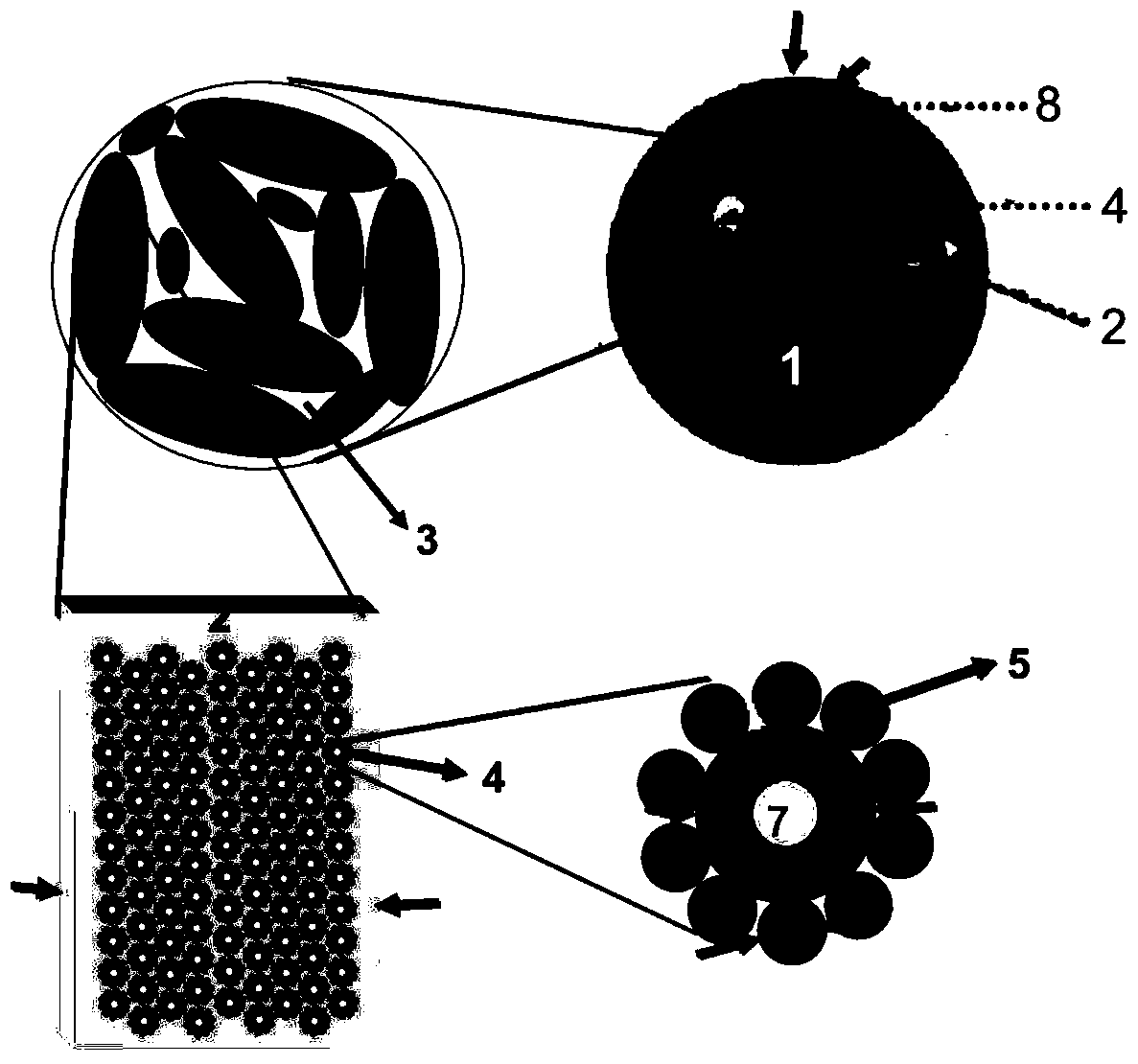

A silicon-based composite negative electrode material for lithium-ion batteries and its preparation method

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of poor electrochemical cycle stability of materials and batteries, hinder the large-scale application of silicon negative electrode materials, and achieve good lithium ion transmission performance, ensure electrochemical stability, and improve the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Get 23g silicon nanoparticles (particle size D50 is 100nm), 10g glucose and 2.5g S-p are dispersed in the mixed solvent of 700g water and 100g ethanol, through ultrafine ball milling 1h, then through spray drying, obtain granular powder, the granular powder The powder was calcined at 200° C. for 0.5 h in a tube vacuum furnace under argon protection to obtain material A.

[0041] The above-mentioned material A, 5g polyacrylic acid, 0.25g carbon fiber and 172.5g Ks-6 were dispersed in a mixed solvent of 700g water and 100g ethanol, ball milled for 2h, and then spray-dried to obtain a granular powder. Material B was obtained by calcining at 300° C. for 0.5 h in a vacuum furnace under the protection of argon.

[0042] Take 15g of the above-mentioned material B and 5g of medium-temperature pitch and disperse in 25g of toluene, stir and mix to obtain a paste mixture C, put the paste C into a vacuum tube furnace, protect it with argon, and calcinate at 1050°C for 90min to obta...

Embodiment 2

[0046] Get 23g silicon nanoparticles (particle diameter D50 is 500nm), 10g glucose and 2.5g S-p are dispersed in the mixed solvent of 500g water and 100g ethanol, through ultrafine ball milling 3h, then through spray drying, obtain granular powder, the granular powder The powder was calcined at 200° C. for 0.5 h in a tube vacuum furnace under argon protection to obtain material A.

[0047] The above-mentioned material A, 5g polyacrylic acid, 0.25g carbon fiber and 172.5g Ks-6 were dispersed in a mixed solvent of 700g water and 100g ethanol, ball milled for 3h, and then spray-dried to obtain a granular powder, which was placed in a tube Material B was obtained by calcining at 300° C. for 0.5 h in a vacuum furnace under the protection of argon.

[0048] Take 15g of the above-mentioned material B and 5g of medium-temperature pitch and disperse in 25g of toluene, stir and mix to obtain a paste mixture C, put the paste C into a vacuum tube furnace, protect it with argon, and calcin...

Embodiment 3

[0051] Get 34.5g silicon nanoparticles (particle size D50 is 100nm), 10g glucose and 2.5g S-p are dispersed in the mixed solvent of 1000g water and 100g ethanol, through ultrafine ball milling 1h, then through spray drying, obtain granular powder, the particle The powder was calcined at 200° C. for 0.5 h in a tube vacuum furnace under the protection of argon to obtain material A.

[0052] The above-mentioned material A, 10g polyacrylic acid, 0.25g carbon fiber and 172.5g Ks-6 were dispersed in a mixed solvent of 700g water and 100g ethanol, ball milled for 2h, and then spray-dried to obtain granular powder. Material B was obtained by calcining at 300° C. for 0.5 h in a vacuum furnace under the protection of argon.

[0053] Disperse 15g of the above-mentioned material B and 7.25g of medium-temperature pitch in 40g of toluene, stir and mix to obtain a paste mixture C, put the paste mixture C in a vacuum tube furnace, protect it with argon, and calcinate at 950°C for 120min to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com