Welding wire powder flux core, flux cored wire, its preparation method, application, ultra-high strength steel welding process

A technology of flux-cored welding wire and welding wire, which is applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of restricting the development and application of ultra-high-strength steel and the lagging development of ultra-high-strength welding materials, and achieve good welding processability and melting Metallized mechanical properties are good, the effect of no cracks on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

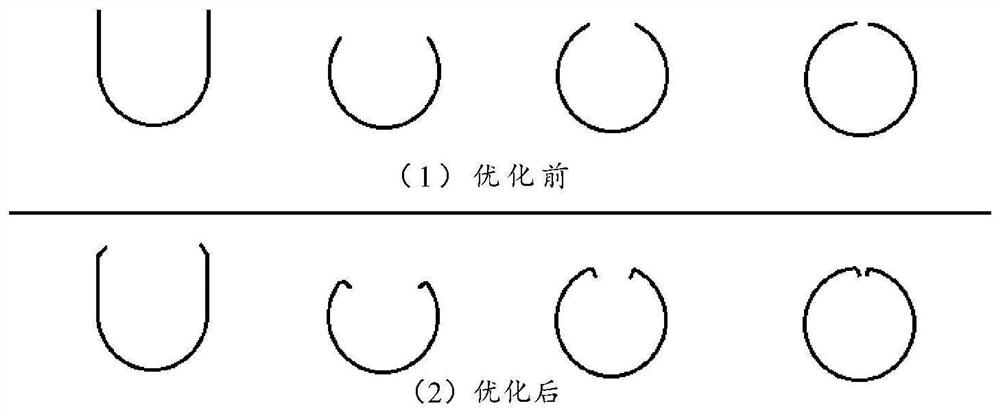

[0072] According to a third aspect of the present invention, there is provided a preparation method of the above-mentioned flux-cored welding wire, comprising the following steps:

[0073] First roll the steel strip into a U-shaped cross-section shape, then fill the welding wire powder flux prepared according to the formula into the U-shaped steel strip according to the filling rate of 12-18%, roll and reduce the diameter to a diameter of 1.0-1.6 mm wire.

[0074] Specifically, the welding wire is realized in the following ways:

[0075] Select 12 × 0.8 (width of 12mm, thickness of 0.8mm) SPCC steel strip. Roll it into a U shape first. According to the design of the flux core ratio, the powder is prepared and fully mixed, and the powder is rolled and reduced into a welding wire with a diameter of 1.2mm.

[0076] According to a fourth aspect of the present invention, an application of the above-mentioned flux-cored welding wire in the field of manufacturing pressure vessels ...

Embodiment 1

[0095] A 1500MPa grade ultra-high-strength steel welding flux-cored welding wire, including SPCC hollow welding wire and powder flux core. Iron 6%, titanium iron 5%, nickel powder 10%, bismuth oxide 0.6%, rutile 28%, sodium fluoride 5%, aluminum iron 2.8%, manganese carbonate 0.6%, potassium feldspar 0.4%, iron powder balance, The fill rate is 12.5%.

[0096] The welding process is: voltage 25V; current 230A; wire feeding speed: 410 / min; gas flow rate: 15L / min; distance of welding wire extending from contact tip: 19mm. The above-mentioned process has good welding processability, small spatter, beautiful welding seam shape, and no cracks on the surface. The mechanical properties of the deposited metal are shown in Table 1.

Embodiment 2

[0098] A 1400-1600MPa grade ultra-high-strength steel welding flux-cored welding wire, including SPCC hollow welding wire and powder flux core, the powder flux core ratio is: high carbon ferrochromium 12%, electrolytic manganese 7%, molybdenum ferrous 6% , ferrovanadium 7%, ferrotitanium 2%, nickel powder 15%, rutile 25%, sodium fluoride 3.8%, aluminum ferrous 4%, bismuth oxide 0.5%, manganese carbonate 0.7%, potassium feldspar 1.4%, iron powder remaining The filling rate is 16.5%.

[0099] The welding process is: voltage 26V; current 240A; wire feeding speed: 510 / min; gas flow rate: 25L / min; distance of welding wire extending from contact tip: 25mm. The above-mentioned process has good welding processability, small spatter, beautiful welding seam shape, and no cracks on the surface. The mechanical properties of the deposited metal are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com