A device and method for repairing cracks in hot work dies

A technology of hot-working mold and repair method, applied in the field of mold crack repair, can solve the problems of lack of wide applicability and environmental protection economy, reducing material crack propagation, and large gradient of structure change, so as to improve the efficiency of diffusion connection and crack repair. Lift, small size change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

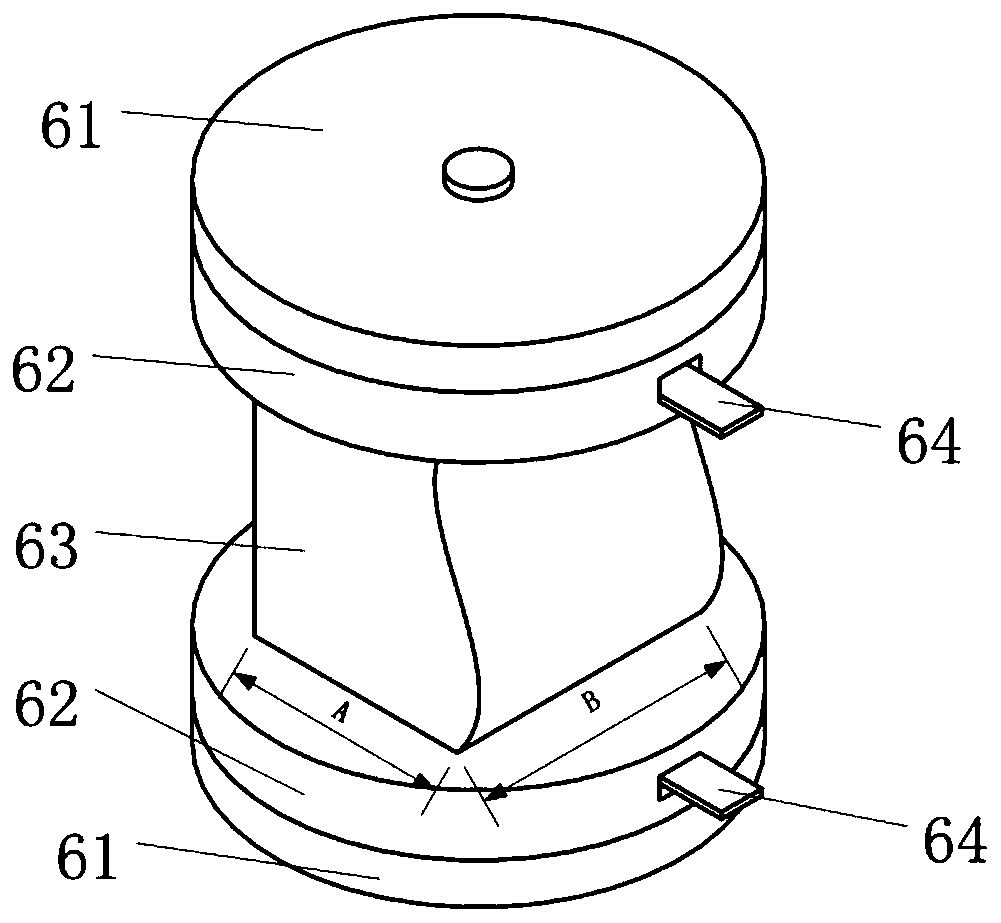

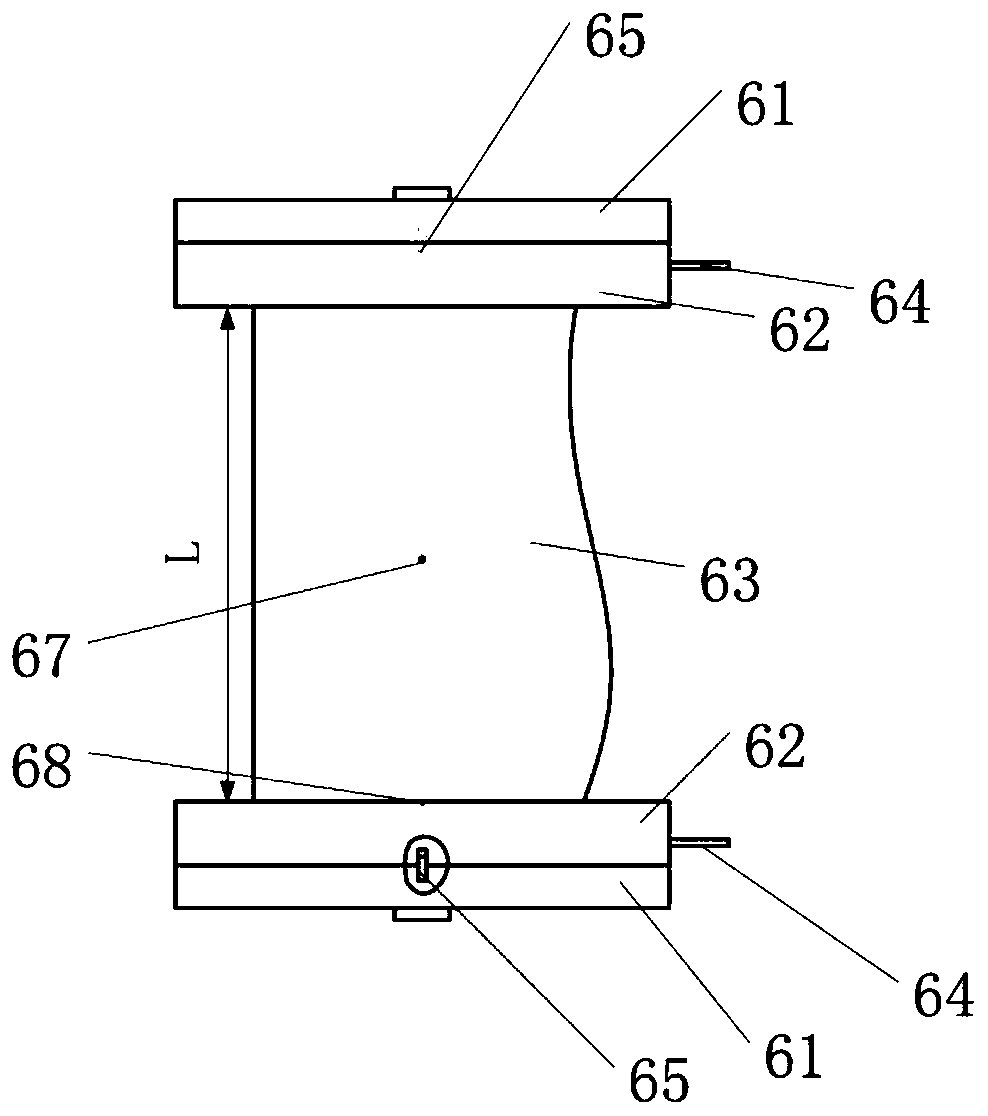

[0044] Embodiment 1, as Figure 6 As shown, a method for repairing cracks in a hot-working die. In this embodiment, a hot-working die made of 2520 material for hot forming of a titanium alloy in service is taken as an example. The specific process is as follows:

[0045] (1) Preparation work:

[0046] Cleaning: Perform routine cleaning on the hot work mold 63 that has been in service for 60 working cycles, remove the sundries and lubricants on the surface of the hot work mold 63, then put the hot work mold 63 into the ultrasonic cleaning pool, add 1:1 water alcohol The solution is not overheated to make the mold 63, and ultrasonically cleaned for 30-40 minutes to remove the oil stains and powders in the surface adhesion and surface cracks of the hot-worked mold 63.

[0047] Measurement: simply measure the length, width and height of the hot-working mold 63 L*B*A=600mm*600mm*200mm; measure the center crack with a length of 20 μm through non-destructive testing, and the directi...

Embodiment 2

[0055] Embodiment 2, as Figure 6 As shown, a method for repairing cracks in a hot-working die. In this embodiment, a hot-working die made of 2520 material for hot forming of a titanium alloy in service is taken as an example. The specific process is as follows:

[0056] (1) Preparation work:

[0057] Cleaning: Perform routine cleaning on the hot work mold 63 that has been in service for 60 working cycles, remove the sundries and lubricants on the surface of the hot work mold 63, then put the hot work mold 63 into the ultrasonic cleaning pool, add 1:1 water alcohol The solution is not overheated to make the mold 63, and ultrasonically cleaned for 30-40 minutes to remove the oil stains and powders in the surface adhesion and surface cracks of the hot-worked mold 63.

[0058] Measurement: simply measure the length, width and height of the hot-working mold 63 L*B*A=600mm*600mm*200mm; measure the center crack with a length of 20 μm through non-destructive testing, and the directi...

Embodiment 3

[0066] Embodiment 3, as Figure 6 As shown, a method for repairing cracks in a hot-working die. In this embodiment, a hot-working die made of 2520 material for hot forming of a titanium alloy in service is taken as an example. The specific process is as follows:

[0067] (1) Preparation work:

[0068] Cleaning: Perform routine cleaning on the hot work mold 63 that has been in service for 60 working cycles, remove the sundries and lubricants on the surface of the hot work mold 63, then put the hot work mold 63 into the ultrasonic cleaning pool, add 1:1 water alcohol The solution is not overheated to make the mold 63, and ultrasonically cleaned for 30-40 minutes to remove the oil stains and powders in the surface adhesion and surface cracks of the hot-worked mold 63.

[0069] Measurement: simply measure the length, width and height of the hot-working mold 63 L*B*A=600mm*600mm*200mm; measure the center crack with a length of 20 μm through non-destructive testing, and the directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com