A kind of medium temperature solder containing copper and its alloy

A brazing material and medium temperature technology, which is applied in metal processing equipment, welding/cutting media/materials, welding media, etc., can solve the problem that the working temperature cannot meet the requirements, and the mechanical strength of the brazing process performance brazing joints cannot meet the use requirements , reduce the melting point and other issues, achieve excellent wettability and spreadability, inhibit the volatilization and splashing of phosphorus, and reduce the temperature range of the solid-liquid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is not limited to the specific embodiments listed below, but also includes any combination of the specific embodiments.

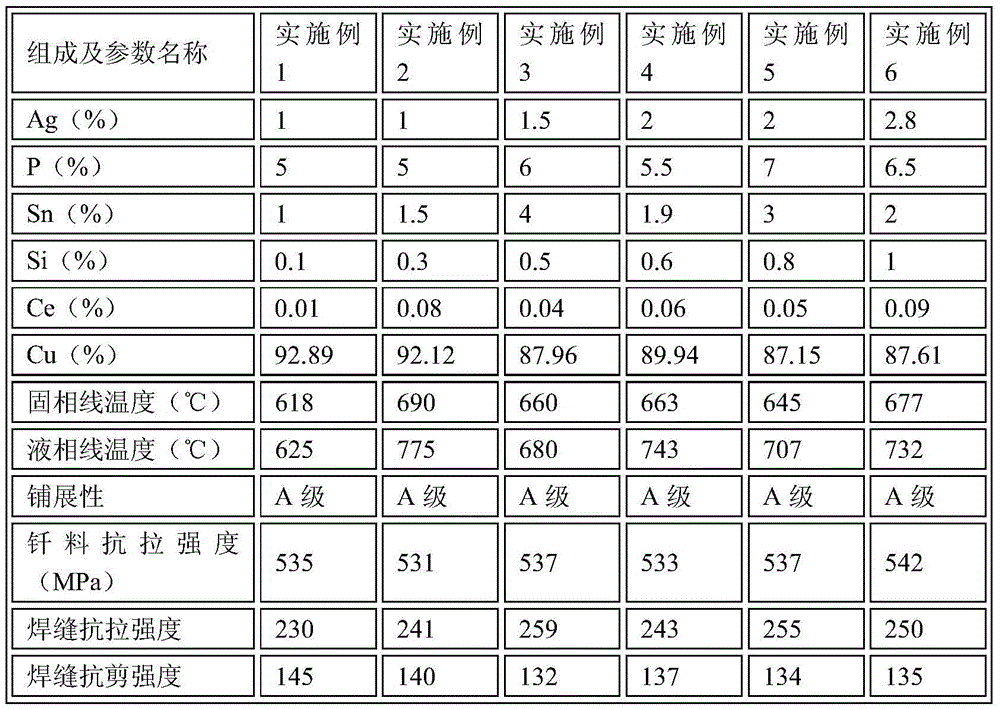

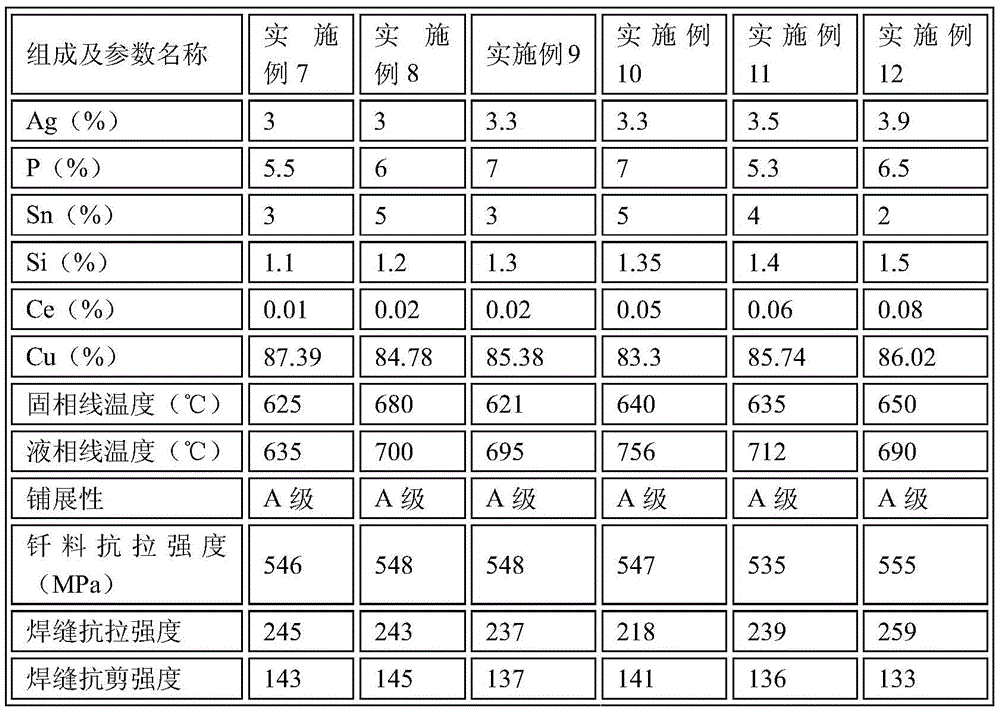

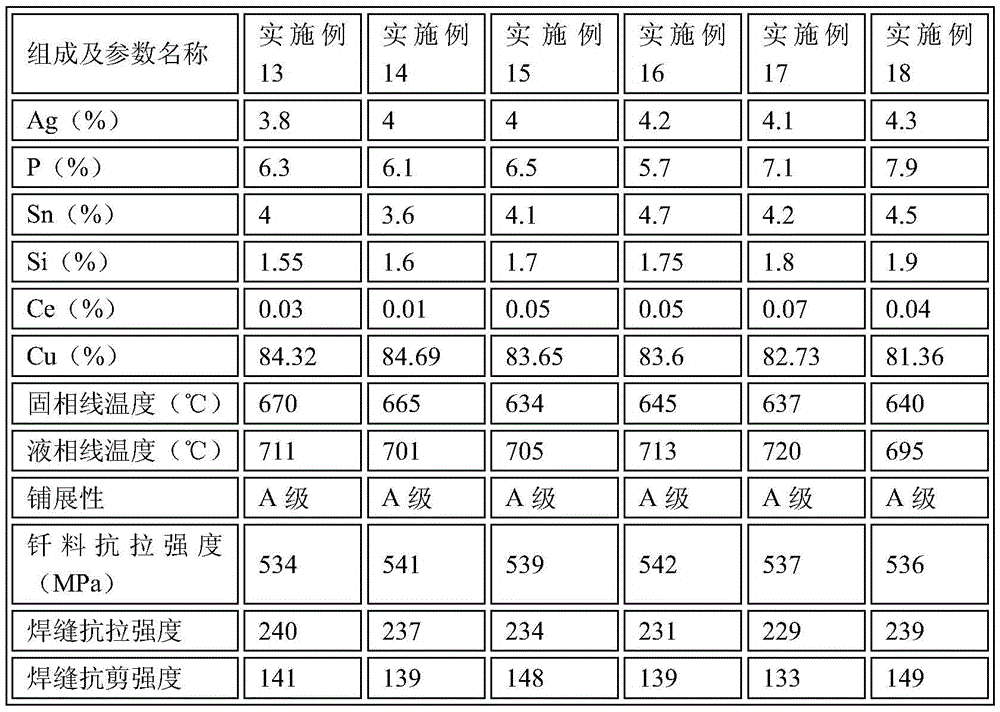

[0022] The specific parameters in each embodiment are referring to Table 1-Table 4, and Table 1 is the relevant data of embodiment 1 to embodiment 6 of the present invention, and table 2 is the relevant data of embodiment 7 of the present invention and embodiment 12, and table 3 is this The relevant data of the 13th paper embodiment 18 of the invention embodiment, the table 4 is the relevant data of the 19th paper embodiment 24 of the present invention embodiment.

[0023] Table 1 is the relevant data of Embodiment 1 to Embodiment 6 of the present invention.

[0024]

[0025] Table 2 is the relevant data of Embodiment 7 to Embodiment 12 of the present invention.

[0026]

[0027] Table 3 is the relevant data of Example 13 to Example 18 of the present invention.

[0028]

[0029] Table 4 shows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com