A kind of high-nickel material whose surface is coated with lithium aluminum silicate and whose surface is doped with fluorine, and its preparation method

A lithium aluminum silicate and surface coating technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of not taking into account the lithium ion and electronic conductivity characteristics of the coating layer, and restricting the electrochemical performance of high-nickel ternary materials. , the decrease of electronic conductivity of materials, etc., to achieve the effect of low cost, simple preparation process and industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

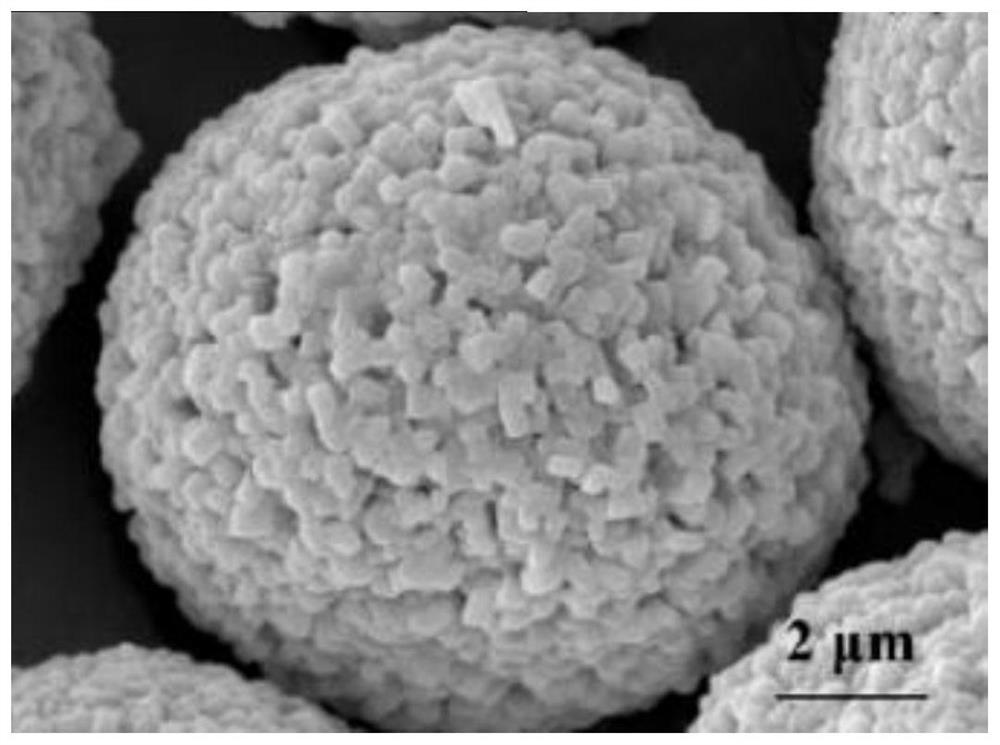

[0048] The preparation method of the high nickel material coated with lithium aluminum silicate on the surface and doped with fluorine on the surface of the present embodiment is carried out according to the following steps:

[0049] (1) take by weighing an appropriate amount of aluminum n-butoxide and ethyl silicate and dissolve in ethanol according to an equimolar ratio, add ethanolamine with an equimolar amount of aluminum n-butoxide as a dispersant, obtain a clear and transparent solution after fully stirring, in Dilute the volume to 0.1 mol / L with deionized water in the volumetric flask; weigh a certain mass of 811-type nickel-cobalt-manganese ternary cathode material precursor according to the mass ratio of 1% lithium aluminum silicate coating, and stir at room temperature well mixed to obtain a mixture;

[0050] (2) drying the mixture obtained in step (1) under vacuum conditions, after pre-firing the dried material at 600° C. for 6 hours in an air atmosphere, sieve to o...

Embodiment 2

[0059] The preparation method of the high nickel material coated with lithium aluminum silicate on the surface and doped with fluorine on the surface of the present embodiment is carried out according to the following steps:

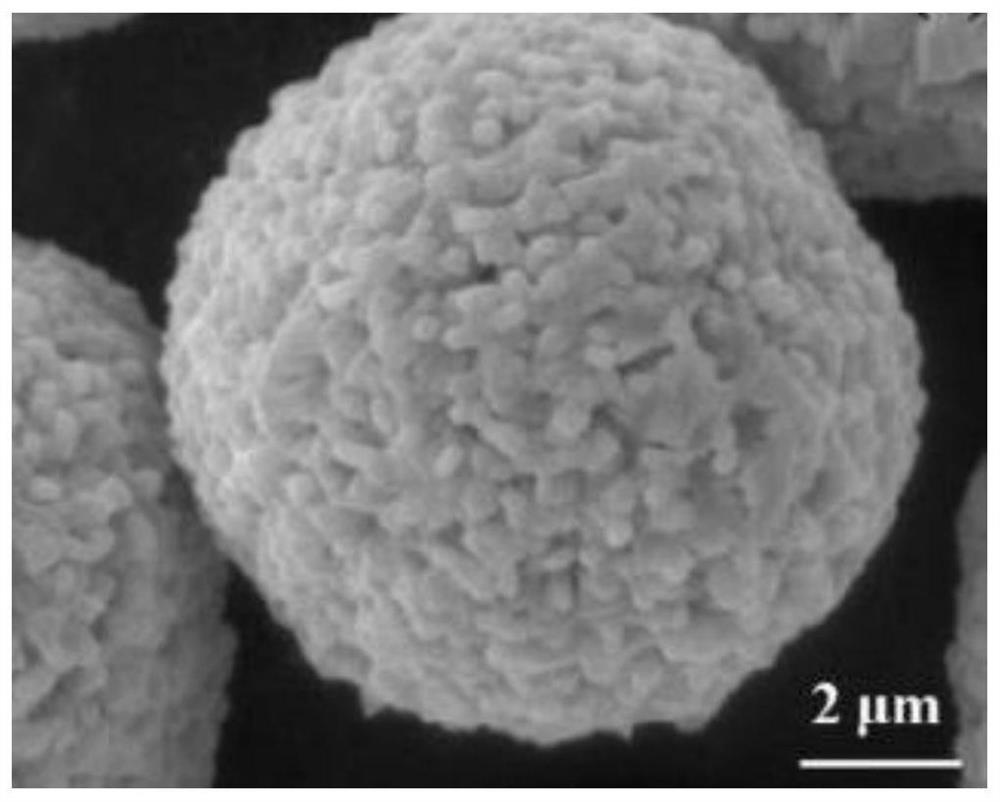

[0060] (1) Weigh a certain mass of 811-type nickel-cobalt-manganese ternary positive electrode material precursor, add equimolar ratio of aluminum oxide and silicon dioxide according to the 1% mass ratio of lithium aluminum silicate coating, and at room temperature Stir and mix thoroughly to obtain a mixture;

[0061] (2) after the obtained mixture is pre-fired at 600 DEG C for 6h under air atmosphere, sieve to obtain undersize;

[0062] (3) The obtained undersize is mixed with lithium hydroxide in a molar ratio of 1:1.1, and sintered at 750° C. for 30 hours in a pure oxygen atmosphere to obtain a high-nickel ternary material coated with lithium aluminum silicate;

[0063] (4) The high nickel ternary material coated with lithium aluminum silicate is uni...

Embodiment 3

[0066] The preparation method of the high nickel material coated with lithium aluminum silicate on the surface and doped with fluorine on the surface of the present embodiment is carried out according to the following steps:

[0067] (1) take by weighing an appropriate amount of aluminum sec-butoxide and ethyl silicate and dissolve in ethanol according to an equimolar ratio, add ethanolamine with an equimolar amount of aluminum sec-butoxide as a dispersant, obtain a clear and transparent solution after fully stirring, in Dilute the volume to 0.1 mol / L with deionized water in the volumetric flask; weigh a certain mass of nickel-cobalt-aluminum (LiNi 0.8 Co 0.15 Al 0.05 O 2 ) material precursor, stir and mix well at room temperature to obtain a mixture;

[0068] (2) drying the mixture obtained in step (1) under vacuum conditions, after pre-firing the dried material at 600° C. for 6 hours in an air atmosphere, sieve to obtain undersize;

[0069] (3) The obtained undersize is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com