Lithium ion solid electrolyte and preparation method and application thereof

A solid electrolyte, lithium-ion battery technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of unstable electrochemical properties, hinder the practical application of all-solid-state batteries, etc., and achieve good electrochemical compatibility and excellent thermodynamic stability. The effect of high conductivity and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

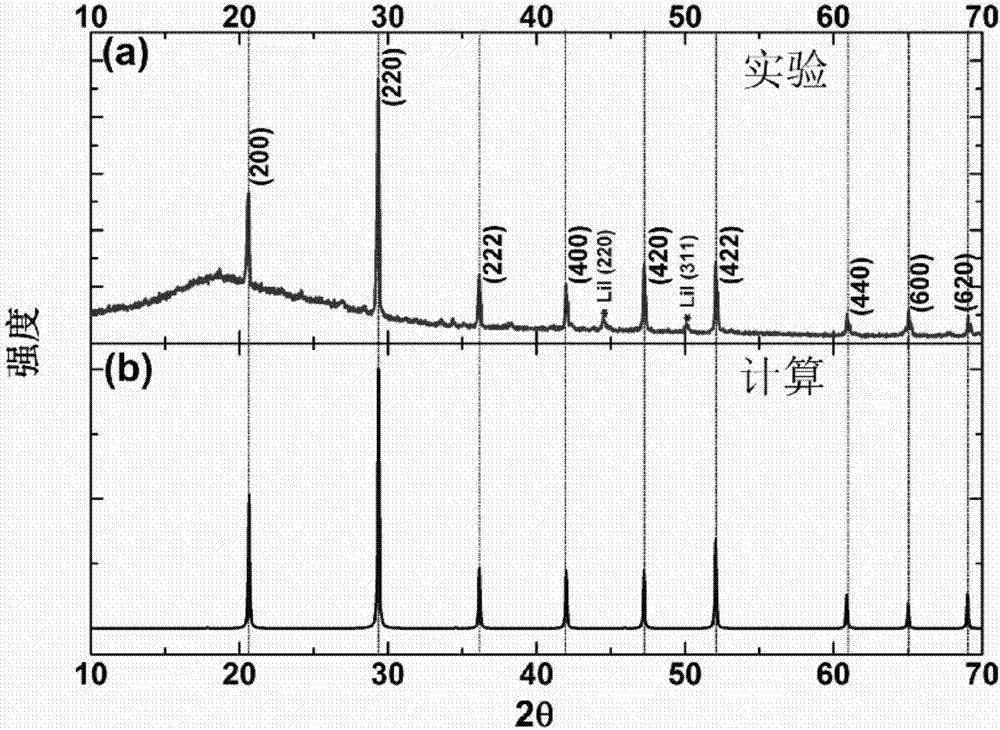

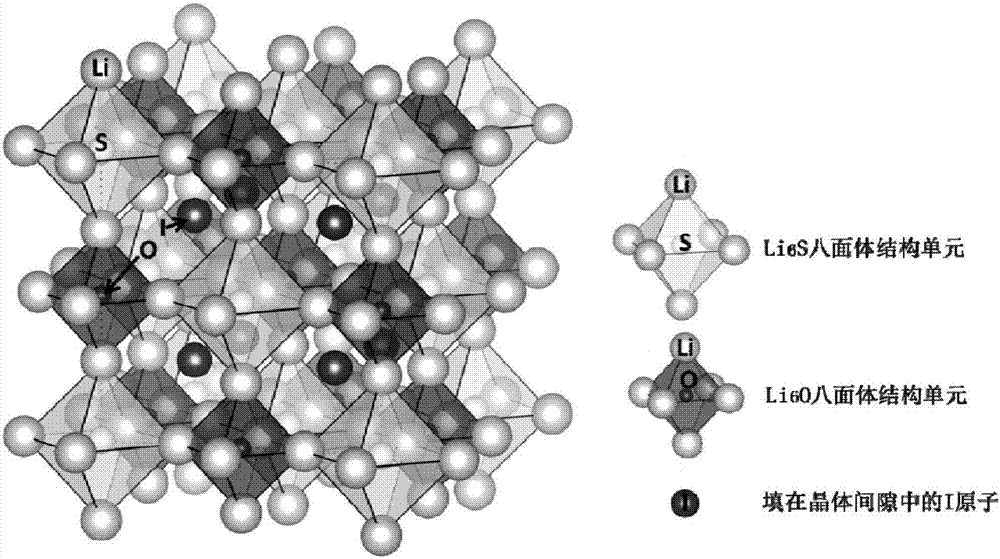

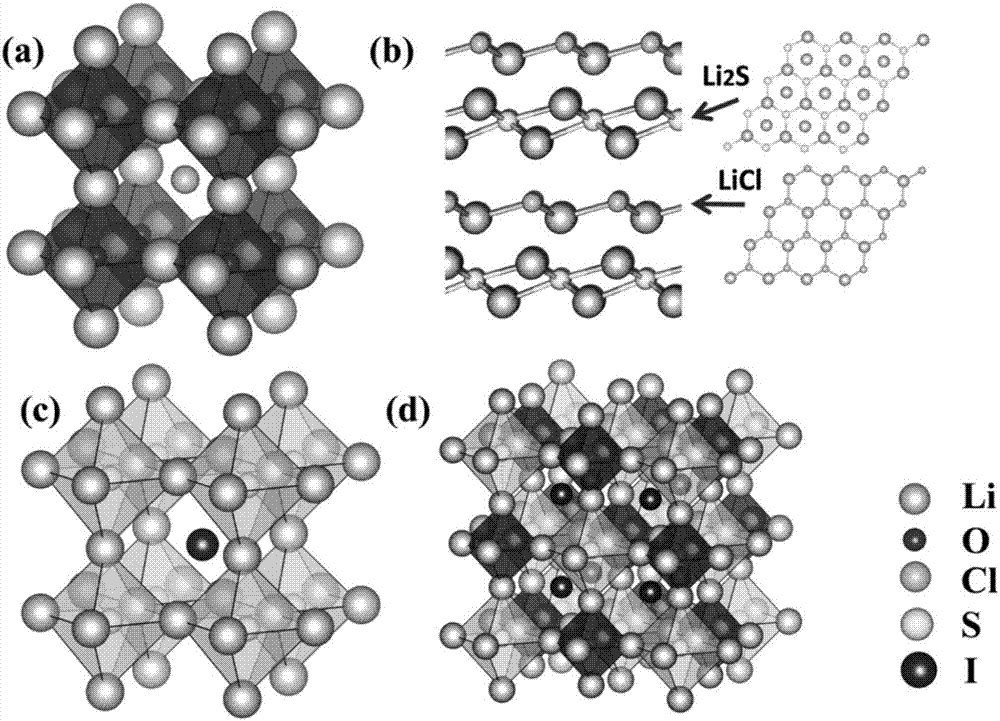

[0050] The lithium-ion solid electrolyte of the present embodiment has a chemical composition of Li 3 OCl, the structure is as image 3 (a) shown.

[0051] The preparation method of the lithium ion solid electrolyte of the present embodiment comprises the following steps:

[0052] 1) Lithium oxide (Li 2 O) and lithium chloride (LiCl) powders were dried in a vacuum oven for 24 hours, and then in a glove box, under the protection of an argon atmosphere, lithium oxide and lithium chloride were uniformly mixed, put into a ball mill jar, and several A zirconia ball milling ball with a diameter of 10mm is sealed in a ball milling jar. Take the sealed ball mill jar out of the glove box, put it into a full-range planetary ball mill for ball milling, set the speed of the ball mill to 280rpm, and keep the ball mill for 20 minutes for each ball mill, and let it stand for cooling for 5 minutes; the total time of ball milling is 3 hours, and the precursor body;

[0053] 2) Under the p...

Embodiment 2

[0056] The lithium-ion solid electrolyte of the present embodiment has a chemical composition of Li 3 o 1.25 Cl 0.5 .

[0057] The preparation method of the lithium ion solid electrolyte of the present embodiment comprises the following steps:

[0058] 1) Lithium oxide (Li 2 O) and lithium chloride (LiCl) powders were dried in a vacuum oven for 24 hours, and then in a glove box, under the protection of an argon atmosphere, lithium oxide and lithium chloride were uniformly mixed, put into a ball mill jar, and several A zirconia ball milling ball with a diameter of 10mm is sealed in a ball milling jar. Take the sealed ball mill tank out of the glove box, put it into a full-range planetary ball mill for ball milling, set the speed of the ball mill to 250rpm, and keep the ball mill for 20 minutes for each ball mill, and let it stand for cooling for 5 minutes; the total time of ball milling is 10 hours, and the precursor body;

[0059]2) Under the protection of argon atmosphe...

Embodiment 3

[0062] The lithium-ion solid electrolyte of the present embodiment has a chemical composition of Li 3.125 o 1.125 Cl 0.875 .

[0063] The preparation method of the lithium ion solid electrolyte of the present embodiment comprises the following steps:

[0064] 1) Lithium oxide (Li 2 O) and lithium chloride (LiCl) powders were dried in a vacuum oven for 24 hours, and then in a glove box, under the protection of an argon atmosphere, lithium oxide and lithium chloride were uniformly mixed, put into a ball mill jar, and several A zirconia ball milling ball with a diameter of 10mm is sealed in a ball milling jar. Take the sealed ball mill tank out of the glove box, put it into the omnidirectional planetary ball mill for ball milling, set the speed of the ball mill to 350rpm, and keep the ball mill for 20 minutes for each ball mill, and let it stand for cooling for 5 minutes; the total time of ball milling is 10h, and the precursor body;

[0065] 2) Under the protection of an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com