Orthohexagonal crystal silicon solar wafer and solar battery manufactured thereby

A technology of solar silicon wafers and solar cells, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the output power of a single cell, not improving the utilization rate of silicon rods, and the effective area of the cell is small, so as to reduce the return to the furnace Volume, area increase, effect of increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

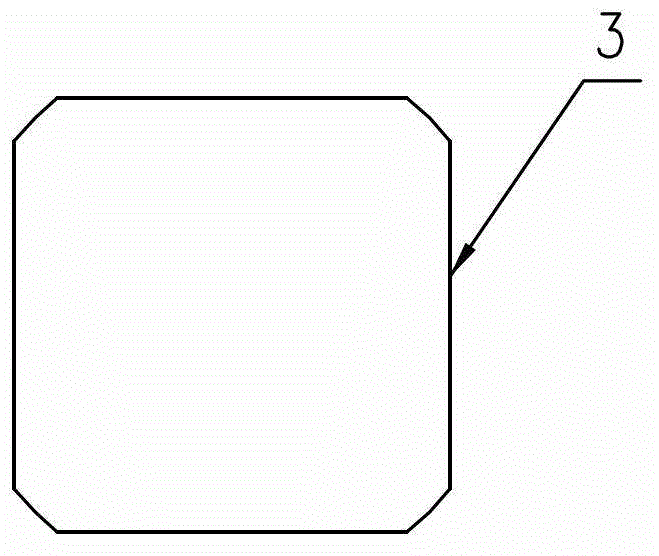

Embodiment 1

[0029] Such as Figure 5-7 As shown, it is a regular hexagonal crystalline silicon solar silicon wafer of the present invention, including a silicon wafer. The resulting sheet. In this embodiment, the regular hexagonal silicon wafer 5 is cut into regular hexagonal columns 6 along the axial direction of the inscribed regular hexagon of the cross section of the cylindrical silicon rod 1 , and then sliced. Specifically, the crystalline silicon rod 1 with a cross-sectional diameter of 200 mm is square cut into a regular hexagonal column 6 with a side length of 100 mm, and then the regular hexagonal column 6 is sliced to form a regular hexagonal silicon wafer 5 . The cut-off scrap of the crystalline silicon rod is greatly reduced, the utilization rate of the crystalline silicon rod is improved, the amount of returning to the furnace is reduced, and the production cost is saved.

[0030] A solar cell made of the regular hexagonal crystalline silicon solar silicon wafer. The reg...

Embodiment 2

[0032] The crystalline silicon rod with a cross-sectional diameter of 165mm is square cut into a regular hexagonal column with a side length of 82.5mm. After slicing, the regular hexagonal silicon wafer undergoes texturing, diffusion, plasma etching, and chemical vapor deposition to reduce reflection. Film, screen printing paste, sintering process to make a regular hexagonal solar cell, solar cell side length 82.5mm, effective area 17683mm 2 .

[0033] Compared with quasi-square silicon wafers and batteries, regular hexagonal silicon wafers and batteries, the edge material cutting loss of crystal silicon rods is reduced by 5-15%, the area of silicon wafers and batteries is increased by 5-15%, and the battery power is increased by 5- 15%. For example, for silicon wafers and batteries made of 6.5' crystalline silicon rods, the utilization rate of quasi-square silicon wafers to crystalline silicon rods is 72.4%, and the utilization rate of regular hexagonal silicon wafers to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com