Method for low-temperature diffusion welding of tungsten and low-activation steel

A low-activation steel, diffusion welding technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as unfavorable joints, slow release, and reduce joints, to improve diffusion coefficient, reduce diffusion activation energy, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

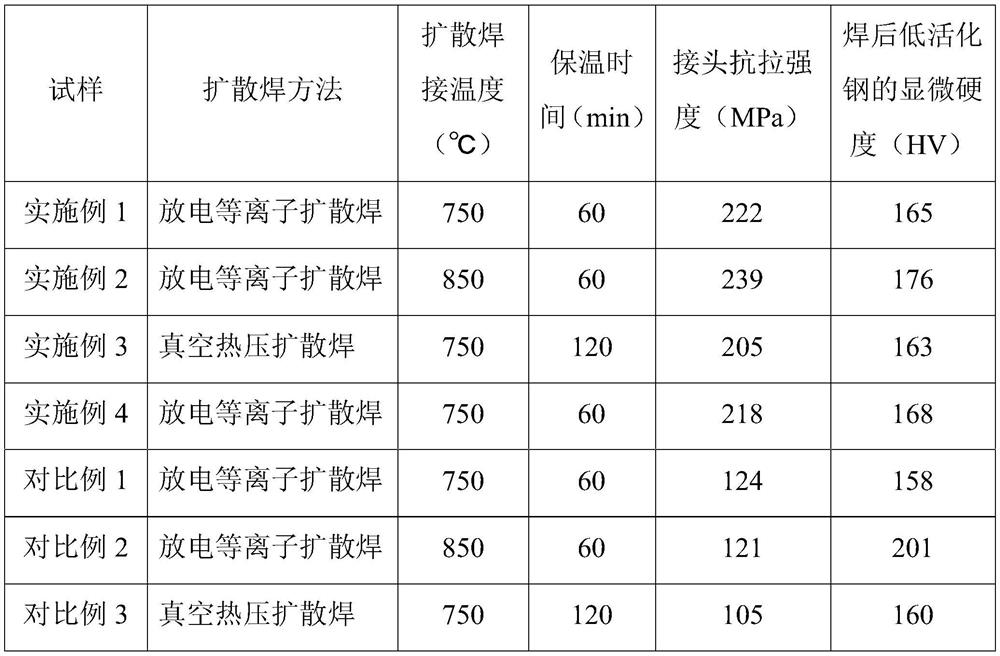

Embodiment 1

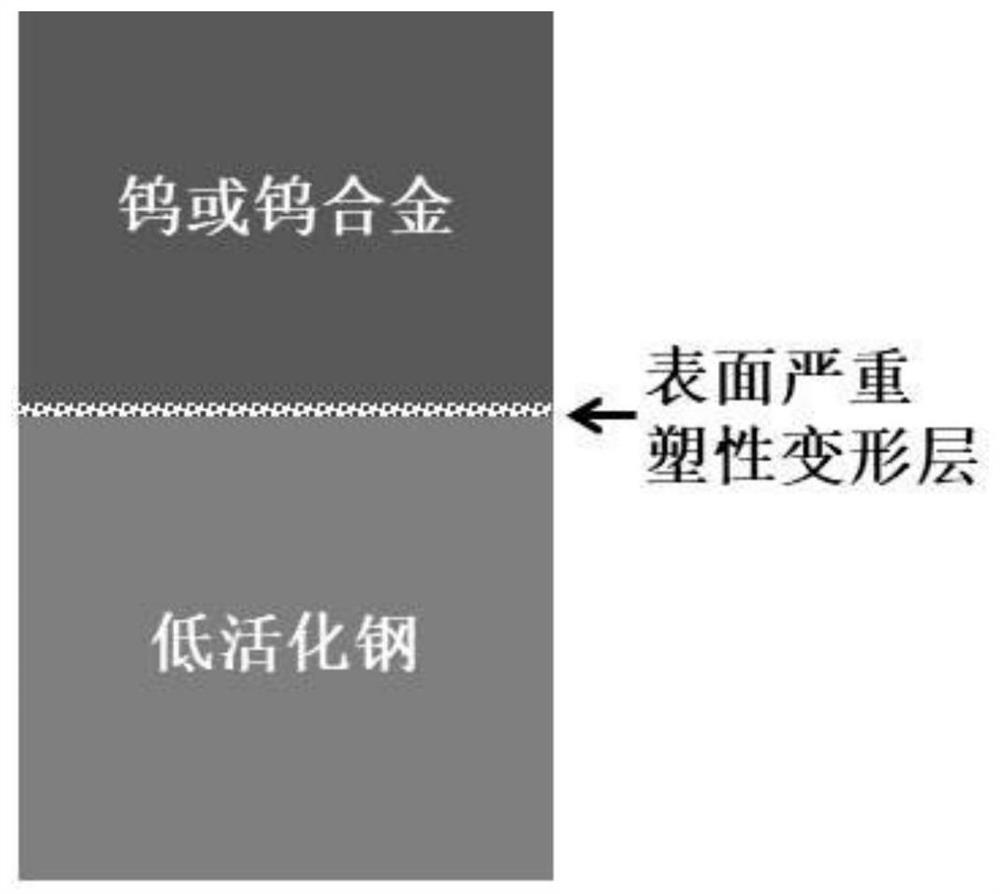

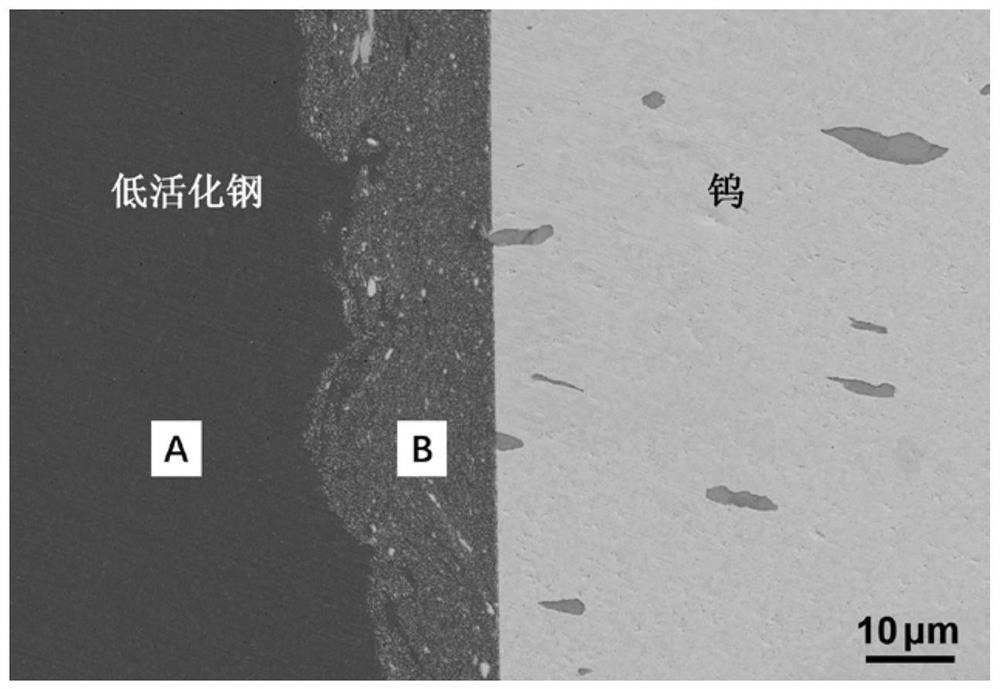

[0024] A method for low-temperature diffusion welding of tungsten and low-activation steel, comprising: performing severe plastic deformation treatment on the surface of the low-activation steel to refine the surface and near-surface grain size to the nanometer level, and obtain the low-activation steel with modified surface structure ; Diffusion welding is used to weld tungsten and surface structure modified low-activation steel.

[0025] Among them, the specific process of performing severe plastic deformation on the surface of low-activation steel is as follows:

[0026] 1) Cut the low activation steel into For the cylinder, use SiC sandpaper of different meshes to polish the upper and lower surfaces and sides and then polish to obtain a smooth surface with a surface roughness Ra≤5μm;

[0027] 2) Put the polished low-activation steel into absolute ethanol for ultrasonic cleaning for 10 minutes, and then dry it;

[0028] 3) Select two ball milling tanks with an inner diam...

Embodiment 2

[0040] This embodiment is the same as the embodiment 1, the only difference is that the diffusion connection temperature is 850°C.

Embodiment 3

[0042] The specific process of carrying out the severe plastic deformation treatment on the surface of the low-activation steel is the same as that in Example 1.

[0043] A method for low-temperature diffusion welding of tungsten and low-activation steel, comprising the following steps:

[0044] 1) Process pure tungsten and low-activation steel with surface structure modification into 8mm×9mm×8mm blocks;

[0045] 2) Use SiC sandpaper of different meshes to grind and polish the surface to be welded of tungsten and low-activation steel to a surface roughness Ra≤5μm;

[0046] 3) Put the above-mentioned polished tungsten and low-activation steel into acetone in turn for ultrasonic cleaning for 10 minutes, wipe the surface of tungsten and low-activation steel to be welded with absolute ethanol and blow dry;

[0047] 4) Put the combination of tungsten / low-activation steel in the graphite mold, and then put the graphite mold with the sample to be welded into the vacuum hot-press fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com