Metal-doped amorphous carbon film temperature-sensing element and preparation method therefor

A technology of metal doping and sensing elements, which is applied in thermometers, metal material coating technology, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve the limitations of substrate materials, unfavorable component integration, and limited diamond films. Temperature sensor application range and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

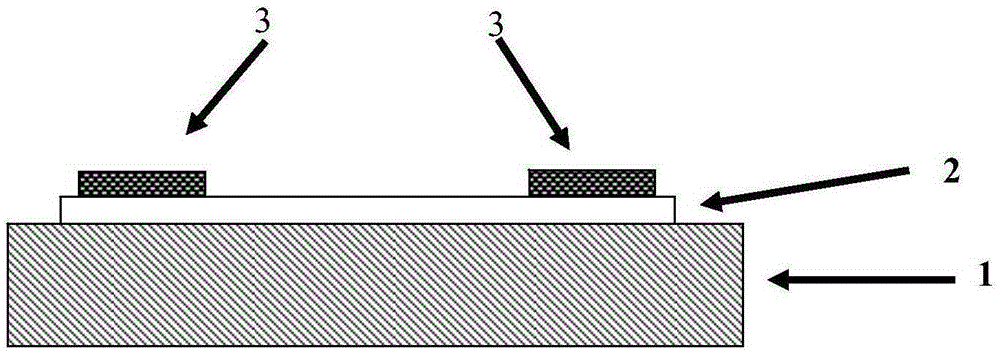

[0041] In this embodiment, the structure of the temperature sensing element is as follows figure 1 shown by Al 2 o 3 Composed of substrate 1, tungsten-doped amorphous carbon film 2 and silver colloidal electrode 3, tungsten-doped amorphous carbon film 2 is located on Al 2 o 3 On the surface of the substrate 1 , the silver glue electrode 3 is located on the surface of the tungsten-doped amorphous carbon film 2 .

[0042] Tungsten-doped amorphous carbon film 2 composed of C diamond phase sp 3 and graphite phase sp 2 Hybrid state, tungsten atoms and / or tungsten carbides, and H atoms, where tungsten atoms and / or tungsten carbides are distributed in sp 2 covalent bond and sp 3 The irregular carbon space network matrix structure formed by covalent bonds.

[0043] The preparation method of the temperature sensing element comprises the following steps:

[0044] (1)Al 2 o 3 The substrate was ultrasonically cleaned with ethanol, dried and placed in a vacuum chamber, pre-evacua...

Embodiment 2

[0052] In this embodiment, the structure of the temperature sensing element is completely the same as that in Embodiment 1.

[0053] In this embodiment, the preparation method of the temperature sensing element is basically the same as that in Embodiment 1, except that the magnetron sputtering target current in step (2) is 1.8A.

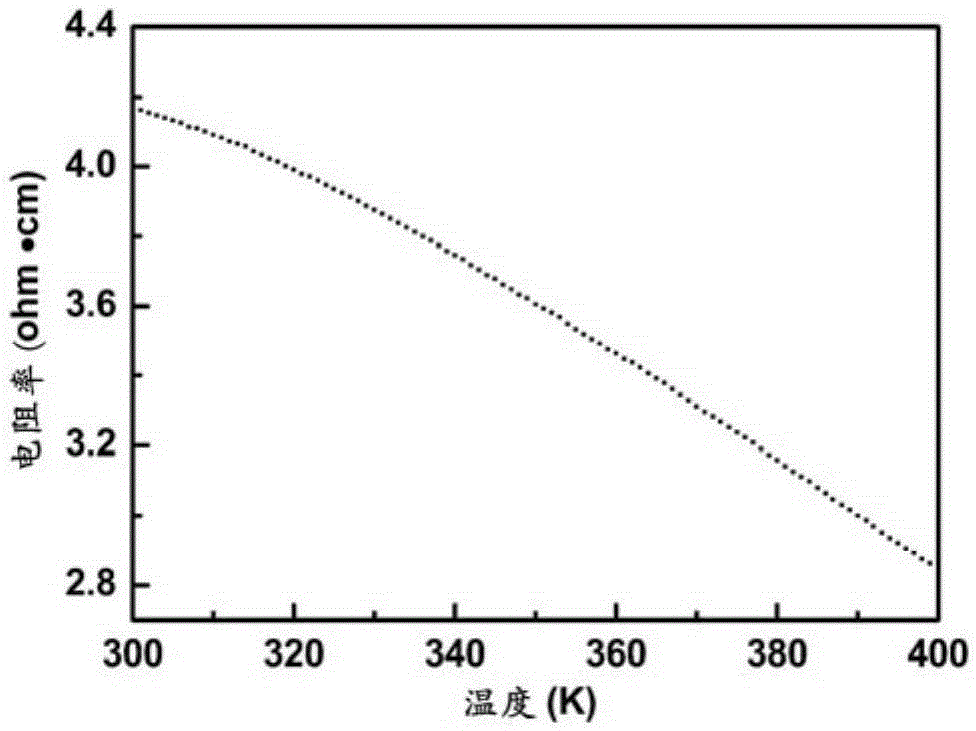

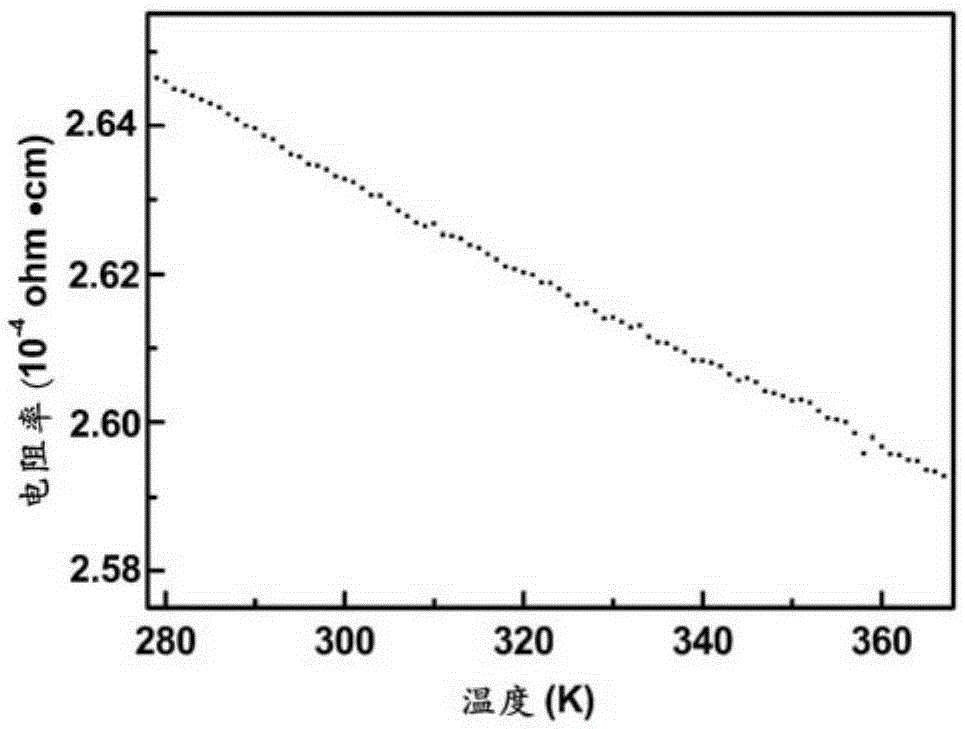

[0054] The same as in Example 1, using the four-point method, the relationship between the resistivity of the temperature sensing element prepared above in the range of 278K to 368K as a function of temperature was tested by a comprehensive physical property measurement system (PhysicalPropertyMeasurementSystem, PPMS), and the results are as follows: image 3 As shown, through the following formula:

[0055] T C R = ( R - R 0 ) / R 0 ...

Embodiment 3

[0058] In this embodiment, the structure of the temperature sensing element is as follows figure 1 shown by Al 2 o 3 Composed of substrate 1, copper-chromium co-doped amorphous carbon film 2 and silver glue electrode 3, copper-chromium co-doped amorphous carbon film 2 is located on Al 2 o 3 On the surface of the substrate 1, the silver glue electrode 3 is located on the surface of the copper-chromium co-doped amorphous carbon film 2.

[0059] CuCr-doped amorphous carbon film 2 composed of C diamond phase sp 3 and graphite phase sp 2 Hybrid state, copper, chromium atoms and / or copper chromium carbides, and H atoms, where copper chromium atoms and / or copper chromium carbides are distributed in sp 2 covalent bond and sp 3 The irregular carbon space network matrix structure formed by covalent bonds.

[0060] The preparation method of the temperature sensing element comprises the following steps:

[0061] (1)Al 2 o 3 The substrate was ultrasonically cleaned with ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com