A preparation method and product of nuclear power high-temperature nickel-based alloy composite welding wire

A nickel-based alloy, composite welding wire technology, applied in welding equipment, metal processing equipment, welding medium and other directions, can solve the problems of poor molten metal fluidity, affecting the quality of welding seam forming, expensive welding wire, etc., to ensure high temperature plasticity. , The effect of reducing crack sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Pretreatment: Clean the surface of the high-temperature nickel-based alloy welding wire, polish the surface with sandpaper, and then polish it, and then in 50°C sodium hydroxide (20g / L), trisodium phosphate (30g / L ) and sodium silicate (30g / L) mixed solution for 10min. Finally, electrolytic polishing was carried out in the mixed acid of 80% acetic acid plus 20% perchloric acid, the electrolytic voltage was 27V, and the electrification was 7s to obtain welding wire I;

[0046] (2) Nickel plating: prepare Watt type electrolyte, electroplating solution comprises nickel sulfate hexahydrate, nickel chloride hexahydrate, boric acid, nickel layer is electroplated on the surface of welding wire I, makes welding wire II, and electroplating process parameter is current density 3A / dm 2 , electroplating time 10min, electroplating temperature 45 ℃, stirring speed 300r / min;

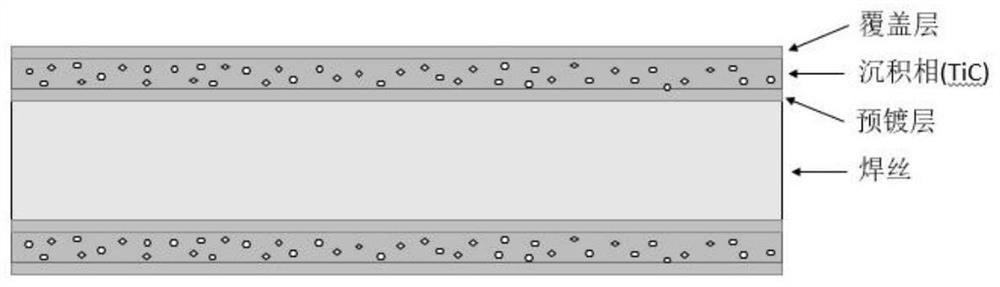

[0047] (3) Plating TiC: prepare TiC electroplating solution, TiC electroplating solution includes: TiC...

Embodiment 2

[0058] (1) Pretreatment: Clean the surface of the high-temperature nickel-based alloy welding wire, polish the surface with sandpaper, and then polish it, and then in 50°C sodium hydroxide (20g / L), trisodium phosphate (30g / L ) and sodium silicate (30g / L) mixed solution for 10min. Finally, electrolytic polishing was carried out in the mixed acid of 80% acetic acid plus 20% perchloric acid, the electrolytic voltage was 27V, and the electrification was 7s to obtain welding wire I;

[0059] (2) Nickel plating: prepare a Watt-type electrolyte, and the electroplating solution includes 400g / LNiSO 4 , 45g / LNiCl 2 , 50g / L H 3 BO 3 , the balance is water, electroplating a nickel layer on the surface of welding wire I to produce welding wire II, and the electroplating process parameters are current density 3A / dm 2 , electroplating time 10min, electroplating temperature 45 ℃, stirring speed 300r / min;

[0060] (3) Plating TiC: prepare TiC electroplating solution, TiC electroplating so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com