Patents

Literature

31results about How to "Grain boundary refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel high-strength corrosion-resistant rare earth aluminum alloy material and preparation method

The invention provides a novel high-strength corrosion-resistant rare earth aluminum alloy material and a preparation method. Based on a high-strength Al-Zn-Mg alloy, a proper amount of elements of Cu, rare earth Ce, rare earth Sc and rare earth Er are added, and the novel Al-Zn-Mg-Cu-Ce-Sc-Er aluminum alloy material is prepared. The material has the beneficial effects of being high in strength, good in plasticity and toughness, resistant to corrosion, good in fatigue resistance and the like. The material is a structural material which can be widely applied to aviation, spaceflight, ships and warships and means of conveyance. The production and preparation method of the material is simple and easy to practice, the processing technology of the material is easy to control, raw materials are sufficient and easy to obtain, the production cost is low, and the material has very wide production and application prospects.

Owner:HEFEI UNIV OF TECH

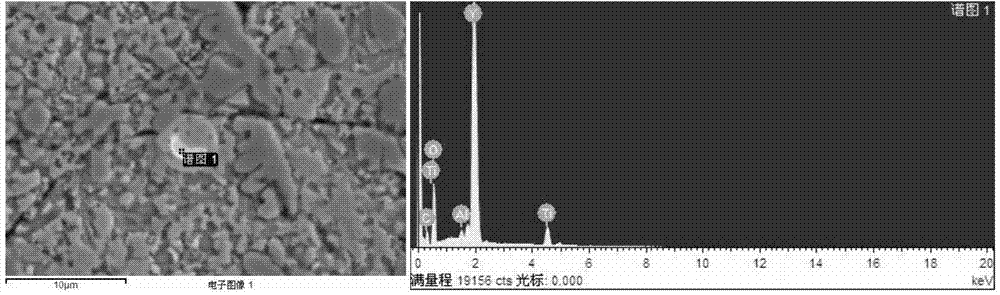

Titanium alloy laser cladding surface reinforcing method

ActiveCN103668186AImprove surface qualityImprove organizationMetallic material coating processesHardnessWear resistance

The invention relates to a titanium alloy laser cladding surface reinforcing method which comprises the following steps: mixing the following components by weight: 50-100% of Co42 cobalt-based self-fluxing alloy powder, 0-50% of B4C0, 0-50% of SiC, 0-39% of TiN, 0-1.5% of Y2O and 0-1.5% of CeO2, uniformly blending the mixture powder into paste by using a sodium silicate solution, uniformly coating the paste mixture powder on the surface of a titanium alloy, keeping the coating uniform in thickness, drying in air naturally, and performing laser cladding on the coating on the surface of the titanium alloy. By the adoption of the method provided by the invention, the microstructure of a cladding layer can be improved, and the hardness and the wear-resistance of the cladding layer can be further improved.

Owner:SHANDONG UNIV

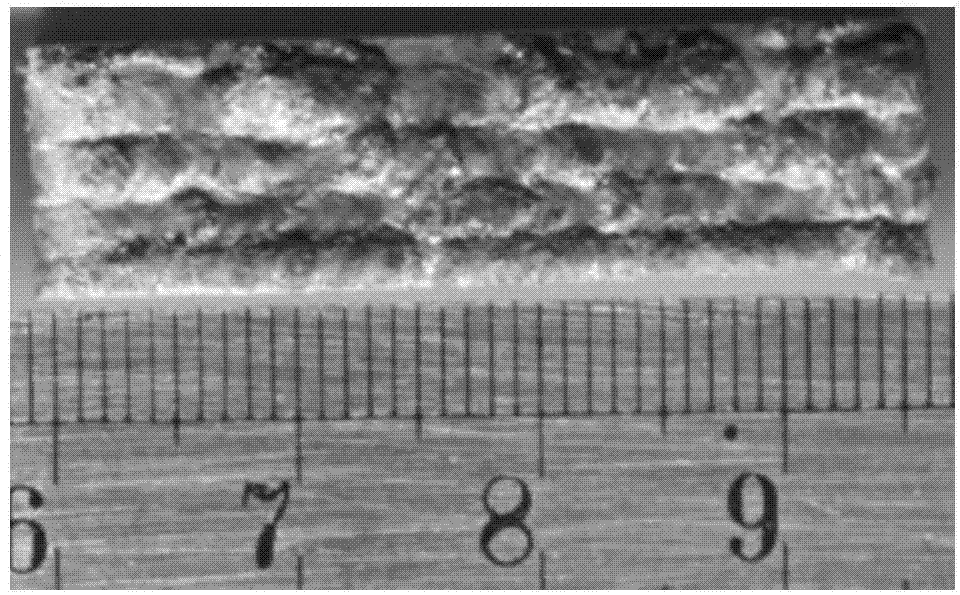

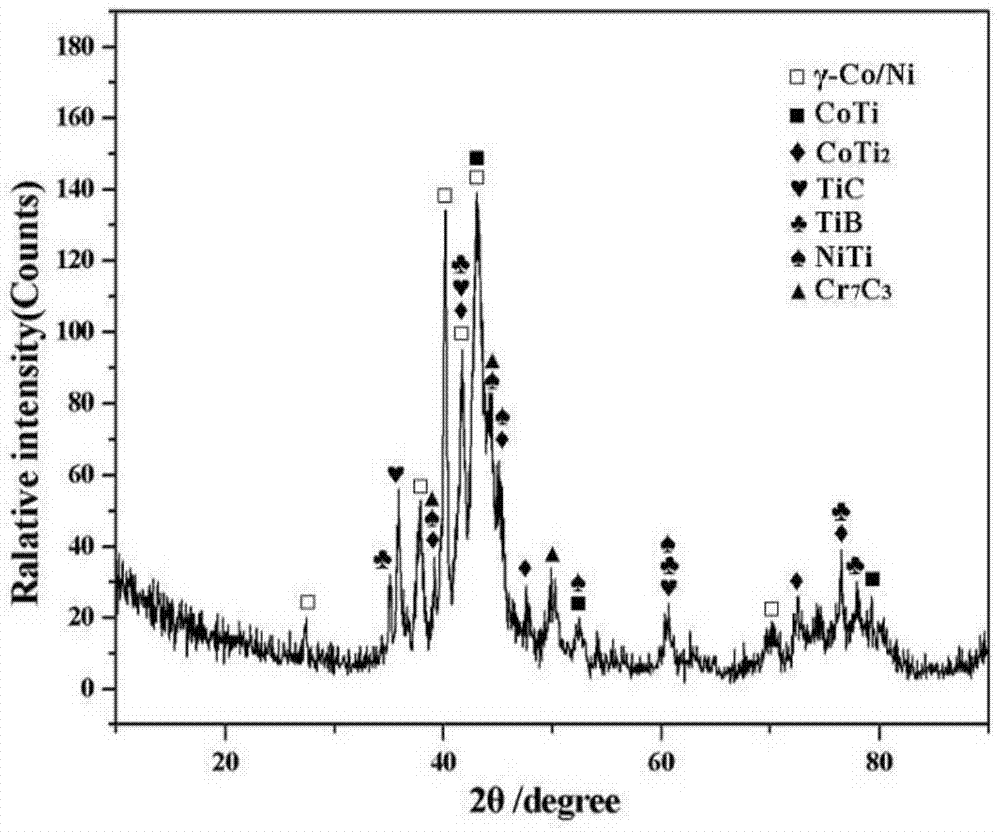

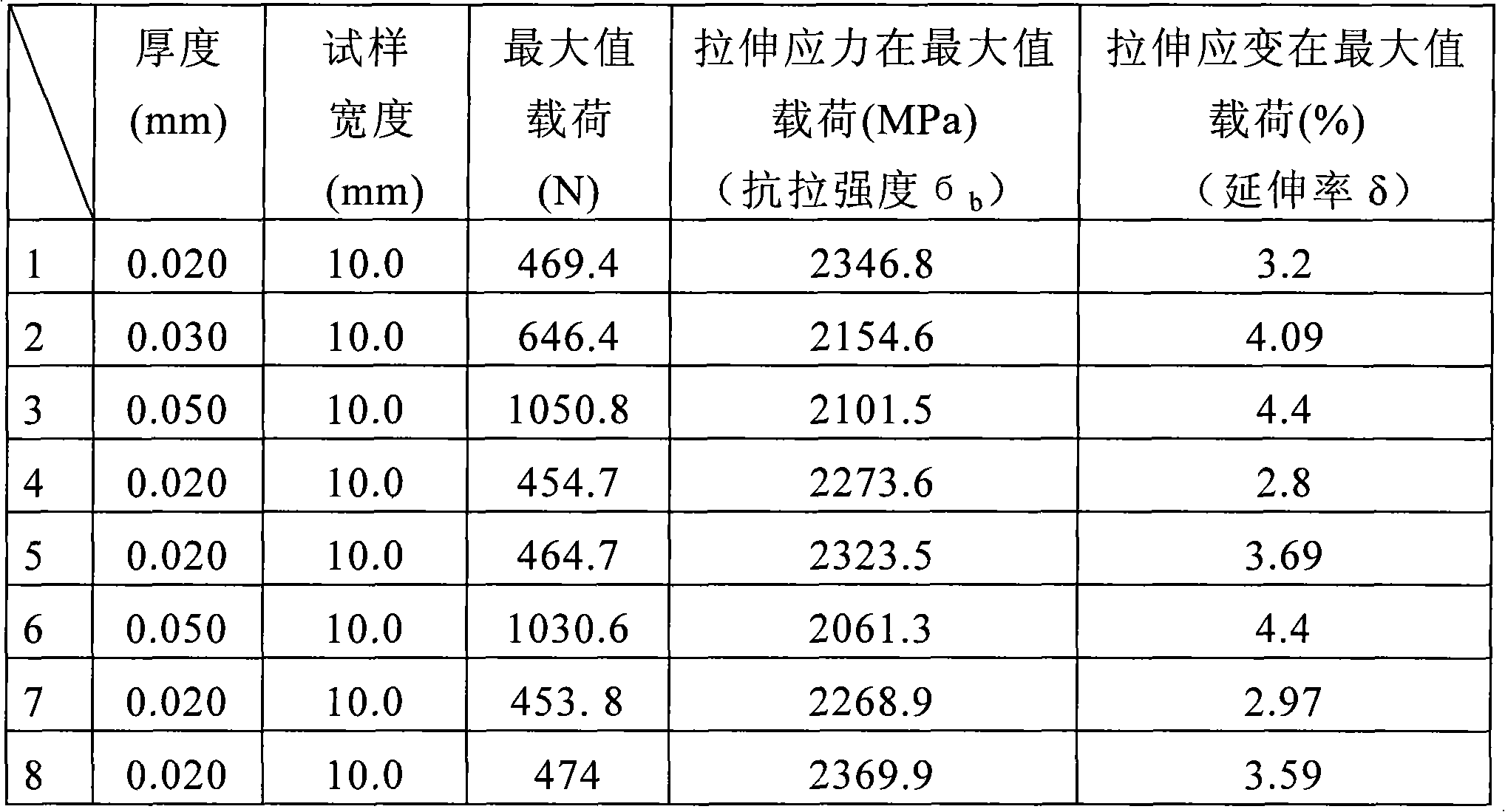

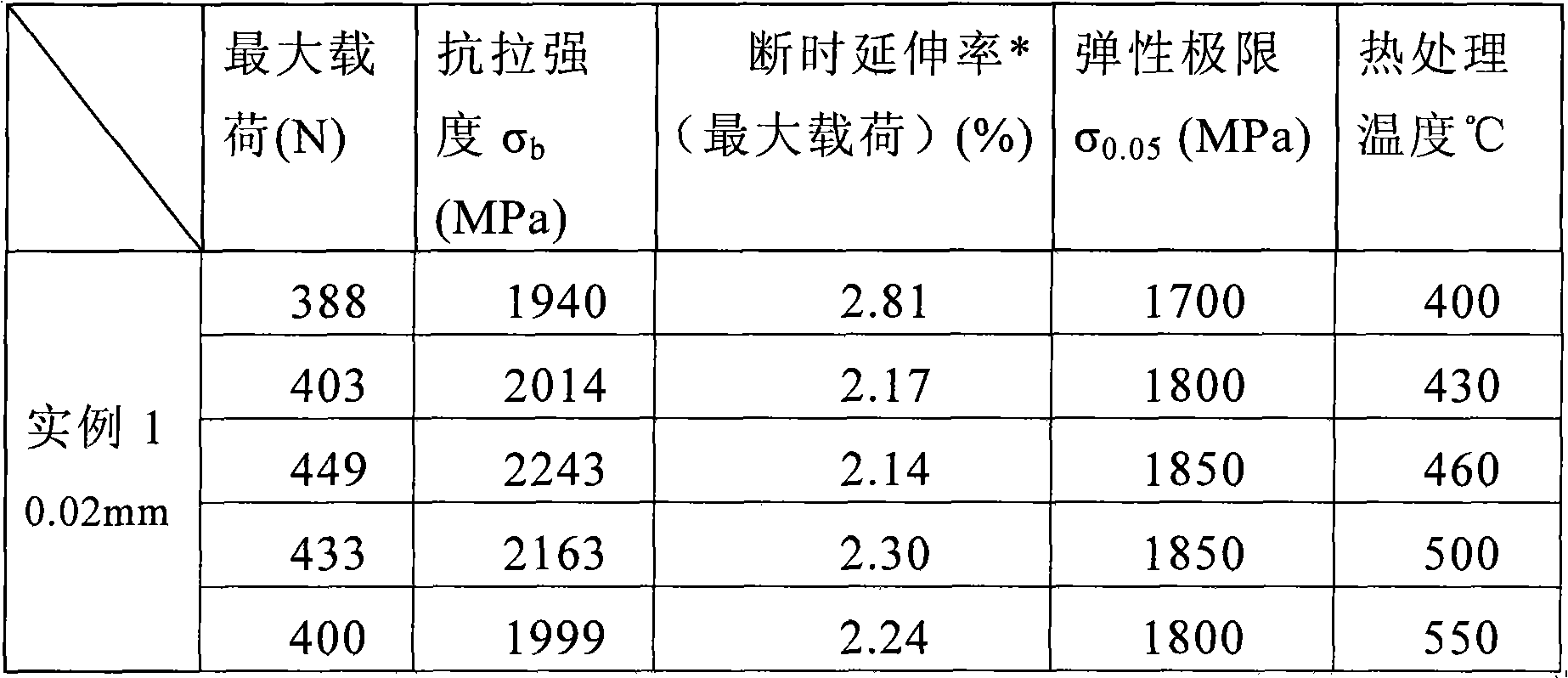

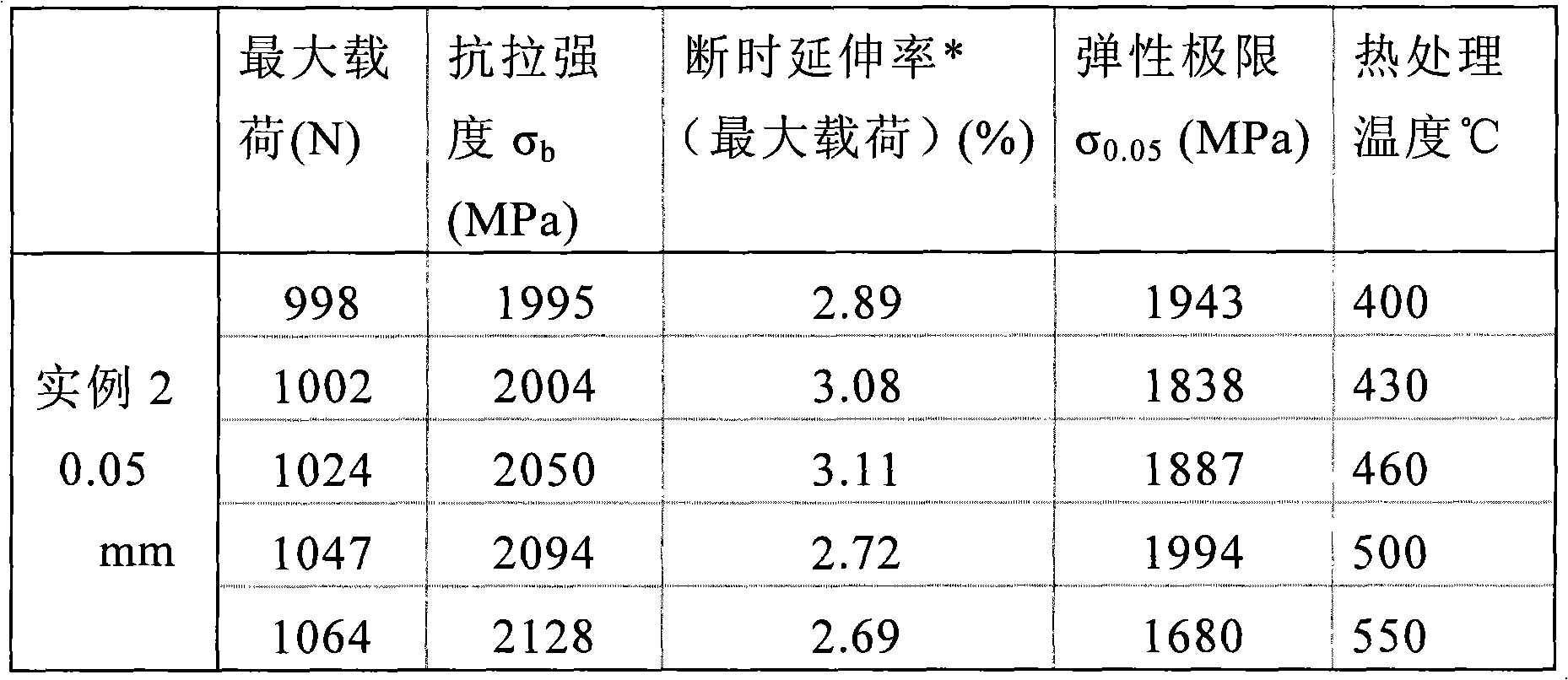

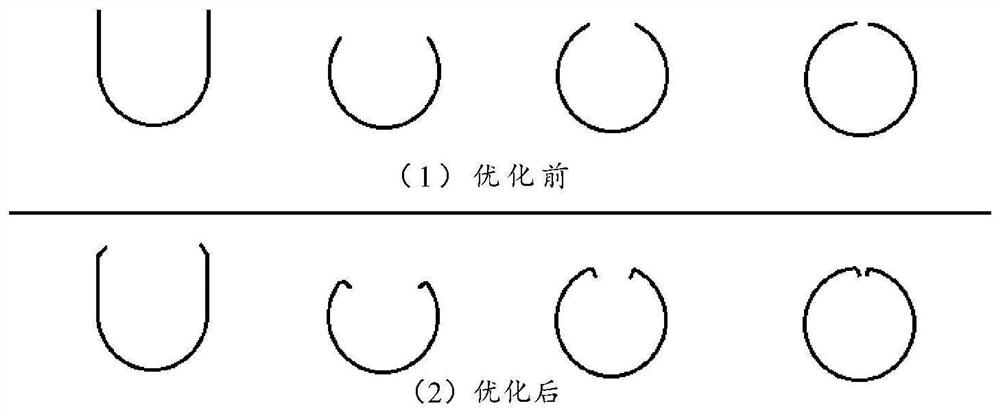

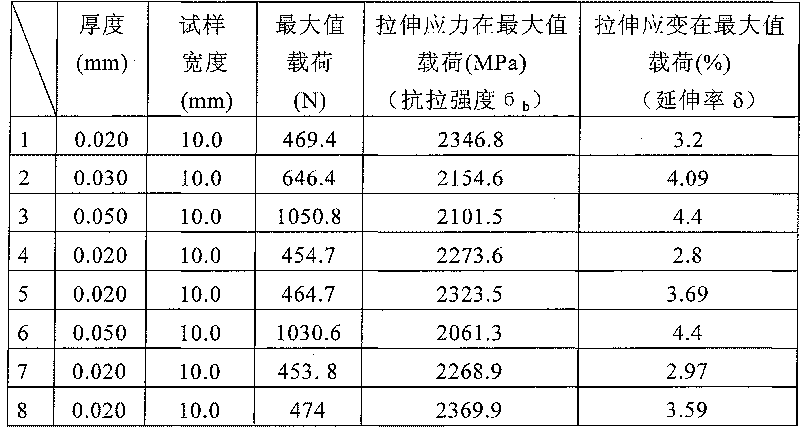

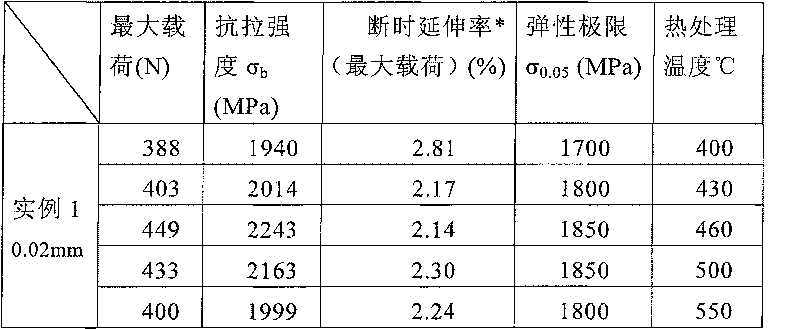

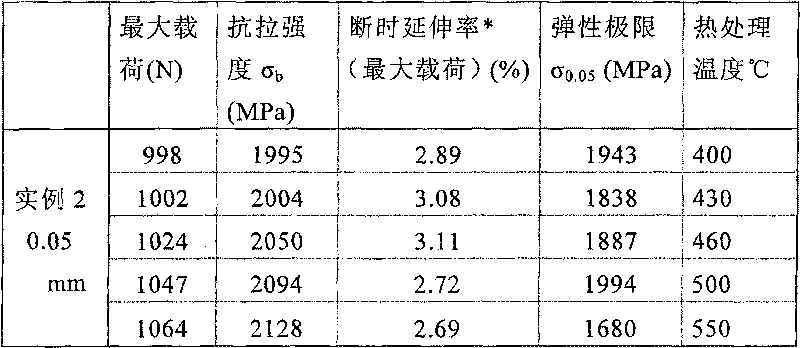

Cobalt-based high elastic alloy, manufacture method thereof, ultra-thin strip made from the alloy and manufacture method thereof

InactiveCN101311285AImprove toughnessGrain refinementRoll mill control devicesMetal rolling arrangementsMaterials preparationSolution treatment

The invention provides a co-based high elastic alloy. The chemical components (by weight percentage) are as follows: Co, 38 to 42 percent; Ni, 14 to 17 percent; Cr, 18 to 22 percent; Mo, 3 to 7 percent; W, 4.0 to 6.5 percent; Si, less than 1.0 percent; Mn, less than 2.5 percent; Nb, less than 1.0 percent; Zr, less than or equal to 0.5 percent; B, less than 0.1 percent; C, less than 0.12 percent; S, less than 0.004 percent; P, less than 0.02 percent; the rest, Fe. The invention also provides a manufacturing method of the co-based high elastic alloy, namely, vacuum melting and vacuum consumable double-vacuum melting technology; wherein, the thickness of an ultrathin strip material of the co-based high elastic alloy which contains the components is 0.02 to 0.05mm. The manufacturing method for the ultrathin strip material of the co-based high elastic alloy comprises the following steps: after cold rolling and blank material preparation as well as solution treatment, self-consumable ingots are rolled coldly into thin strips by certain cold processing technique; the performance of the thin strips is improved by ageing heat treatment in reducing atmosphere or high vacuum; finally, the ultrathin strip material of the co-based high elastic alloy is obtained with the thickness of 0.05mm plus or minus 0.002mm, high accuracy and high performance. The ultrathin strip material of the co-based high elastic alloy made according to the invention not only has the advantage of good mechanical and physical property but also has the advantages of thin thickness, high accuracy and good consistency when processed into elastic elements.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

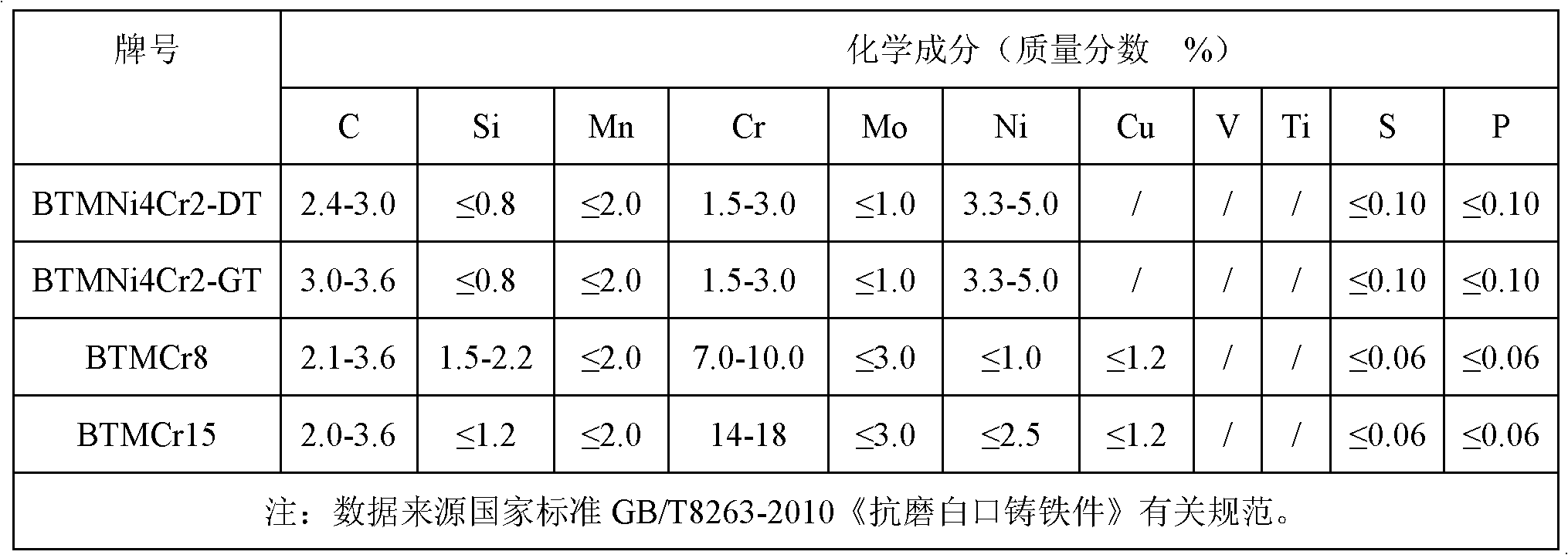

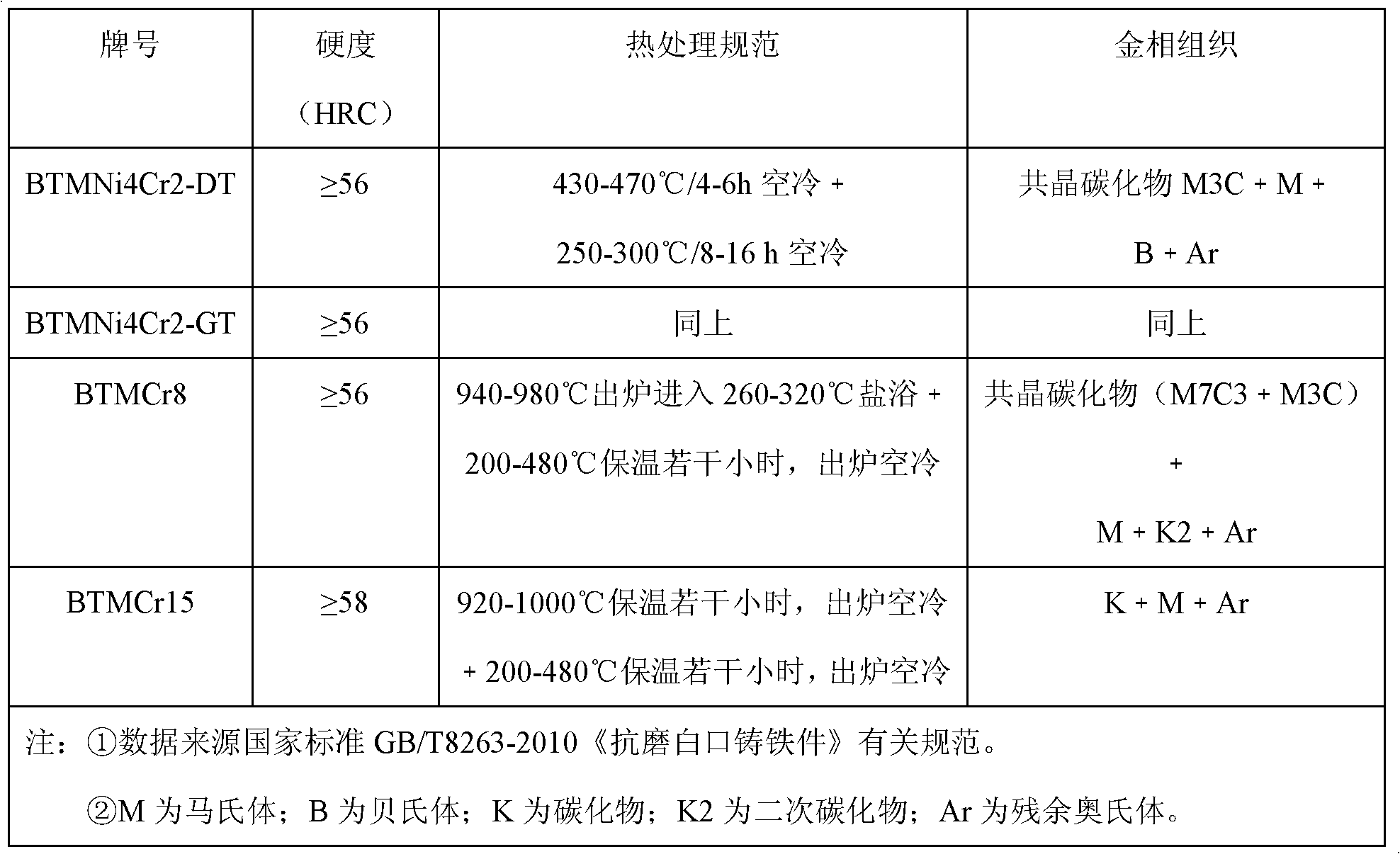

Wear-resistant white cast iron material and preparation method thereof

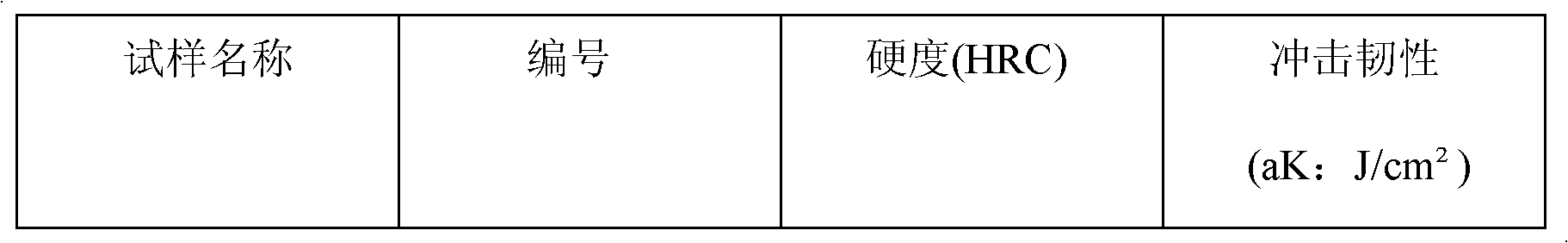

The invention discloses a wear-resistant white cast iron material, which consists of the following elements in percentage by weight: 2.2 to 3.2 percent of C, less than or equal to 1.2 percent of Si, 2.0 to 3.5 percent of Mn, 7.0 to 10.0 percent of Cr, 0.2 to 1.2 percent of Cu, 0.06 to 0.3 percent of V, 0.02 to 0.15 percent of Ti, 0.001 to 0.003 percent of B, 0.02 to 0.06 percent of Al, 0.02 to 0.15 percent of RE, less than or equal to 0.06 percent of S, less than or equal to 0.06 percent of P, and the balance of Fe. The wear-resistant white cast iron material has the hardness (HRC) of more than or equal to 56, the impact toughness aK of more than or equal to 6J / cm<2>, and a metallographic structure consisting of martensite, carbide (M7C3+a small amount of M3C), secondary carbide and a small amount of retained austenite. The wear-resistant white cast iron material does not contain noble metals such as molybdenum, nickel and the like; and compared with the traditional medium-chromium cast iron material, the wear-resistant white cast iron material has the advantages that the production cost can be greatly saved and the material has good economic benefit.

Owner:驻马店市三山耐磨材料有限公司

High-temperature carburizing steel, high-temperature carburizing steel component and preparation method thereof

ActiveCN110373607ASuppress grain coarseningHigh fatigueProcess efficiency improvementSteelmakingChemical composition

The invention designs low-cost high-temperature carburizing steel for a high-temperature carburizing environment with a temperature higher than 1000 DEG C. The low-cost high-temperature carburizing steel consists of the following chemical components in percentage by weight: 0.16-0.20% of C, less than or equal to 0.04% of Si, 0.75-0.90% of Mn, 1.15-1.25% of Cr, 0.20-0.30% of Mo, 0.040-0.050% of Al,0.0120-0.0180% of N, less than or equal to 0.025% of P, 0.015-0.025% of S, less than or equal to 0.0010% of O and the balance of Fe and inevitable impurities. An Al / N ratio is controlled to be 2.0-4.0, Si content is controlled to be relatively low, and a deoxidation process in steelmaking and a stopper rod curve control process in continuous casting are combined, so that large-scale production and continuous casting can be realized, extra process treatment does not need to perform before high-temperature carburizing, a steel structure before carburizing does not need to strictly control and the process is greatly simplified. Grade of a B-class rough system, fine system impurities and Ds impurities of high-temperature carburizing steel is lower than 0.5, carburizing can be simulated for 2-6 hours at a temperature of 1000-1030 DEG C and mixed crystal is avoided. The carburizing steel can be effectively guaranteed in fatigue life after being applied to parts such as a gear.

Owner:SGIS SONGSHAN CO LTD

Method for carrying out anatonosis by adopting laser plasma impact wave in chemical heat treatment process

InactiveCN102978628AReduced activation energy for diffusionImprove diffusion efficiencyCorrosion resistantMaterials science

The invention relates to a method for carrying out anatonosis by adopting laser plasma impact waves in a chemical heat treatment process. According to the method, induction to generate plasma impact waves are generated by induction with high-power short-pulse laser, act on materials and are combined with chemical heat treatment, thereby improving the surface property of metal materials and members and enhancing the oxidation resistance, abrasion resistance and corrosion resistance of the metal material and the members, wherein the chemical heat treatment can be alumetizing, carburization, nitridation, aluminum-chromium penetration and the like. The method disclosed by the invention has the beneficial effects that the temperature of the chemical heat treatment in order to obtain identical penetration layer depth, the temperature of the chemical heat treatment can be obviously reduced, and the treatment time is shortened, thereby reducing the deformation of workpieces.

Owner:AIR FORCE UNIV PLA

Special copper alloy powder for laser-sensing composite fusion-covering high-strength high-conductivity copper alloy coating

InactiveCN103074517AImprove high temperature oxidation resistanceEfficient preparationHeat inorganic powder coatingTungstenMagnesium

The invention discloses special copper alloy powder for a laser-sensing composite fusion-covering high-strength high-conductivity copper alloy coating, and the alloy powder comprises the following chemical components: 2 to 5 percent by weight of titanium (Ti); 1 to 3 percent by weight of magnesium (Mg); 0.1 to 0.5 percent by weight of Zirconium (Zr); 0.2 to 1 percent by weight of boron (B); 5 to 10 percent by weight of aluminum (Al); 8 to 15 percent by weight of nickel (Ni); 0.8 to 2 percent by weight of niobium (Nb), 3 to 8 percent by weight of tungsten (W); 0.01 to 0.5 percent by weight of hafnium (Hf); 0.05 to 0.5 percent by weight of scandium (Sc); and balance of copper (Cu). The special copper alloy powder has the advantages that the special copper alloy powder has good technical compatibility with technical characteristics of the laser-sensing composite fusion covering, a crack-free copper alloy coating with high wearing resistance, high conductivity and excellent high-temperature flexibility can be prepared under a high efficient condition, the effective balance and combination of high strength and high conductivity of the copper alloy can be realized, and the special copper alloy powder has wide application prospect in the fields such as surface enhancing and repairing for copper crystallization rollers, copper crystallizers and electromagnetic gun rails.

Owner:NANCHANG HANGKONG UNIVERSITY

Abrasive-wear-resistant rare-earth-containing Ni-Cr-Fe alloy powder material and application thereof

The invention discloses an abrasive-wear-resistant rare-earth-containing Ni-Cr-Fe alloy powder material and application thereof. The abrasive-wear-resistant rare-earth-containing Ni-Cr-Fe alloy powder material comprises the following components in percentage by weight: 2.0%-3.0% of C, 3.0%-4.0% of B, 2.5%-3.5% of Si, 18%-20% of Ni, 16%-18% of Cr, 0.3%-0.5% of Ce and Fe in balancing amount. Rear earth is added into the powder material, so that the performance of the powder material is improved, and the content of a precious metal in powder material is reduced to lower the cost of the powder material; owing to the addition of rear earth, the hard phase in a coating structure is distributed uniformly, the binding force between the coating structure and a matrix is enhanced, the coating structure is hindered from stripping during an abrasive wear process, and the abrasive-wear resistance of the coating structure is improved; and problems about surface protection and workpiece repair of large-scale equipment and key parts are solved, the cost is saved, and economic benefits are created.

Owner:LANZHOU INST OF TECH

Dispersion strengthening copper-based composite material for spot-welding electrode and preparation method of dispersion strengthening copper-based composite material

The invention discloses a dispersion strengthening copper-based composite material for a spot-welding electrode and a preparation method of the dispersion strengthening copper-based composite material, and belongs to the technical field of metal-based composite materials. The dispersion strengthening copper-based composite material for the spot-welding electrode is composed of, by mass, 5%-10% of TiC, 0.5%-1% of Ce, 0.5%-1% of La2O3, 0.1%-1% of Al2O3 and the balance Cu. The TiC has the characteristics of being high in hardness, high in melting point and good in heat stability. The TiC and the Cu are not subjected to solid solution with each other. The prepared composite material not only has the TiC characteristics of being high in strength, high in hardness and high in melting point but also has the Cu characteristics of being high in electrical conductivity, high in thermal conductivity and the like. Furthermore, the strength, abrasion resistance and high-temperature resistance of copper can be improved through the TiC. The light rare earth element Ce and the light rare earth oxide La2O3 have the effects of strengthening the grain boundary and refining crystal grains, and thus the strength and machinability of the composite material can be improved.

Owner:HENAN UNIV OF SCI & TECH

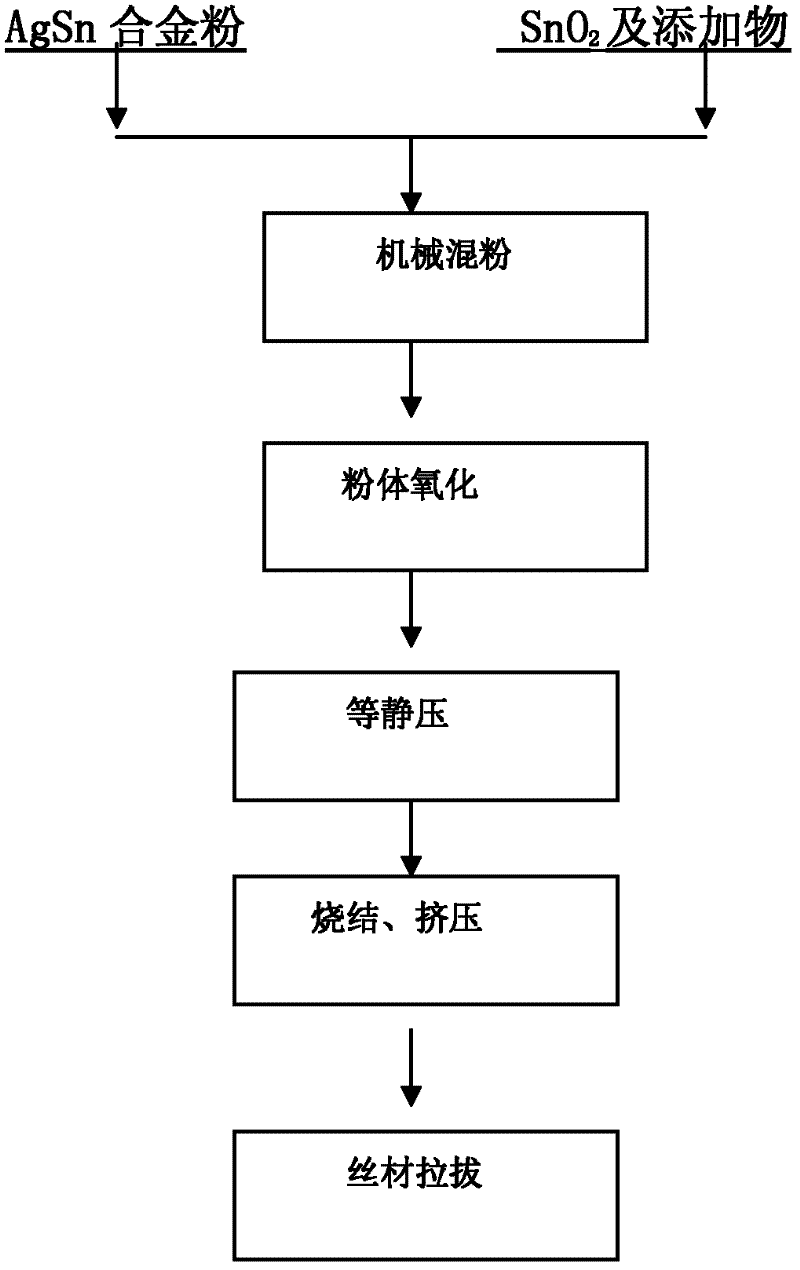

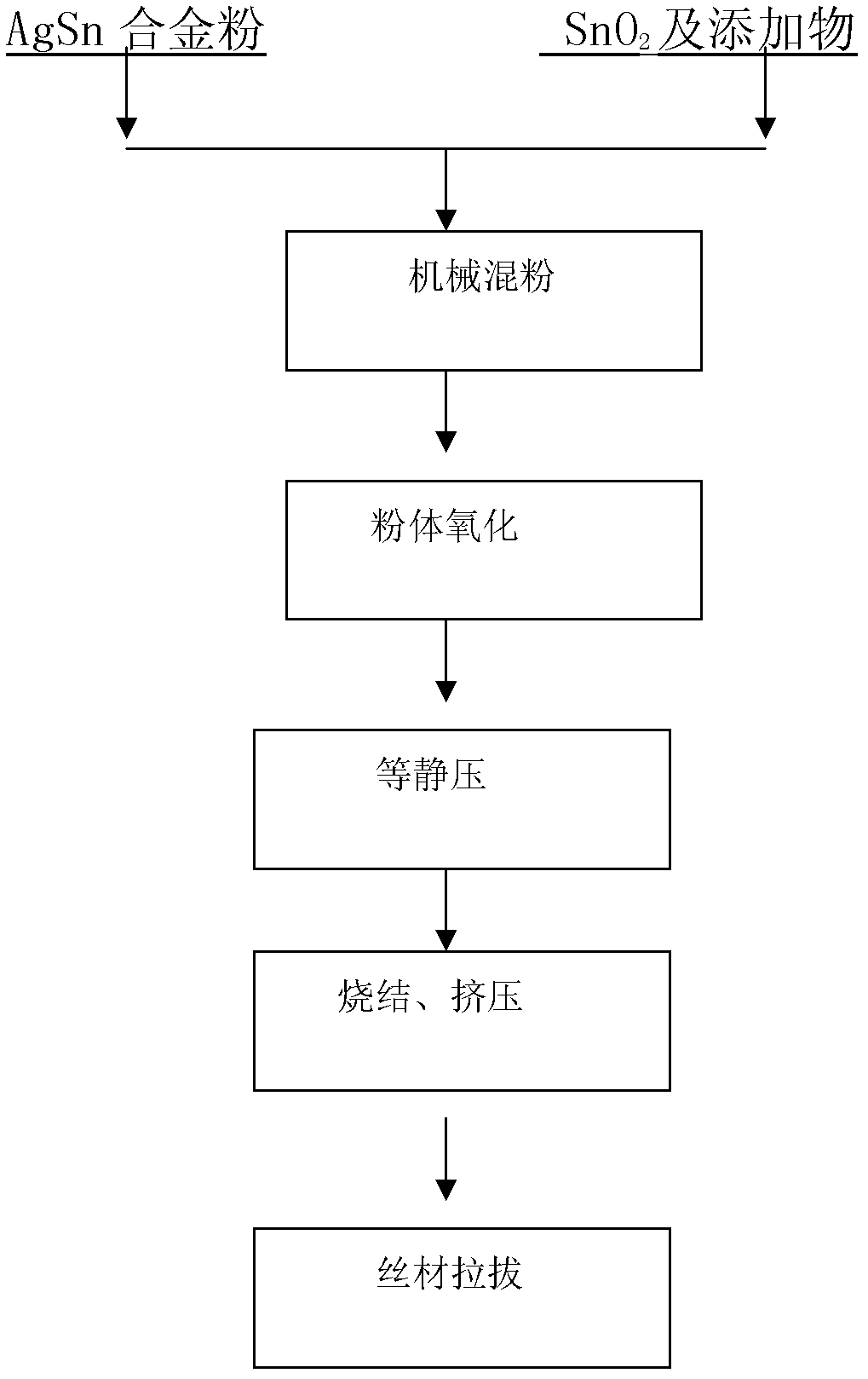

Preparation method for silver stannic oxide wire

A preparation method for a silver stannic oxide wire includes the steps of uniformly mixing prepared AgSn (silver-stannum) powder and SnO2 (stannic oxide) powder with additives, wherein the additives optionally comprise one or more of CuO (cupric oxide), GeO2 (germanium dioxide), Dy2O3(dysprosium oxide), WO3 (tungsten trioxide), WC (tungsten carbide) and W (tungsten); then placing the mixed powder into an aerobic environment; pressing the oxidized powder into a spindle by an isostatic press under the pressure; sintering the spindle at the high temperature; extruding the sintered spindle into a wire and drawing the extruded wire into the wire with the corresponding diameter. Silver stannic oxide particles prepared by the method are fine and uniform in metallographic structures, the types of the additives are unlimited, and processability, rivet forging performance and electrical performance of the materials are improved.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

High-conductivity high-elasticity palladium-based alloy, heat treatment process and application

The invention discloses a high-conductivity high-elasticity palladium-based alloy, a heat treatment process and application. The palladium-based alloy comprises, by mass, 40-60 wt.% of Pd, 25-45 wt.%of Cu, 5-15 wt.% of Ag, 1.5-5 wt.% of Ru and 0-2.0 wt.% of modified elements, wherein the modified elements are one or two of La, Ce, Gd, Y, Ga, Zr and B. The heat treatment process comprises the steps of carrying out burdening, carrying out smelting, carrying out casting, carrying out rolling, carrying out annealing, carrying out drawing and carrying out intermediate annealing, and after the intermediate annealing step is completed, aging solution strengthening treatment needs to be carried out on a prepared alloy wire. The conductivity of the palladium-based alloy ranges from 15% to 25%IACS,the elasticity modulus ranges from 115 GPa to 125GPa, the hardness Hv0.1 ranges from 360 to 460, the resistance temperature coefficient ranges from 2.0 to 4.0x10<-4>K<-1>, the yield strength ranges from 1075 MPa to 1125MPa, and the ductility ranges from 2% to 10%. The high-conductivity high-elasticity palladium-based alloy can be used for a micromotor electric brush wire, a potentiometer electricbrush wire and a semiconductor test probe, wherein the probe can be a Cobra probe or a cantilever type probe or a vertical type probe or a spring type probe.

Owner:昆明贵研新材料科技有限公司

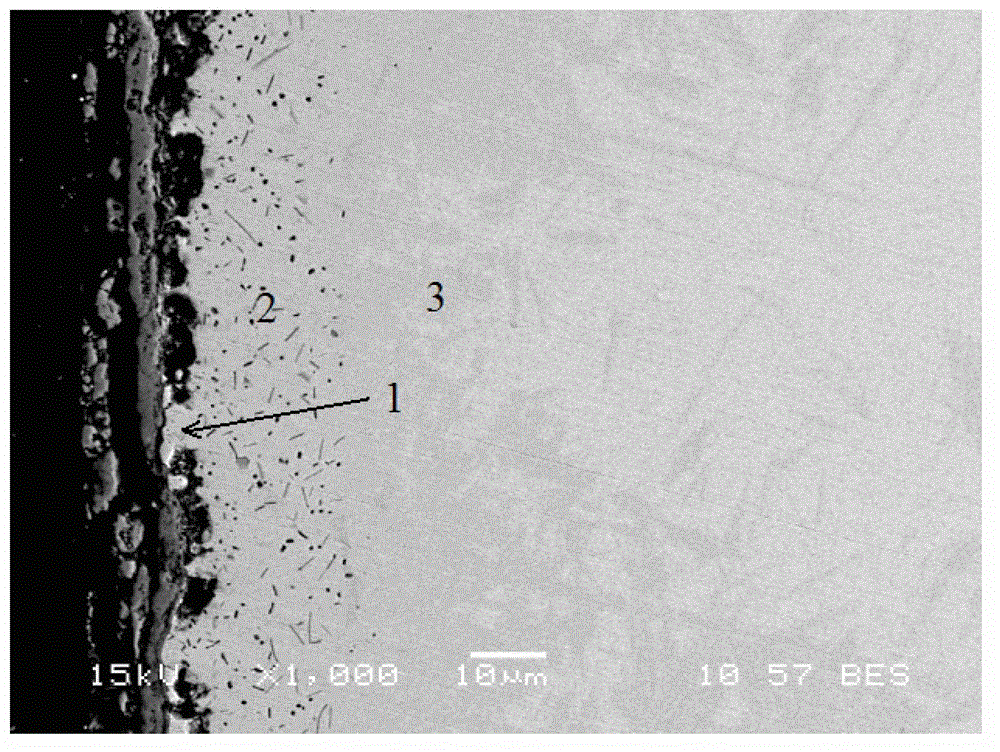

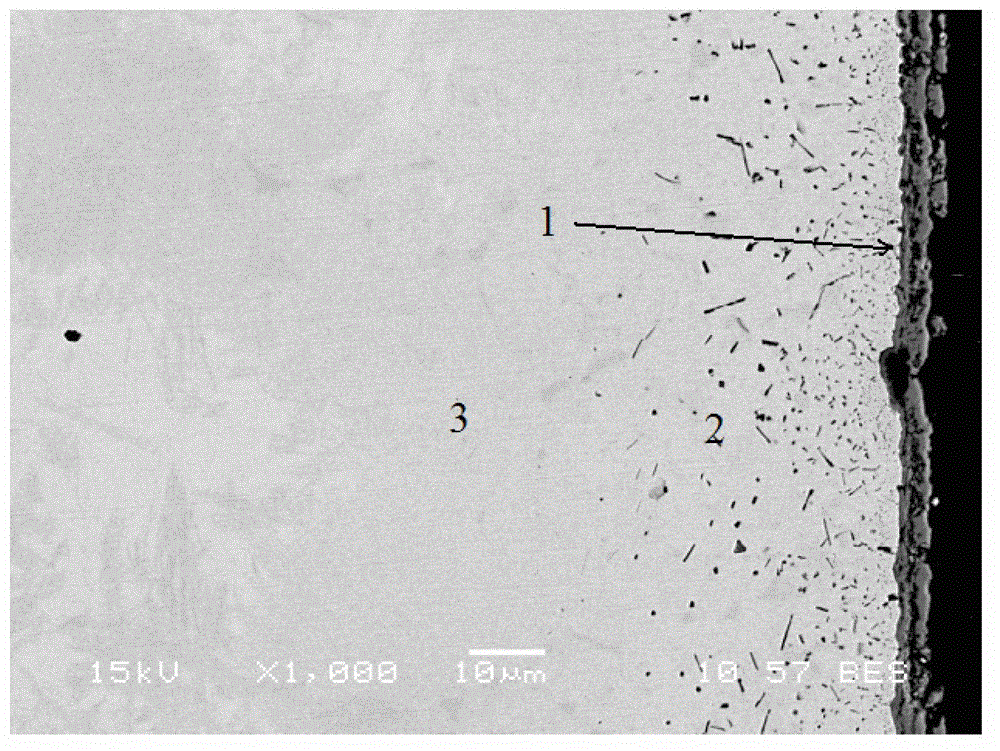

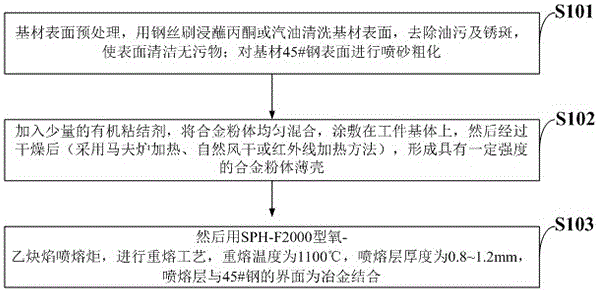

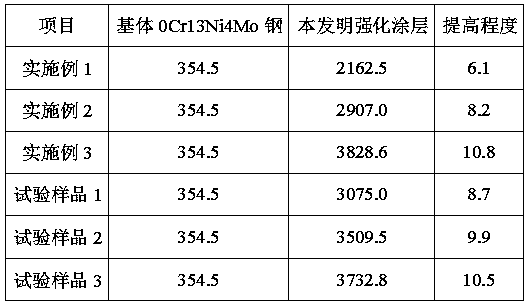

Strengthened coating on surface of transmission component of agricultural machine and preparing method of strengthened coating

ActiveCN110468405AWith variable stiffnessFracture hasMetallic material coating processesHigh entropy alloysShape-memory alloy

The invention provides a strengthened coating on the surface of a transmission component of an agricultural machine. The strengthened coating comprises the following raw materials in parts by weight:10-13.5 parts of high entropy alloy powder, 31-40 parts of hard alloy powder, and 46.5-59 parts of shape memory alloy powder. A preparing method comprises the following specific preparing steps of atfirst, separately grinding the nickel-base high entropy alloy powder, the hard alloy powder and the shape memory alloy powder in fine powders by a ball grinding mill; and then mixing the three alloy fine powders, adding an organic binding agent, sufficiently and uniformly mixing at a room temperature, smearing and heating, thereby obtaining the strengthened coating. The high entropy alloy powder,the hard alloy powder and the shape memory alloy powder are smashed, and are uniformly bound together by the organic binding agent, wherein the hardness of high entropy alloy and the hardness of hardalloy are higher, the high entropy alloy and the hard alloy are mainly used for improving the wear resistance of the transmission component of the agricultural machine, however the shape memory alloyis added to facilitate improving the toughness of the coating and prevent brittle rupture and falling of the coating due to too hard high entropy alloy and hard alloy, so that the service life of thetransmission component of the agricultural machine is effectively prolonged.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

High-temperature and high-conductivity iron-base alloy

The invention relates to a high temperature resisting high-conductivity iron-base alloy material suitable for the technical field of electrometallurgy and electrochemistry, in particular to high-temperature and high-conductivity iron-base alloy. The high-temperature and high-conductivity iron-base alloy is characterized in that the high-temperature and high-conductivity iron-base alloy is prepared from, by weight, 1%-30% of Cu, 0.1%-0.5% of rare earth metal, 0.1%-5% of one or two of Mo and W, 0.1%-5% of one or two of Ni and Co, 0.1%-1% of at least two of Al, Mg, Ca and Zn, 0.035% of impurities C, S and P or less and the balance iron, and the sum of the chemical composition contents is 100%. The high-temperature and high-conductivity iron-base alloy has the beneficial effects of being good in conductivity, small in expansion coefficient, excellent in mechanical performance and resistant to corrosion.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Liquid metal flame-retardant Be-containing titanium alloy for 500-1200 degrees

The invention discloses novel liquid metal flame-retardant Be-containing titanium alloy for 500-1200 degrees. The alloy comprises the following components in percentage by weight: 1.0-1.2 percent of Be, 2.5-2.8 percent of Sn, 3.0-3.2 percent of In, 1.4-1.6 percent of Bi, 0.2-0.4 percent of W, 1.5-1.8 percent of Ta, 4.2-4.5 percent of Co, 0.2-0.4 percent of Se and the balance of titanium. The material is the flame-retardant titanium alloy based on low-melting point liquid metal formed the surface of the titanium alloy at a high temperature and provides a material science solution for titanium alloy combustion at a high temperature due to friction or external fire. The implementation and the industrialization of the alloy can greatly promote the China's commercial upgrading needs on high-quality titanium alloy materials in the high-end field.

Owner:GUANGZHOU YUZHI TECH CO LTD

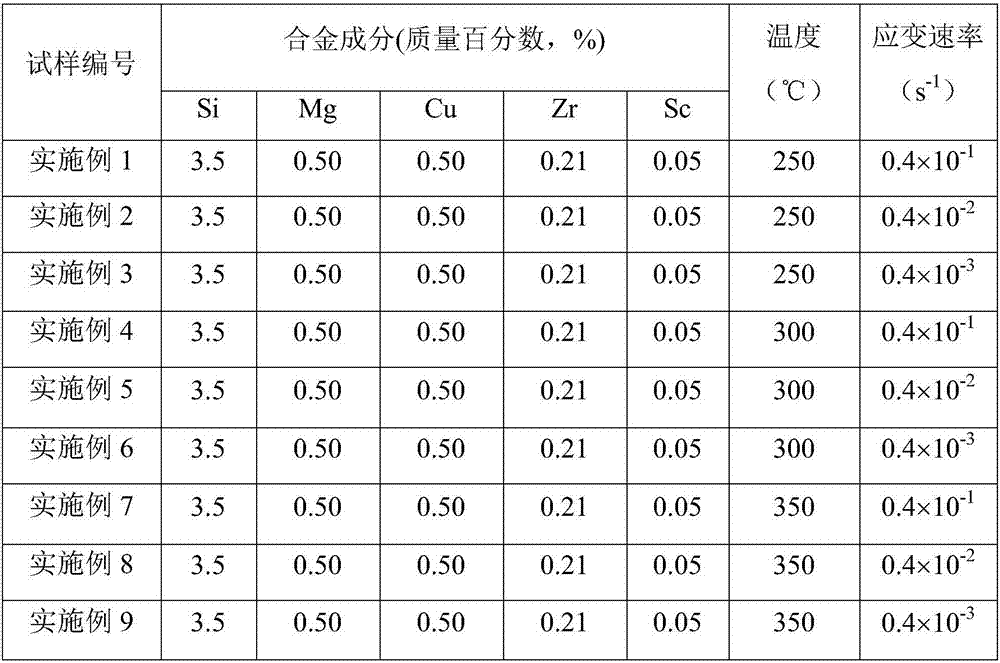

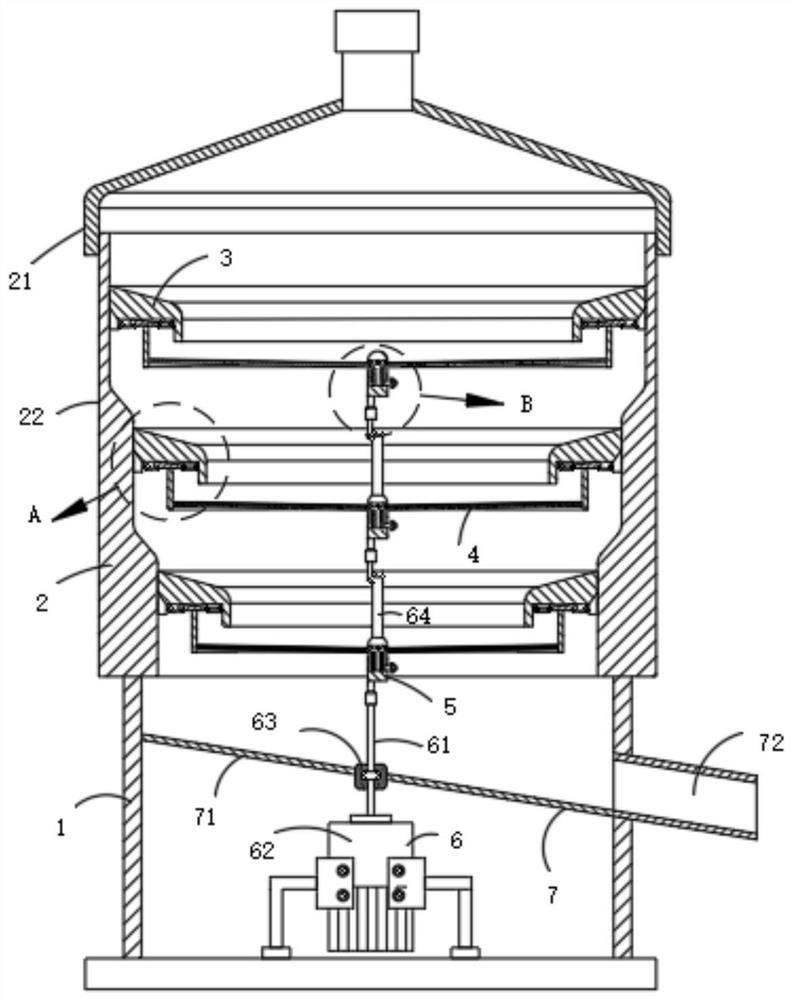

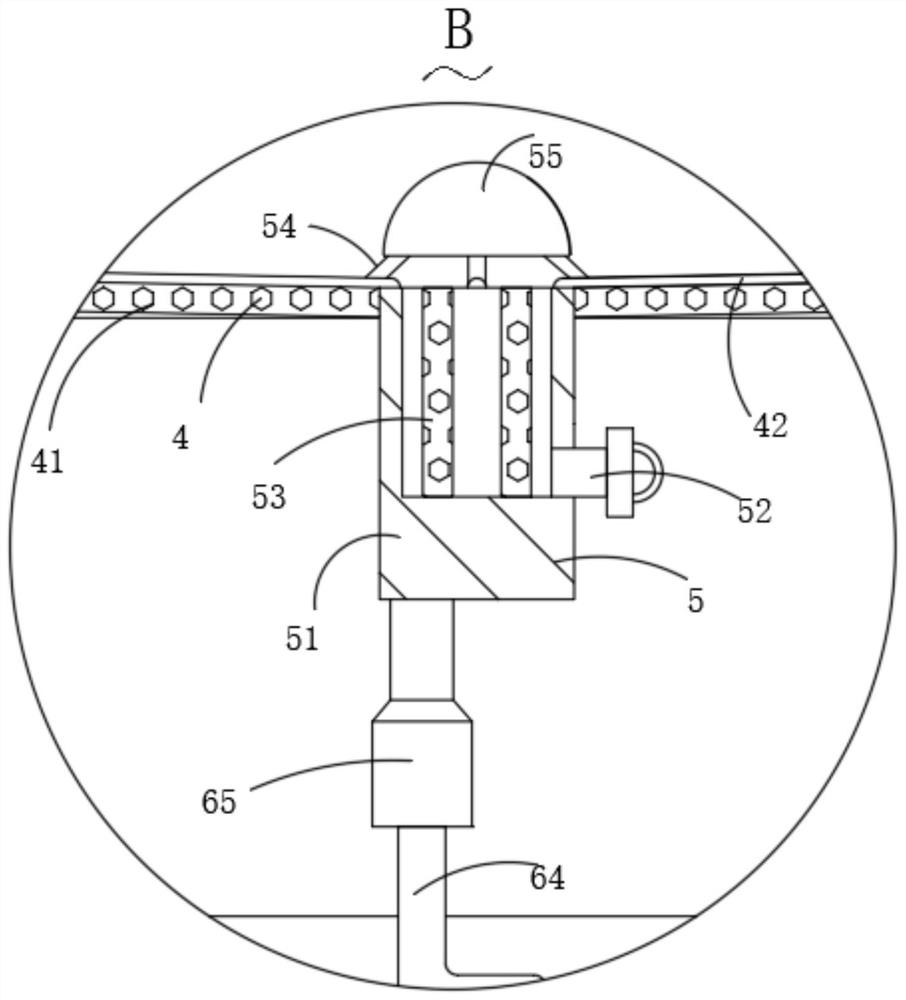

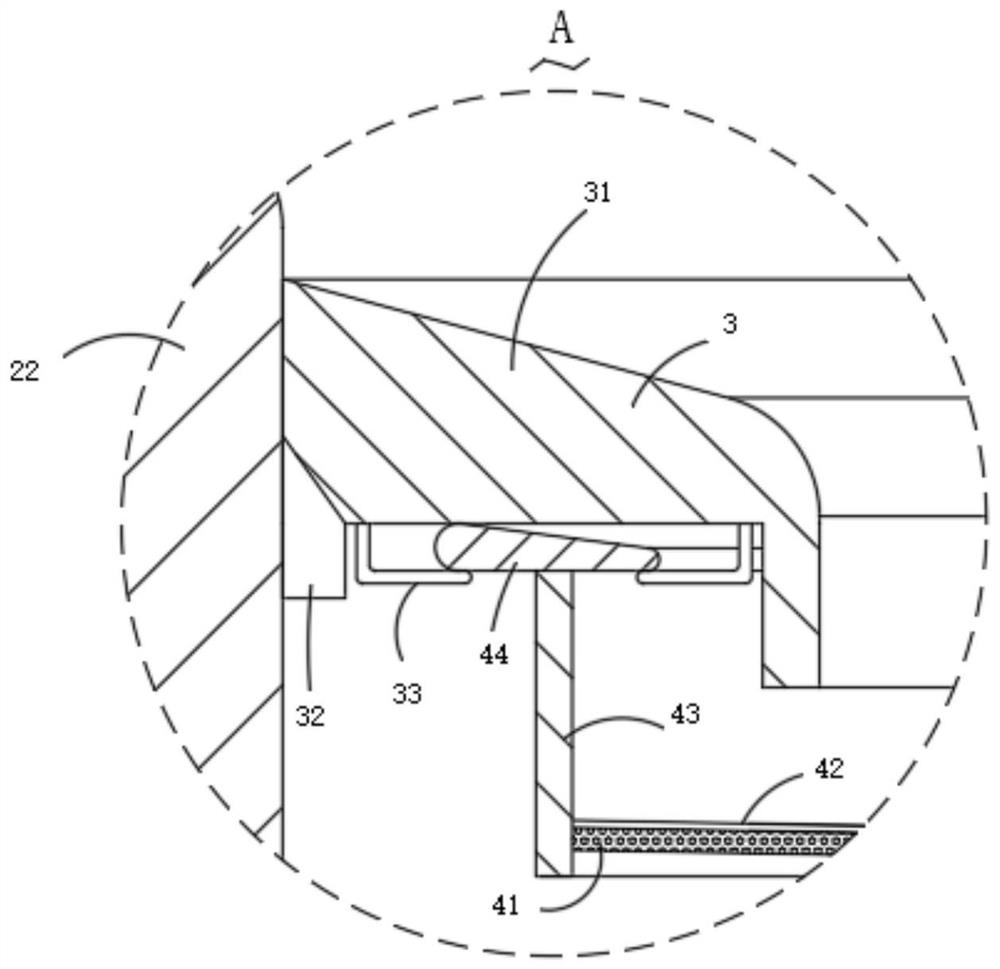

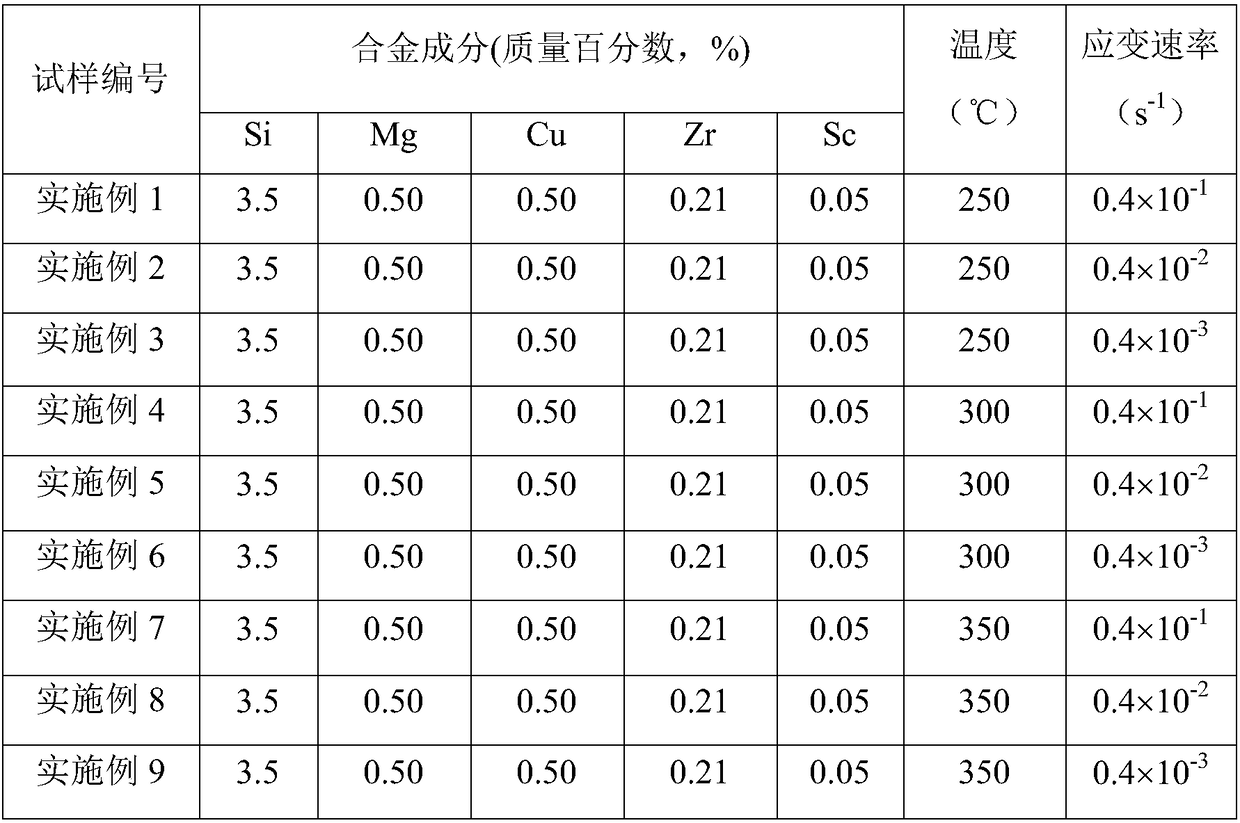

Method for high-strength Al-Si casting-forging alloy preparation through microalloying and warm compaction process recombination

The invention discloses a method for high-strength Al-Si casting-forging alloy preparation through microalloying and warm compaction process recombination. On the basis of components of a traditional Al-Si casting-forging alloy, a minute amount of elements including Mg, Cu, Zr and rare earth Sc are added for alloying modification; and casting ingots are obtained through smelting casting and then subjected to warm compaction treatment under the proper temperature and strain rate so as to prepare a high-strength Al-Si casting-forging alloy. Compared with the Al-Si casting alloy produced through a current traditional process, the high-strength Al-Si casting-forging alloy prepared through the method is remarkably improved in performance, the process method adopted for high-strength Al-Si casting-forging alloy preparation is simple and easy to achieve, the production cost is low, very wide production and application prospects are achieved in the field of aviation, spaceflight, car and machinery manufacturing, and the method is suitable for extensive industrialization.

Owner:HEFEI UNIV OF TECH

A kind of selective laser melting particle reinforced high entropy alloy material and preparation method thereof

ActiveCN113881885BHelp changeRealize component designSievingAdditive manufacturing apparatusSelective laser meltingHigh entropy alloys

The invention relates to the technical field of alloy materials, in particular to a selective laser melting particle-enhanced high-entropy alloy material and a preparation method thereof. Perform powder screening; Step 2: Use the mechanical alloying method to obtain a uniform mixed powder from the high-entropy alloy powder and particle-enhanced powder obtained in Step 1; Step 3: Prepare the mixed powder obtained in Step 2 by selective laser melting (SLM) technology Sample; Step 4: Perform solid solution strengthening and aging treatment on the SLM sample obtained in Step 3. The invention realizes the composition design of the high-entropy alloy by adding an appropriate amount of Ti and Al to the FeCoNiCr high-entropy alloy, and adds Al in the high-entropy alloy. 2 O 3 The strengthening phase and the heat treatment of the sample by selective laser melting can significantly improve the properties of FeCoNiCr high-entropy alloys through strengthening, which is beneficial to prolong the working life of the formed parts and widen the range of working conditions.

Owner:安徽中科春谷激光产业技术研究院有限公司

Welding wire powder flux core, flux cored wire, its preparation method, application, ultra-high strength steel welding process

ActiveCN112276416BMeet welding needsImprove toughnessArc welding apparatusWelding/cutting media/materialsFerrochromeSolder material

The invention provides a welding wire powder flux core, a flux-cored welding wire, its preparation method, application, and an ultra-high-strength steel welding process, and relates to the technical field of welding materials. The welding wire powder flux core includes the following components in weight percentage: Subdivision: high carbon ferrochrome 7‑12%; electrolytic manganese 5‑15%; ferromolybdenum 5‑10%; ferrovanadium 3‑10%; ferrotitanium 1‑5%; %; sodium fluoride 2‑5%; aluminum iron 1‑5%; bismuth oxide 0.3‑0.8%; manganese carbonate 0.4‑1.0%; potassium feldspar 0.4‑2.0%; iron powder balance. The flux-cored material and flux-cored welding wire of the present invention can meet the welding requirements of ultra-high-strength steel with a tensile strength of 1400-1600MPa, and have good welding manufacturability, small spatter, beautiful weld shape, no cracks on the surface, and the formed deposited metal is mechanically Good performance.

Owner:北京智双科技发展有限公司

Cobalt-based high elastic alloy, manufacture method thereof, ultra-thin strip made from the alloy and manufacture method thereof

InactiveCN101311285BImprove toughnessGrain refinementRoll mill control devicesMetal rolling arrangementsMaterials preparationSolution treatment

The invention provides a co-based high elastic alloy. The chemical components (by weight percentage) are as follows: Co, 38 to 42 percent; Ni, 14 to 17 percent; Cr, 18 to 22 percent; Mo, 3 to 7 percent; W, 4.0 to 6.5 percent; Si, less than 1.0 percent; Mn, less than 2.5 percent; Nb, less than 1.0 percent; Zr, less than or equal to 0.5 percent; B, less than 0.1 percent; C, less than 0.12 percent; S, less than 0.004 percent; P, less than 0.02 percent; the rest, Fe. The invention also provides a manufacturing method of the co-based high elastic alloy, namely, vacuum melting and vacuum consumabledouble-vacuum melting technology; wherein, the thickness of an ultrathin strip material of the co-based high elastic alloy which contains the components is 0.02 to 0.05mm. The manufacturing method forthe ultrathin strip material of the co-based high elastic alloy comprises the following steps: after cold rolling and blank material preparation as well as solution treatment, self-consumable ingotsare rolled coldly into thin strips by certain cold processing technique; the performance of the thin strips is improved by ageing heat treatment in reducing atmosphere or high vacuum; finally, the ultrathin strip material of the co-based high elastic alloy is obtained with the thickness of 0.05mm plus or minus 0.002mm, high accuracy and high performance. The ultrathin strip material of the co-based high elastic alloy made according to the invention not only has the advantage of good mechanical and physical property but also has the advantages of thin thickness, high accuracy and good consistency when processed into elastic elements.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

High-conductivity copper-cobalt alloy for electrode and preparation method of high-conductivity copper-cobalt alloy

The invention provides a high-conductivity copper-cobalt alloy for an electrode and a preparation method of the high-conductivity copper-cobalt alloy. The high-conductivity copper-cobalt alloy comprises, by weight, 0.1%-1% of Be, 1.2%-2.8% of Co, 0.5%-1.7% of Ni, 0.1%-0.5% of Zr and the balance Cu. The preparation method comprises the following steps that S1, burdening is conducted according to the weight percentage of all the components, S2, the temperature of a smelting furnace is increased to a certain temperature, Be, Co, Ni and Zr are added, S3, the temperature of the smelting furnace continues to be increased to a certain temperature, Cu is added, and alloy liquid is obtained after smelting is completed. Through the mutual strengthening effect between the alloys, the conductivity of the copper-cobalt alloy is improved. And meanwhile, through strict performance detection, the copper-cobalt alloy has good conductive performance and relatively high mechanical performance, room-temperature performance, high-temperature performance and wear resistance.

Owner:镇江市镇特合金材料有限公司

A kind of preparation method of high-strength Al-Si casting and forging alloy

The invention discloses a method for high-strength Al-Si casting-forging alloy preparation through microalloying and warm compaction process recombination. On the basis of components of a traditional Al-Si casting-forging alloy, a minute amount of elements including Mg, Cu, Zr and rare earth Sc are added for alloying modification; and casting ingots are obtained through smelting casting and then subjected to warm compaction treatment under the proper temperature and strain rate so as to prepare a high-strength Al-Si casting-forging alloy. Compared with the Al-Si casting alloy produced through a current traditional process, the high-strength Al-Si casting-forging alloy prepared through the method is remarkably improved in performance, the process method adopted for high-strength Al-Si casting-forging alloy preparation is simple and easy to achieve, the production cost is low, very wide production and application prospects are achieved in the field of aviation, spaceflight, car and machinery manufacturing, and the method is suitable for extensive industrialization.

Owner:HEFEI UNIV OF TECH

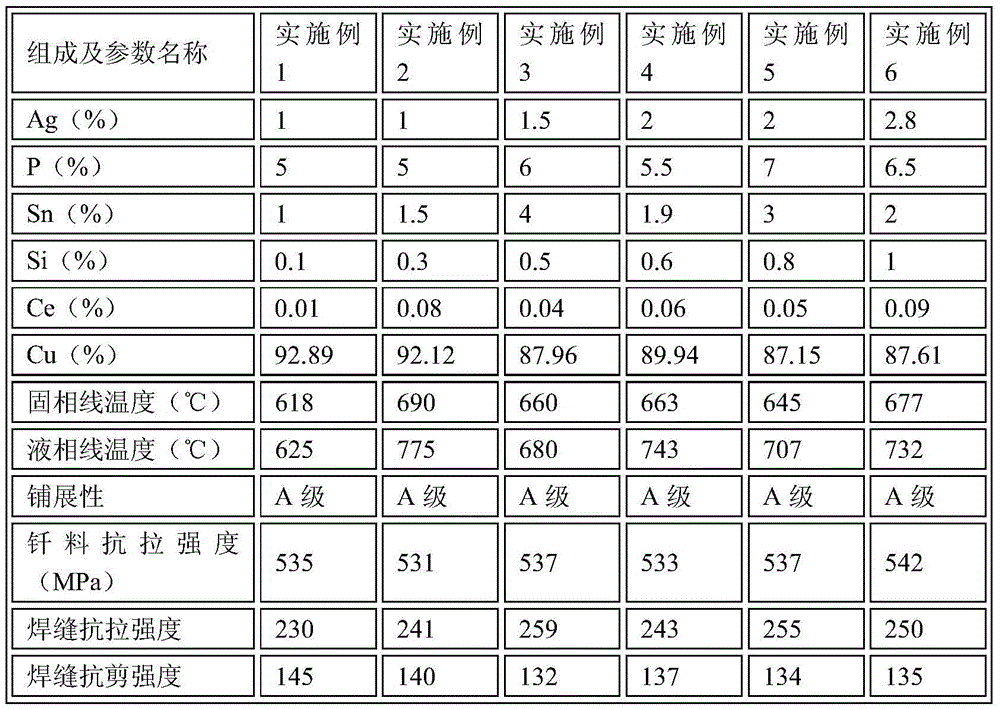

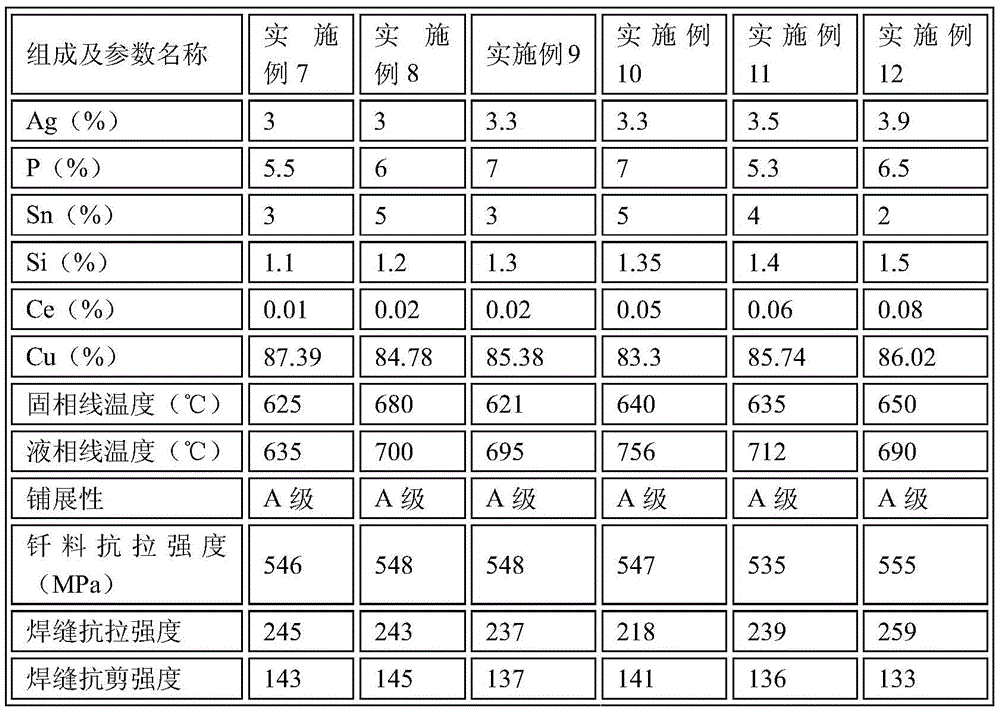

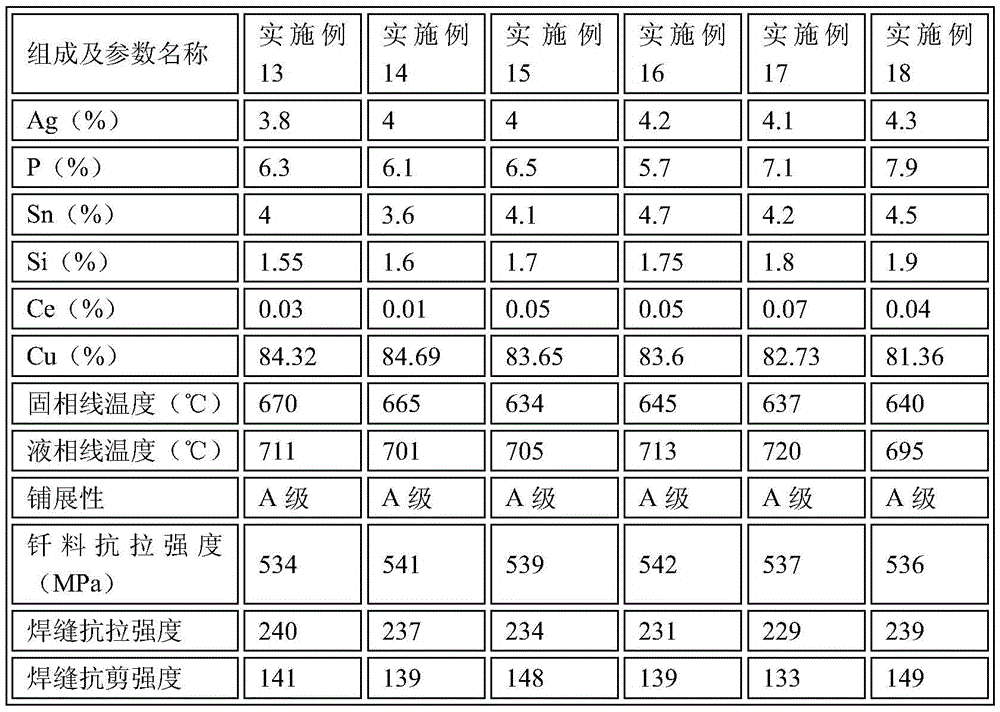

A kind of medium temperature solder containing copper and its alloy

ActiveCN104339099BPrevent volatilizationSuppress splashWelding/cutting media/materialsSoldering mediaPhosphorCerium

The invention discloses a medium-temperature solder containing copper and a copper alloy. The medium-temperature solder comprises the following components by weight percent: 1-5 percent of silver, 5-8 percent of phosphor, 1-6 percent of tin, 0.1-2.5 percent of silicon, 0.01-0.1 percent of cerium and the balance of copper. The medium-temperature solder disclosed by the invention has the advantages that the melting temperature of the solder is reduced, and the flowability is good; besides, the solder has good permeability and ductility and can infiltrate into a tiny clearance without generating a sand hole; meanwhile, the solder is used in an environment with greater temperature difference, and the damage to a weld seam is avoided. The medium-temperature solder disclosed by the invention is greatly used in the refrigeration industry.

Owner:李文康

A high-strength corrosion-resistant rare earth aluminum alloy material and its preparation method

The invention provides a novel high-strength corrosion-resistant rare earth aluminum alloy material and a preparation method. Based on a high-strength Al-Zn-Mg alloy, a proper amount of elements of Cu, rare earth Ce, rare earth Sc and rare earth Er are added, and the novel Al-Zn-Mg-Cu-Ce-Sc-Er aluminum alloy material is prepared. The material has the beneficial effects of being high in strength, good in plasticity and toughness, resistant to corrosion, good in fatigue resistance and the like. The material is a structural material which can be widely applied to aviation, spaceflight, ships and warships and means of conveyance. The production and preparation method of the material is simple and easy to practice, the processing technology of the material is easy to control, raw materials are sufficient and easy to obtain, the production cost is low, and the material has very wide production and application prospects.

Owner:HEFEI UNIV OF TECH

Preparation method for silver stannic oxide wire

A preparation method for a silver stannic oxide wire includes the steps of uniformly mixing prepared AgSn (silver-stannum) powder and SnO2 (stannic oxide) powder with additives, wherein the additives optionally comprise one or more of CuO (cupric oxide), GeO2 (germanium dioxide), Dy2O3(dysprosium oxide), WO3 (tungsten trioxide), WC (tungsten carbide) and W (tungsten); then placing the mixed powder into an aerobic environment; pressing the oxidized powder into a spindle by an isostatic press under the pressure; sintering the spindle at the high temperature; extruding the sintered spindle into a wire and drawing the extruded wire into the wire with the corresponding diameter. Silver stannic oxide particles prepared by the method are fine and uniform in metallographic structures, the types of the additives are unlimited, and processability, rivet forging performance and electrical performance of the materials are improved.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Special copper alloy powder for laser-sensing composite fusion-covering high-strength high-conductivity copper alloy coating

InactiveCN103074517BImprove high temperature oxidation resistanceEfficient preparationHeat inorganic powder coatingNiobiumHafnium

The invention discloses special copper alloy powder for a laser-sensing composite fusion-covering high-strength high-conductivity copper alloy coating, and the alloy powder comprises the following chemical components: 2 to 5 percent by weight of titanium (Ti); 1 to 3 percent by weight of magnesium (Mg); 0.1 to 0.5 percent by weight of Zirconium (Zr); 0.2 to 1 percent by weight of boron (B); 5 to 10 percent by weight of aluminum (Al); 8 to 15 percent by weight of nickel (Ni); 0.8 to 2 percent by weight of niobium (Nb), 3 to 8 percent by weight of tungsten (W); 0.01 to 0.5 percent by weight of hafnium (Hf); 0.05 to 0.5 percent by weight of scandium (Sc); and balance of copper (Cu). The special copper alloy powder has the advantages that the special copper alloy powder has good technical compatibility with technical characteristics of the laser-sensing composite fusion covering, a crack-free copper alloy coating with high wearing resistance, high conductivity and excellent high-temperature flexibility can be prepared under a high efficient condition, the effective balance and combination of high strength and high conductivity of the copper alloy can be realized, and the special copper alloy powder has wide application prospect in the fields such as surface enhancing and repairing for copper crystallization rollers, copper crystallizers and electromagnetic gun rails.

Owner:NANCHANG HANGKONG UNIVERSITY

Alloy material for high-temperature-resistant pump valve and production process thereof

InactiveCN112593137AImprove anti-wear performanceImprove high temperature resistanceMolten metal pouring equipmentsCarbideHardness

The invention relates to the technical field of alloy materials for high-temperature-resistant pump valves, and discloses an alloy material for a high-temperature-resistant pump valve. The alloy material comprises the following raw materials in percentage by weight: 2.65-3.0% of C, 0.5-0.8% of Si, 0.5-0.8% of Mn, 24.0-28.0% of Cr, 0.9-1.2% of Mo, 0.6-0.9% of W, 0.9-1.2% of Cu, 0.3-0.5% of V, 0.06-0.15% of Ti, 0.04-0.12% of RE, 0.04-0.06% of S, 0.04-0.06% of P, 0.3-0.4% of a refining agent, and the balance of Fe and unavoidable impurities. According to the alloy material for the high-temperature-resistant pump valve and a production process of the alloy material, Mo and W alloys and strong carbide forming elements such as V and Ti are added for compound use, V and Ti are the strong carbideforming elements, grains are refined, grain boundaries are purified, the form, size, number and distribution of carbide are improved, the effect of improving the comprehensive performance of the material is very obvious, and the high-temperature stability and red hardness of carbide are better, so that the pump valve shows higher wear resistance and high-temperature resistance in a high-temperature operation environment.

Owner:江苏椿宇机械制造有限公司

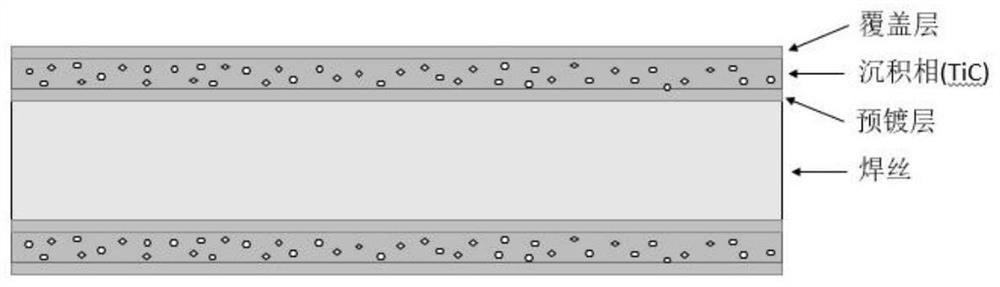

A preparation method and product of nuclear power high-temperature nickel-based alloy composite welding wire

ActiveCN111136405BInhibition of dissolutionGrain boundary refinementWelding/cutting media/materialsSoldering mediaCrack resistanceNuclear power

The invention discloses a preparation method of high-temperature nickel-based alloy composite welding wire for nuclear power and its products, belonging to the field of welding technology, comprising the following steps: cleaning the surface of the high-temperature nickel-based alloy welding wire, followed by mechanical grinding, polishing, and alkali cleaning Oil and electropolishing treatment to produce welding wire I; electroplating nickel layer on the surface of welding wire I to produce welding wire II; electroplating TiC coating on the nickel layer of welding wire II to produce welding wire III; electroplating on the TiC coating of welding wire III The nickel layer is used to prepare a nuclear power high-temperature nickel-based alloy composite welding wire; the nuclear power high-temperature nickel-based alloy composite welding wire prepared by the invention has low cost and high DDC crack resistance.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of highly conductive and highly elastic palladium-based alloy, heat treatment process and application

ActiveCN112063879BEasy to processStable structureMetal/alloy conductorsElectrical resistance and conductanceMicro motor

The invention discloses a high-conductivity and high-elasticity palladium-based alloy, heat treatment process and application. The palladium-based alloy includes 40-60wt.% of Pd, 25-45wt.% of Cu, and 5-15wt.% of Ag , 1.5-5wt.% of Ru and 0-2.0wt.% of modifying elements, wherein the modifying elements are one or two of La, Ce, Gd, Y, Ga, Zr and B. The heat treatment process includes the steps of batching, smelting, casting, rolling, annealing, drawing and intermediate annealing. After the intermediate annealing step is completed, the obtained alloy wire needs to be subjected to aging solid solution strengthening treatment. The electrical conductivity of the palladium-based alloy is between 15-25% IACS, the elastic modulus is between 115-125GPa, and the hardness Hv 0.1 Between 360 and 460, the temperature coefficient of resistance is 2.0 to 4.0×10 ‑4 K ‑1 Between, yield strength between 1075 ~ 1125MPa, elongation between 2 ~ 10%. It can be used for brush wires of micro motors, brush wires of potentiometers and semiconductor test probes, wherein the probes can be Cobra probes, cantilever probes, vertical probes or spring probes.

Owner:昆明贵研新材料科技有限公司

Machine body aluminum cast support

The invention relates to a machine body aluminum cast support. The machine body aluminum cast support comprises a base, a frame and a brace, wherein the upper part of the base is an isosceles trapezoid while the lower part of the base is a rectangle; the length of the rectangle is equal to that of the bottom of the trapezoid; the frame is fixed on the base and is formed by combining three side surfaces; an included angle between each two adjacent side surfaces is 120 degrees; the brace is inlaid on the frame; the lower part of the brace is a rectangular cylinder structure; and the upper part of the brace is a first cylinder structure which is placed horizontally. The machine body aluminum cast support is reasonable in design, high in hardness and simple and convenient to mount. Moreover, the base, the frame and the brace of the machine body aluminum cast support are made of three-dimensional weave fiber / aluminum alloy composite materials, so that the machine body aluminum cast support which is excellent in overall performance, light in weight and low in cost can be obtained.

Owner:宁波吉胜铸业有限公司

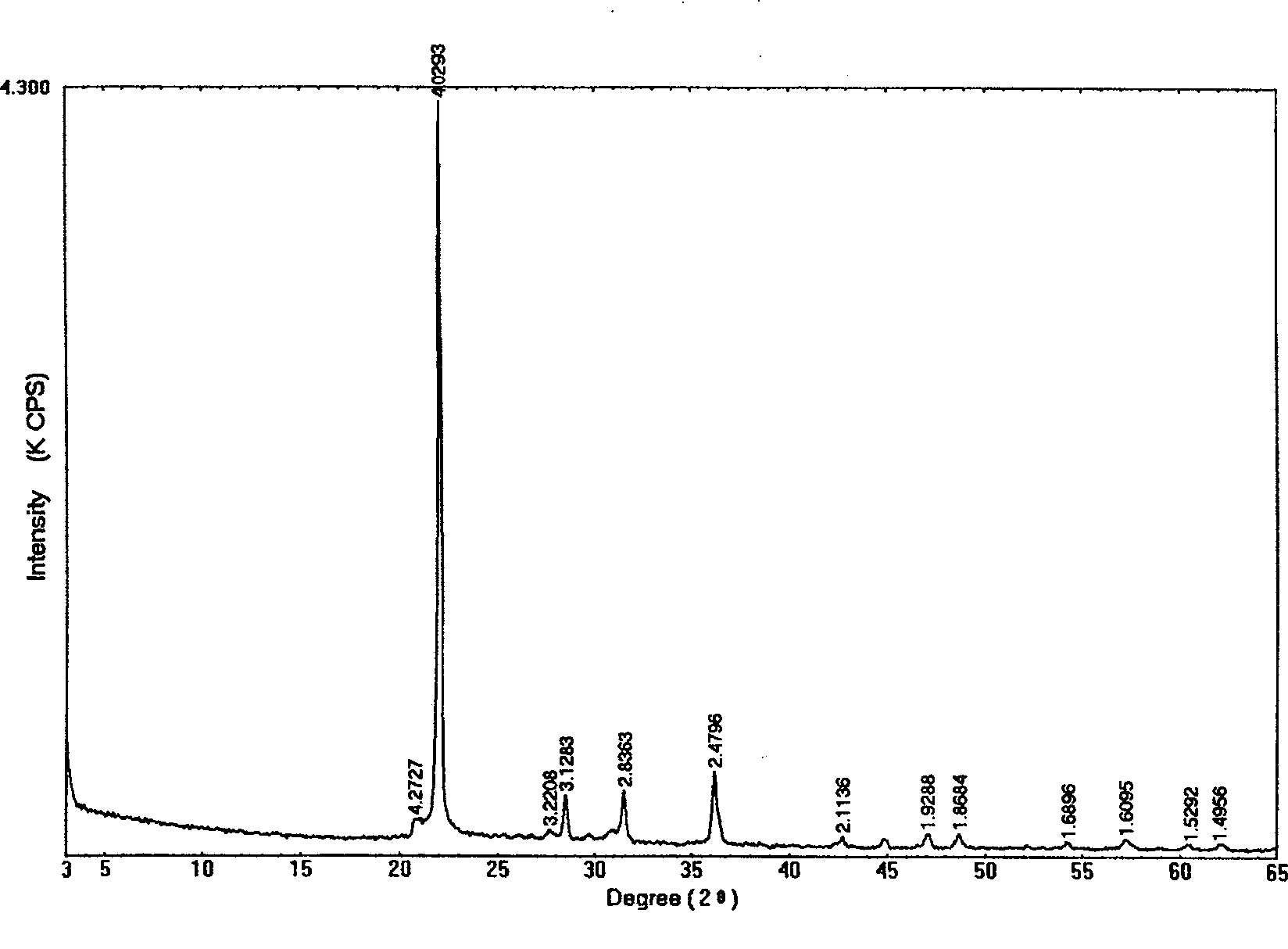

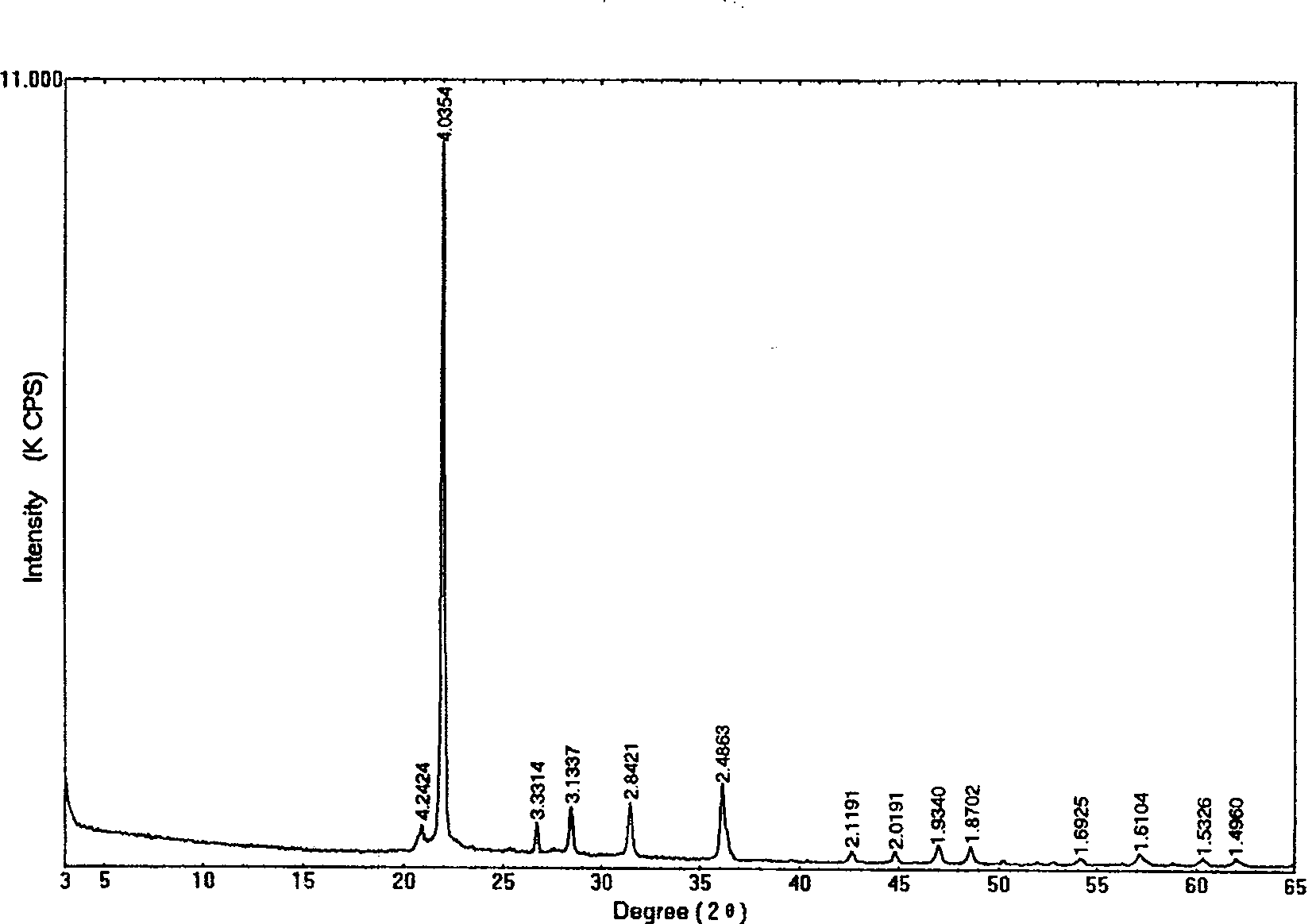

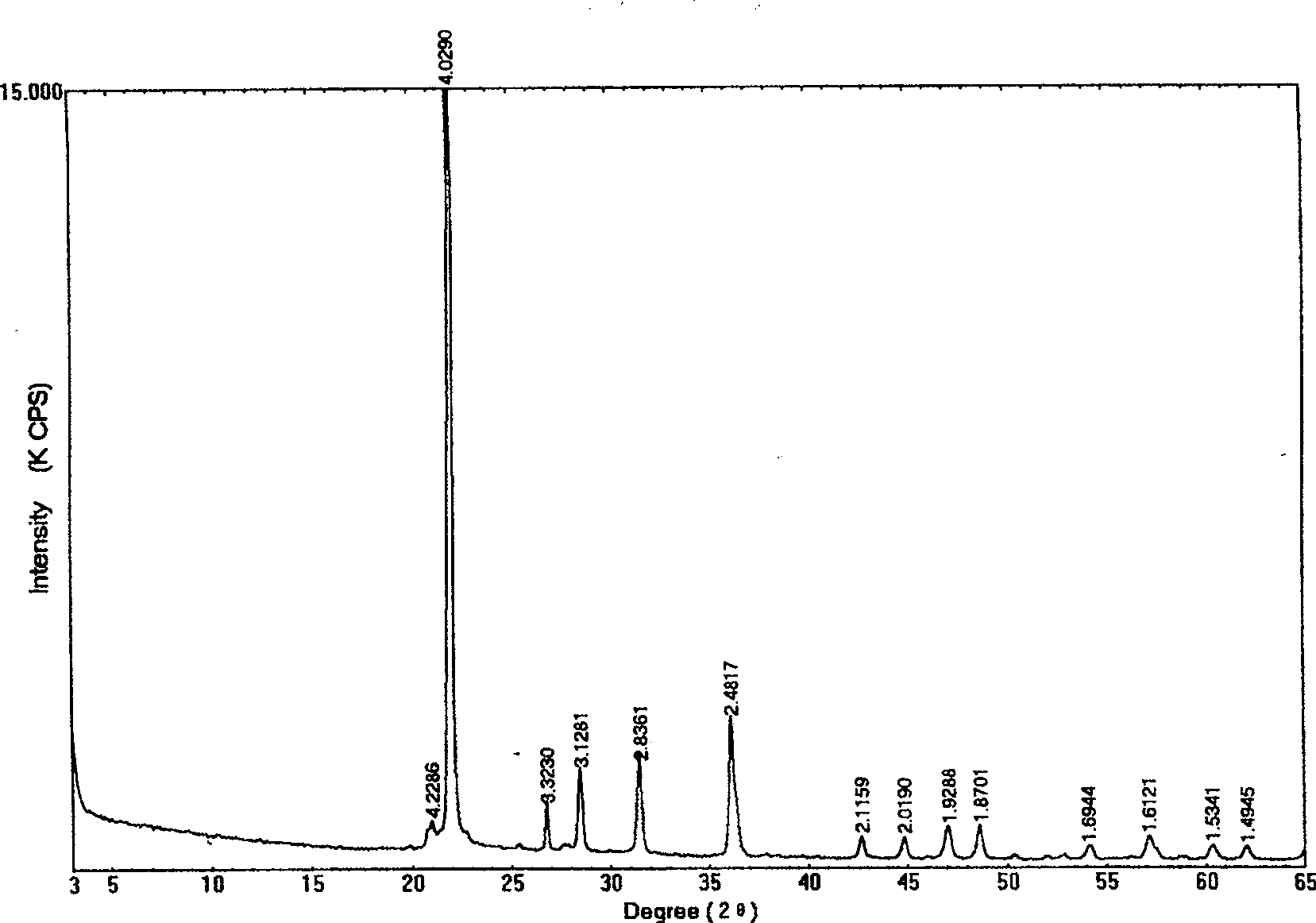

Composite phase-change catalyst for preparing quartz and use

InactiveCN100486698CReduce dosageSolve the contradiction between supply and demandPhysical/chemical process catalystsGlass shaping apparatusPhase changeCristobalite

This invention relates to a phase change catalyst for calcining quartz prepares cristobalite and application. A composite phase changes catalyst of prepared cristobalite, which characteristic lie in that it is composed of KCl powder and MoO3 powder composition with mass ratio: 5-10:1-5. the application of the prepared cristobalite composite phase changes catalyst, its feature lie in: the composite quartz powder mixed composite phase change catalyst to get batch, the enter quality of composite phase changes catalyst is 6% - 15% of quartz powder quality; the batch heat on the speed of 2degree centigrade-10degree centigrade per minute to 1300degree centigrade and insulated for six hours, get products of the quartz phase more than 94%. The composite catalyst used for calcining quartz to prepare cristobalite, the transited temperature reduce (1300degree centigrade) from quartz to cristobalite, and its conversion rate is more than 94%, composite phase change catalyst used little.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Surface strengthening coating of agricultural machinery transmission components and preparation method thereof

ActiveCN110468405BImprove mechanical propertiesImprove corrosion resistanceMetallic material coating processesHigh entropy alloysShape-memory alloy

The invention provides a strengthened coating on the surface of a transmission component of an agricultural machine. The strengthened coating comprises the following raw materials in parts by weight:10-13.5 parts of high entropy alloy powder, 31-40 parts of hard alloy powder, and 46.5-59 parts of shape memory alloy powder. A preparing method comprises the following specific preparing steps of atfirst, separately grinding the nickel-base high entropy alloy powder, the hard alloy powder and the shape memory alloy powder in fine powders by a ball grinding mill; and then mixing the three alloy fine powders, adding an organic binding agent, sufficiently and uniformly mixing at a room temperature, smearing and heating, thereby obtaining the strengthened coating. The high entropy alloy powder,the hard alloy powder and the shape memory alloy powder are smashed, and are uniformly bound together by the organic binding agent, wherein the hardness of high entropy alloy and the hardness of hardalloy are higher, the high entropy alloy and the hard alloy are mainly used for improving the wear resistance of the transmission component of the agricultural machine, however the shape memory alloyis added to facilitate improving the toughness of the coating and prevent brittle rupture and falling of the coating due to too hard high entropy alloy and hard alloy, so that the service life of thetransmission component of the agricultural machine is effectively prolonged.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com