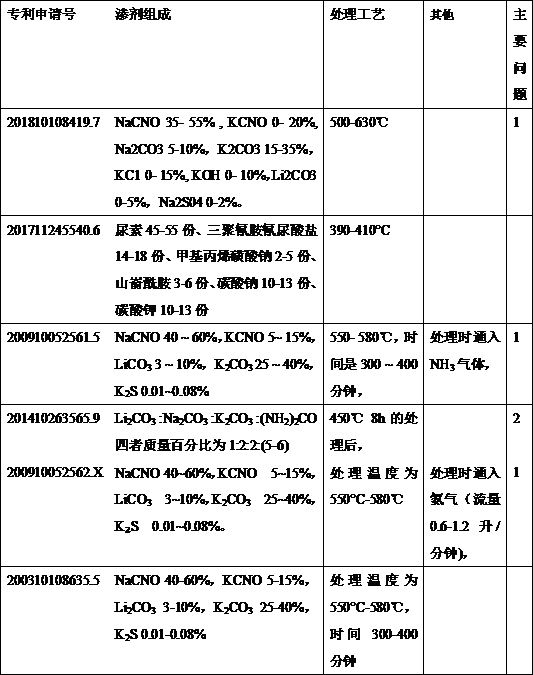

Low-temperature oxygen-carbonitriding treating agent used for improving liquid metal corrosion resistance of stainless steel

A liquid metal, carbon-nitrogen-oxygen technology, applied in metal material coating process, solid-state diffusion coating, coating, etc., can solve the failure of cooling system, affect the mechanical and physical properties of materials, composition and surface morphology changes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

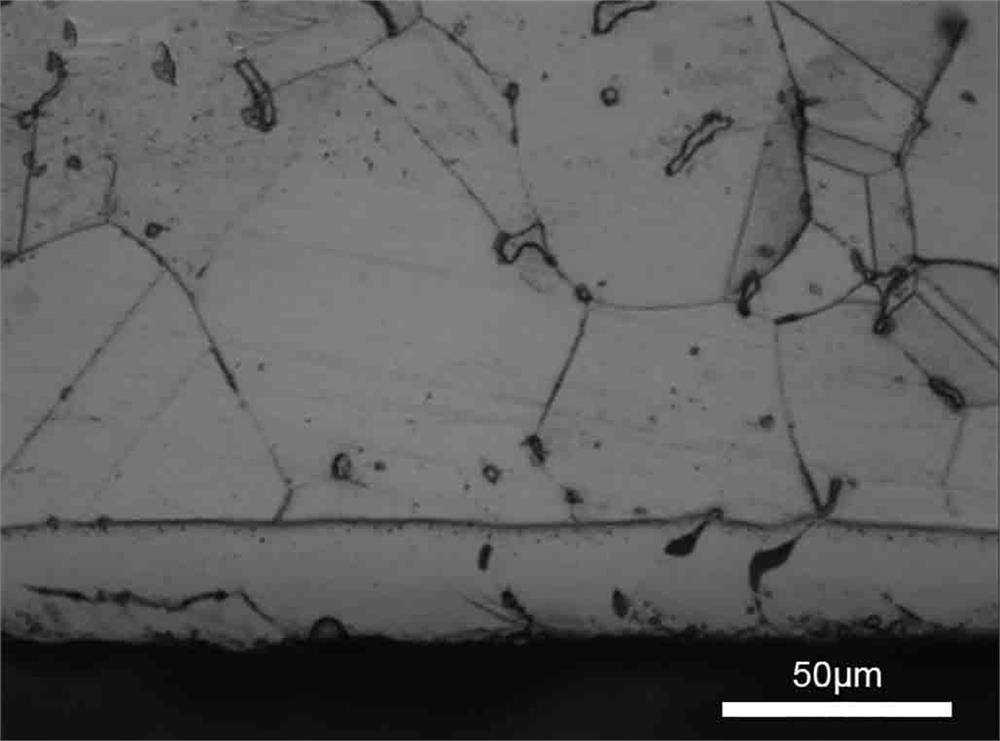

[0024] A low-temperature carbonitriding treatment agent for improving the corrosion resistance of stainless steel to liquid metal in this embodiment consists of the following components by weight percentage: KCNO 35%, NaCNO 30%, K 2 CO 3 9%, Na 2 CO 3 8.5%, Li 2 CO 3 3%, NaOH6%, KOH 4%, Ce(OH) 3 3%, Na 2 SO4 0.2%, K 2 SO 4 0.3%. This embodiment is suitable for use under the process condition of 430°C, and the treatment agent is used in a stable environment. The metallographic results of the cross-section of 316L austenitic stainless steel after treatment at 430 °C and 8 hours are as follows: figure 1 As shown, the thickness of the bright white layer is 26.1 μm, and the microhardness of the surface layer reaches 1150HV0.1.

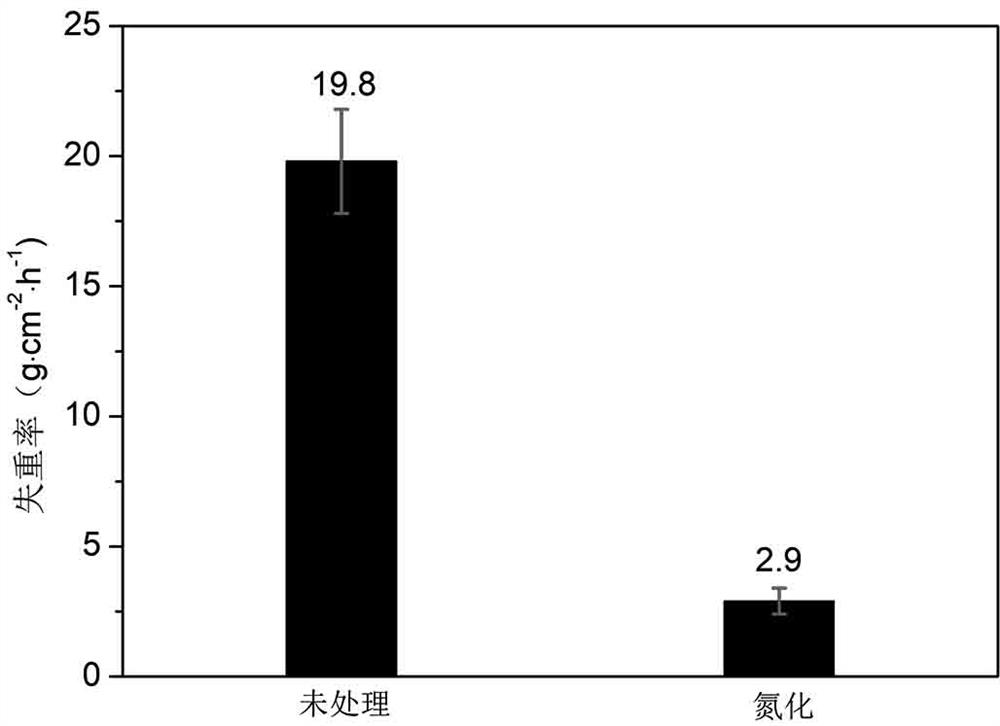

[0025] figure 2 It is the corrosion depth of 2000h of 316L austenitic stainless steel in liquid metal solution at 550°C. It can be seen that after the austenitic stainless steel is treated with a low-temperature carbonitriding treatment ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com