A kind of preparation method of ti-al system gradient protective screen material

A protective screen, ti-al technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of ceramic panel fracture, insufficient protective performance, perforation, peeling, etc., to promote diffusion and increase sample contact area. , the effect of reducing the diffusion activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

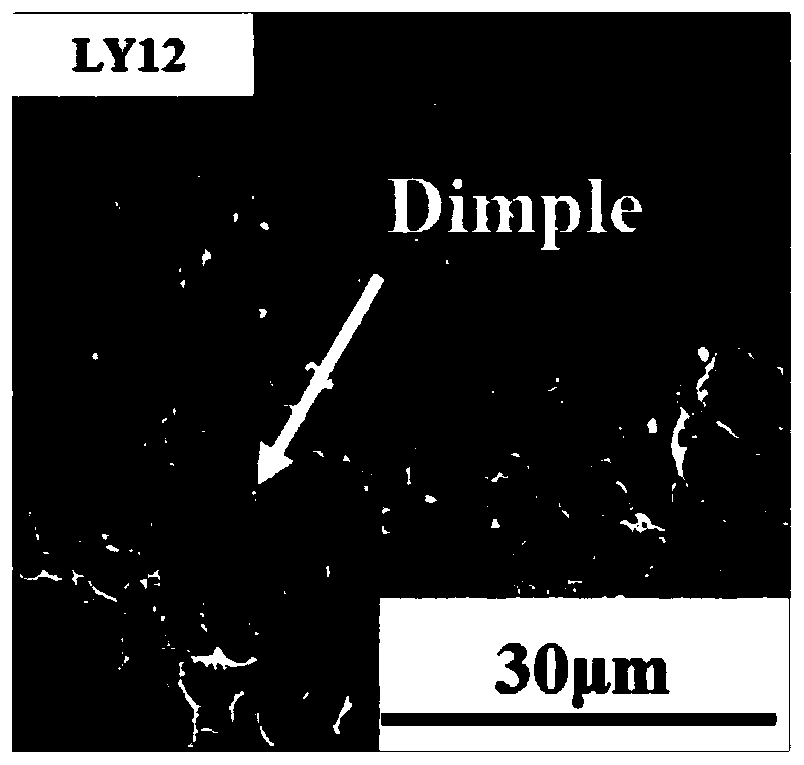

Embodiment 1

[0052] The titanium alloy sheet 4 and the aluminum alloy sheet 3 are diffusely connected, wherein: the titanium alloy sheet is Ф100*0.5mmTC4 titanium alloy sheet, the aluminum alloy sheet is Ф100*4.2mm1060 aluminum sheet, and the density after connection is 13.59g / ㎡. Ensure that the surface roughness of the sample before welding is: the roughness value Sa of Ti is 109.90 μm, the roughness value Sa of Al is 101.43 μm, and when the sample to be welded is placed, the scratch direction remains parallel. Diffusion bonding process conditions are: welding temperature 410 ℃, holding time 120min, welding pressure 20MPa. The LY12 aluminum shot with a diameter of Ф9.9mm is used for the dynamic loading test projectile of the second-level light gas gun, and the impact initial velocity is 3.08km / s.

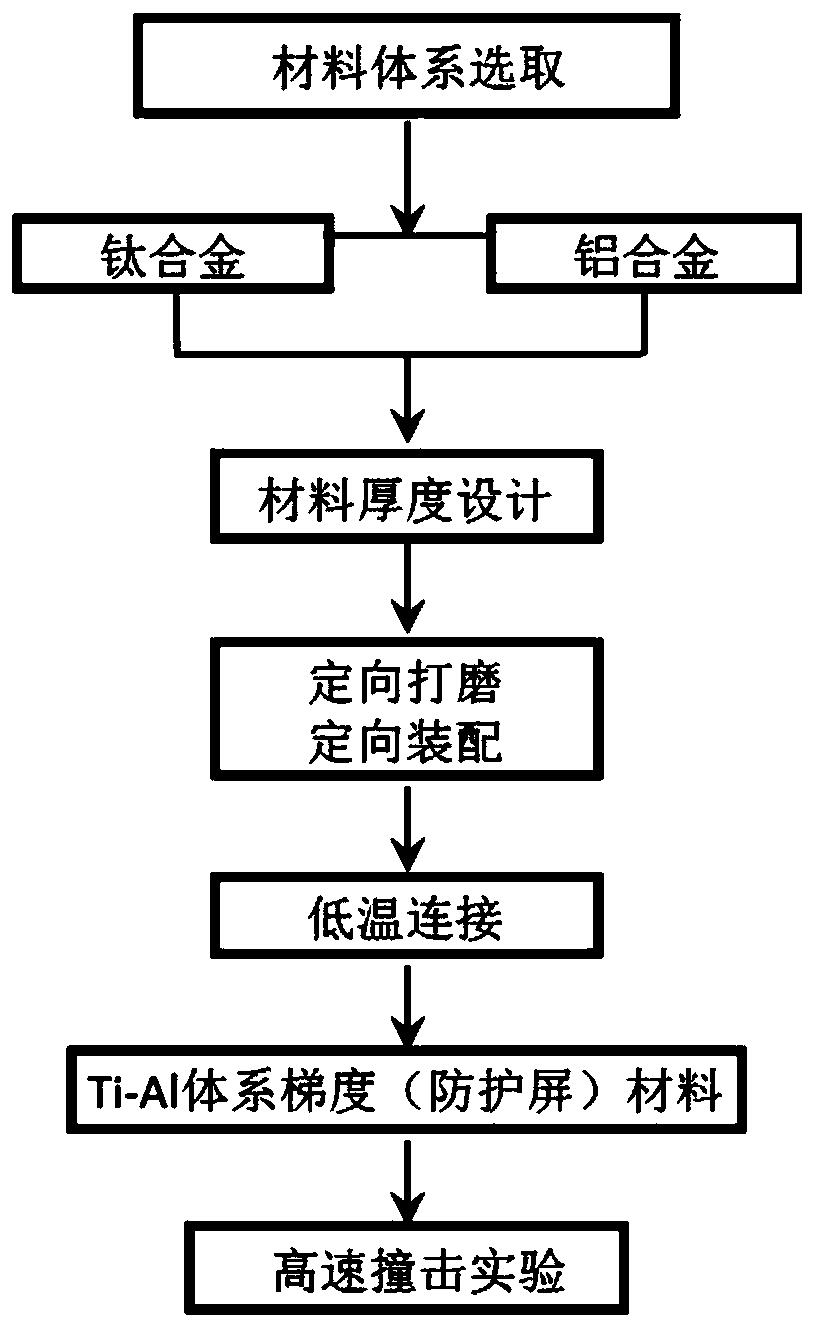

[0053] see figure 1 , the specific steps of preparing the Ti-Al system gradient protective screen material are as follows:

[0054] 1. Directional grinding:

[0055] The base metal titanium ...

Embodiment 2

[0068] The titanium alloy sheet and the aluminum alloy sheet are diffusely connected, wherein: the titanium alloy sheet is Ф100*0.5mmTC4 titanium alloy sheet, the aluminum alloy sheet is Ф100*4.2mm1060 aluminum sheet, and the density after connection is 13.59g / ㎡. Ensure that the surface roughness of the sample before welding is: the roughness value Sa of Ti is 101.90 μm, the roughness value Sa of Al is 111.43 μm, and when the sample to be welded is placed, the scratch direction is kept parallel. Diffusion bonding process conditions are: welding temperature 410 ℃, holding time 120min, welding pressure 20MPa. The LY12 aluminum shot with a diameter of Ф9.9mm is used for the dynamic loading test projectile of the second-level light gas gun, and the impact initial velocity is 3.08km / s.

[0069] see figure 1 , the specific steps of preparing the Ti-Al system gradient protective screen material are as follows:

[0070] 1. Directional grinding:

[0071] The base metal titanium allo...

Embodiment 3

[0081] The titanium alloy sheet and the aluminum alloy sheet are diffusely connected, wherein: the titanium alloy sheet is Ф100*0.5mmTC4 titanium alloy sheet, the aluminum alloy sheet is Ф100*4.2mm1060 aluminum sheet, and the density after connection is 13.59g / ㎡. Ensure that the surface roughness of the sample before welding is: the roughness value Sa of Ti is 69.12 μm, the roughness value Sa of Al is 67.91 μm, and when the sample to be welded is placed, the scratch direction is kept parallel. Diffusion bonding process conditions are: welding temperature 410 ℃, holding time 120min, welding pressure 20MPa.

[0082] The specific steps for preparing the Ti-Al system gradient protective screen material are as follows:

[0083] 1. Directional grinding:

[0084] The base material used was cut into the required size by wire cutting, and ultrasonically cleaned with acetone solution for 10 min. Use a surface grinder to process titanium alloy sheets and aluminum alloy sheets into shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com