Preparation method for silver stannic oxide wire

A silver tin oxide, wire technology, applied in the direction of contacts, electrical components, electrical switches, etc., can solve the problems of low material strength, poor compactness, difficult processing, etc., achieve high strength specific modulus, and enhance welding resistance. And the effect of burnout resistance and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

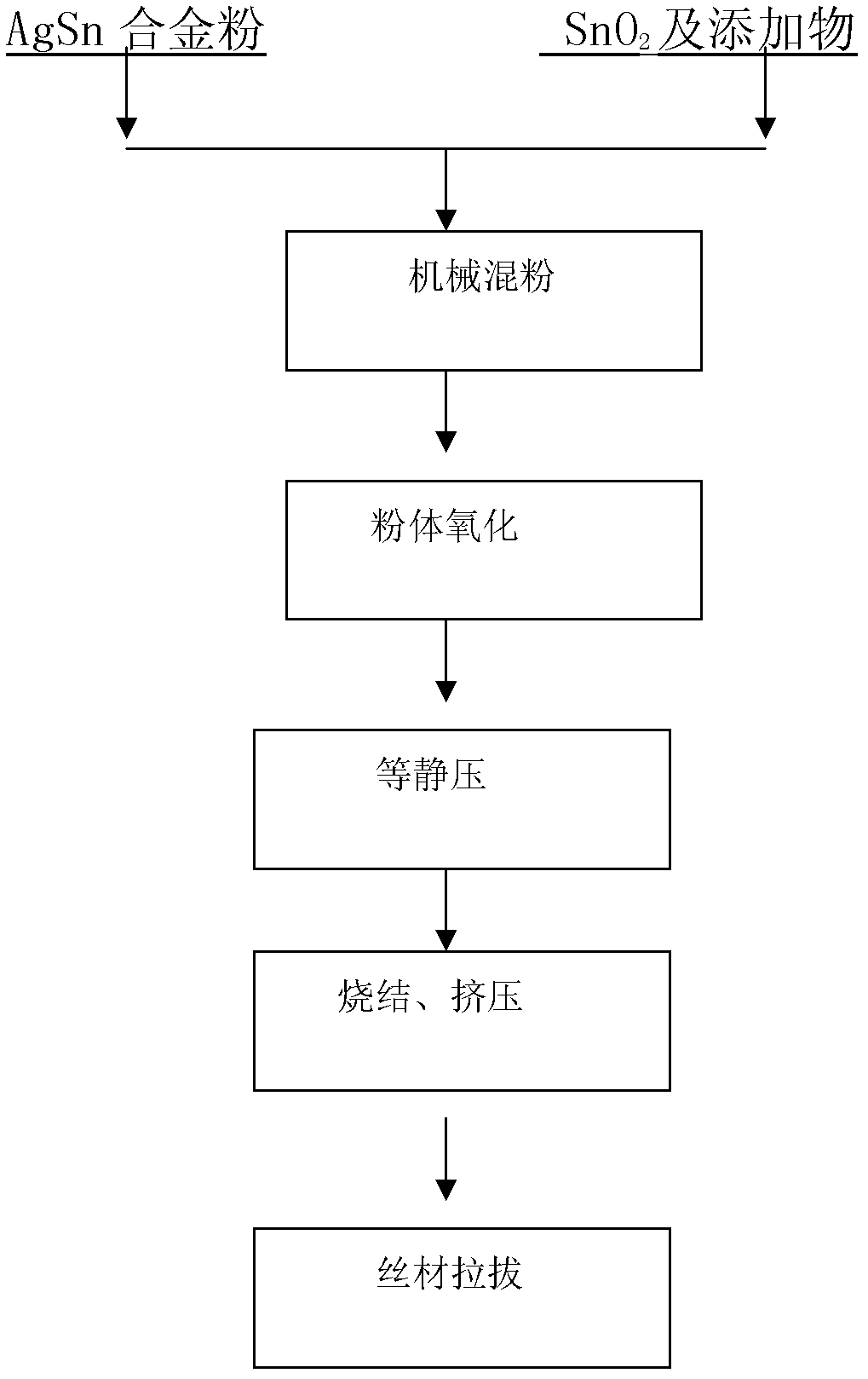

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Ag ingots, Sn ingots and Cu rods are smelted, then water atomized, the powder is dried, the powder is passed through a 350 mesh sieve, and SnO with an average particle size of 2-3 μm and a weight percentage of 5% is added. 2 , with an average particle size of 1-2 μm and 1% by weight of WO 3 The average particle size is 1-2μm, the weight percentage is 0.1% WC, the powder is mechanically mixed for 3 hours, and the uniformly mixed powder is oxidized at a temperature of 350°C in the air environment for 1 hour, and then the powder is oxidized under the oxygen pressure and temperature of 0.6MPa. Oxidize at 850°C for 4 hours. After oxidation, the powder is isostatically pressed at 80MPa and held for 5 seconds, and pressed into a spindle with a diameter of 85-88mm. The spindle is kept at 880°C for 6 hours and the temperature is lowered by 700°C. Keep warm for 1 hour, extrude into a Ф4mm wire, and then hot draw the wire into a Ф1.88mm wire.

[0035] The physical ...

Embodiment 2

[0039] Embodiment 2: Ag ingots, Sn ingots and In ingots are smelted, then atomized, the powder is dried, the powder is passed through a 350 mesh sieve, and an additive of 35% by weight is added. The additive has an average particle size of 2- 3μm SnO 2 , GeO, Dy with an average particle size of 1-2μm 2 o 3 . After all the above powders were mechanically mixed for 3 hours, they were oxidized at 550°C for 3 hours in the air environment, and then raised to 850°C for 8 hours. In isostatic pressing at 220MPa, it is pressed into a spindle with a diameter of 105-108mm. The spindle is kept and sintered at a temperature of 880°C for 7 hours, extruded into a diameter of Ф8mm, and then the wire is hot-drawn into a wire of Ф1.88mm.

[0040] The physical properties of the materials are compared in the following table

[0041]

[0042] Metallographic structure such as Figure 7 As shown, the grains of the refined product in this embodiment are uniform.

[0043] In contrast, the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com