A kind of selective laser melting particle reinforced high entropy alloy material and preparation method thereof

A technology of selective laser melting and high-entropy alloys, applied in chemical instruments and methods, additive processing, additive manufacturing, etc., can solve the problems of reducing powder screening efficiency, delay grain growth, promote transformation, and nucleation rate-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

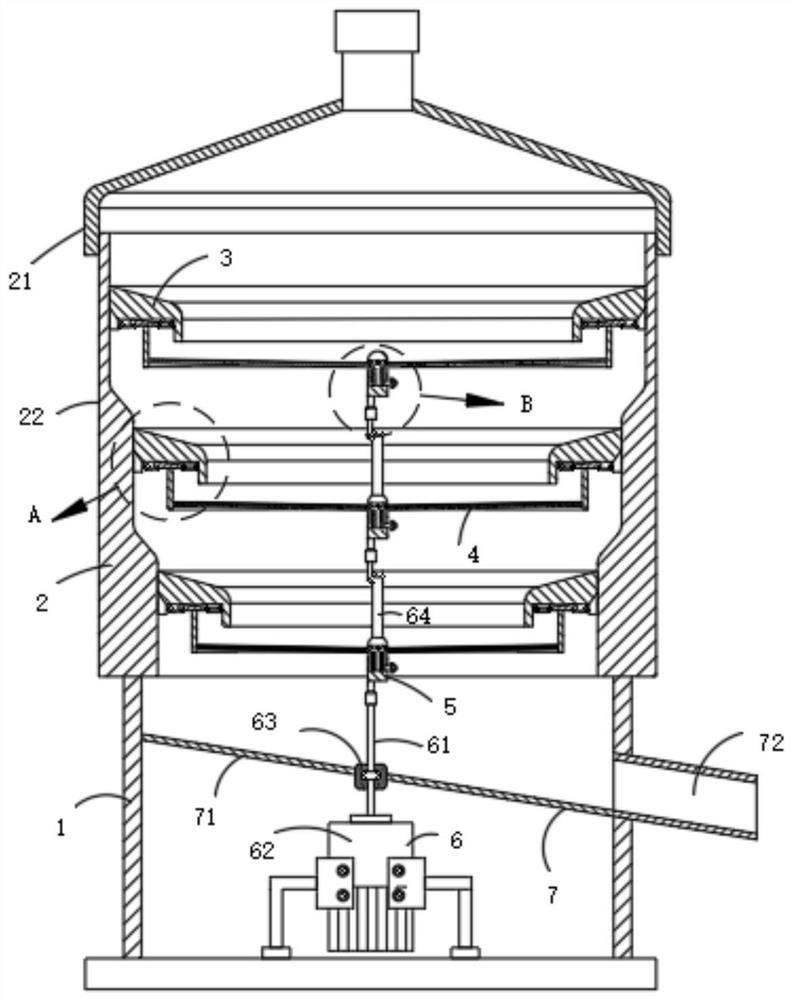

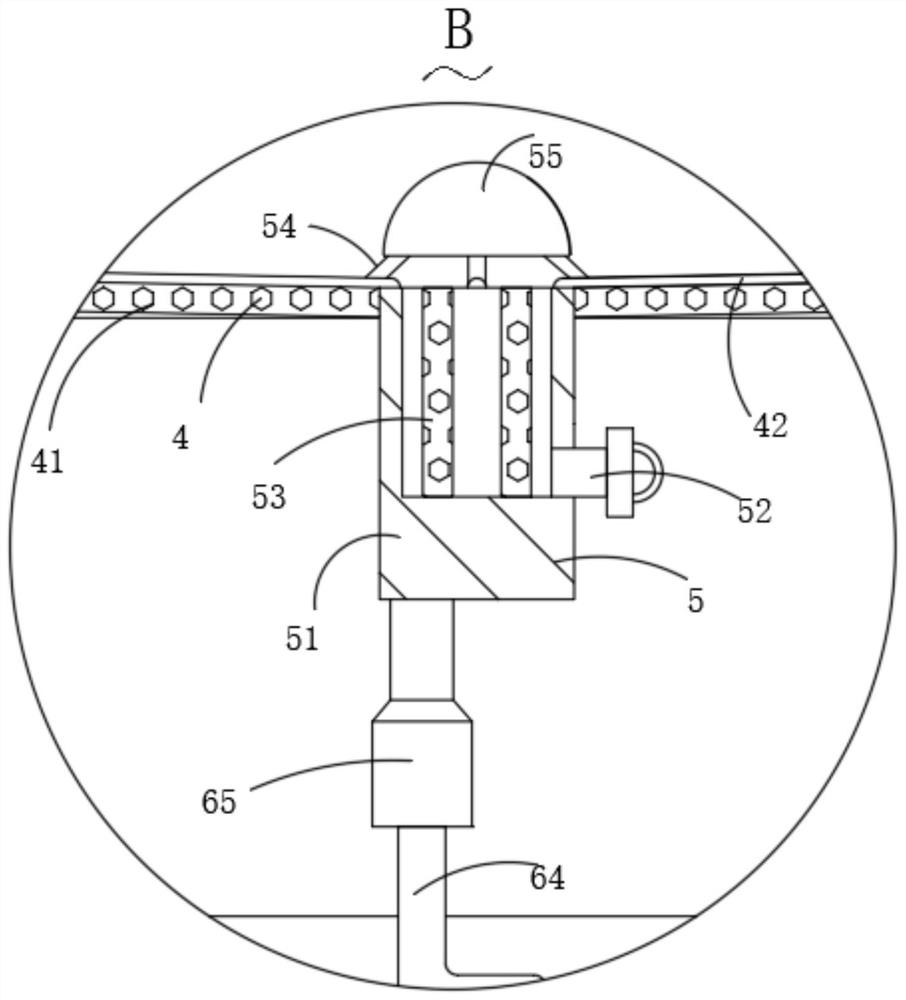

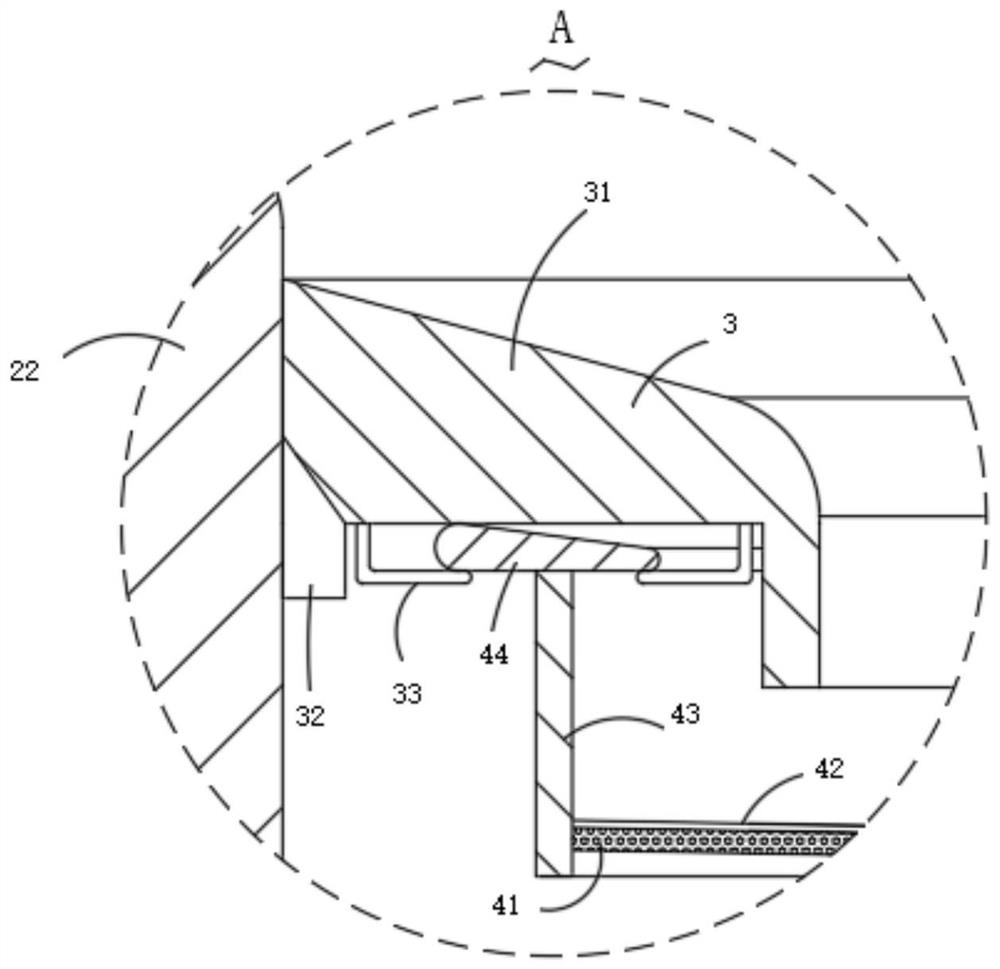

Image

Examples

preparation example Construction

[0038] A method for preparing a particle-enhanced high-entropy alloy material by selective laser melting, comprising the following steps:

[0039] Step 1: prepare high-entropy alloy powder by vacuum induction melting gas atomization method, and then sieve the powder through a screening device;

[0040] In the step 1, the vacuum induction smelting gas atomization method for preparing high-entropy alloy powder is to first use vacuum induction smelting and vacuum consumable remelting to prepare the high-entropy alloy master alloy, and then put the prepared master alloy into the melting crucible. The melting chamber is evacuated. When the pressure drops below 0.1Pa, more than 99.99% high-purity argon is charged until the pressure of the melting chamber returns to the standard atmospheric pressure. After complete melting, pour the molten metal into the tundish and conduct supersonic gas atomization to make powder; the atomization medium is high-purity argon gas of more than 99.99%,...

Embodiment 1

[0055] The atomic ratio of each element in the high-entropy alloy is Fe:Co:Cr:Ni:Ti:Al=25-2x:25-2x:25-2x:25-2x:3x:5x, where x=1, namely (FeCoNiCr) 92 Ti 3 Al 5

[0056] The melting temperature is 1700℃, and the atomization pressure is 6MPa;

[0057] Al 2 O 3 Hard particles, the average particle size is 1um, and its mass ratio accounts for 3% of the entire mixed powder;

[0058] The speed of the main disc of the ball mill is 200r / min, the rotation direction of the star disc is opposite to that of the main disc, the speed is 100r / min, and the ball milling time is 2h;

[0059] Before forming, the mixed powder is preheated in a vacuum drying oven, and then formed using NCL-M2150T selective laser melting SLM equipment. Ar gas is used in the forming chamber to protect the oxygen content at 2500ppm, the substrate temperature is 100℃, the spot diameter is 80um, and the powder layer is thick. 40um, laser power 240W, scanning speed 1000mm / s 2 O 3 Particle Reinforcement (FeCoNiCr...

Embodiment 2

[0062] The atomic ratio of each element in the high-entropy alloy is Fe:Co:Cr:Ni:Ti:Al=25-2x:25-2x:25-2x:25-2x:3x:5x, where x=0.75, namely (FeCoNiCr) 94 Ti 2.25 Al 3.75

[0063] The melting temperature is 1680℃, and the atomization pressure is 6MPa;

[0064] Al 2 O 3 Hard particles, the average particle size is 1um, and its mass ratio accounts for 2% of the entire mixed powder;

[0065] The speed of the main disc of the ball mill is 200r / min, the rotation direction of the star disc is opposite to that of the main disc, the speed is 100r / min, and the ball milling time is 1.5h;

[0066] Before forming, the mixed powder is preheated in a vacuum drying oven, and then formed using NCL-M2150T selective laser melting SLM equipment. Ar gas is used in the forming chamber to protect the oxygen content at 2500ppm, the substrate temperature is 100℃, the spot diameter is 80um, and the powder layer is thick. 40um, laser power 230W, scanning speed 1000mm / s 2 O 3 Particle Reinforcemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com