Accelerant for gem grade colorless diamond and preparation method thereof

A catalyst and diamond technology, applied in the field of synthetic diamond, can solve the problems of inability to obtain colorless diamonds, and achieve the effects of expanding solid solubility, smooth surface and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

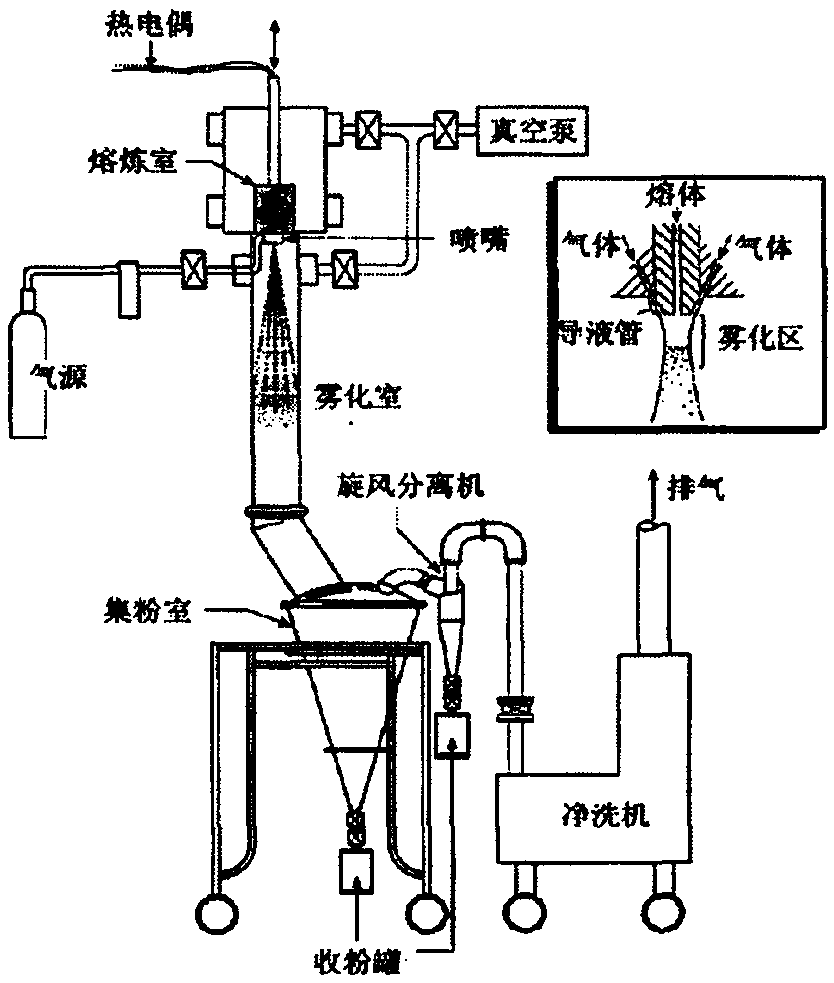

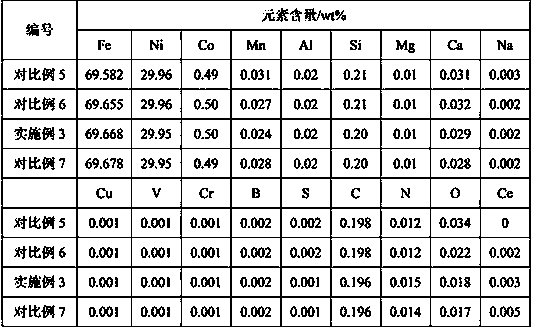

[0039] The gem-grade colorless diamond catalyst of this embodiment includes the following raw materials in weight percentage: Fe 60%, Ni 25%, Co 0.1%, Si 0.1%, and rare earth element Ce 0.1%. The preparation method of the gem-grade colorless diamond catalyst includes the following steps: 1) melting and mixing; 2) gas atomization powder production, the atomization medium is nitrogen, the atomization pressure is 2.5MPa, and the alloy prepared by gas atomization The powder needs to pass through a 250-mesh sieve; 3) Primary pressing, using isostatic pressing; 4) Vacuum treatment, first heat the material in a vacuum furnace at 850°C for 6 hours, and then hold it at 980°C for 5 hours; 5) Secondary pressing.

Embodiment 2

[0041] The gem grade colorless diamond catalyst of the present embodiment comprises the following raw materials in weight percentage: Fe 80%, Ni 35%, Co1%, Si 0.5%, rare earth element Ce 0.8%;

[0042] The preparation method of catalyst is the same as embodiment 1.

Embodiment 3

[0044] The gem-grade colorless diamond catalyst formula of the present embodiment includes the following raw materials in weight percentage: Fe 70%, Ni 29.8%, Co 0.5%, Si 0.2%, rare earth element Ce 0.4%;

[0045] The preparation method of catalyst is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com