Cobalt-based high elastic alloy, manufacture method thereof, ultra-thin strip made from the alloy and manufacture method thereof

A manufacturing method and high-elasticity technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as difficult control of plate shape, difficult processing of ultra-thin strips, and fragile and broken strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

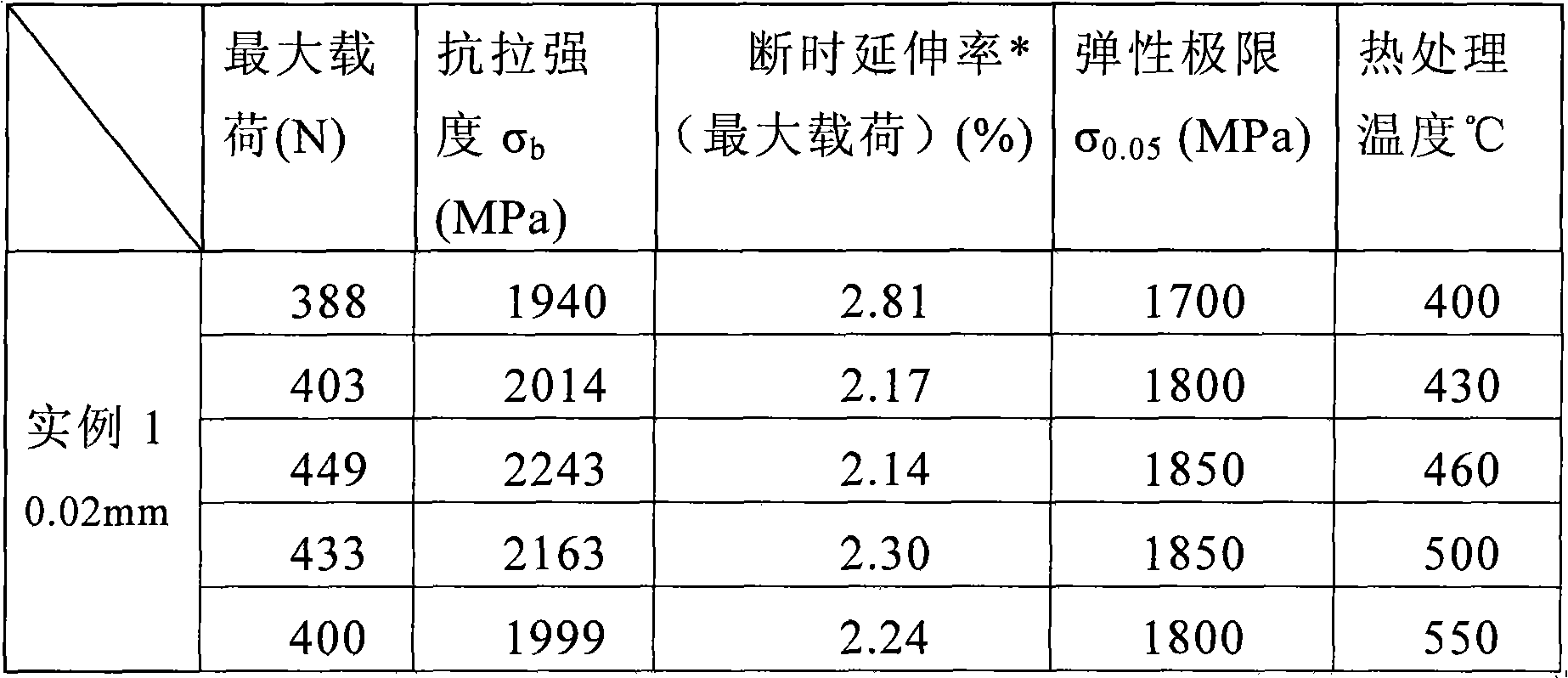

example 1

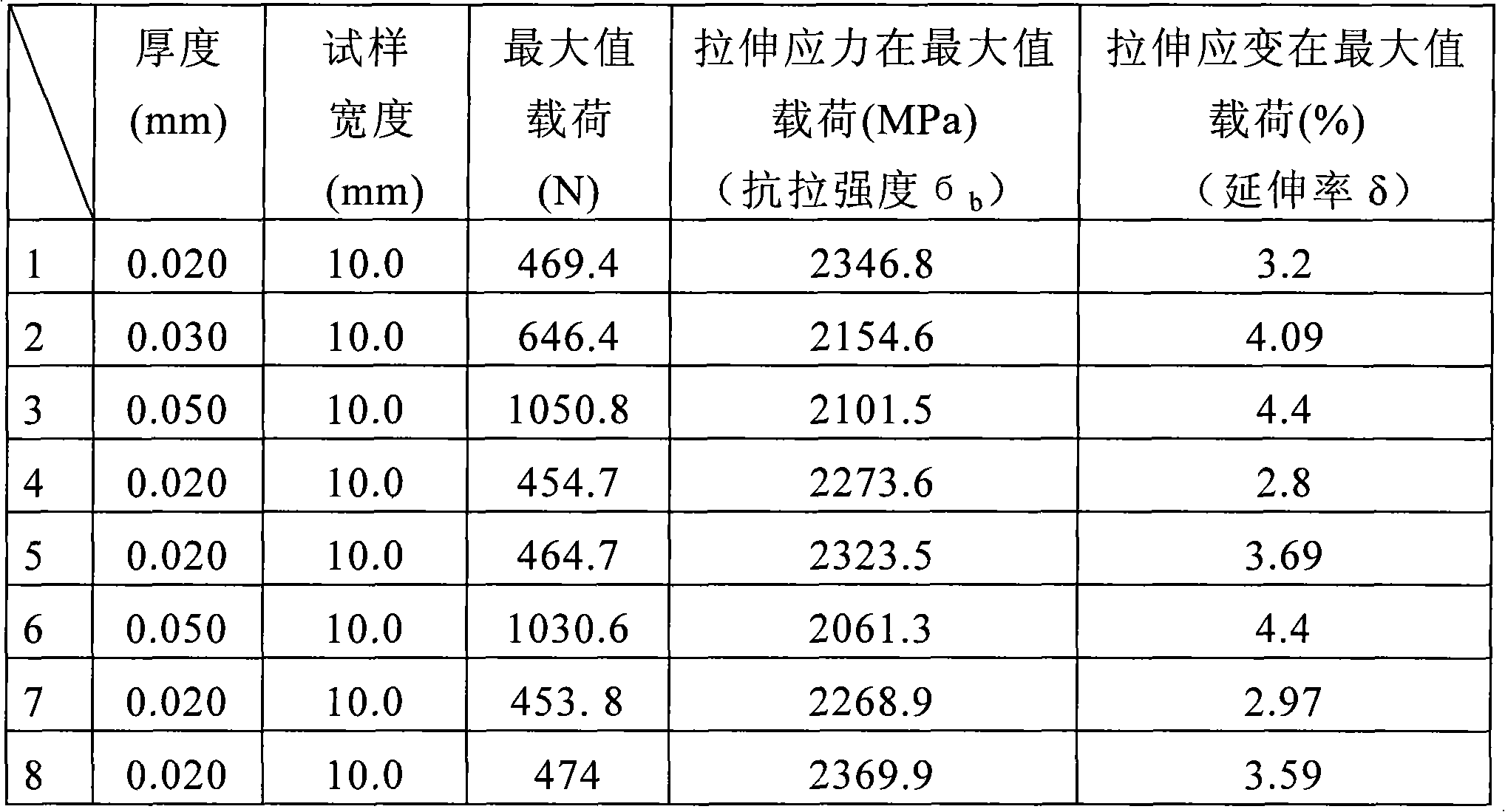

[0034] Example 1: Select high-quality metal raw materials such as Co, Cr, Ni, Fe, W, Mo, Nb, Zr, etc. to control the content of C, S, P, etc.; B is added in the form of Fe-B.

[0035] The alloy composition (%Wt, see No.6 in Table 2) is as follows: Co: 40.01, Ni: 16.05, Cr: 20.76, Mo: 3.61, W: 5.25, Si: 0.30, Mn: 2.02, Nb: 0.17, Zr : 0.5, B: 0.02, C: 0.079, S: 0.0019, P: 0.01, Yu: Fe;

[0036] The smelting uses a 25Kg vacuum furnace. After the main components are completely melted and refined for 20 minutes, elements such as Si, Mn, Nb, Zr, and B are added under the protection of Ar, and the steel is tapped and cast into two round bars of Φ55mm; Self-consumption into Φ80mm steel ingot; steel ingot peeled and hot forged into 30mm +5 ×90 +5 ×Lmm slab, after peeling, it is hot-rolled into a strip blank with a thickness of 3.5×90×Lmm; the strip blank is pickled and surface polished in a four-roll mill for cold rolling, and then cold-rolled multiple times on a two-roll or four-rol...

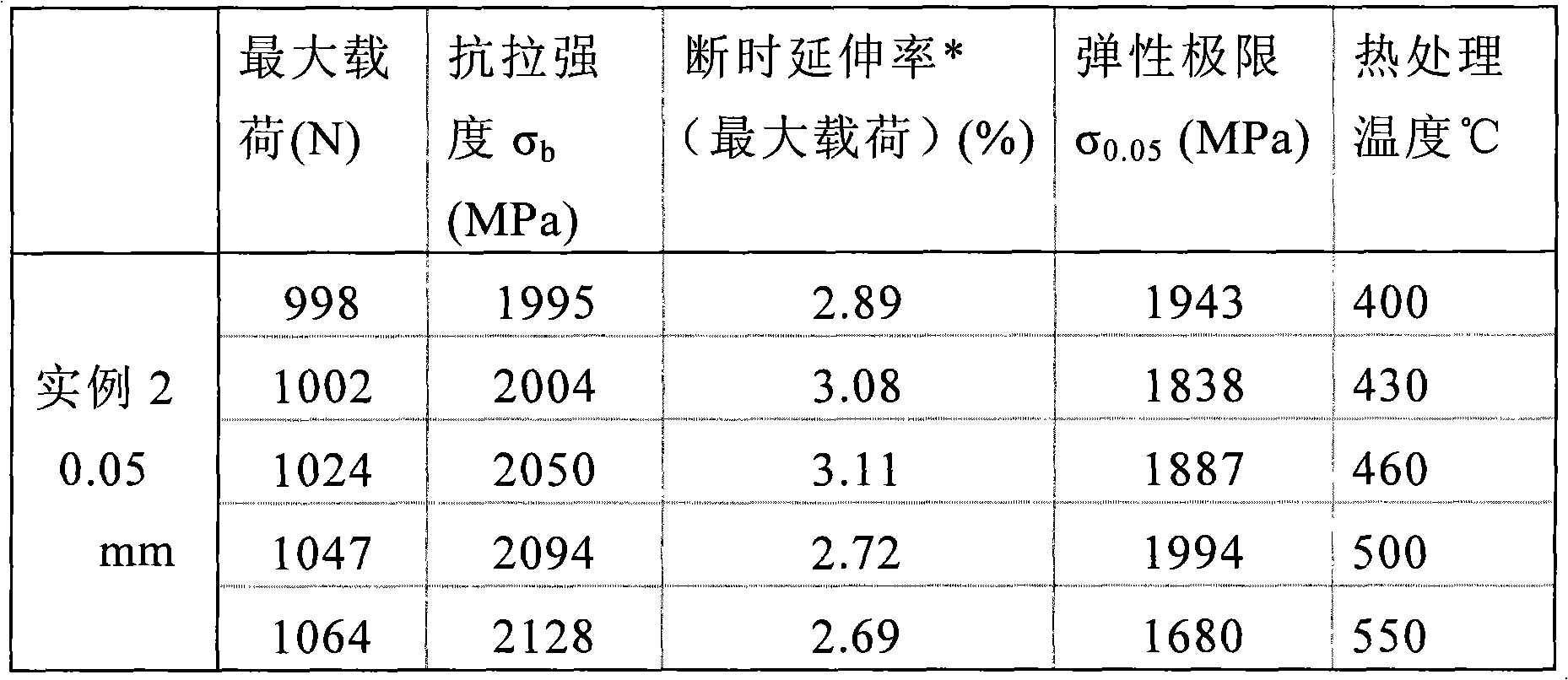

example 2

[0040] Example 2: Select high-quality metal raw materials such as Co, Cr, Ni, Fe, W, Mo, Nb, Zr, etc. to control the content of C, S, P, etc.; B is added in the form of Fe-B.

[0041] The alloy composition (%Wt see No.2 in Table 2) is as follows: Co: 39.8, Ni: 16.12, Cr: 20.32, Mo: 3.64, W: 4.73, Si: 0.36, Mn: 1.88, Nb: 0.12, Zr: 0.4, B: 0.02, C: 0.067, S: 0.0029, P<0.010, remainder: Fe;

[0042] The smelting uses a 25Kg vacuum furnace. After the main components are completely melted and refined for 20 minutes, elements such as Si, Mn, Nb, Zr, and B are added under the protection of Ar, and the steel is tapped and cast into two round bars of Φ55mm; Self-consumption into Φ80mm steel ingot; steel ingot peeled and hot forged into 30mm +5 ×90 +5 ×Lmm slab, after peeling, it is hot-rolled into a strip blank with a thickness of 3.5×90×Lmm; the strip blank is pickled and surface polished in a four-roll mill for cold rolling, and then cold-rolled multiple times on a two-roll or four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com