Preparation method of Cr-containing TiCN-based composite coating

A composite coating and composite powder technology, applied in the direction of coating, metal material coating process, melt spraying, etc., to achieve the effect of reducing the amount of wear, enhancing hardness and wear resistance, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

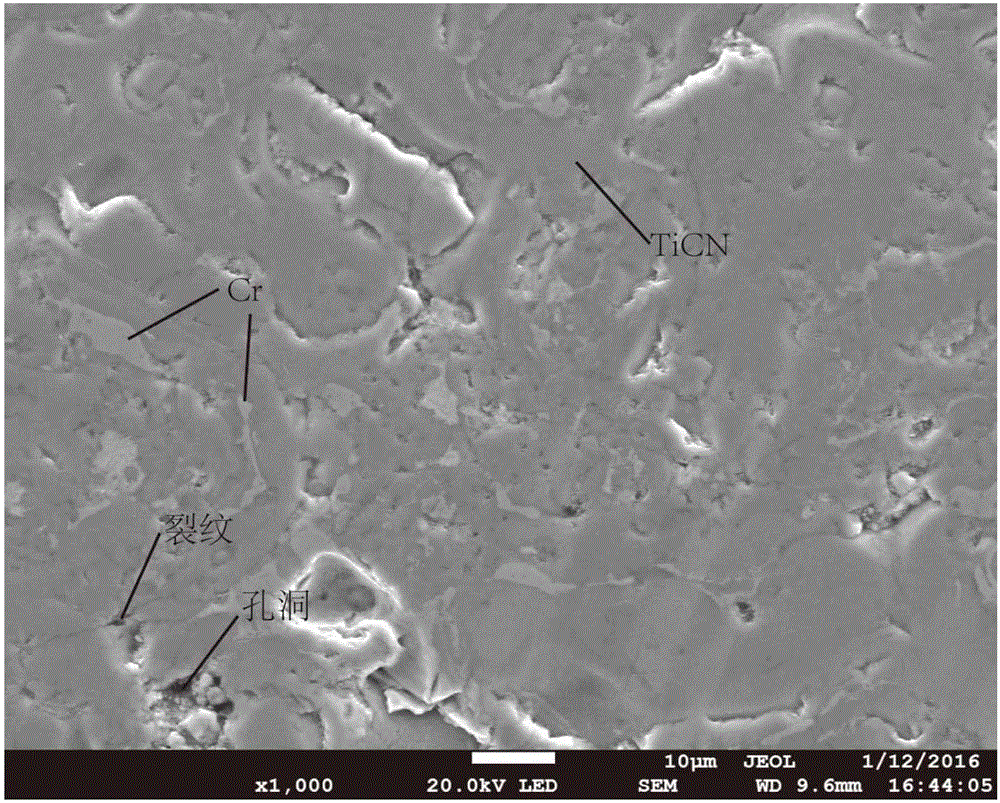

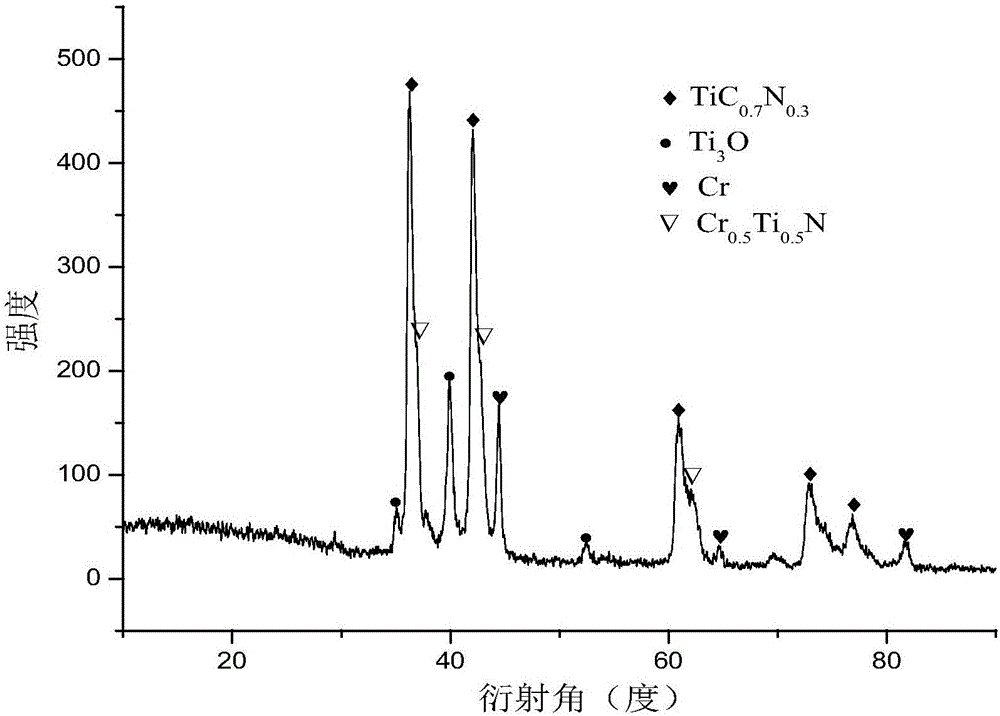

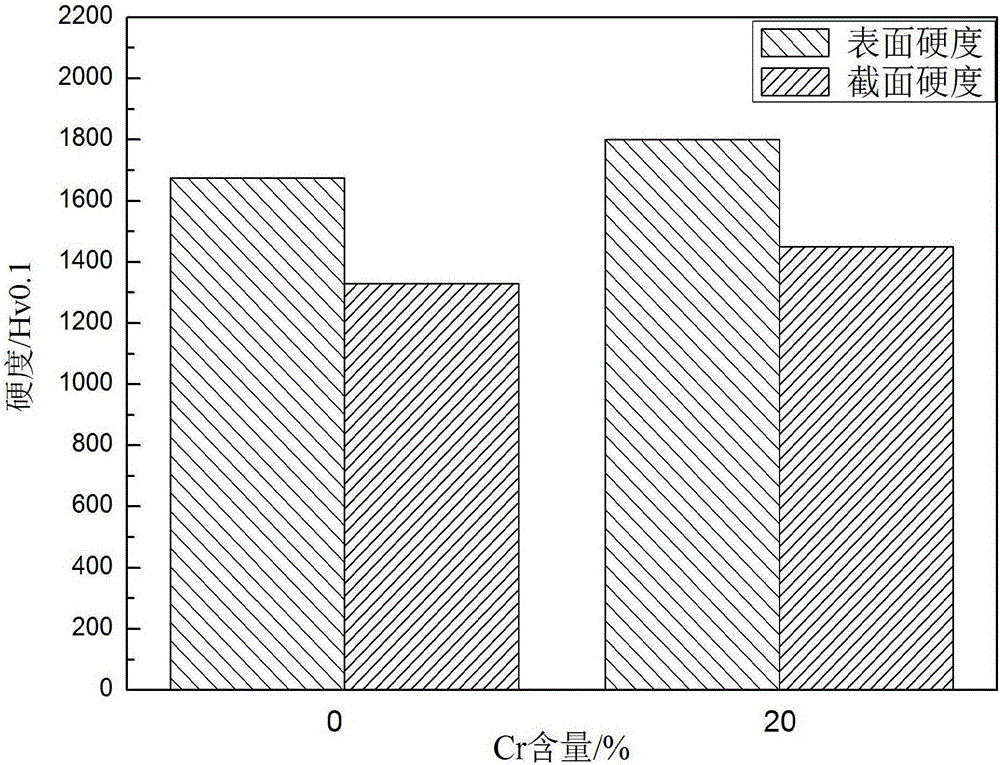

[0035] In this example, a reactive plasma spraying process was used to prepare a micro-nano-scale multi-scale TiCN-Cr metal-based ceramic composite coating on the surface of the 45# steel substrate sample, and the main phase of the prepared coating was TiC 0.7 N 0.3 , Cr mainly exists in the form of Cr element in the coating, and a small amount dissolves into the TiCN lattice to form Cr-Ti-N ternary phase Cr 0.5 Ti 0.5 N.

[0036] The preparation method of this coating is as follows:

[0037] (1) Put the 45# steel substrate sample into the TPS-1 air pressure sandblasting machine, and perform sandblasting and roughening treatment on the surface. The abrasive particles are sucked into the nozzle, accelerated in the high-pressure airflow, and sprayed onto the surface of the substrate. , to obtain a clean and rough surface, thereby increasing the bonding force between the substrate and the coating;

[0038] (2) Using graphite as the carbon source, according to the mass ratio o...

Embodiment 2

[0047] In this example, a reactive plasma spraying process was used to prepare a micro-nano-scale multi-scale TiCN-Cr metal-based ceramic composite coating on the surface of the 45# steel substrate sample, and the main phase of the prepared coating was TiC 0.7 N 0.3 , Cr mainly exists in the form of Cr element in the coating, and a small amount dissolves into the TiCN lattice to form Cr-Ti-N ternary phase Cr 0.5 Ti 0.5 N.

[0048] The preparation method of the coating is as follows:

[0049] Graphite is used as the carbon source, and the mass ratio of Ti and C powder is 5:1. Before spraying the coating, Ni-10%wtAl self-fluxing alloy powder with a thickness of 110 μm is pre-sprayed on the surface of the steel substrate as the bottom layer (or bonding bottom layer), the quality of Cr powder is 30% of the quality of composite powder to obtain the original feeding composite powder for spraying, adjust working current 500A, arc voltage 70V, spray, other steps are identical with ...

Embodiment 3

[0056] In this example, a reactive plasma spraying process was used to prepare a micro-nano-scale multi-scale TiCN-Cr metal-based ceramic composite coating on the surface of a 304 stainless steel substrate sample, and the main phase of the prepared coating was TiC 0.7 N 0.3 , Cr mainly exists in the form of Cr element in the coating, and a small amount dissolves into the TiCN lattice to form Cr-Ti-N ternary phase Cr 0.5 Ti 0.5 N.

[0057] The preparation method of the coating is as follows:

[0058] Graphite is used as the carbon source, and the mass ratio of Ti and C powder is 5:1. Before spraying the coating, Ni-10%wtAl self-fluxing alloy powder with a thickness of 110 μm is pre-sprayed on the surface of the steel substrate as the bottom layer (or bonding bottom layer), the quality of Cr powder is 25% of the quality of composite powder to obtain the original feeding composite powder for spraying, adjust working current 500A, arc voltage 70V, spray, other steps are identic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com