[0050] The chemical composition in the steel plate includes by mass percentage: C: 0.16%, Si: 0.10%, Mn: 0.30%, P≤0.015%, S≤0.005%, Cr: 4.00%, Ni: 0.30%, Mo: 0.20% , Als: 0.045%, B: 0.0012%, Ca: 0.0015%, Nb: 0.025%, Ti: 0.012%, Cu: 0.41%, wherein the mass ratio of Ca element to S element is greater than 3, and the rest is Fe and unavoidable impurity elements.

[0051] The preparation method of the above-mentioned anti-corrosion and wear-resistant steel plate comprises the following steps:

[0052] Alloy batching is carried out first, and the chemical composition includes: C: 0.16%, Si: 0.10%, Mn: 0.30%, P≤0.015%, S≤0.005%, Cr: 4.00%, Ni: 0.30%, Mo : 0.20%, Als: 0.045%, B: 0.0012%, Ca: 0.0015%, Nb: 0.025%, Ti: 0.012%, Cu: 0.41%, and the rest are Fe and unavoidable impurity elements.

[0053] The alloy ingredients in the above proportions are sm...

Embodiment 2

[0059] This embodiment provides another anti-corrosion and wear-resistant steel plate and a preparation method thereof.

[0060] The chemical composition in the steel plate includes by mass percentage: C: 0.14%, Si: 0.25%, Mn: 1.00%, P≤0.015%, S≤0.005%, Cr: 6.00%, Ni: 0.45%, Mo: 0.32% , Als: 0.038%, B: 0.0014%, Ca: 0.0023%, Nb: 0.025%, Ti: 0.014%, Cu: 0.40%, wherein the mass ratio of Ca element to S element is greater than 4, and the rest is Fe and unavoidable impurity elements.

[0061] The preparation method of the above-mentioned anti-corrosion and wear-resistant steel plate comprises the following steps:

[0062] Alloy batching is carried out first, and the chemical composition includes: C: 0.14%, Si: 0.25%, Mn: 1.00%, P≤0.015%, S≤0.005%, Cr: 6.00%, Ni: 0.45%, Mo : 0.32%, Als: 0.038%, B: 0.0014%, Ca: 0.0023%, Nb: 0.025%, Ti: 0.014%, Cu: 0.40%, and the rest are Fe and unavoidable impurity elements.

[0063] The alloy ingredients in the above proportions are smelted into ...

Embodiment 3

[0067] This embodiment provides yet another anti-corrosion and wear-resistant steel plate and a preparation method thereof.

[0068] The chemical composition in the steel plate includes: C: 0.22%, Si: 0.10%, Mn: 0.30%, P≤0.015%, S≤0.005%, Cr: 5.10%, Ni: 1.25%, Mo: 0.62%, Als: 0.045%, B: 0.0012%, Ca: 0.0015%, Nb: 0.02%, V: 0.038%, Ti: 0.012%, Cu: 0.41%, wherein the mass ratio of Ca element to S element is greater than 3, and the rest is Fe and unavoidable impurity elements.

[0069] The preparation method of the above-mentioned anti-corrosion and wear-resistant steel plate comprises the following steps:

[0070] Alloy batching is carried out first, and the chemical composition includes: C: 0.22%, Si: 0.10%, Mn: 0.30%, P≤0.015%, S≤0.005%, Cr: 5.10%, Ni: 1.25%, Mo : 0.62%, Als: 0.045%, B: 0.0012%, Ca: 0.0015%, Nb: 0.02%, V: 0.038%, Ti: 0.012%, Cu: 0.41%, and the rest are Fe and unavoidable impurity elements.

[0071] The alloy ingredients in the above proportions are smelted i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com