Fe-al/al for fusion reactor tritium breeding cladding 2 o 3 Tritium blocking coating and preparation method thereof

A technology of tritium breeding and fusion reactor, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problem of deteriorating the mechanical properties of steel substrates, sacrificing the corrosion resistance and radiation resistance of coatings, and increasing energy consumption and other issues, to achieve the effects of shortening the annealing time, making the preparation process green and environmentally friendly, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

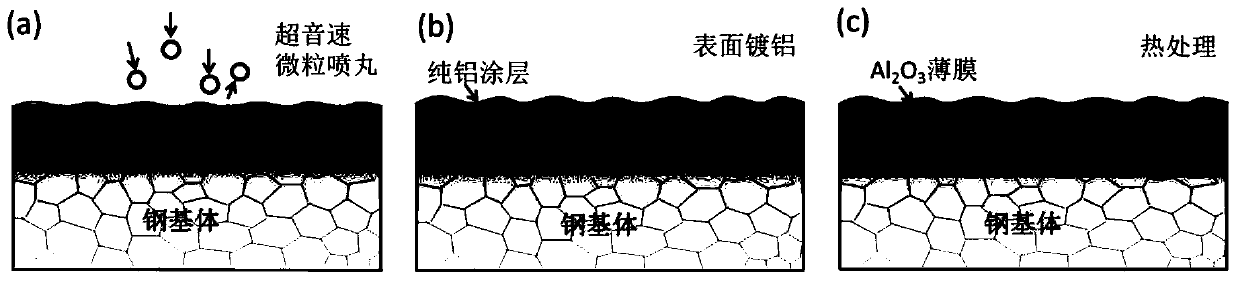

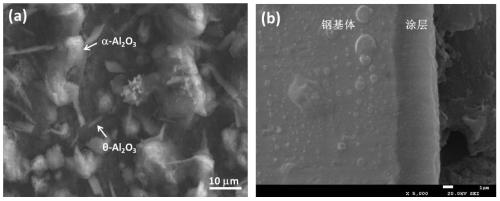

[0035] Fe-Al / Al for Fusion Reactor Tritium Breeding Cladding 2 o 3 Tritium blocking coating, its preparation method is as follows:

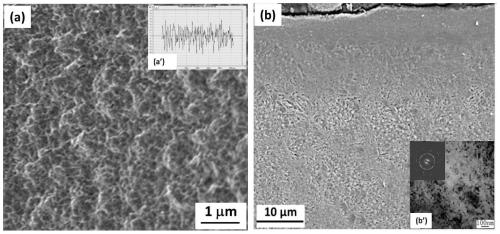

[0036] (1) Fix the cleaned 100Cr6 steel sheet in front of the nozzle of the supersonic particle shot blasting equipment, the distance between the surface to be sprayed and the nozzle is 30mm, the carrier gas pressure of the supersonic particle bombardment equipment is 2.5MPa, and the nozzle walking speed is 1mm / s ( The shot peening area converted into unit time is 1.5cm 2 / s), the shot peening incident angle is 90°, the shot peening medium is spherical alumina powder (corundum powder), and the diameter is 60 μm;

[0037] (2) Place the shot-peened steel base material obtained in step (1) in a magnetron sputtering vacuum chamber, and the background vacuum pressure of the vacuum chamber is 8.0×10 -4 Pa, under the condition of sputtering power of 100W, radio frequency magnetron sputtering coating is carried out, the Al target with a purity of not ...

Embodiment 2

[0046] Fe-Al / Al for Fusion Reactor Tritium Breeding Cladding 2 o 3 Tritium blocking coating, its preparation method is as follows:

[0047] (1) Fix the cleaned 304 stainless steel sheet in front of the nozzle of the supersonic particle shot blasting equipment, the distance between the surface to be sprayed and the nozzle is 40mm, the carrier gas pressure of the supersonic particle bombardment equipment is 1.5MPa, and the nozzle walking speed is 3mm / s (Converted to the peening area per unit time is 4.5cm 2 / s), shot peening incidence angle 90º, shot peening medium is spherical alumina powder (corundum powder), diameter 40μm;

[0048] (2) Place the shot-peened steel base material obtained in step (1) in a magnetron sputtering vacuum chamber with a background vacuum pressure of 8.0×10 -4 Pa, radio frequency magnetron sputtering coating at a sputtering power of 100W, using an Al target with a purity of not less than 99.95wt% as the sputtering source, passing through an Ar body ...

Embodiment 3

[0052] Fe-Al / Al for Fusion Reactor Tritium Breeding Cladding 2 o 3 Tritium blocking coating, its preparation method is as follows:

[0053](1) Fix the cleaned 304 stainless steel sheet in front of the nozzle of the supersonic particle shot blasting equipment, the distance between the surface to be sprayed and the nozzle is 40mm, the carrier gas pressure of the supersonic particle bombardment equipment is 1.5MPa, and the nozzle walking speed is 3mm / s (Converted to the peening area per unit time is 4.5cm 2 / s), shot peening incidence angle 90º, shot peening medium is spherical alumina powder (corundum powder), diameter 40μm;

[0054] (2) Place the shot-peened steel base material obtained in step (1) in a magnetron sputtering vacuum chamber with a background vacuum pressure of 8.0×10 -4 Pa, radio frequency magnetron sputtering coating at a sputtering power of 100W, using an Al target with a purity of not less than 99.95wt% as the sputtering source, passing through an Ar body d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com