Positive electrode active material and preparation method thereof, positive electrode and lithium ion secondary battery

A technology of positive active material and modified material, applied in secondary batteries, active material electrodes, positive electrodes, etc., can solve problems such as easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

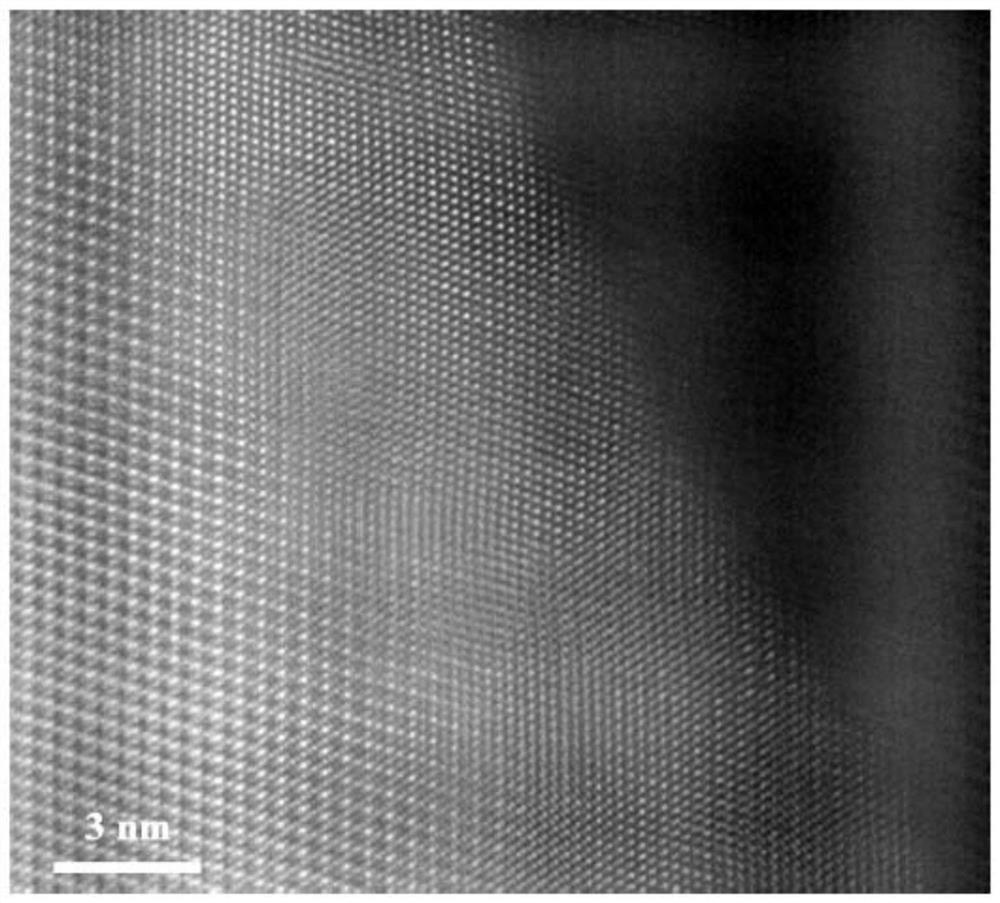

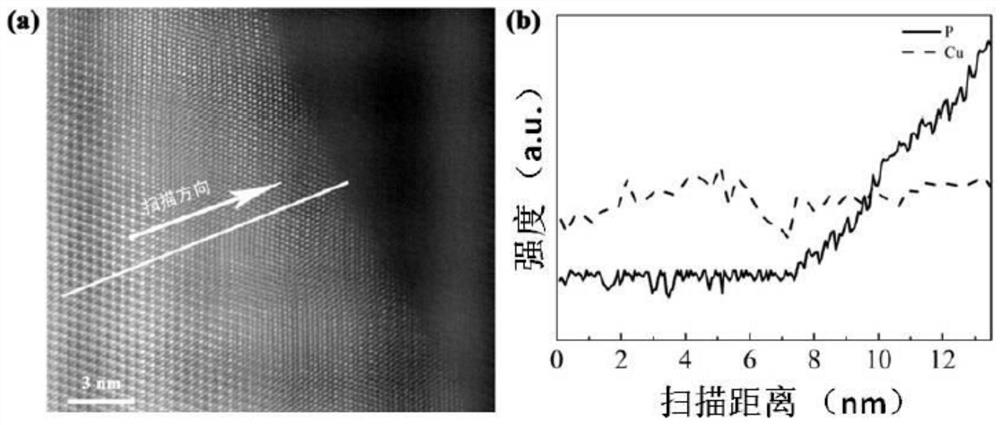

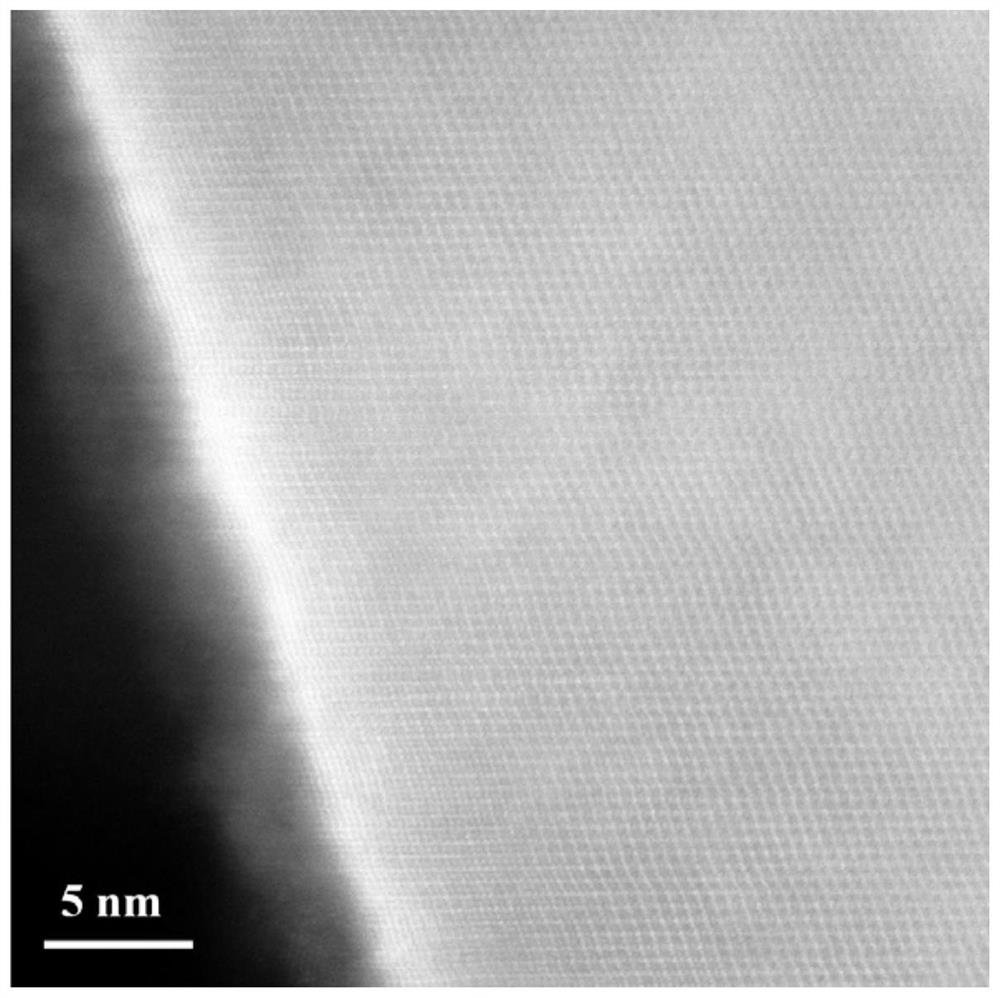

Image

Examples

preparation example Construction

[0065] Embodiments of the present invention also provide a method for preparing the positive electrode active material, comprising the following steps:

[0066] a. Provide the lithium nickel manganese oxide modified material;

[0067] b. Mixing the lithium nickel manganese oxide modified material with the organic compound to obtain a coating mixture;

[0068] or mixing the lithium nickel manganese oxide modified material with the precursor of the organic compound, and heating to obtain a coating mixture; and

[0069] c. The coating mixture is heated and reacted at 120° C. to 400° C. for 2 hours to 20 hours.

[0070] In some embodiments, the step of providing the lithium nickel manganese oxide modified material includes:

[0071] a1. Mixing a phosphorus source, a rock-salt-like phase inducer and a lithium nickel manganese oxide spinel structure material to obtain a doping mixture; and

[0072] a2. Sintering the doped mixture at 600° C. to 1200° C. for 0.5 hours to 20 hours. ...

Embodiment 1

[0109] 18g of LiNi 0.5 mn 1.5 o 4 Material (Shandong Qixing Energy Materials Co., Ltd.), 0.54g CuO and 0.267g (NH 4 ) 2 HPO 4 Mix evenly, and calcinate the obtained mixture in oxygen at 600°C for 5 hours, with a heating rate of 3°C / min and a cooling rate of 5°C / min, to obtain a phosphorus-doped lithium nickel manganese oxide modified material.

[0110] Weigh pyrophthalic anhydride and 4,4'-diaminodiphenyl ether at a molar ratio of 1:1, use dimethylacetamide as a solvent to synthesize a 10% polyamic acid solution, and then prepare 1% Polyamic acid solution, take 8mL polyamic acid solution, stir for 1h in an argon atmosphere, add 10g of lithium nickel manganese oxide modified material obtained in the above steps, heat and stir, keep at 60°C for 30 minutes, and keep at 120°C 30 minutes, 60 minutes at 200°C, 60 minutes at 300°C, and 10 minutes at 400°C for imidization to yield surface-gradient P-doped, post-coated polyimide nickel manganese Lithium Oxide positive electrode a...

Embodiment 2

[0115] 18g of LiNi 0.4 mn 1.6 o 4 Material (Shandong Qixing Energy Materials Co., Ltd.), 0.54gH 3 PO 4 Uniformly mixed with 1g of oxalic acid and calcined the resulting mixture in the air at 600°C for 5h, with a heating rate of 3°C / min and a cooling rate of 5°C / min, to obtain a phosphorus-doped lithium nickel manganese oxide modified material.

[0116] Using N-methylpyrrolidone as a solvent, prepare a polyamic acid solution with a mass concentration of 4%, and then prepare a 1% polyamic acid solution, take 8mL of the polyamic acid solution, stir for 1h in an argon atmosphere, and then add 10g of the above steps to obtain The lithium nickel manganese oxide modified material was heated and stirred, kept at 55°C for 30 minutes, at 125°C for 30 minutes, at 205°C for 60 minutes, at 305°C for 60 minutes and at 390°C 10 minutes, to realize imidization, and obtain a lithium nickel manganese oxide cathode active material with surface gradient P doping and post-coating with polyimid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com