A processing method for improving aluminum die casting and precision forging dies

A processing method, aluminum die-casting technology, applied in the direction of metal processing equipment, metal material coating technology, solid diffusion coating, etc., can solve the problem of reducing the use efficiency, increasing the cost of mold use, and not being able to effectively improve the life of the mold and the demoulding effect, etc. problem, to achieve the effect of smooth element distribution gradient, increased fluidity, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

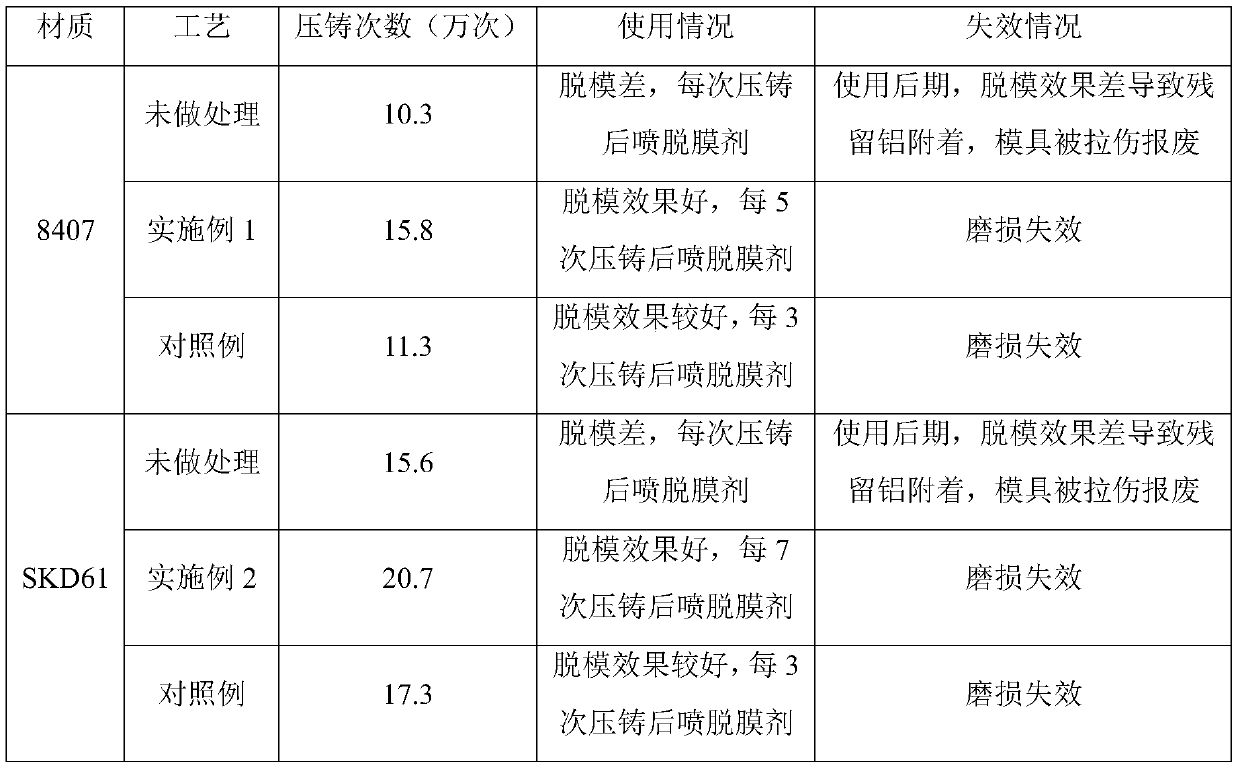

Embodiment 1

[0032] A kind of processing method that improves die-casting mold (material is the aluminum die-casting mold of Sweden ASSAB 8407 steel) performance, comprises the following steps:

[0033] (1) Soaking: remove the residual aluminum attached to the surface of the mold during the pressure test, the temperature is ≥30°C, and the time is 80 minutes;

[0034] (2) Preheating: Put the mold into the air heating tank, heat up to 345±5°C at a speed of 10°C / min, keep it warm for 15 minutes, then raise the temperature to 425±5°C at a speed of 10°C / min, and keep it warm for 20 minutes ;

[0035] (3) Lanthanum yttrium carbonitride ion infiltration: put the preheated mold into the lanthanum yttrium carbonitride ion infiltration tank, use the lanthanum yttrium carbonitride ion infiltration agent to infiltrate the lanthanum yttrium carbonitride ion, the temperature is 445±5℃ , the time is 100 minutes;

[0036] (4) lanthanum yttrium ion activation: put the mold infiltrated with carbon nitroge...

Embodiment 2

[0046] A processing method for improving the performance of a die-casting die (material is an aluminum die-casting die of SKD61), comprising the following steps:

[0047] (1) Soaking: remove the residual aluminum attached to the surface of the mold during the pressure test, the temperature is ≥30°C, and the time is 80 minutes;

[0048] (2) Preheating: Put the mold into the air heating tank, heat up to 345±5°C at a speed of 15°C / min, keep it warm for 10 minutes, then raise the temperature to 400±5°C at a speed of 10°C / min, and keep it warm for 30 minutes ;

[0049] (3) Lanthanum yttrium carbonitride ion infiltration: put the preheated mold into the lanthanum yttrium carbonitride ion infiltration tank, use the lanthanum yttrium carbonitride ion infiltration agent to infiltrate the lanthanum yttrium carbonitride ion, the temperature is 450±5℃ , the time is 150 minutes;

[0050] (4) Lanthanum yttrium ion activation: put the mold infiltrated with lanthanum yttrium ions into the i...

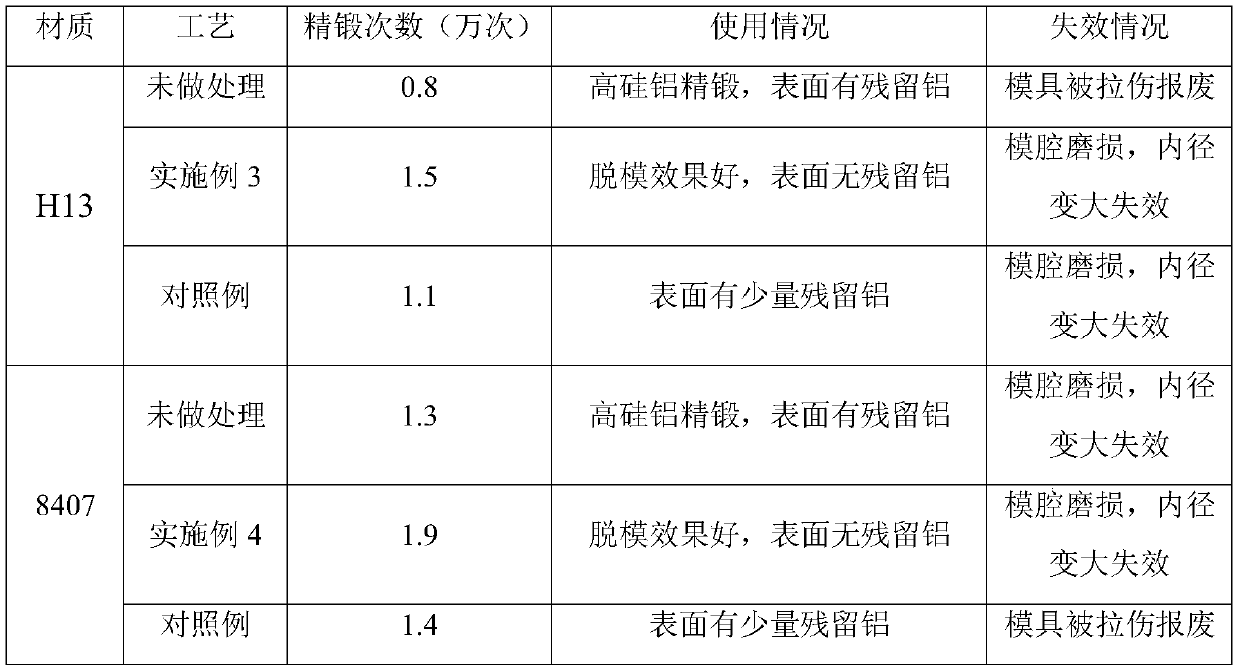

Embodiment 3

[0060] A processing method for improving the performance of a precision forging die (material is a precision forging die of H13), comprising the following steps:

[0061] (1) Soaking: remove the residual aluminum attached to the surface of the mold during the pressure test, the temperature is ≥30°C, and the time is 60 minutes;

[0062] (2) Preheating: Put the mold into the air heating tank, raise the temperature to 300±5°C at a rate of 10°C / min and keep it warm for 10 minutes, then raise the temperature to 395±5°C at a rate of 5°C / min and keep it warm for 30 minutes;

[0063] (3) Infiltration of lanthanum yttrium carbonitride ions: put the preheated mold into the lanthanum yttrium carbonitride ion infiltration tank, use lanthanum carbonitride yttrium ion infiltration agent to infiltrate lanthanum yttrium carbonitride ions, the temperature is 455±5℃ , the time is 200 minutes;

[0064](4) lanthanum yttrium ion activation: put the mold infiltrated with lanthanum yttrium carbon n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com