Wear-resistant and corrosion-resistant aluminum alloy drill rod preparation method and prepared aluminum alloy drill rod

An aluminum alloy, anti-corrosion technology, applied in the direction of drill pipe, drilling equipment, drill pipe, etc., can solve the problems that affect the efficiency of oil field drilling and production, electrochemical corrosion of joints, poor wear resistance of materials, etc., achieve good insulation performance, prevent electrical shock Double corrosion, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a wear-resistant and anti-corrosion aluminum alloy drill pipe of the present embodiment 1 is described in detail below, and the parameters in the process and the obtained results are shown in the corresponding data of the embodiment 1 in Table 1.

[0029] Step 1. Form the aluminum alloy drill pipe, decontaminate, degrease and deburr the surface.

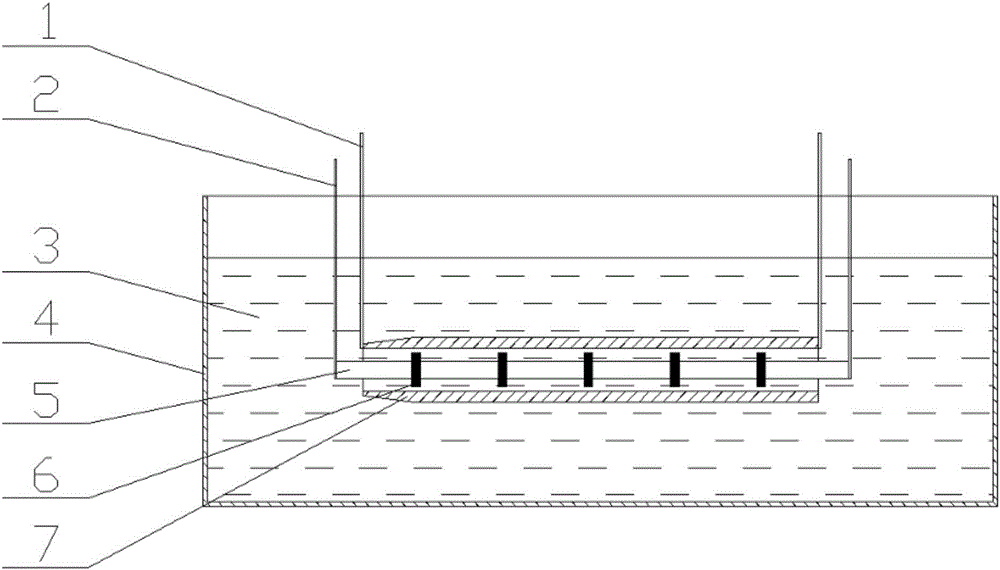

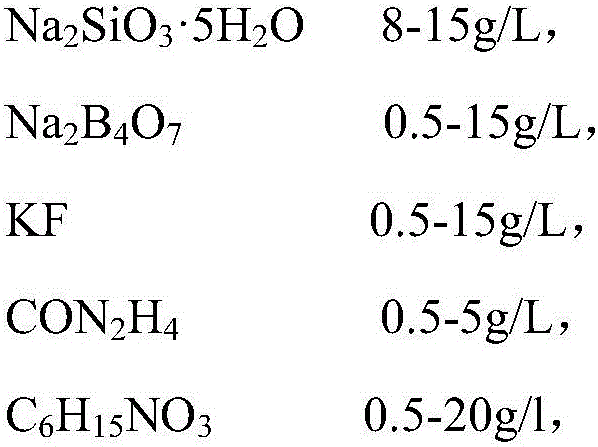

[0030] Step 2, configuration solution 3: according to the number of kilograms shown in the data of Example 1 in Table 1, take by weighing Na 2 SiO 3 ·5H 2 O, Na 2 B 4 o 7 , KF, CON 2 h 4 、C 6 h 15 NO 3 , KOH as solute, add in the stainless steel tank 4 that 1000L deionized water is housed, mix well.

[0031] Step 3, hoisting the aluminum alloy drill pipe: the positive lead wire 1 is electrically connected closely with the aluminum alloy drill pipe 7, and the aluminum alloy drill pipe is hoisted; the negative lead wire 2 is closely electrically connected with the stainless steel auxiliary cathod...

Embodiment 2

[0039] The preparation of the aluminum alloy drill pipe in this embodiment 2, the method steps are the same as in embodiment 1, the difference is that the technical parameters corresponding to embodiment 2 shown in table 1 are adopted, and the wear-resistant layer obtained is also corresponding to embodiment 2 in table 1 shown in the data, and will not be repeated here.

[0040] In the process of sealing treatment in step 5 of the present invention, as long as the aluminum alloy drill pipe obtained in step 4 is soaked in 10-60g / l nickel acetate solution at 40-50°C for 18-25min, the effect of sealing treatment can be achieved. Further improve corrosion resistance

Embodiment 3

[0042] The preparation of the aluminum alloy drill pipe in this embodiment 3, the method steps are the same as in embodiment 1, the difference is that the technical parameters corresponding to embodiment 3 shown in table 1 are adopted, and the wear-resistant layer obtained is also corresponding to embodiment 3 in table 1 shown in the data, and will not be repeated here. The solution and parameters used in the sealing treatment of the aluminum alloy drill pipe obtained in Step 4 are different from those in Example 1, as shown in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com