Preparation method of silicon-containing layered double hydroxide

A hydroxide and bimetal technology is applied in the field of preparation of silicon-containing layered bimetallic hydroxide, can solve the problems of environmental pollution, single synthesis method, energy waste and the like, achieves good crystallinity, simple preparation process, Low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of silicon-containing layered double metal hydroxide, comprising the following steps:

[0035] (1) Weigh 2.864g magnesium hydroxide, 1.136g aluminum hydroxide and 196g agate balls (ball-to-material ratio 49:1), add them to a 100mL ball mill jar, and ball mill them at 1500rpm for 4h to obtain the hydroxide mixture; 0.178 g of the obtained hydroxide mixture was stirred and dispersed in 30 mL of water to obtain a hydroxide mixture dispersion.

[0036] (2) Add 17 μL of SiCl to the hydroxide mixture dispersion obtained in step (1) 4 , stir well to obtain a suspension, transfer the obtained suspension to a glass bottle, and place it in an oven at 80°C for 24 hours, then cool it to room temperature naturally, filter, wash the obtained precipitate with water three times, and store it at 60°C After drying for 24 hours, Mg-Al-Si LDHs powder is obtained, which is silicon-containing layered double metal hydroxide powder.

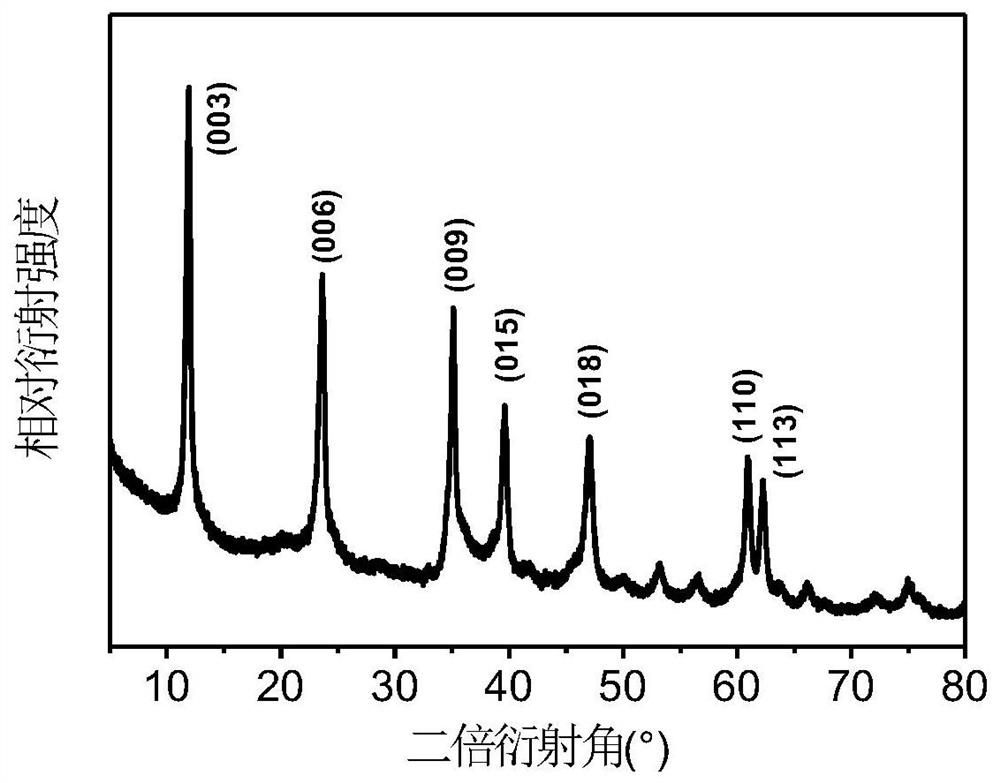

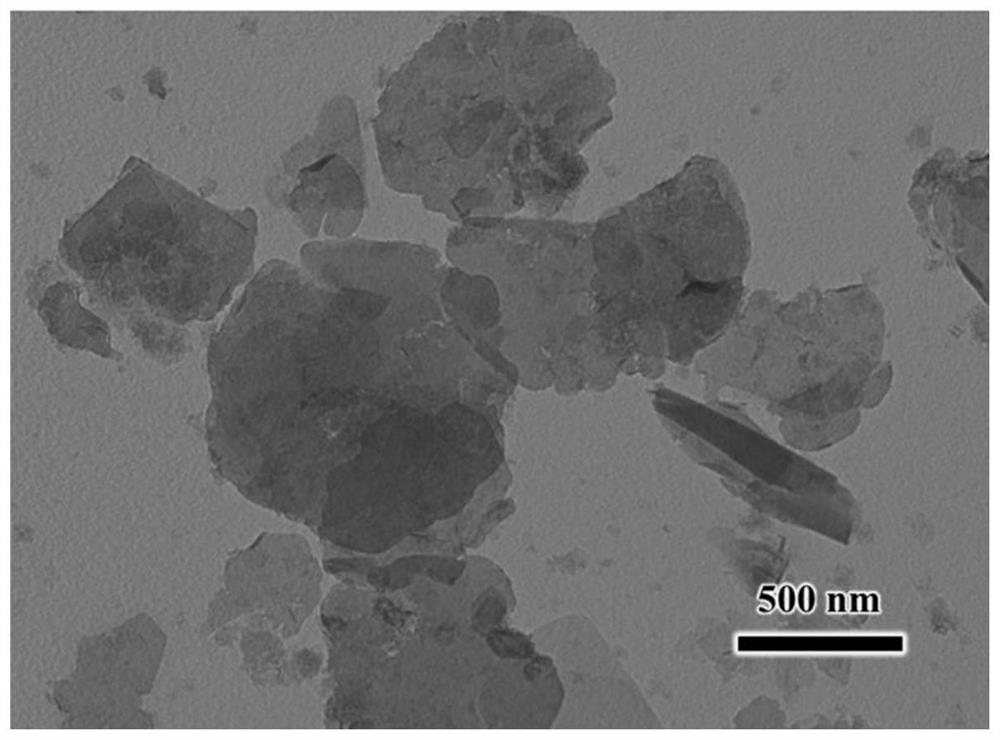

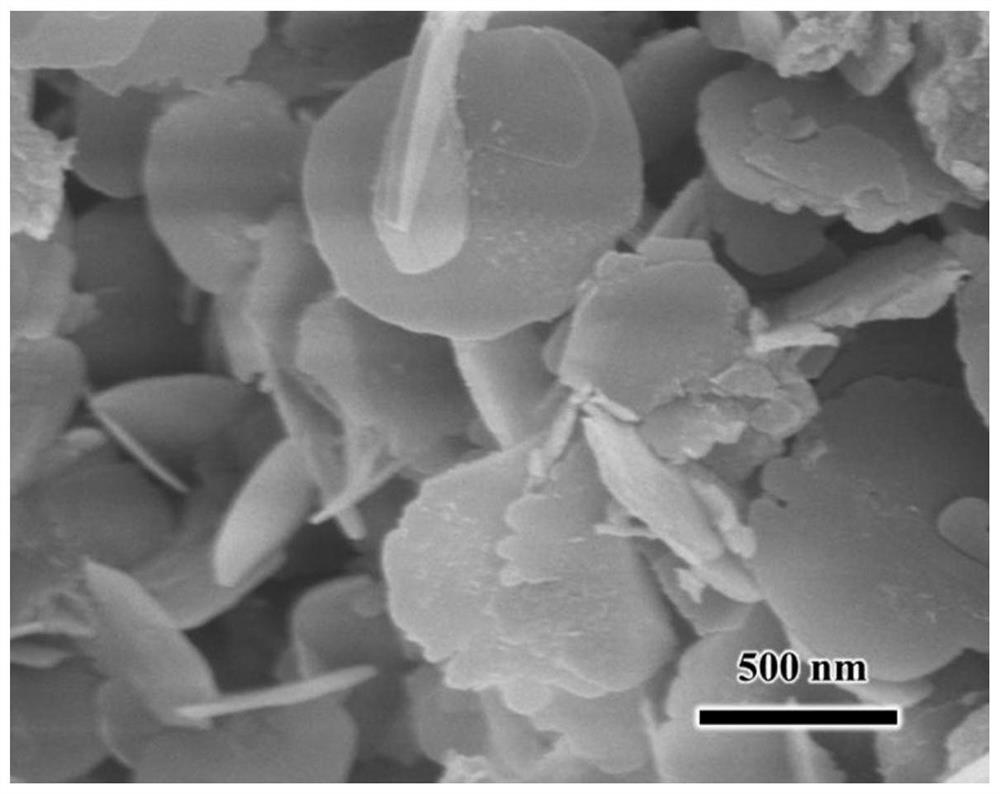

[0037] The XRD pattern of the Mg-Al-...

Embodiment 2

[0039] A preparation method of silicon-containing layered double metal hydroxide, comprising the following steps:

[0040] (1) Weigh 2.760g magnesium hydroxide, 1.240g aluminum hydroxide and 196g agate balls (ball-to-material ratio 49:1), add them to a 100mL ball mill jar, and ball mill them at 1500rpm for 4h to obtain a hydroxide mixture; 0.163 g of the obtained hydroxide mixture was stirred and dispersed in 30 mL of water to obtain a hydroxide mixture dispersion.

[0041] (2) Add 8.5 μL of SiCl to the hydroxide mixture dispersion obtained in step (1) 4 , fully stirred to obtain a suspension, transferred the obtained suspension to a glass bottle, and placed it in an oven at 80°C for 24 hours, then naturally cooled to room temperature, filtered, and washed the obtained precipitate with water for 3 times, at 60°C After drying for 24 hours, Mg-Al-Si LDHs powder is obtained, which is silicon-containing layered double metal hydroxide powder.

Embodiment 3

[0043] A preparation method of silicon-containing layered double metal hydroxide, comprising the following steps:

[0044] (1) Weigh 2.890g nickel hydroxide, 1.110g ferric hydroxide and 196g agate balls (ball-to-material ratio 49:1), add them to a 100mL ball mill jar, and ball mill them at 1500rpm for 4h to obtain a hydroxide mixture; 0.288 g of the obtained hydroxide mixture was stirred and dispersed in 30 mL of water to obtain a hydroxide mixture dispersion.

[0045] (2) Add 17 μL of SiCl to the hydroxide mixture dispersion obtained in step (1) 4 , fully stirred to obtain a suspension, transferred the obtained suspension to a glass bottle, and placed it in an oven at 80°C for 24 hours, then naturally cooled to room temperature, filtered, and washed the obtained precipitate with water for 3 times, at 60°C Dry for 24 hours to obtain Ni-Fe-Si LDHs powder, that is, silicon-containing layered double metal hydroxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com