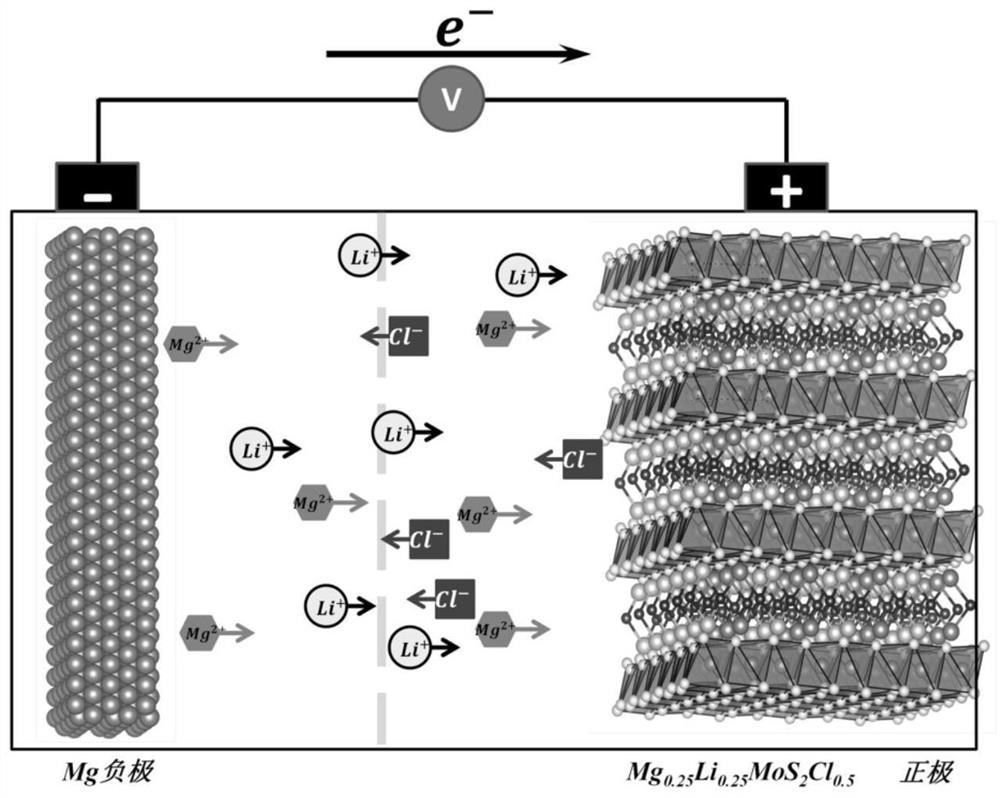

A kind of magnesium ion battery material and preparation method thereof, magnesium ion battery composite material and preparation method thereof

A technology of magnesium ion battery and composite material, applied in the field of magnesium ion battery material and its preparation, can solve the problems of detachment, limited number of ions, inability to realize fast charging and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The magnesium ion battery material of the present embodiment, chemical formula is Mg 0.25 MoS 2 .

[0072] The preparation method of the magnesium ion battery material of the present embodiment comprises the steps:

[0073] 1) Weigh ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2) and thioacetamide (C 2 h 5 NS) spare. Ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2 ) and thioacetamide (C 2 h 5 NS) in a molar ratio of 0.095:1.34:2.14.

[0074] Ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2 ) and thioacetamide (C 2 h 5 NS) into a 50mL polytetrafluoroethylene reactor, add 30mL of deionized water to the reactor, and stir for 30 minutes at room temperature. After the reactants are completely dissolved, seal the reactor and put it in a blast drying oven at 200°C In, react 24h. The reaction kettle was naturally cooled to room temperature, and the reaction mixture in th...

Embodiment 2

[0080] The magnesium ion battery material of the present embodiment, chemical formula is Mg 0.5 MoS 2 .

[0081] The preparation method of the magnesium ion battery material of the present embodiment comprises the steps:

[0082] 1) Weigh ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2 ) and thioacetamide (C 2 h 5 NS) spare. Ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2 ) and thioacetamide (C 2 h 5 NS) in a molar ratio of 0.095:0.67:2.14.

[0083] Ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2 ) and thioacetamide (C 2 h 5 NS) into a 50mL polytetrafluoroethylene reactor, add 30mL of deionized water to the reactor, and stir for 30 minutes at room temperature. After the reactants are completely dissolved, seal the reactor and put it in a blast drying oven at 200°C In, react 24h. The reaction kettle was naturally cooled to room temperature, and the reaction mixture in th...

Embodiment 3

[0089] The magnesium ion battery material of the present embodiment, chemical formula is Mg 0.75 MoS 2 .

[0090] The preparation method of the magnesium ion battery material of the present embodiment comprises the steps:

[0091] 1) Weigh ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2 ) and thioacetamide (C 2 h 5 NS) spare. Ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2 ) and thioacetamide (C 2 h 5 NS) in a molar ratio of 0.095:0.45:2.14.

[0092] Ammonium molybdate (H 24 Mo 7 N 6 o 24 4H 2 O), magnesium chloride (MgCl 2 ) and thioacetamide (C 2 h 5 NS) into a 50mL polytetrafluoroethylene reactor, add 30mL of deionized water to the reactor, and stir for 30 minutes at room temperature. After the reactants are completely dissolved, seal the reactor and put it in a blast drying oven at 200°C In, react 24h. The reaction kettle was naturally cooled to room temperature, and the reaction mixture in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com