Method for quickly preparing aluminum-iron alloy coating on surface of metal material

An aluminum-iron alloy and metal material technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of limited effect, high heating temperature, long holding time, etc., to shorten heating and burn-through time, improve temperature uniformity, increase the effect of heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

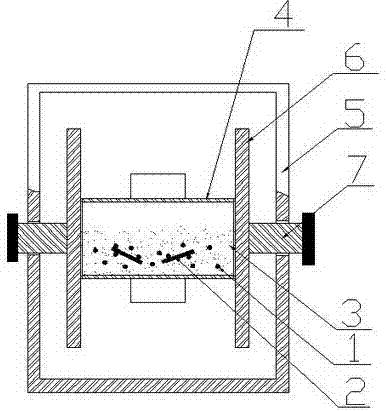

[0027] according to figure 1 As shown, the medium ball 1, the workpiece 2 to be treated, and the composite powder 3 are mixed together and placed in the sealing drum 4, and the sealing drum 4 is put into the aluminizing furnace 5 for heating. The sealing drum 4 is connected with the turntable 6 on one side through the flange, and then connected with the mechanical energy device through the transmission shaft 7, and placed in the aluminizing furnace 5 for heating. Processing technology and result:

[0028] The main components (percentage by weight) of the composite powder are 30wt% aluminum powder, 68wt% iron-aluminum powder, 2wt% ammonium chloride, the particle size of the aluminum powder and the iron-aluminum powder is 100 mesh, and the particle size of the ammonium chloride is 200 mesh. The filling amount of the composite powder in the sealed drum is 72% of the space of the sealed drum. Fill the composite powder and matrix material into the sealed drum, seal the drum and p...

Embodiment 2

[0031] Processing technology and result:

[0032] The main components (percentage by weight) of the composite powder are 30wt% aluminum powder, 65wt% iron-aluminum powder, 5wt% ammonium chloride, and the particle size of the aluminum powder, iron-aluminum powder and ammonium chloride are all 200 mesh. The weight percentages of composite powder and ceramic balls (4mm in diameter) are 70wt% and 30wt% respectively, and the filling amount in the sealed drum is 72% of the space of the sealed drum. Fill the composite powder, ceramic balls and matrix material into the sealed drum, seal the drum and put it into the aluminizing furnace, turn on the mechanical energy device to rotate the drum at a certain speed, so that the composite powder, ceramic balls and the matrix material in the drum are fully mixed After a few minutes, turn off the mechanical energy device, raise the temperature of the aluminizing furnace to 500°C, turn on the mechanical energy device, adjust the drum speed to 2...

Embodiment 3

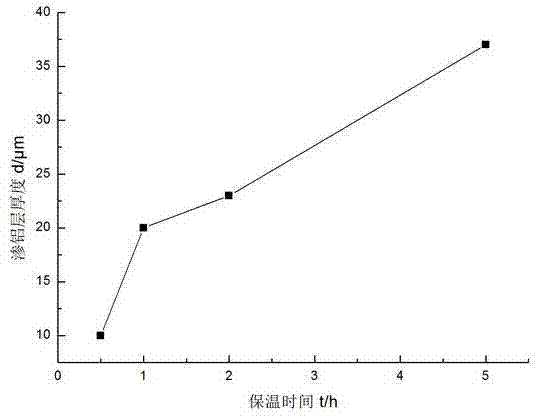

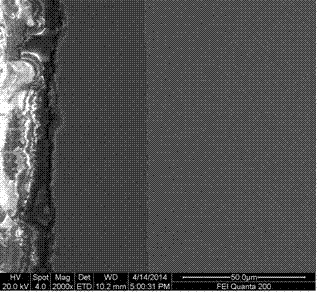

[0035] Processing technology and result:

[0036] The main components (percentage by weight) of the composite powder are 30wt% aluminum powder, 68wt% iron-aluminum powder, 2wt% ammonium chloride, the particle size of the aluminum powder and the iron-aluminum powder is 100 mesh, and the particle size of the ammonium chloride is 200 mesh. The filling amount of the composite powder in the sealed drum is 85% of the space of the sealed drum. Fill the composite powder and the workpiece to be treated into the sealed drum, seal the drum and put it into the aluminizing furnace, turn on the mechanical energy device to rotate the drum at a certain speed, so that the composite powder, medium balls and the workpiece to be infiltrated in the drum are fully mixed, After a few minutes, turn off the mechanical energy device, raise the temperature of the aluminizing furnace to 550°C, turn on the mechanical energy device, adjust the drum speed to 50r / min, keep warm for 5 hours, and take it out f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com