Method for carrying out anatonosis by adopting laser plasma impact wave in chemical heat treatment process

A laser plasma and chemical heat treatment technology, which is applied in the field of surface engineering technology and laser processing, can solve the problems of high energy consumption, long diffusion time, and high diffusion temperature, so as to increase diffusion channels, improve diffusion efficiency, and reduce diffusion activation energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0017] The laser parameter requirements of the embodiment of the present invention are: the laser wavelength is 1064 / 532nm, the pulse width is on the order of nanoseconds, and the laser power density is 3-8GW / cm 2 , The spot overlap rate is 50-75%, and the size and shape of the spot are selected according to the structural characteristics of the workpiece. The chemical heat treatment process can be aluminizing, carburizing, nitriding or aluminizing chromium, etc.

[0018] The technical solution step that the present invention adopts is:

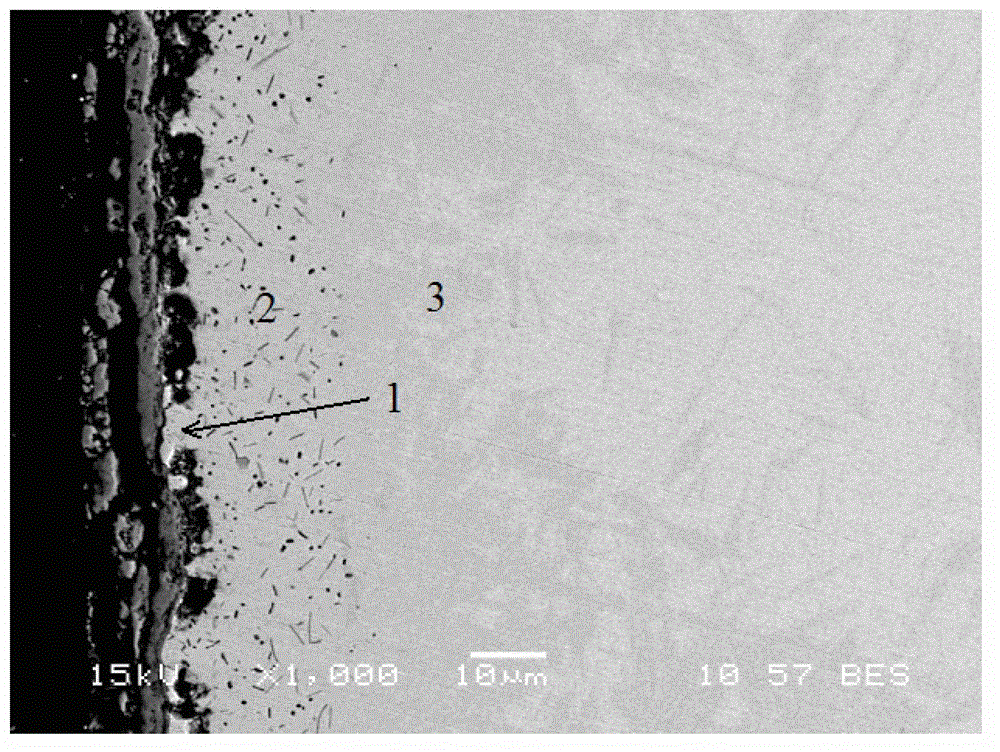

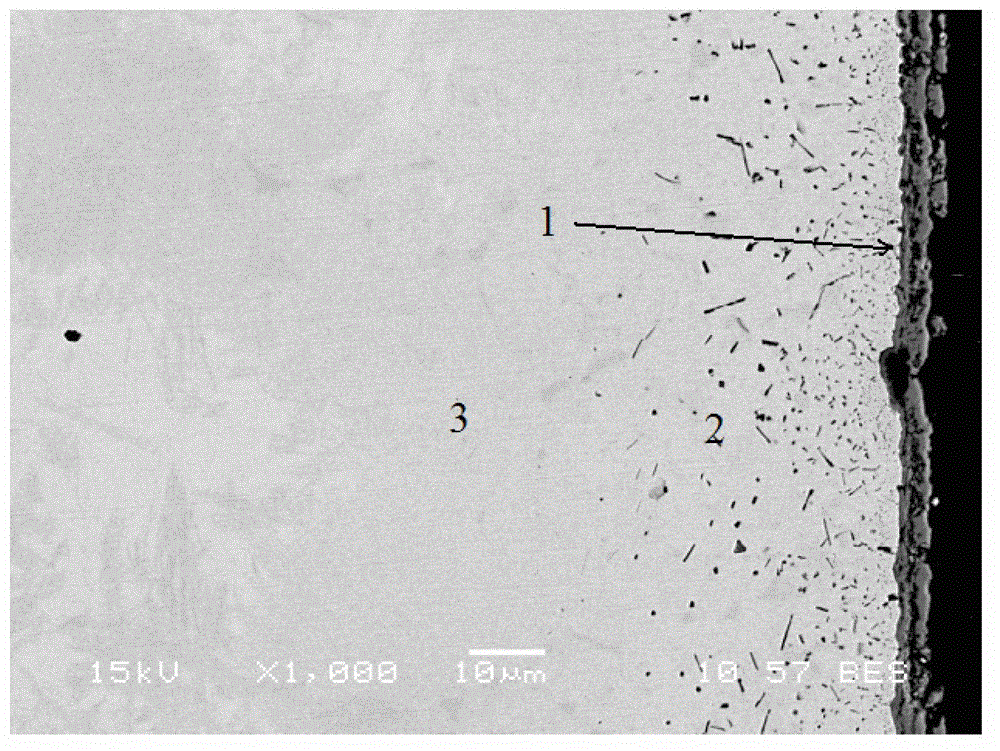

[0019] (a) Clamp the specimen to the motion system, using a high power density of 3-8GW / cm 2 , ns-level short-pulse laser is irradiated on the absorbing protective layer, the coating absorbs the laser energy, and induces plasma shock waves to act on the surface of the workpiece; the plasma shock waves act on the area to be tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com