Nitriding salt for low-temperature salt-bath nitriding

A technology of salt bath nitriding and nitriding salt, applied in the field of nitriding salt, which can solve the problems of high applicable temperature of nitriding base salt and unsuitability for low temperature treatment, etc., and achieve the effect of good wear resistance and corrosion resistance of workpieces

Inactive Publication Date: 2011-10-19

SICHUAN UNIV

View PDF2 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the current salt bath nitriding treatment technology has the following disadvantages: the nitriding base salt is suitable for a relatively high temperature, generally between 520 and 600°C, and is not suitable for low temperature treatment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

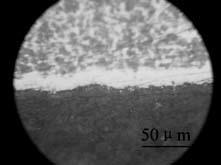

[0015] Present embodiment 1 nitride salt is made up of following composition by weight percentage: CO(NH 2 ) 2 55%, K 2 CO 3 12%, Na 2 CO 3 6%, Li 2 CO 3 6%, NaCl 10.5%, KCl 10.5%. This embodiment 1 is suitable for use under the nitriding process condition of 450° C., and the environment of the nitriding salt bath is stable. K55 steel nitride metallographic results are as follows figure 1 shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a nitriding salt for low-temperature salt-bath nitriding, which comprises the following components in percentage by weight: 45 to 55 percent of CO(NH2)2, 5 to 15 percent of K2CO3, 3 to 15 percent of Na2CO3, 3 to 15 percent of Li2CO3, 5 to 15 percent of NaCl and 5 to 15 percent of KCl. When the nitriding salt is used, the temperature for common salt-bath nitriding is lowered, and the use temperature range of the conventional nitriding salts is raised. In addition, the nitriding salt also has the advantages that: the deformation of a process workpiece is small; the equipment is simple; environment-friendly operation is realized; and the like.

Description

technical field [0001] The invention relates to a nitride salt used in a low-temperature salt bath nitriding process. Background technique [0002] The salt bath nitriding process technology is also called soft nitriding treatment technology, which uses the active nitrogen atoms generated by the decomposition of cyanate to penetrate into the workpiece, forming an iron compound layer and diffusion layer on the surface of the workpiece, thereby improving the wear resistance of iron-based materials resistance, corrosion resistance and fatigue strength. Therefore, salt bath nitriding has been widely used in production practice. However, the currently applied salt bath nitriding treatment technology has the following disadvantages: the applicable temperature of the nitriding base salt is relatively high, generally between 520 and 600°C, which is not suitable for low temperature treatment. Contents of the invention [0003] The purpose of the invention is to overcome the high ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C8/50

Inventor 王均熊计张太平

Owner SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com