Preparation method of low-cost light-weight high-entropy alloy/aluminum oxide composite coating on surface of magnesium alloy

A high-entropy alloy and composite coating technology, applied in the direction of pressure inorganic powder coating, can solve the problems of high cost, easy to wear, single high-entropy alloy coating density, and easy corrosion of magnesium alloy, so as to improve service performance and cost Low, excellent corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0025] (1) Use 1000-mesh and 2000-mesh sandpaper to polish the surface of the AZ91D magnesium alloy substrate in sequence, and then use the sandblasting process to roughen the surface of the substrate and remove surface impurities and oxides. The sandblasting pressure is 0.5MPa, and the sandblasting The time is 15s, the mesh number of the sand shot is 100-200 mesh, and finally the substrate for cold spraying is obtained.

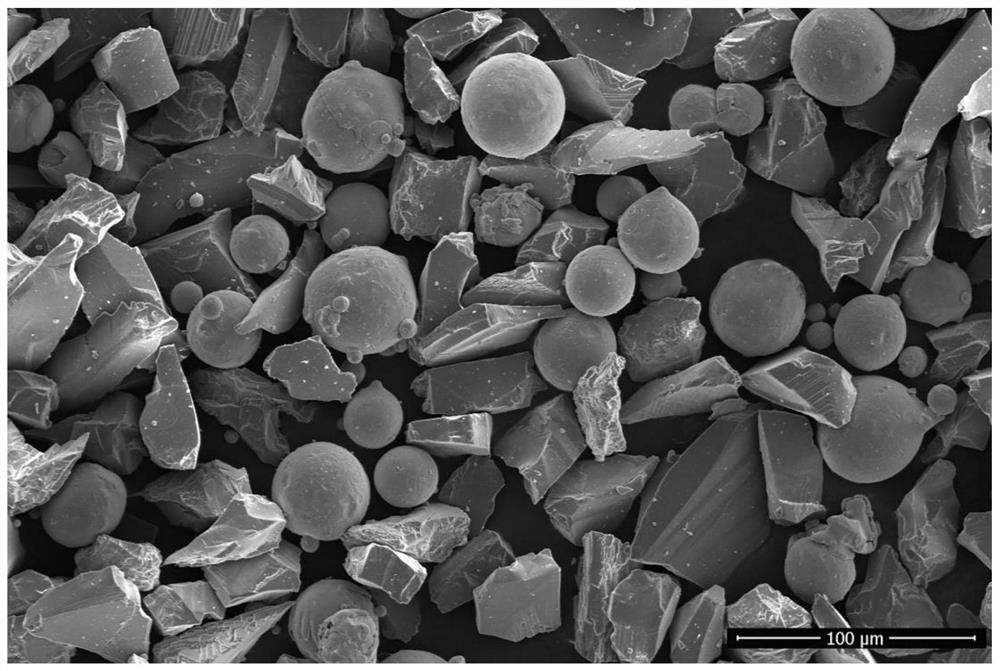

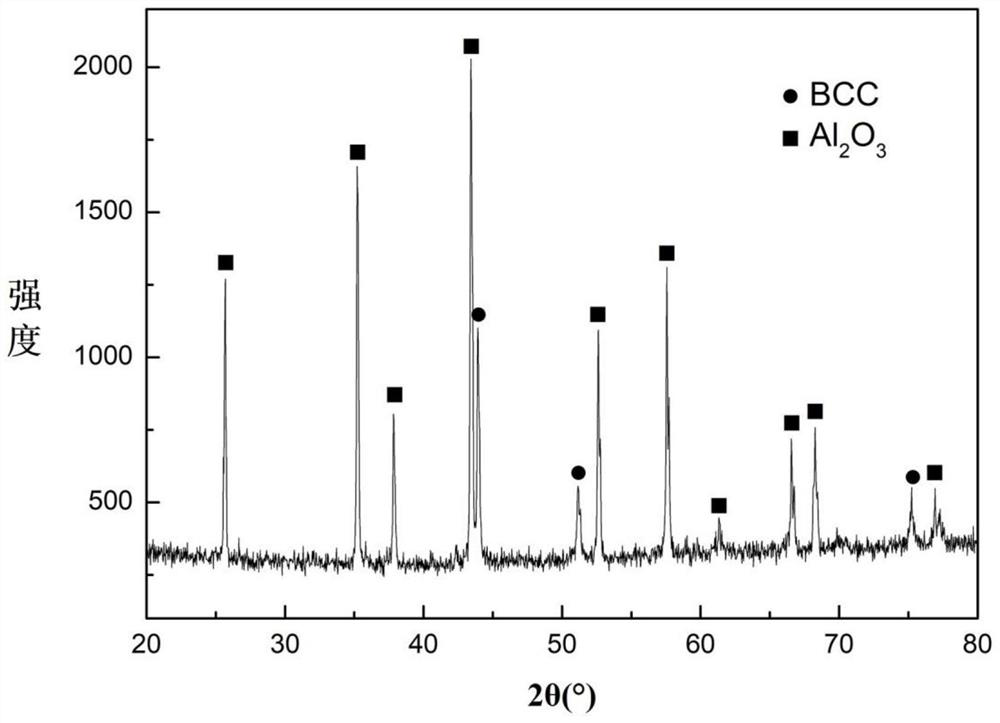

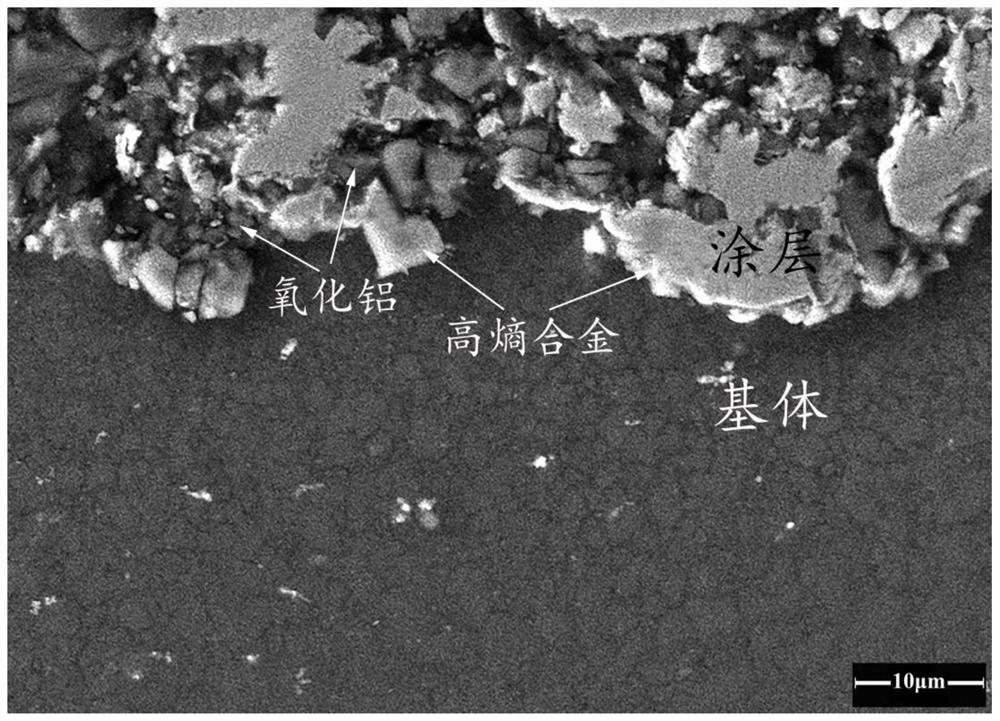

[0026] (2) Use Co, Cr, Fe, Ni raw materials with a purity of more than 99.5%, use mechanical methods to remove the surface oxide scales of raw metal Co, Cr, Fe, Ni, and use industrial ethanol to ultrasonically clean the raw metal, and then use an oven 70 ℃ hot air drying; Co, Cr, Fe, Ni four elements are weighed and proportioned according to the equiatomic ratio for the preparation of alloys; the four raw materials are put into the vacuum electric arc furnace for melting, and the melting chamber is evacuated, when the vacuum degree up to 5.0×10 -2 After Pa,...

Embodiment example 2

[0033] (1) Use 1000-mesh and 2000-mesh sandpaper to polish the surface of the AZ91D magnesium alloy substrate in sequence, and then use the sandblasting process to roughen the surface of the substrate and remove surface impurities and oxides. The sandblasting pressure is 0.5MPa, and the sandblasting The time is 15s, the mesh number of the sand shot is 100-200 mesh, and finally the substrate for cold spraying is obtained.

[0034] (2) Use Co, Cr, Fe, Ni raw materials with a purity of more than 99.5%, use mechanical methods to remove the surface oxide scales of raw metal Co, Cr, Fe, Ni, and use industrial ethanol to ultrasonically clean the raw metal, and then use an oven 70 ℃ hot air drying; Co, Cr, Fe, Ni four elements are weighed and proportioned according to the equiatomic ratio for the preparation of alloys; the four raw materials are put into the vacuum electric arc furnace for melting, and the melting chamber is evacuated, when the vacuum degree up to 5.0×10 -2 After Pa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com