Preparation method for rare-earth metal-molybdenum binary diffusion coating on surface of kovar alloy

A technology of rare earth metal and permeation coating, which is applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problems of thin permeation coating, poor comprehensive performance of Kovar alloy, low binary permeation rate, etc. Achieve the effect of low cost, low diffusion activation energy, and remarkable comprehensive effect of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method of the present embodiment comprises the following steps:

[0026] Step 1. Pretreatment of the Kovar alloy substrate: it is necessary to thoroughly remove the oil stains, residues and oxide film on the surface of the substrate to obtain a clean active surface. Place the Kovar alloy substrate in alcohol and ultrasonically clean it for 15 minutes to remove surface grease; use a sandblasting machine to treat the surface of the Kovar alloy substrate, choose 46# brown corundum for sandblasting roughening treatment, and the sandblasting pressure is 0.4MPa; After taking it out, wash it with deionized water and alcohol, and dry it to obtain a Kovar alloy matrix.

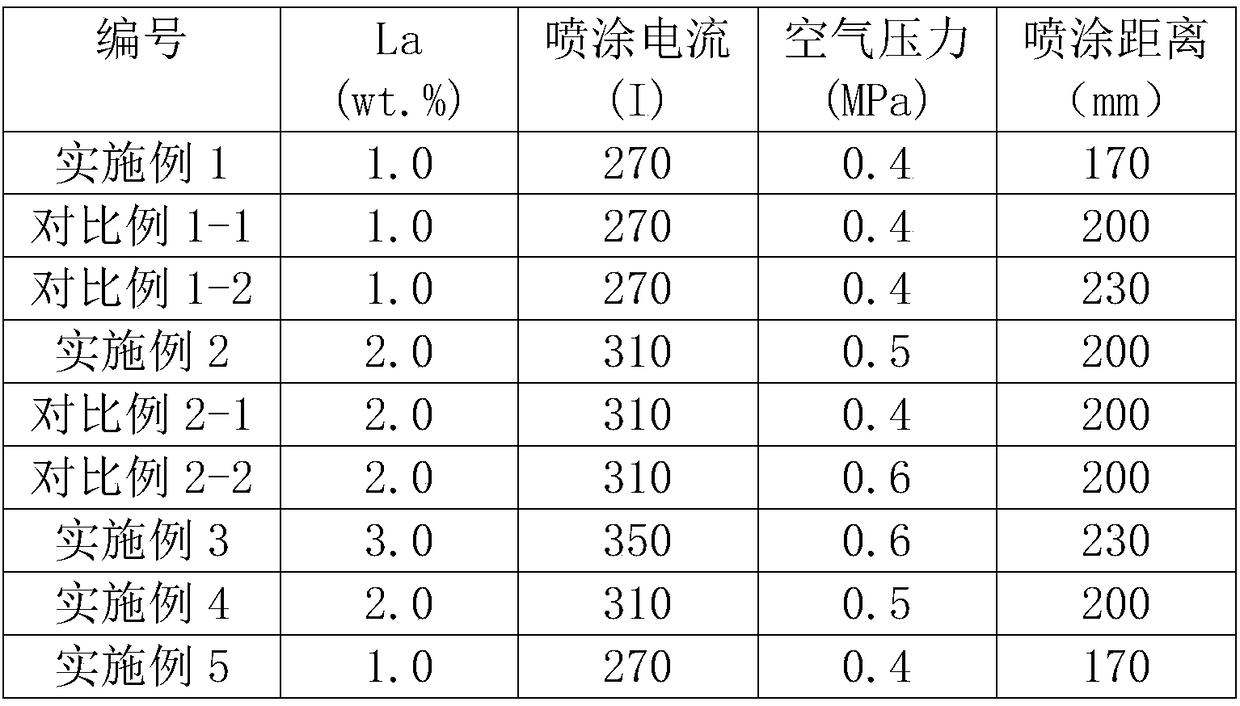

[0027] Step 2, preparing the rare earth metal-molybdenum binary coating: the rare earth metal is used as the infiltration activator in the coating system, and lanthanum (La), cerium (Ce), neodymium (Nd) or samarium (Sm) are selected respectively. In view of the space, they will not be given one by one. Tak...

Embodiment 2

[0035] The method of the present embodiment comprises the following steps:

[0036] Step 1. It is necessary to thoroughly remove the oil, residue and oxide film on the surface of the substrate to obtain a clean active surface. Place the Kovar alloy substrate in alcohol and ultrasonically clean it for 15 minutes to remove surface grease; use a sandblasting machine to treat the surface of the Kovar alloy substrate, choose 46# brown corundum for sandblasting roughening treatment, and the sandblasting pressure is 0.4MPa; After taking it out, wash it with deionized water and alcohol, and dry it to obtain a Kovar alloy matrix.

[0037]Step 2, preparing the rare earth metal-molybdenum binary coating: the rare earth metal is used as the infiltration activator in the coating system, and lanthanum (La), cerium (Ce), neodymium (Nd) or samarium (Sm) are selected respectively. The present invention takes the rare earth La as an example to investigate the influence of different contents of...

Embodiment 3

[0045] The method of the present embodiment comprises the following steps:

[0046] Step 1. It is necessary to thoroughly remove the oil, residue and oxide film on the surface of the substrate to obtain a clean active surface. Place the Kovar alloy substrate in alcohol and ultrasonically clean it for 15 minutes to remove surface grease; use a sandblasting machine to treat the surface of the Kovar alloy substrate, choose 46# brown corundum for sandblasting roughening treatment, and the sandblasting pressure is 0.4MPa; After taking it out, wash it with deionized water and alcohol, and dry it to obtain a Kovar alloy matrix.

[0047] Step 2, preparing the rare earth metal-molybdenum binary coating: the rare earth metal is used as the infiltration activator in the coating system, and lanthanum (La), cerium (Ce), neodymium (Nd) or samarium (Sm) are selected respectively. The present invention takes the rare earth La as an example to investigate the influence of different contents o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com