Elastic hot-melt conductive coating, elastic hot-melt conductive film and preparation method

A conductive coating, hot-melt technology, applied in the field of material chemistry, can solve the problems of lack of elasticity, poor toughness and flexibility, and unsuitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

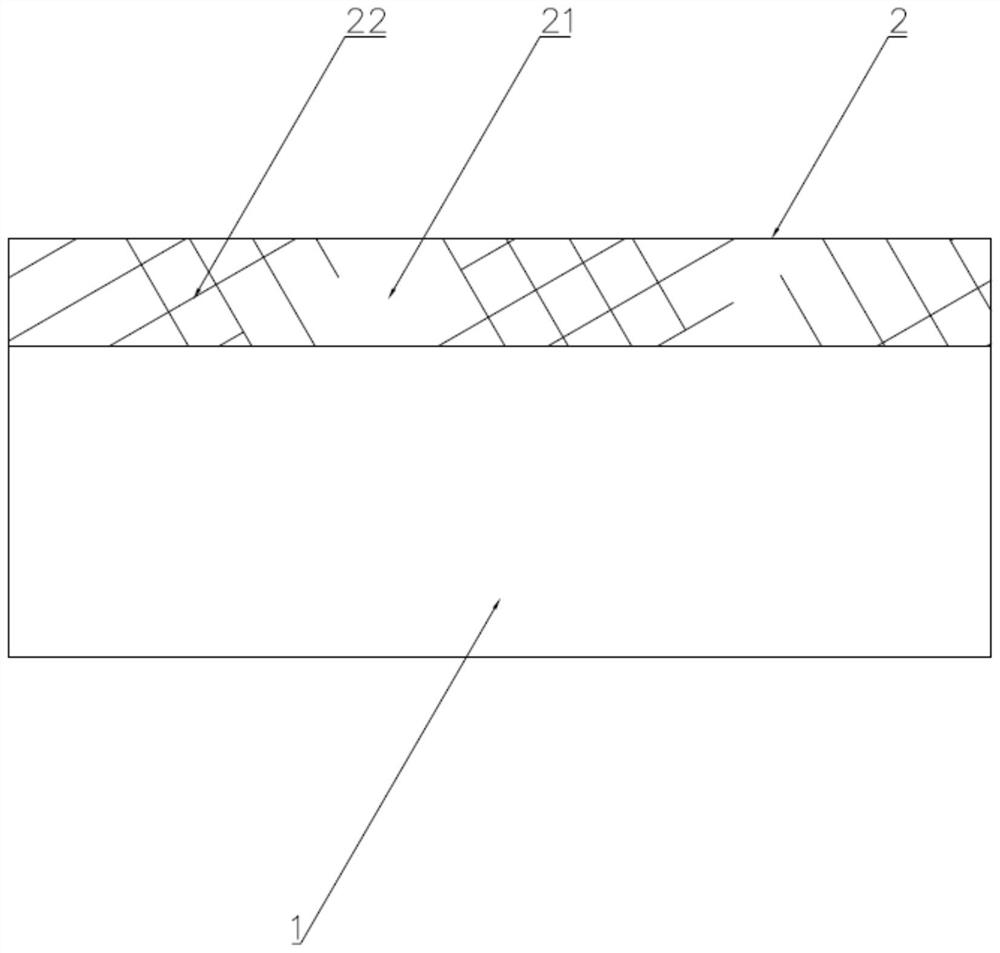

[0031] The invention provides an elastic hot-melt conductive coating, an elastic hot-melt conductive film and a preparation method thereof, comprising:

[0032] 1. An elastic hot-melt conductive coating, characterized in that: in parts by weight, its raw material components mainly include: 48.5 parts of acrylic acid modified hydroxyl polyurethane, 5 parts of ethylene glycol methyl ether, 3 parts of polyacrylic acid, polyol 6 parts, 40 parts of carbon fiber and 3.5 parts of other additives; the solid content of the elastic hot-melt conductive coating is 35%, the viscosity is 1300cps, and the conductivity is 700 S / m.

[0033] Preferably, the melting temperature of the acrylic modified hydroxyl polyurethane is 120°C-140°C, the solid content is 20%-50%, and the viscosity is 10cps-1000cps.

[0034] Preferably, the other additives include but not limited to one or more of defoamers, anti-settling agents, pH regulators and adhesion promoters.

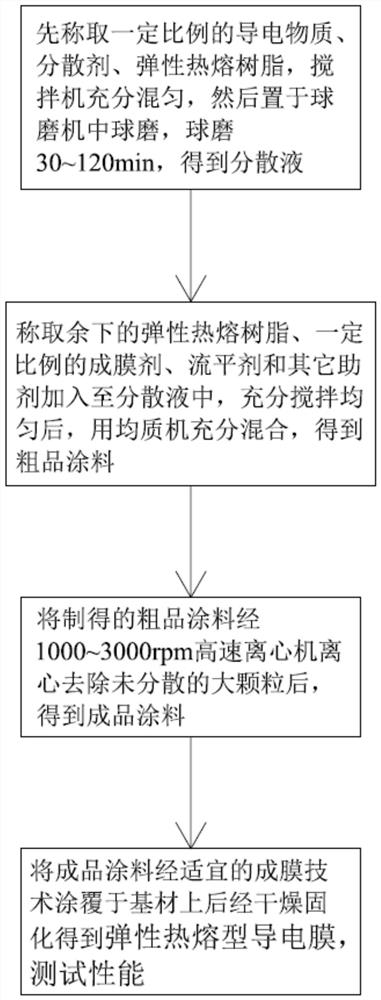

[0035] A preparation method of elastic...

Embodiment 2

[0042] The invention provides an elastic hot-melt conductive coating, an elastic hot-melt conductive film and a preparation method thereof, comprising:

[0043] 1. An elastic hot-melt conductive coating, characterized in that: in parts by weight, its raw material components mainly include: 46.5 parts of water-based acrylic modified hydroxyl polyurethane emulsion, 6 parts of vinyl glycol butyl ether, polyacrylic acid 3.5 parts, 5 parts of polyols, 35 parts of multi-walled carbon nanotubes and 4 parts of other additives; the solid content of the elastic hot-melt conductive coating is 20%, the viscosity is 90cps, and the conductivity is 1200 S / m.

[0044] Preferably, the other additives include but not limited to one or more of defoamers, anti-settling agents, pH regulators and adhesion promoters.

[0045] A preparation method of elastic hot-melt type conductive paint, comprising the following steps:

[0046] (1) First weigh 35 parts of multi-walled carbon nanotubes, 5 parts of po...

Embodiment 3

[0052] The invention provides an elastic hot-melt conductive coating, an elastic hot-melt conductive film and a preparation method thereof, comprising:

[0053] 1. An elastic hot-melt conductive coating, characterized in that: in parts by weight, its raw material components mainly include: 35 parts of water-based acrylic modified hydroxyl polyurethane emulsion, 4 parts of vinyl glycol butyl ether, polyacrylic acid 2.5 parts, 5 parts of polyols, 50 parts of graphene and 3.5 parts of other additives; the solid content of the elastic hot-melt conductive coating is 25%, the viscosity is 200cps, and the conductivity is 860 S / m.

[0054] Preferably, the other additives include but not limited to one or more of defoamers, anti-settling agents, pH regulators and adhesion promoters.

[0055] A preparation method of elastic hot-melt type conductive paint, comprising the following steps:

[0056] (1) First weigh 50 parts of graphene, 5 parts of polyol, and 25 parts of water-based acryli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com